Preparation method of mixed anode material for lithium battery

A technology of mixing positive electrode materials and lithium batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that hinders the wide application of carbon fluoride materials, does not fundamentally solve the initial voltage hysteresis of carbon fluoride, and is difficult to greatly improve lithium - The discharge rate of fluorinated carbon batteries can improve the initial discharge voltage hysteresis, improve the high current discharge performance, and improve the low temperature discharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Preparation method of mixed positive electrode material for lithium battery, doping Ag in fluorinated carbon material 2 V 4 o 11 materials, the process of doping includes:

[0021] Step 1. Follow FFC: Ag 2 V 4 o 11 : The mass ratio of solvent=1:0.01-0.8:1.5-3, the carbon fluoride, Ag 2 V 4 o 11 and the solvent are put into a ball mill, mixed and ball milled at a speed of 100-500 rpm for 12-24 hours, and a mixed slurry is formed in the ball mill;

[0022] Step 2. Dry the mixed slurry at 60°C-120°C for 5-20h, and cool it down to room temperature naturally to obtain a dry mixture;

[0023] Step 3. After passing the dry mixture in step 2 through a 100-400 mesh sieve, the obtained powder is used as the mixed positive electrode material for the lithium battery of the present invention.

[0024] The solvent is one of ethanol, ethylene glycol, isopropanol or water.

[0025] The ball mill is an agate ball mill jar, and during ball milling, ball agate mill beads are pla...

Embodiment 1

[0027] Step 1. Take 0.2g Ag 2 V 4 o 11 As a doping material, put it into the agate ball mill jar as a ball mill together with 4g of carbon fluoride, then add 6g of ethanol, and put the ball agate into the agate ball mill jar according to the mass ratio of carbon fluoride and ball milling beads as 1:10 Grinding beads, the diameter of the ball milling beads is 5-15mm, and the materials in the agate ball milling tank are ball milled and mixed for 12 hours under the condition of 300 rpm to form a mixed slurry; by putting in ball agate grinding beads, the two materials can be better mixed Mix well to increase the mixing effect.

[0028] Step 2. Put the mixed slurry formed in step 1 into a drying oven, dry it at 80°C for 10 hours, take it out, and cool it down to room temperature of 25°C naturally to obtain a dry mixture;

[0029] Step 3. After passing the dried mixture in step 2 through a 300-mesh sieve, the obtained powder is used as the mixed positive electrode material for th...

Embodiment 2

[0031] Step 1. Take 0.28g of Ag 2 V 4 o 11 As a doping material, put 4g of carbon fluoride into the agate ball milling jar as a ball mill, then add 7g of ethanol, and then put balls into the agate ball milling jar according to the mass ratio of carbon fluoride and ball milling beads at a ratio of 1:10. Agate grinding beads, the diameter of ball agate grinding beads is in the range of 5-15mm, and the material in the agate ball milling tank is ball milled and mixed for 24h under the condition of 200 rpm to form a mixed slurry;

[0032] Step 2. Put the mixed slurry formed in step 1 into a drying oven, dry it at 80°C for 10 hours, take it out, and cool it down to room temperature of 25°C naturally to obtain a dry mixture;

[0033] Step 3. After passing the dried mixture in step 2 through a 200-mesh sieve, the obtained powder is used as the mixed positive electrode material for the lithium battery of the present invention.

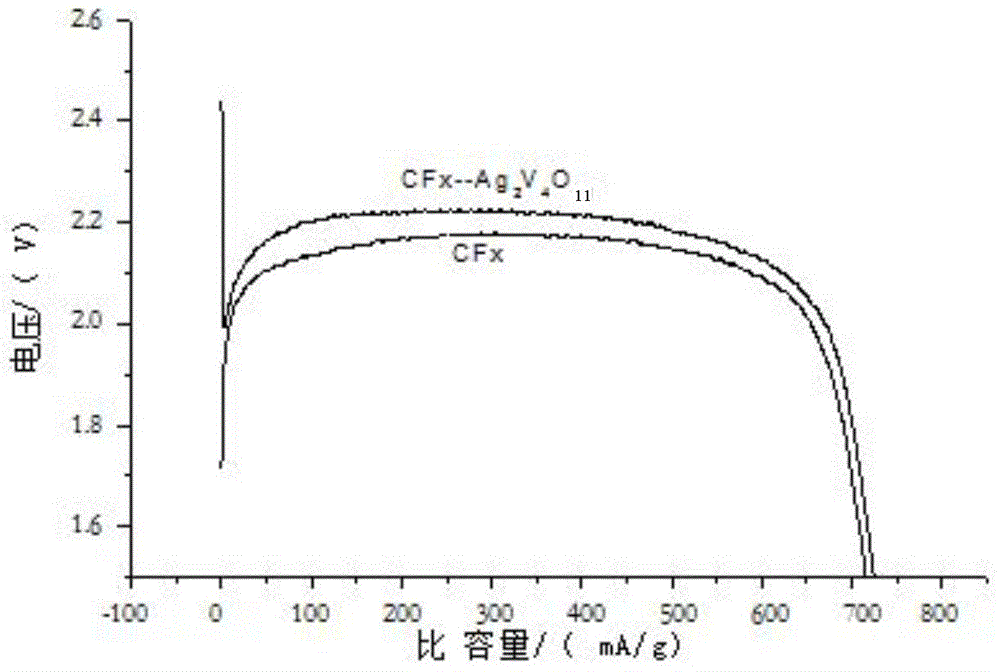

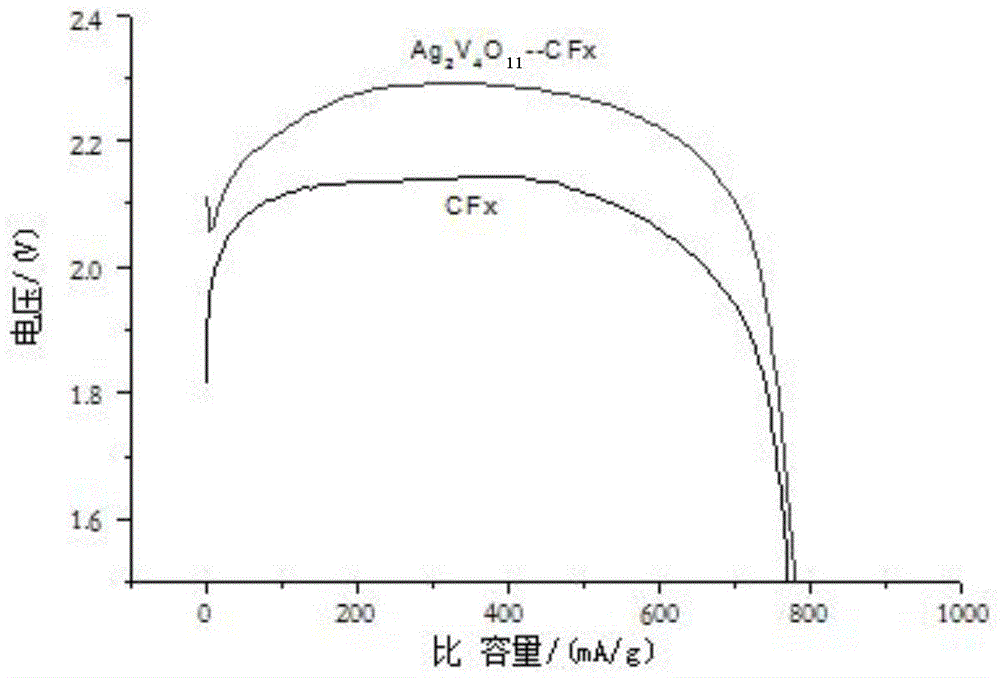

[0034] The mixed positive electrode material prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com