Binding agent coating surface of diaphragm as well as preparation method and application of binding agent

A binder and separator technology, applied in the direction of adhesive types, nitrile copolymer adhesives, etc., can solve the problems that affect battery life and safety performance, rate performance is difficult to meet the actual needs of power batteries, and cell deformation, etc. To achieve the effect of shortening the transmission path, improving the rate discharge and cycle performance, and firmly bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

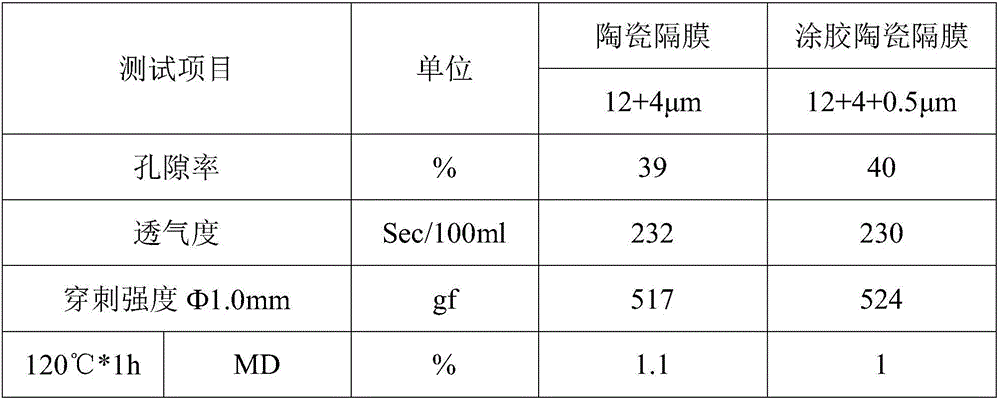

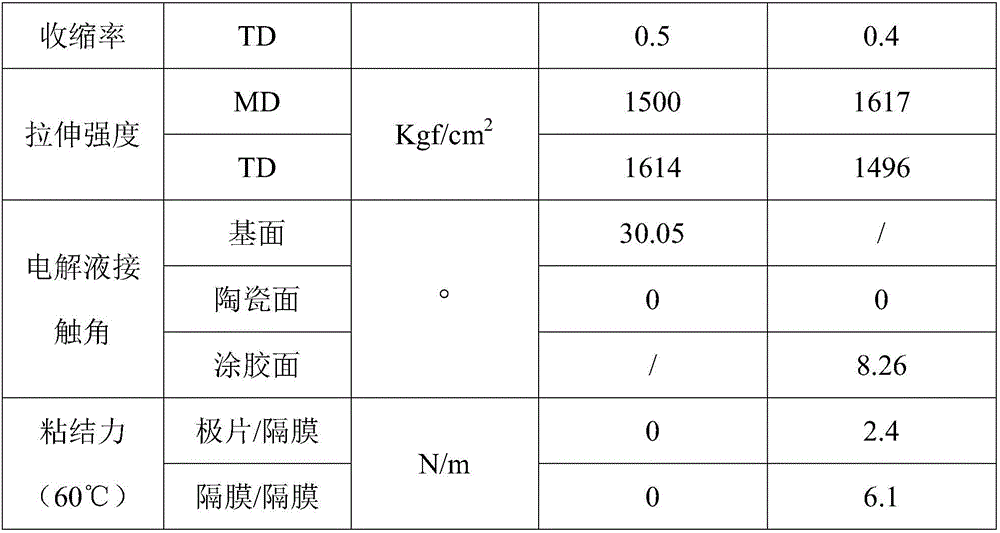

Image

Examples

Embodiment 1

[0019] The molar ratio of acrylonitrile, methyl methacrylate, acrylic acid, acrylamide, and water is 1.5:1:1:0.5:20, and the initiator ammonium persulfate accounts for 5% of the total amount of reactants; the above raw materials are of analytical grade and above purity.

[0020] Preparation:

[0021] Acrylonitrile was prepared as a 40% aqueous solution and added dropwise to the reactor within 1.5 hours; acrylamide was prepared as a 30% aqueous solution and added dropwise to the reactor within 1.5 hours; The amount of 5% is prepared into a 20% aqueous solution, which is added dropwise to the reactor within 2.5 hours. The remaining reactants and water are added to the reactor at one time, and the reaction is stirred. The reaction temperature is 30°C, and the reaction time is 2 hours. The solid content of the final active substance is 20%.

Embodiment 2

[0023] The molar ratio of acrylonitrile, methyl methacrylate, methacrylic acid, acrylamide, and water is 2:1:1:0.5:18, and the amount of initiator potassium persulfate is 6% of the total amount of reactants.

[0024] Preparation:

[0025] Acrylonitrile is formulated as a 50% aqueous solution and added dropwise to the reactor within 1 hour; acrylamide is prepared as a 40% aqueous solution and added dropwise to the reactor within 1 hour; The dosage of 15% is formulated into a 15% aqueous solution and added dropwise to the reactor within 2 hours, and the remaining reactants and water are added to the reactor at one time, and the reaction is stirred, the reaction temperature is 70 ° C, and the reaction time is 4 hours. Content 25%.

Embodiment 3

[0027] The molar ratio of acrylonitrile, methyl methacrylate, maleic anhydride, acrylamide, and water is 2:1:1:0.7:15.7, and the amount of initiator hydrogen peroxide and ammonium persulfate is the total amount of reactants 4.5%.

[0028] Preparation:

[0029] Add methyl methacrylate, acrylic acid, and water into the reactor in molar ratio, acrylonitrile is made into a 45% aqueous solution and added dropwise to the reactor within 1 hour, and acrylamide is made into a 45% aqueous solution in 1.5 hours Add it dropwise to the reactor within the time, the initiator hydrogen peroxide and ammonium persulfate are formulated into 10% aqueous solution in the amount of 4.5% of the total amount of the reactant, and drop it into the reactor within 2.5h, the remaining reactant and water Add it to the reactor at one time, stir and react, the reaction temperature is 50°C, the reaction time is 8h, and the solid content of the active substance after the reaction is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com