Battery diaphragm, preparation method thereof and battery

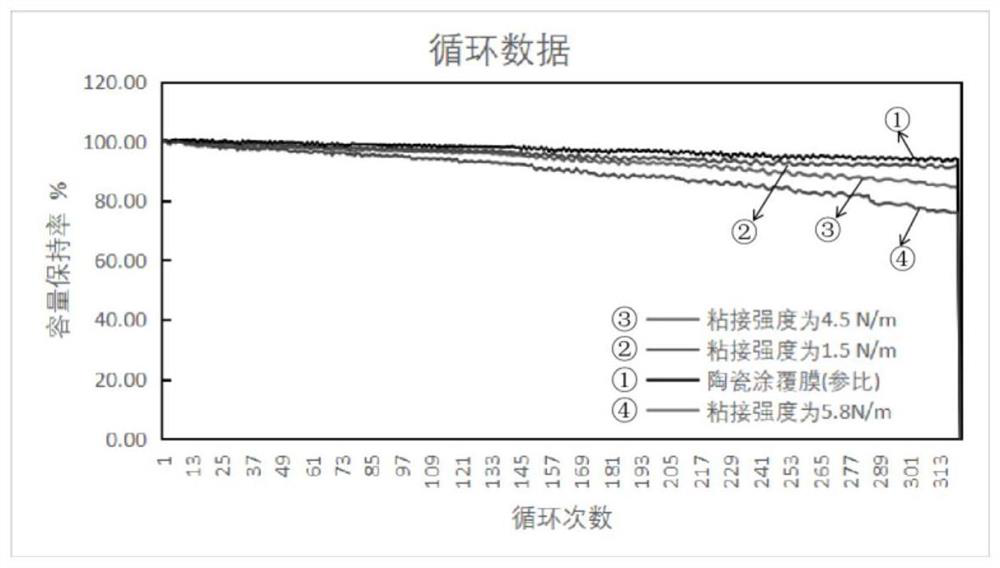

A battery separator and separator technology, applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc., can solve problems such as diving at the end of the battery cycle, blocking holes in the battery diaphragm, and increasing the internal resistance of the battery. Achieve the effect of improving rate discharge and cycle life, low battery internal resistance, and low coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] A second aspect of the embodiments of the present application provides a method for preparing a battery separator, comprising:

[0081] S02. Mix PVDF resin, thickener, binder, water and dispersant evenly to obtain PVDF slurry;

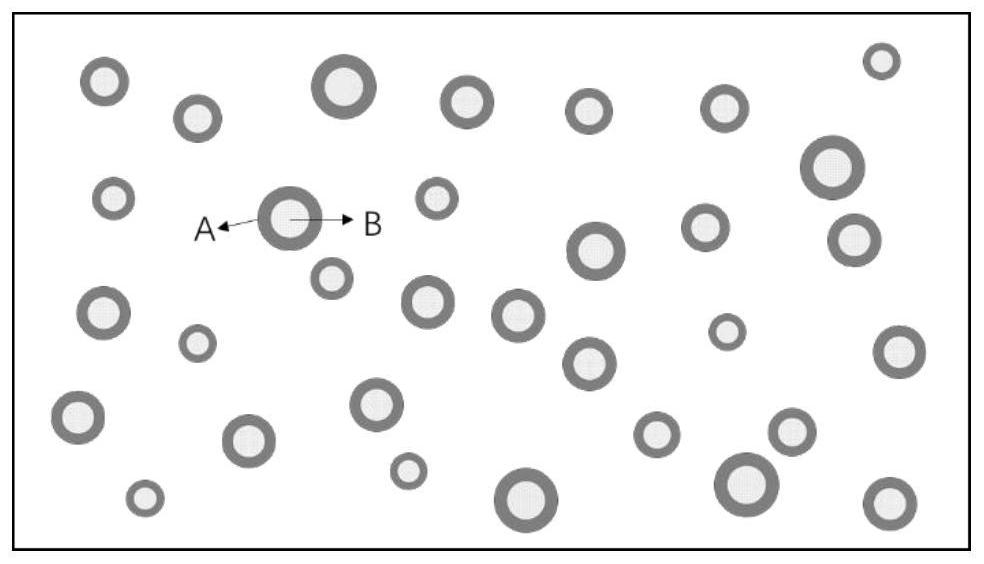

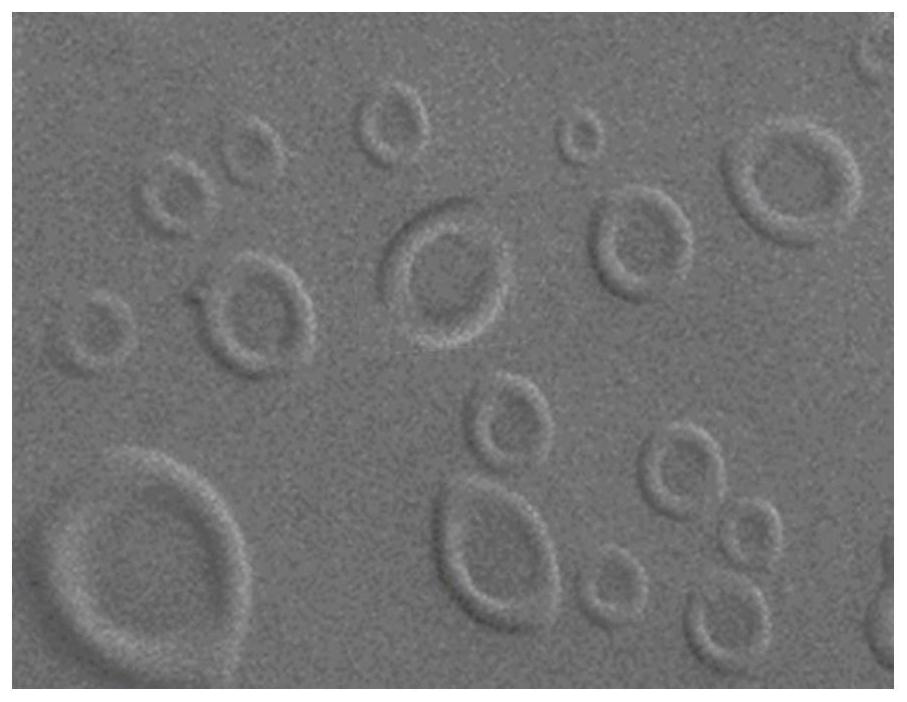

[0082] S04, spray the PVDF slurry on the surface of at least one side of the diaphragm substrate by means of rotary spraying to obtain a PVDF coating comprising ring-like coating points, and the distribution density of the ring-like coating points is 30 pieces / cm 2 ~800 / cm 2 ;

[0083] S06, drying the separator substrate and the PVDF coating sprayed thereon to obtain a battery separator.

[0084] In some embodiments, step S02 in the above preparation method may further include:

[0085] S022. Mix the first PVDF resin, the second PVDF resin and the thickener and knead them evenly to obtain a first mixture. The swelling degree of the first PVDF resin in the ethylene carbonate solvent is 0% to 30%, and the second PVDF The swelling degree of the...

Embodiment 1

[0101] Weigh 8kg of the first PVDF resin, 2kg of the second PVDF resin, 0.1kg of sodium carboxymethyl cellulose and ultrapure water and mix, stir and knead for 20min to form a uniform creamy shape, then add acrylic acid-polyurethane dispersant under stirring and ultrapure water to adjust the solid content of the slurry to form a homogeneous solution; finally, add a polyacrylic acid amine binder to the homogeneous solution, stir and mix evenly to obtain PVDF slurry.

[0102] The PVDF slurry obtained above was coated on one side of the polyethylene diaphragm base material using a high-speed rotary spraying machine, the coating speed was 50 m / min, the rotational speed of the rotating nozzle was 10000 rpm / min, and the battery diaphragm was obtained after drying. Among them, the thickness of the polyethylene diaphragm substrate is 12 μm, the thickness of the single-layer PVDF coating is 2 μm, and the coating area of the PVDF coating accounts for 24.5% of the surface area of the ...

Embodiment 2

[0104] Weigh 10kg of the first PVDF resin and mix with hydroxyethyl cellulose, stir for 30min to form a homogeneous creamy mixture, then add ultrapure water under stirring to adjust the solid content of the slurry and form a homogeneous solution; Add polyacrylic acid amine binder, stir and mix evenly to obtain PVDF slurry.

[0105] The PVDF slurry obtained above was simultaneously coated on both sides of the diaphragm substrate by a high-speed rotary sprayer. The diaphragm substrate was a 9 μm ceramic coating film composed of a 7 μm polyethylene diaphragm and a 2 μm ceramic coating. It is 30m / min, the rotating speed of the rotating nozzle is 8000rpm / min, and the battery separator is obtained after drying. The thickness of the single-layer PVDF coating is 1 μm, and the coating area of the PVDF coating accounts for 18.6% of the surface area of the ceramic coating membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com