A method for extracting vanadium from vanadium-containing ore

A technology for ore and clay vanadium ore, applied in the field of vanadium extraction, can solve the problems of large amount of sulfuric acid, high energy consumption and high cost, and achieve the effects of less residual acid, low energy consumption and strong applicability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

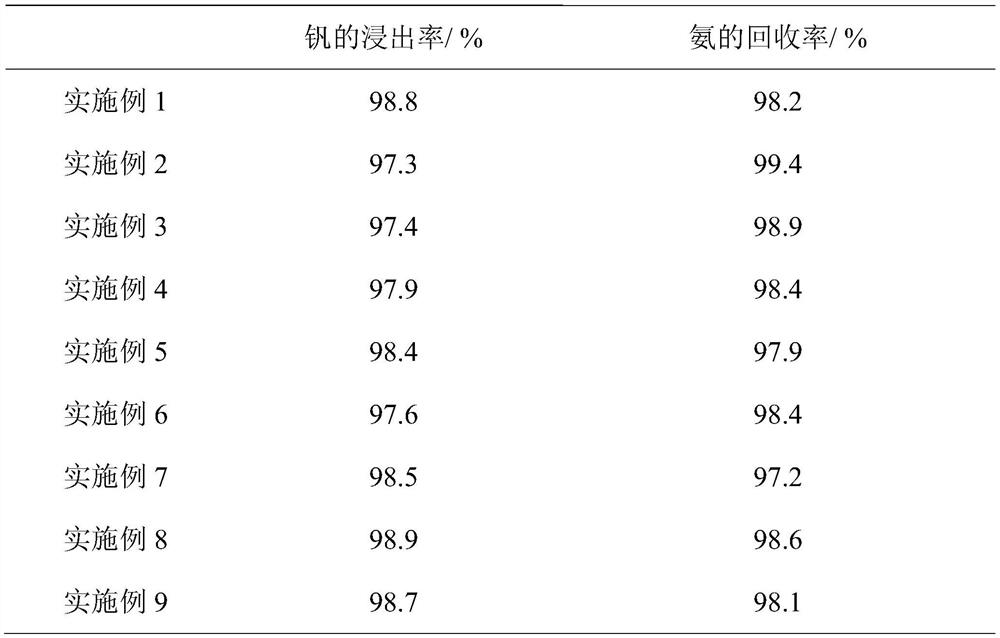

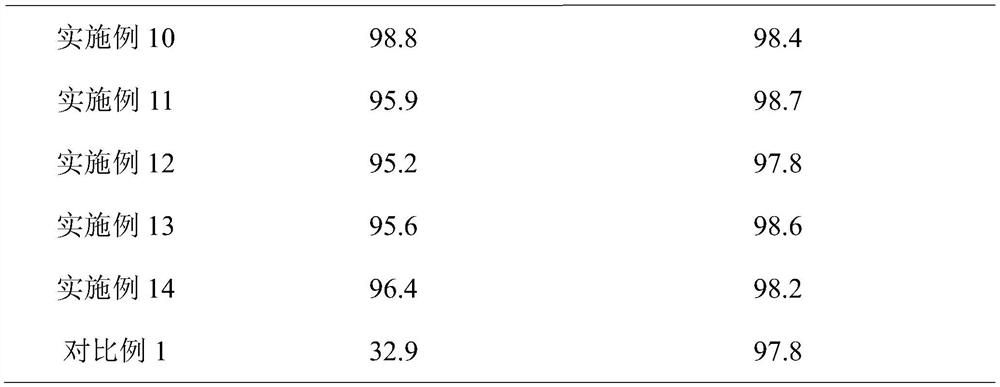

Examples

Embodiment 1

[0065] This embodiment provides a method of extracting vanadium from the vanadium ore, the vanadium ore is the primary stone coal vanadium ore, its main components and content are: V 2 O 5 0.74 wt%, Fe 2 O 3 1.23 wt%, CaO 0.15 wt%, MgO 0.34 wt%, Al 2 O 3 10.72 wt%, K 2 O 3.65 wt%, the remaining ingredients are SiO 2 And C.

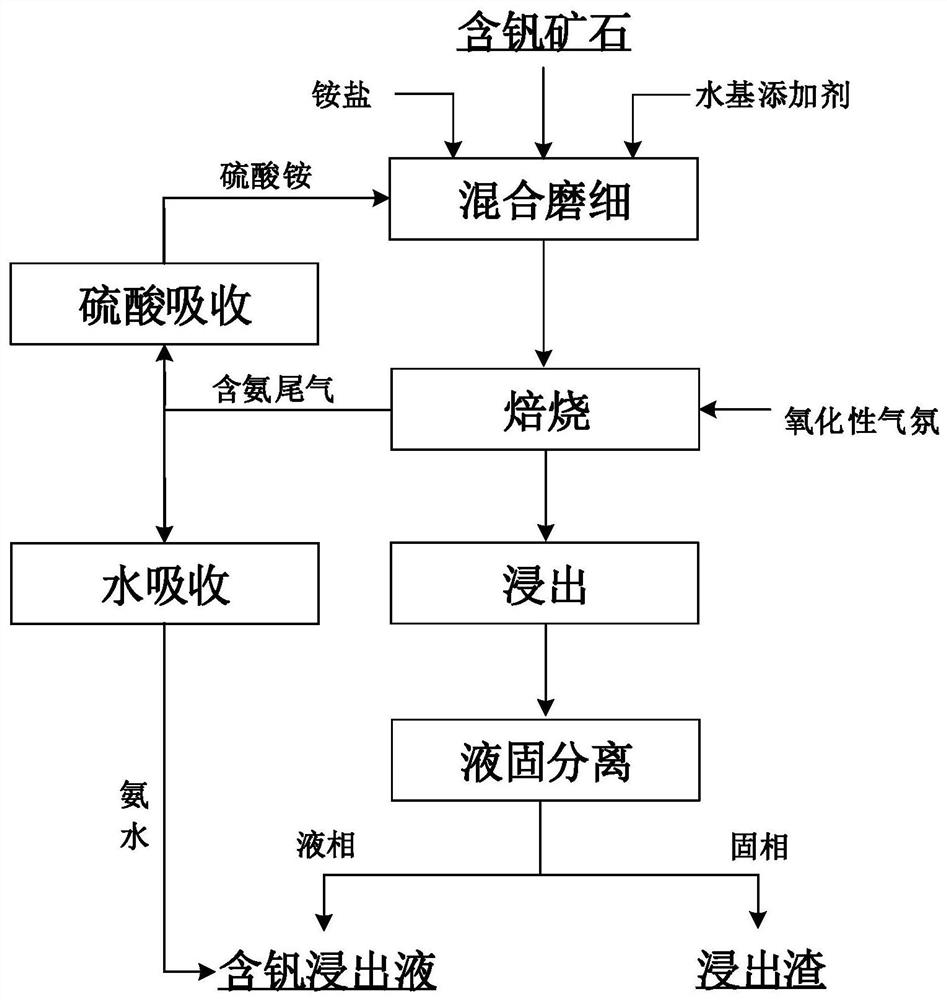

[0066] The process flow chart of the method is figure 1 As shown, including the following steps:

[0067] (1) Mixing the stone coal vanadium and ammonium sulfate and phthalic sulfate is 1: 1.5: 0.07 by mass 1: 1.5: 0.07, and obtain a mixed powder having a particle size of no greater than 150 μm;

[0068] (2) The mixed powder obtained by step (1) is calcined by 20 vol.% Oxygen, 80 vol.% Water vapor, the calcination temperature is 330 ° C, and the ammonia-free gas generated during the calcination process is absorbed. To obtain ammonia water; obtained ammonia water is used in neutralization of vanadium-containing leaching liquid;

[0069] (3) The mixed powder aft...

Embodiment 2

[0071] This embodiment provides a method of extracting vanadium from the vanadium ore, the vanadium ore is the primary stone coal vanadium ore, and its main components and content are the same as in Example 1.

[0072] The method includes the following steps:

[0073] (1) Mixing the stone coal vanadium ore with ammonium sulfate, calcium sulfate and seven water sulfate is 1: 1: 0.03: 0.03 to obtain a mixed powder having a particle size of no greater than 104 μm;

[0074] (2) The mixed powder obtained by step (1) is calcined in the air atmosphere of 1 h, and the calcined temperature is 380 ° C, and the ammonia tail gas generated during the calcination process is absorbed, and ammonium sulfate solution is obtained; ammonium sulfate solution After the ammonium sulfate solid is made, it is returned to recycle;

[0075](3) The mixed powder after the step (2) is allowed to extract 60 min at 65 ° C, and the leached liquid solid ratio is 0.25m. 3 : 1T, then filtered separation to give vana...

Embodiment 3

[0077] This embodiment provides a method of extracting vanadium from the vanadium ore, the vanadium ore is the primary stone coal vanadium ore, the main components and content are: V 2 O 5 1.26WT%, Fe 2 O 3 0.59 wt%, CaO 6.35 wt%, MgO2.17Wt%, Al 2 O 3 7.62 wt%, K 2 O 2.16 wt%, the remaining ingredients are SiO 2 And C.

[0078] The method includes the following steps:

[0079] (1) Mix the stone coal vanadium ore and ammonium hydrogen sulfate and water are mixed, abrupt, and obtain a mixed powder having a particle size of no more than 89 μm;

[0080] (2) The mixed powder obtained by step (1) is calcined by 5 vol.% Air, 95 vol.%, The temperature of 300 ° C, and the ammonia tail gas generated during the calcination process is carried out by water. Absorption to obtain ammonia water; the obtained ammonia water is used in the neutralization of vanadium leaching.

[0081] (3) The mixed powder after the step (2) is fed by water 120 min at 60 ° C, and the leached liquid solid ratio is 3m....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com