Lithium ion secondary battery positive pole piece and production method thereof

A technology of secondary battery and positive electrode sheet, applied in the direction of secondary battery, battery electrode, circuit, etc., can solve the problems of poor heat dissipation, poor electrode adhesion, poor rate performance, etc. Rate performance and safety performance, and the effect of improving electrical conductivity and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

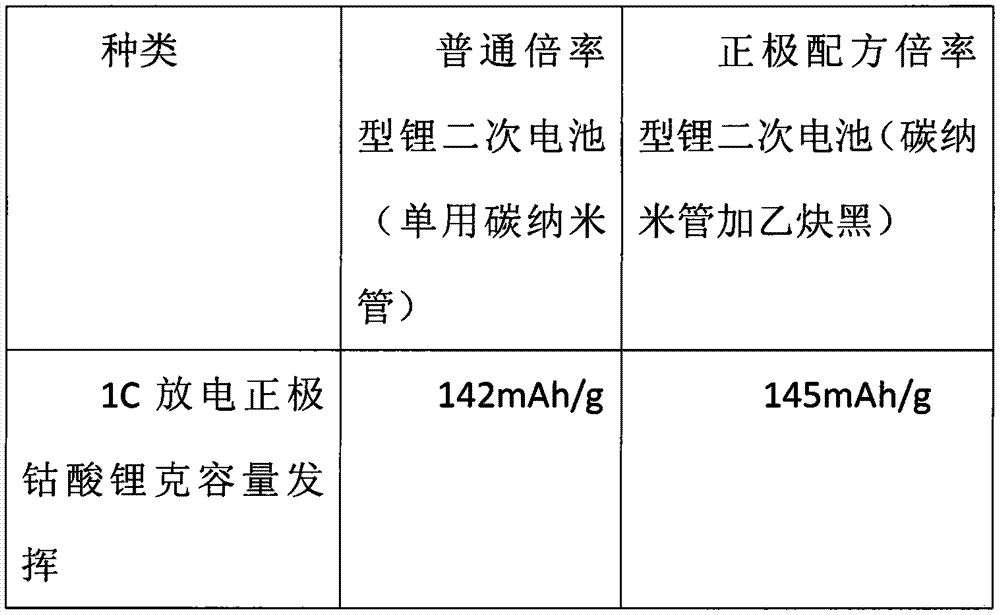

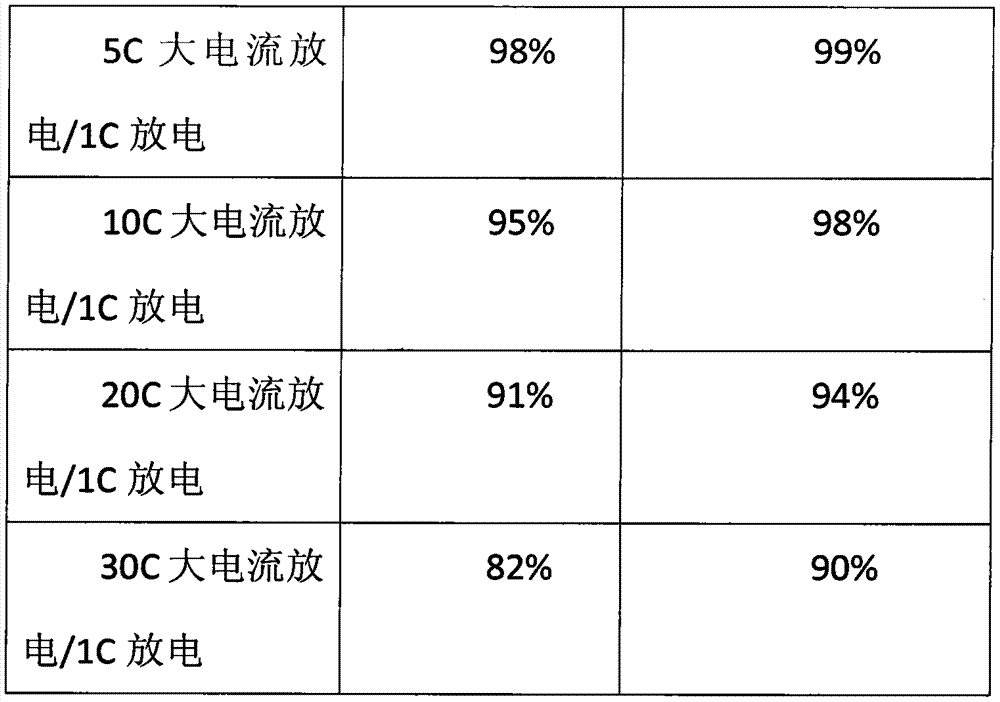

[0014] The lithium ion secondary battery cathode sheet of the present invention comprises active material lithium cobaltate or a mixture of lithium cobaltate and lithium manganate, carbon nanotubes, acetylene black, polyvinylidene fluoride binder, and nitrogen methyl pyrrolidone solvent. Wherein, the average particle size of the carbon nanotubes is 1-10 nm. The active material lithium cobaltate or a mixture of lithium cobaltate and lithium manganate, carbon nanotubes, acetylene black, polyvinylidene fluoride binder, and nitrogen methyl pyrrolidone solvent are respectively 94.5:1.5:2:2 according to the mass ratio: 65 formulated. Carbon nanotubes have good heat transfer performance and have a very large aspect ratio, so their heat exchange performance along the length direction is high. Carbon nanotubes are synthesized by pyrolyzing granular polyethylene at 420-450°C and under H2 atmosphere, using metal Ni as a catalyst. Acetylene black is a carbon black obtained by continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com