Porous electrode lithium-ion battery and preparation method thereof

A lithium-ion battery, porous electrode technology, applied in electrode manufacturing, secondary batteries, circuits, etc., can solve the problem that lithium-ion batteries are difficult to meet high energy density at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

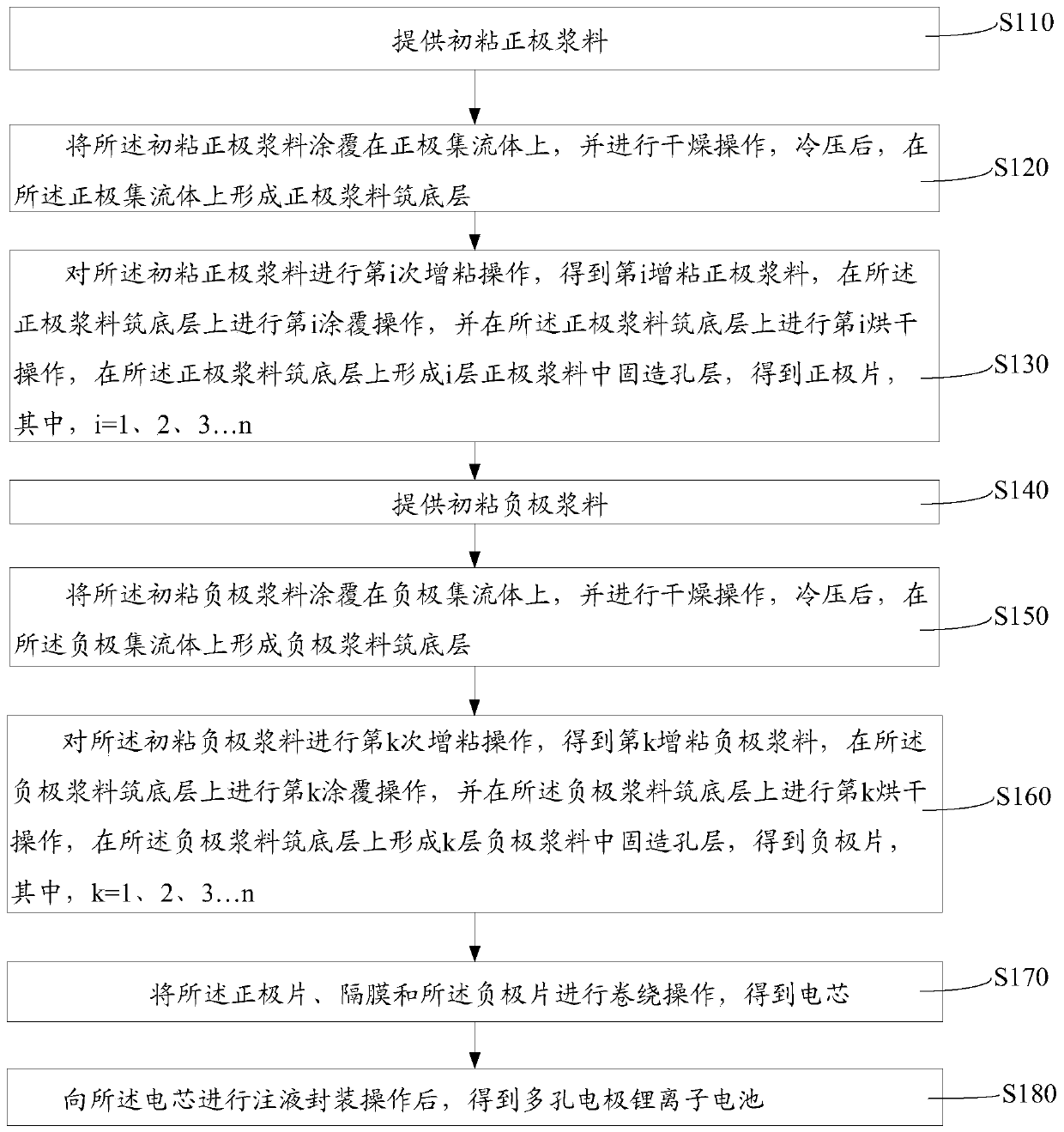

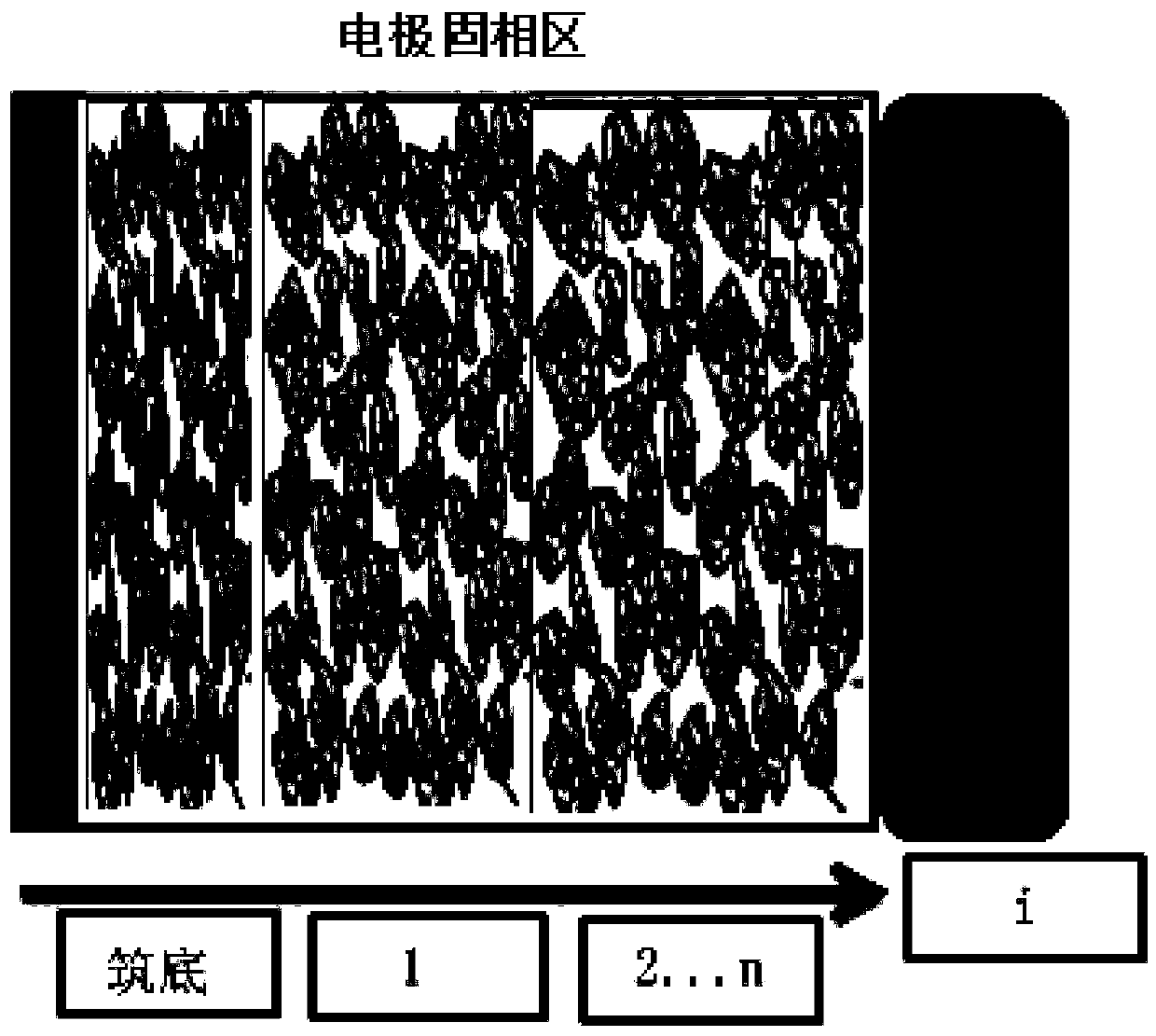

[0039] see figure 1 , in one embodiment, a kind of preparation method of porous electrode lithium-ion battery, comprises the following steps:

[0040] S110, providing an initial-bond positive electrode slurry.

[0041] It can be understood that the positive electrode sheet can be prepared by coating the positive electrode slurry on the positive electrode current collector and drying and cold pressing. The existing process usually coats the positive electrode slurry on the current collector at one time, but uses a higher viscosity Due to the low solvent content of the positive electrode slurry, the texture of the positive electrode slurry will be denser after drying and cold pressing, and the pores will be less, especially the positive electrode slurry close to the current collector is farther away from the electrolyte, so the ability to conduct lithium ions is weaker. Weak, when high-rate discharge or fast charging is required, the number of lithium ions attached to the surfa...

Embodiment 1

[0083] Provide an initial bond positive electrode slurry with a viscosity of 2500mPa·s;

[0084] Use 150g / m 2 The coated surface density of the first bonded positive electrode slurry is coated on the positive electrode current collector, and the drying operation is carried out, and the compacted density is 3.0g / cm 3 After cold pressing, a positive electrode slurry bottom layer is formed on the positive electrode current collector;

[0085] Carry out the first thickening operation on the initially bonded positive electrode slurry to obtain the first thickened positive electrode slurry with a viscosity of 3500mPa·s, perform the first coating operation on the positive electrode slurry for the bottom layer, and Performing a first drying operation on the positive electrode slurry base layer to form a first positive electrode slurry solid pore-forming layer on the positive electrode slurry base layer;

[0086] Carrying out a second thickening operation on the first thickened positiv...

Embodiment 2

[0094] Provide an initial bond positive electrode slurry with a viscosity of 3000mPa·s;

[0095] Use 200g / m 2 The coated surface density of the initial bonding positive electrode slurry is coated on the positive electrode current collector, and the drying operation is carried out, and the compacted density is 4.0g / cm 3 After cold pressing, a positive electrode slurry bottom layer is formed on the positive electrode current collector;

[0096] Carry out the first thickening operation on the initially bonded positive electrode slurry to obtain the first thickened positive electrode slurry with a viscosity of 4500mPa·s, perform the first coating operation on the positive electrode slurry for the bottom layer, and Performing a first drying operation on the positive electrode slurry base layer to form a first positive electrode slurry solid pore-forming layer on the positive electrode slurry base layer;

[0097] Carrying out a second thickening operation on the first thickened po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com