Method for preparing manganese sulfate by using sulfur-containing carbonaceous manganese carbonate ore

A technology of manganese carbonate and manganese sulfate, which is applied in the field of metallurgy, can solve the problems of easy production, difficulty in development and utilization, and obstruction of CO2 escape, etc., and achieve ideal reduction effect, less impurities, and low cost of reduction roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

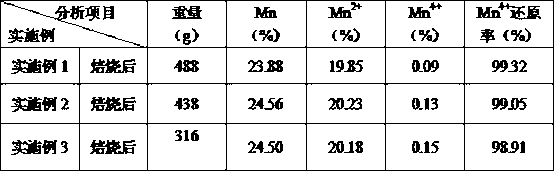

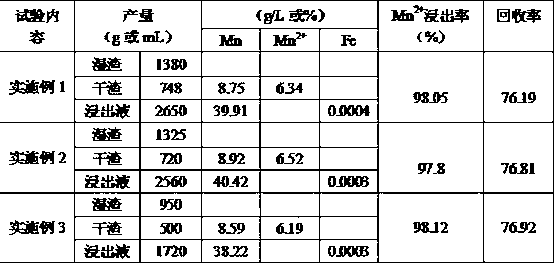

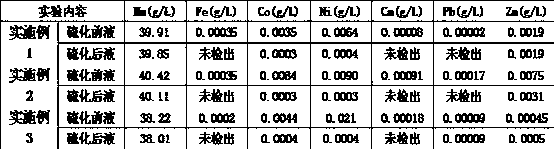

[0015] Embodiment 1 (the percentages described in the following examples are all by weight %)

[0016] 240g 100 mesh sulfur-containing carbonaceous manganese carbonate ore powder (Mn 10.7%, Mn 2+ 10.01%, Mn 4+ 0.11%) and 360g100 mesh pyrolusite powder (Mn 22.83%, Mn 2+ 0.54%, Mn 4+ 21.01%), mixed evenly, put into a ceramic crucible, put into a muffle furnace for roasting, the roasting temperature is 1000°C, the time is 30min, take it out, cool down, put it into the cake, add 3500ml of anolyte (the content of sulfuric acid is 33.82g / L), add 130g of sulfuric acid to make the actual acid consumption 110% of the theoretical value, acid leaching at room temperature (about 25°C) for 120min with stirring, filter, add ammonia water to the filtrate to adjust the pH to 3, filter to remove iron, add 2g to the filtrate Sodium formam, 4g sodium sulfide, stir evenly, filter, the filtrate is pure manganese sulfate liquid.

Embodiment 2

[0018] 200g80 mesh sulfur-containing carbonaceous manganese carbonate ore powder (Mn 10.7%, Mn 2+ 10.01%, Mn 4+ 0.11%) and 360g120 mesh pyrolusite powder (Mn 22.83%, Mn 2+ 0.54%, Mn 4+ 21.01%), mixed evenly, put into a ceramic crucible, put into a muffle furnace for roasting, the roasting temperature is 750°C, the time is 120min, take it out, cool down, put it into a sesame cake, add 3500ml of anolyte (the content of sulfuric acid is 33.82g / L), add 76g of sulfuric acid to make the actual acid consumption 90% of the theoretical value, raise the temperature to 50°C, pickle for 100min under stirring, filter, add ammonia water to the filtrate to adjust the pH to 4.5, filter to remove iron, add 2g of sulfide to the filtrate Ammonium, 4g ferrous sulfide, stir evenly, filter, and the filtrate is pure manganese sulfate liquid.

Embodiment 3

[0020] 200g 100 mesh sulfur-containing carbonaceous manganese carbonate ore powder (Mn 10.7%, Mn 2+ 10.01%, Mn 4+ 0.11%) and 200g100 mesh pyrolusite powder (Mn 22.83%, Mn 2+ 0.54%, Mn 4+ 21.01%) mixed evenly, put into a ceramic crucible, put into a muffle furnace for roasting, the roasting temperature is 850°C, the time is 90min, take it out, cool down, put it into the sesame cake, add 2500ml of anolyte (the content of sulfuric acid is 33.82g / L), add 52g of sulfuric acid to make the actual acid consumption 100% of the theoretical value, acid leaching for 120min under normal temperature stirring, filter, add ammonia water to the filtrate to adjust the pH to 6, filter to remove iron, add 3g of sodium sulfame to the filtrate, stir evenly, Filtration, the filtrate is pure manganese sulfate liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com