Battery diaphragm and preparation method thereof

A separator and battery technology, applied in the field of battery separator and its preparation, can solve problems such as poor bonding performance, and achieve the effects of improving rate discharge and cycle performance, excellent bonding performance, and enhanced bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] According to a second aspect of the present invention, the method for preparing a separator for a battery as described above comprises the following steps:

[0057] A PVDF / PMMA composite coating is sprayed on at least one side of the base film and dried to obtain a separator for batteries.

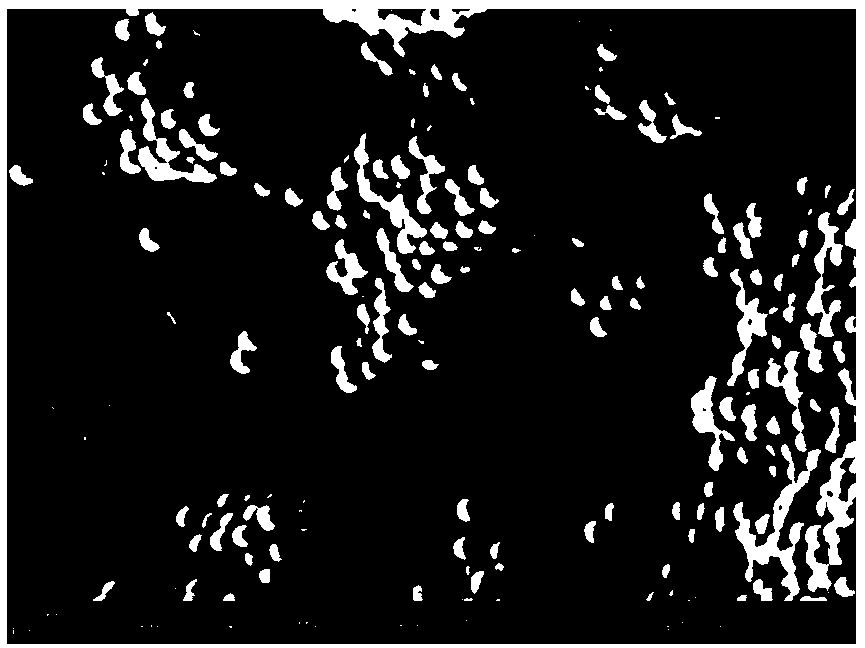

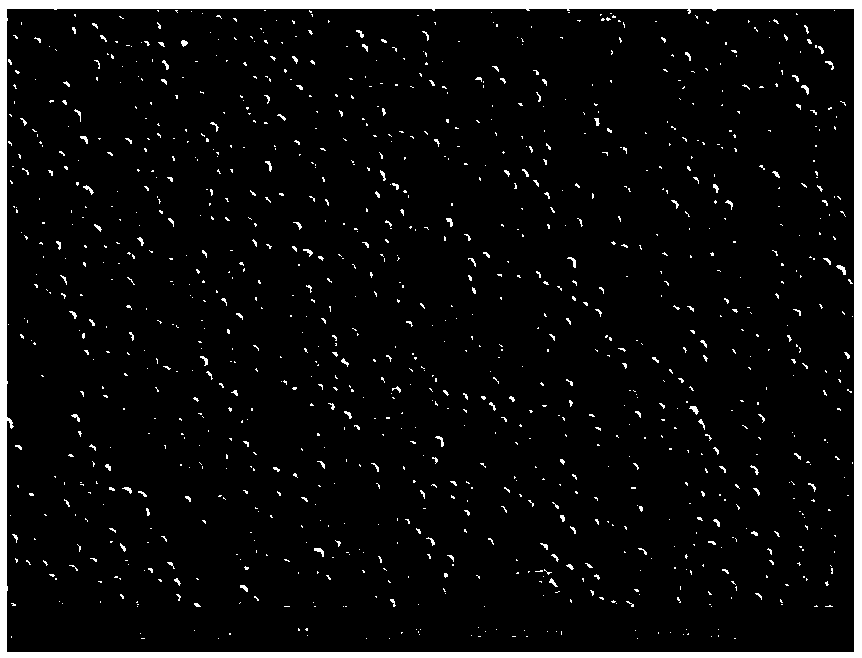

[0058] The principle of spraying: the required spraying material is transported to the rotary table by pressure through the magnetic pump, so that the rotary table rotates at a high speed, the material is cut into small droplets in the rotary table, and the cut droplets are thrown out to the film by centrifugal force .

[0059] The present invention sprays the PVDF / PMMA composite coating on the base film by means of spraying. The method is simple to operate, and the PVDF / PMMA composite coating sprayed in dots is relatively thin, and the diameter of the dots is 0.01-2mm, which can ensure the The air permeability of the battery can be enhanced, and the adhesion between the separator ...

Embodiment 1

[0070] A diaphragm for a battery comprises a polyimide base film and a PVDF / PMMA composite coating coated on one side of the polyimide base film.

[0071] The preparation method of the separator for the battery comprises the following steps:

[0072] Add 32 parts of PVDF and 9 parts of polyoxyethylene alkylphenol ether to 175 parts of water, mix and stir for 118 minutes to disperse evenly, then add 125 parts of PMMA solution and stir for 32 minutes, then add 4 parts of povidone and 5 parts of polyethylene glycol Glycol and 23 parts of α-cyanoacrylate are stirred evenly to obtain a mixed slurry of PVDF and PMMA; using a spraying process, the mixed slurry of PVDF and PMMA is sprayed on one side of a polyimide base film with a thickness of 12um, and the coating The thickness is 0.8um, and then dried in an oven at 40° C. for 3 minutes to obtain a battery separator.

Embodiment 2

[0074] A diaphragm for a battery comprises a polyimide base film and a PVDF / PMMA composite coating coated on one side of the polyimide base film.

[0075] The preparation method of the separator for the battery comprises the following steps:

[0076] Add 28 parts of PVDF and 14 parts of sodium polyacrylate to 185 parts of water, mix and stir for 122 minutes to disperse evenly, then add 115 parts of PMMA solution and stir for 36 minutes, then add 5 parts of polyethylene glycol, 5 parts of povidone, 4 parts Carboxymethyl cellulose and 20 parts of polybutyl acrylate are stirred evenly to obtain a mixed slurry of PVDF and PMMA; using a spraying process, the mixed slurry of PVDF and PMMA is sprayed on one side of a polyimide base film with a thickness of 12um, The thickness of the coating was 1.2um, and then dried in an oven at 50° C. for 2 minutes to obtain a separator for batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com