Lead dioxide coated carbon material, making method and zinc-nickel battery containing the same

A technology for lead dioxide and zinc-nickel batteries, which is applied in battery electrodes, alkaline storage batteries, circuits, etc., and can solve the problems of inability to prepare negative electrode slurry, difficulty in dispersing, and passivation of zinc electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

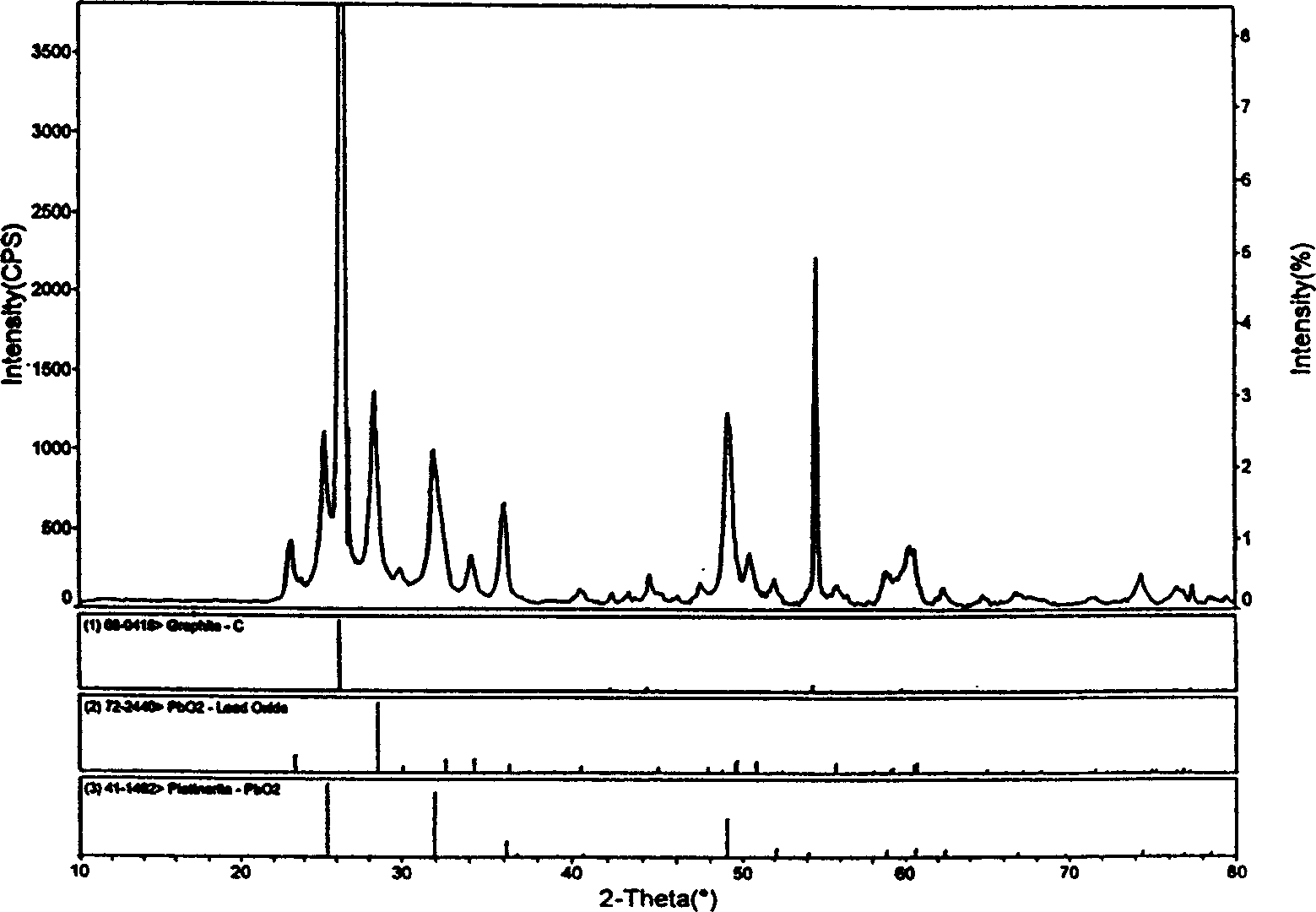

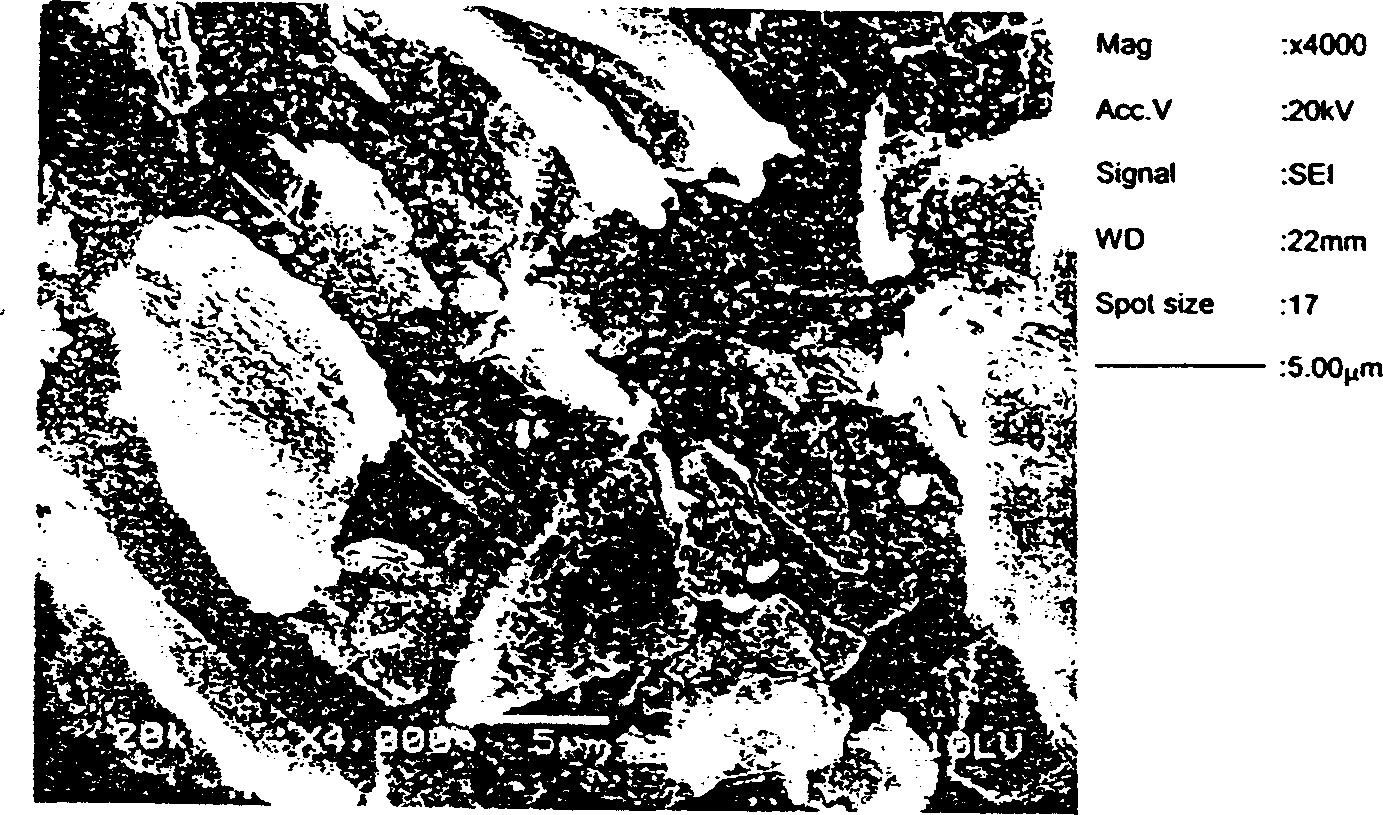

[0041] Take 6 grams of NaClO solution and 2 grams of NaOH to form a solution of 250ml, add 4.8 grams of graphite into the alkaline NaClO solution, and keep stirring. Another 3.04 g of lead acetate was prepared into 100 ml solution, and the lead acetate solution was added dropwise to the alkaline NaClO solution. After the reaction was completed, the solution was filtered with suction, washed with deionized water, and dried. The product is characterized by XRD and SEM, see figure 1 and figure 2 .

Embodiment 2

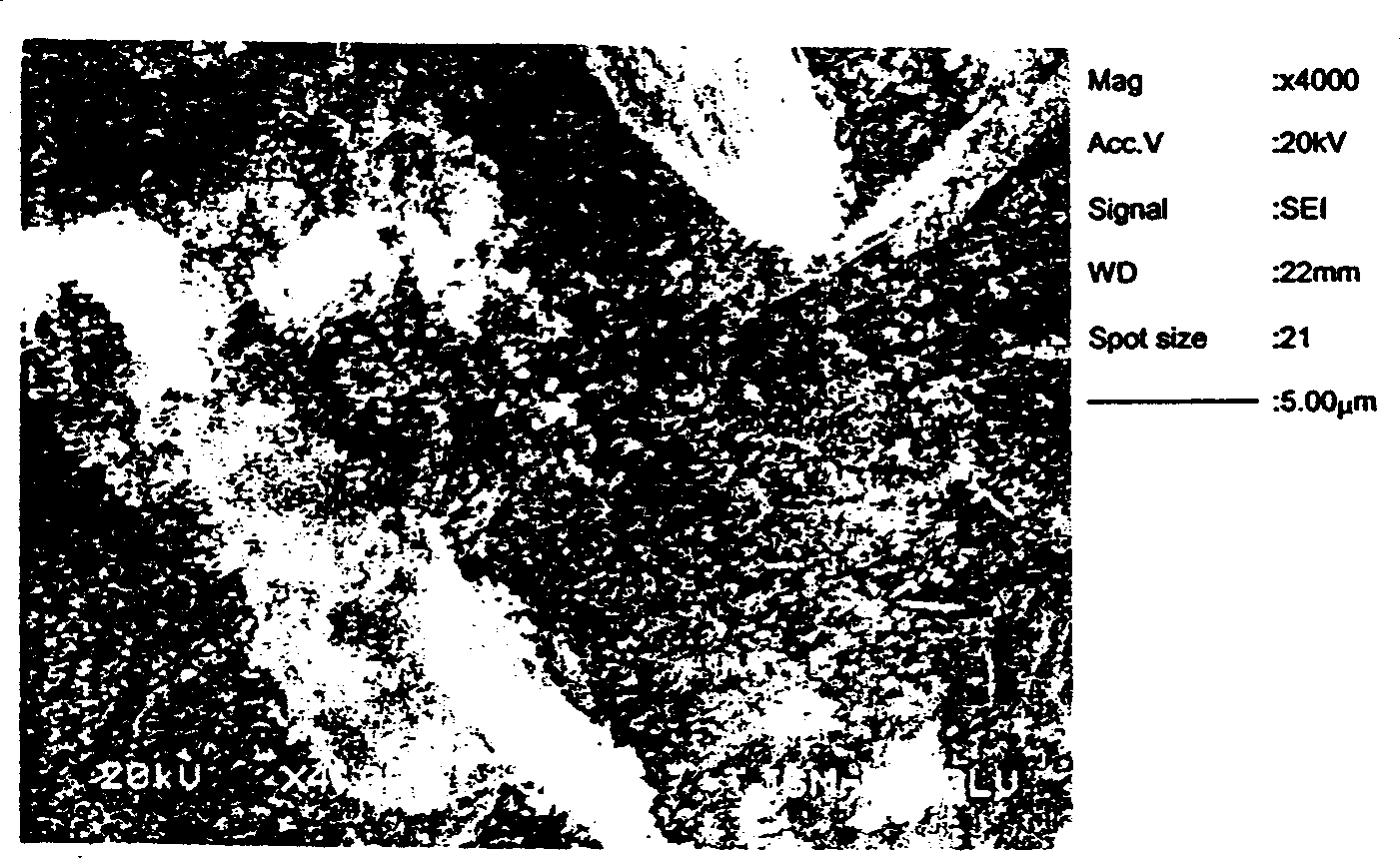

[0043] Take 12 grams of NaClO solution and 4 grams of NaOH to form a solution of 250ml, add 4.8 grams of graphite into the alkaline NaClO solution, and keep stirring. Another 100ml solution of 7.6 grams of lead acetate was taken, and the lead acetate solution was added dropwise to the alkaline NaClO solution. After the reaction was completed, the solution was filtered with suction, washed with deionized water, and dried. The product was characterized by SEM, see image 3 .

Embodiment 3

[0045]Get 5 grams of coated lead dioxide graphite prepared in Example 1, 16 grams of Belgian mercury-free zinc powder, 59 grams of zinc oxide, and 10 grams of calcium hydroxide are mixed uniformly with a mixing device.

[0046] The above mixture was stirred with 4 grams of PTFE, 0.6 grams of PVA, 0.5 grams of HPMC and 40 grams of deionized water to form a viscous slurry. Above-mentioned slurry is attached to the thick 0.07mm that is plated with Pb-Sn alloy plating layer on the punched copper strip of width 33.5mm by drawing machine again. A negative electrode with a length of 220 mm was obtained by drying, rolling, cutting into pieces and welding a drainage tape.

[0047] Stir 92 grams of spherical nickel hydroxide, 7 grams of cobaltous oxide, 11 grams of conductive carbon black, 4 grams of PTFE, 0.2 grams of CMC, and 40 grams of deionized water into a slurry and apply it to the foamed nickel welded with drainage tape On the surface, a positive electrode with a length of 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com