Method for extracting vanadium from vanadium-containing ores

An ore, stone coal vanadium technology, applied in the direction of improving process efficiency, can solve the problems of large amount of sulfuric acid, high energy consumption, high temperature, and achieve the effect of strong applicability of raw materials, solving material adhesion and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

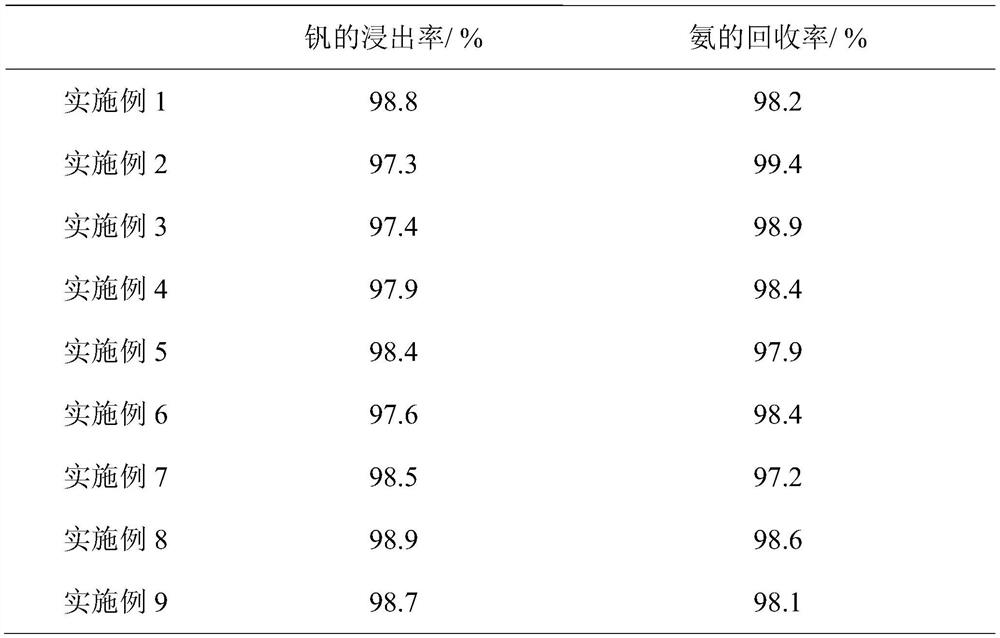

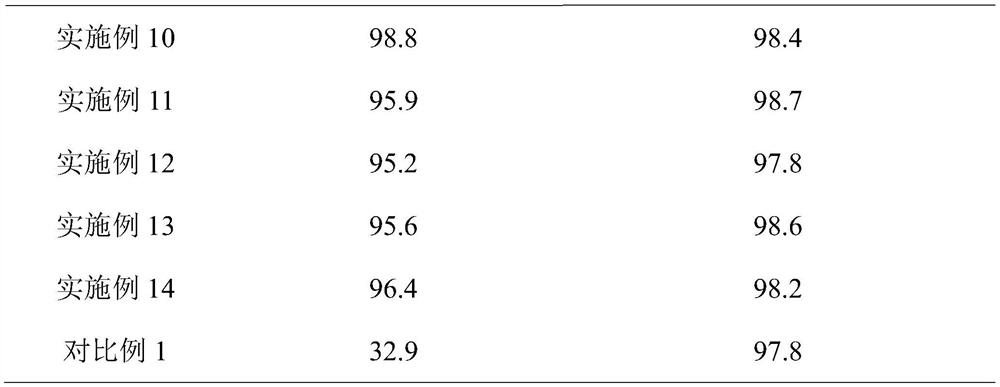

Examples

Embodiment 1

[0065] The present embodiment provides a method for extracting vanadium from vanadium-containing ore, said vanadium-containing ore is primary stone coal vanadium ore, and its main components and content are: V 2 o 5 0.74wt%, Fe 2 o 3 1.23wt%, CaO 0.15wt%, MgO 0.34wt%, Al 2 o 3 10.72wt%, K 2 O 3.65wt%, the rest is SiO 2 and C.

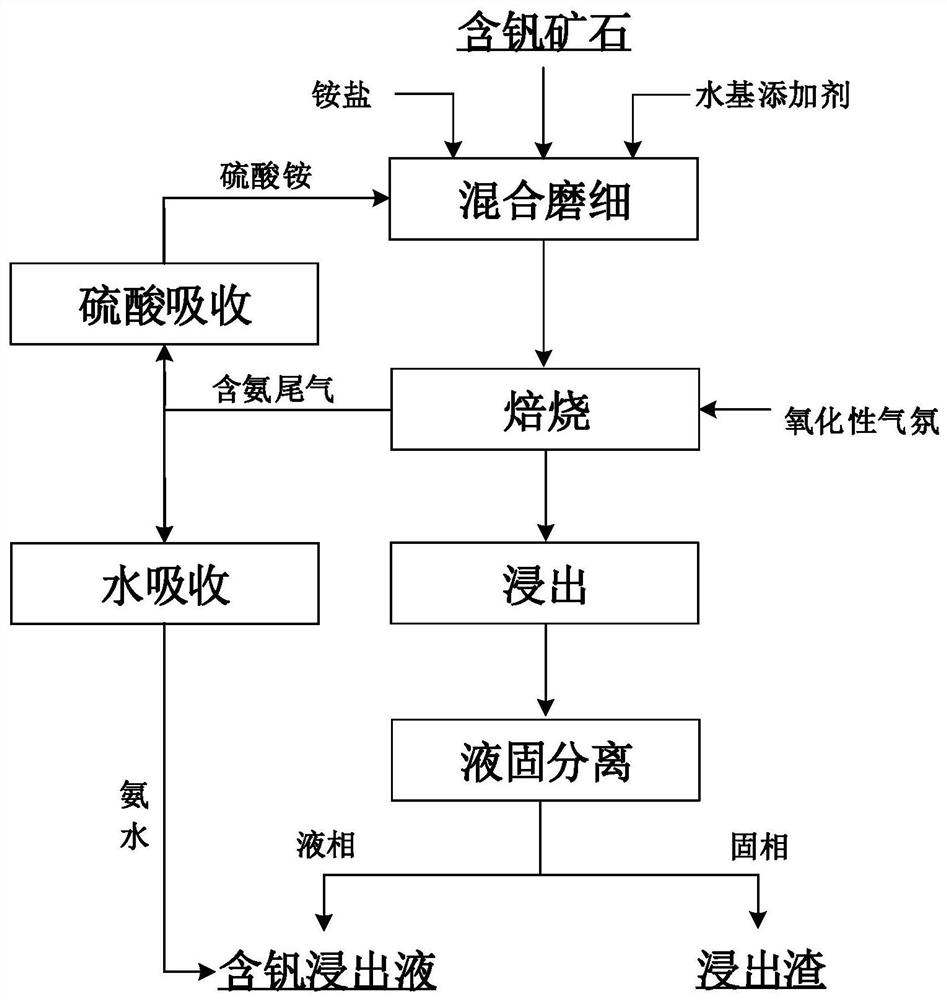

[0066] The process flow diagram of the method is as figure 1 shown, including the following steps:

[0067] (1) Mix and grind the stone coal vanadium ore with ammonium sulfate and magnesium sulfate heptahydrate in a mass ratio of 1:1.5:0.07 to obtain a mixed powder with a particle size not greater than 150 μm;

[0068] (2) Roast the mixed powder obtained in step (1) for 3 hours in an atmosphere containing 20vol.% oxygen and 80vol.% water vapor, the temperature of the roasting is 330°C, and the ammonia-containing tail gas produced during the roasting process is absorbed by water , to obtain ammoniacal liquor; the obtained ammoniacal liquor is...

Embodiment 2

[0071] This embodiment provides a method for extracting vanadium from vanadium-containing ore, the vanadium-containing ore is primary stone coal vanadium ore, and its main components and contents are the same as those in Embodiment 1.

[0072] The method comprises the steps of:

[0073] (1) Mix and grind the stone coal vanadium ore with ammonium sulfate, calcium sulfate dihydrate and ferrous sulfate heptahydrate in a mass ratio of 1:1:0.03:0.03 to obtain a mixed powder with a particle size not greater than 104 μm;

[0074] (2) Roasting the mixed powder obtained in step (1) for 1 h in an air atmosphere, the temperature of the roasting is 380° C., and the ammonia-containing tail gas produced in the roasting process is absorbed by sulfuric acid to obtain an ammonium sulfate solution; the obtained ammonium sulfate solution After being made into solid ammonium sulfate, it is returned for recycling;

[0075](3) The mixed powder after step (2) is roasted is leached with water at 65°...

Embodiment 3

[0077] The present embodiment provides a method for extracting vanadium from vanadium-containing ores, the vanadium-containing ores are primary stone coal vanadium ores, and the main components and contents are respectively: V 2 o 5 1.26wt%, Fe 2 o 3 0.59wt%, CaO 6.35wt%, MgO2.17wt%, Al 2 o 3 7.62wt%, K 2 O 2.16wt%, the rest is SiO 2 and C.

[0078] The method comprises the steps of:

[0079] (1) Mix and grind the stone coal vanadium ore, ammonium bisulfate and water in a mass ratio of 1:1.2:0.2 to obtain a mixed powder with a particle size not greater than 89 μm;

[0080] (2) The mixed powder obtained in step (1) is roasted for 6 hours in an atmosphere containing 5vol.% of air and 95vol.% of water vapor. The temperature of roasting is 300°C. Absorb to obtain ammonia water; the obtained ammonia water is used for the neutralization of vanadium-containing leachate;

[0081] (3) The mixed powder after step (2) is roasted is leached with water at 60°C for 120min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com