Novel preparation method of anode material LiMn2O4 of high-power-performance lithium ion battery

A cathode material, high-performance technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor material rate performance, achieve high crystallinity, ensure performance stability, and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

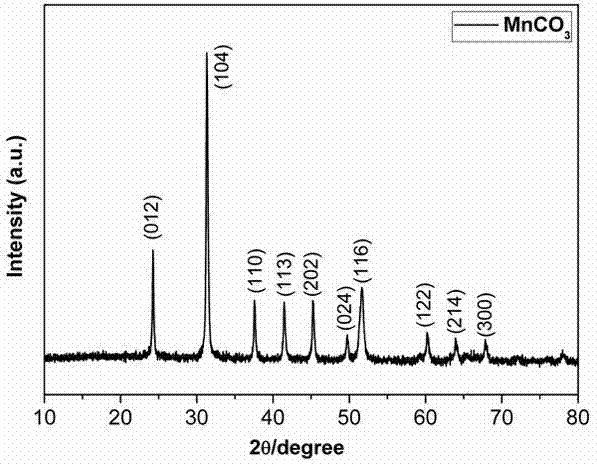

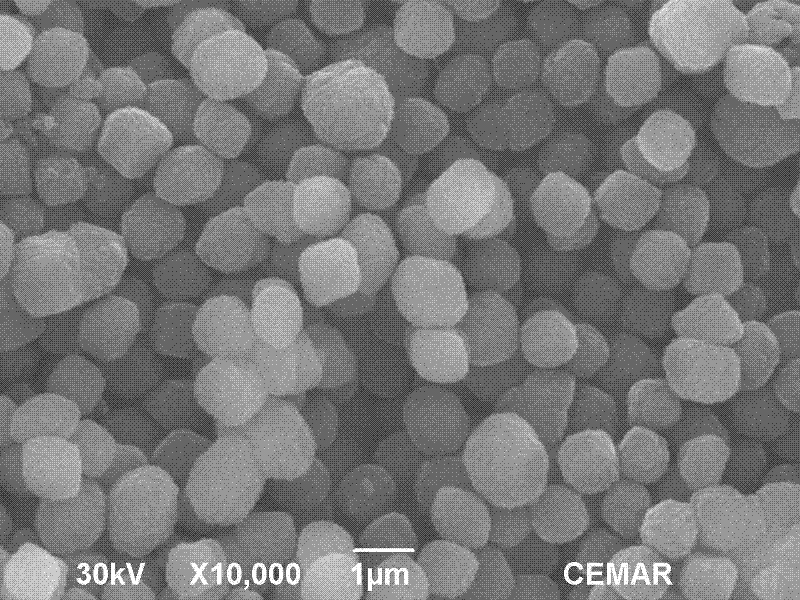

[0038] Weigh 2.969 g of MnCl 2 ·H 2 O, dissolved in 33 mL of ethylene glycol solution, and then added dropwise 1.5─2.0 g of polyethylene glycol 2000, at 50 oC Under the condition of heating in a water bath, slowly add 2.70 g of urea (the molar ratio of manganese dichloride: urea is 1:3) while stirring, and continue stirring for 1 hour while maintaining the temperature. The mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined reactor and reacted at 200°C for 12 hours. After the reactor was cooled to room temperature, the resulting precipitate was separated by filtration, washed three times with deionized water and absolute ethanol, and dried in vacuum at 80°C for 12 hours to obtain white spherical MnCO 3 Precursor.

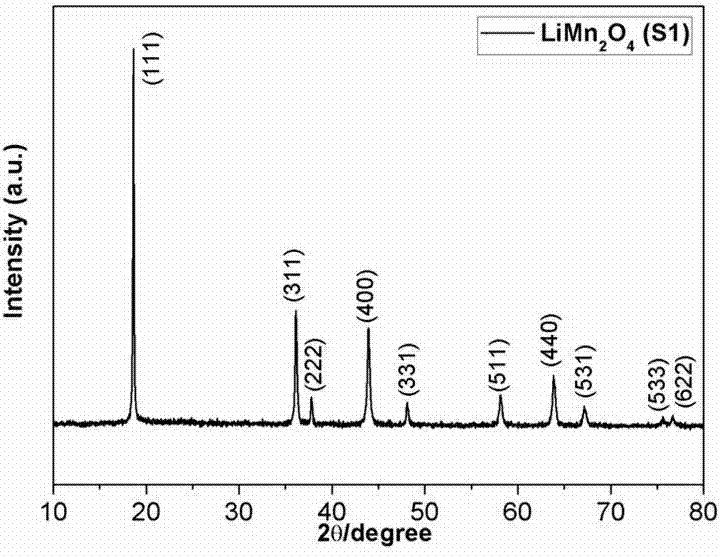

[0039] The eutectic lithium salt 0.38Li(OH) . h 2 O─0.62LiNO 3 With the above product spherical MnCO 3 After the precursors were fully mixed according to the ratio of the substance molar ratio of 1.05:2, they were incubated at 200 °C for ...

Embodiment 2

[0042] Weigh 2.969 g of MnCl 2 ·H 2 O, dissolved in 33 mL of ethylene glycol solution, and then added dropwise 1.5─2.0 g of polyethylene glycol 2000, at 50 oC Under the condition of heating in a water bath, slowly add 2.70 g of urea (the molar ratio of manganese dichloride: urea is 1:3) while stirring, and continue stirring for 1 hour while maintaining the temperature. The mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined reactor and reacted at 200°C for 24 hours. After the reactor was cooled to room temperature, the resulting precipitate was separated by filtration, washed three times with deionized water and absolute ethanol, and dried in vacuum at 80°C for 12 hours to obtain white spherical MnCO 3 Precursor.

[0043] The eutectic lithium salt 0.38LiOH·H 2 O─0.62LiNO 3 With the above product MnCO 3 After fully mixing according to the ratio of 1.1 : 2, heat preservation at 200 °C for 3 h, and then calcined at 700 °C for 8 h to obtain a black produ...

Embodiment 3

[0046] Weigh 2.969 g of MnCl 2 ·H 2 O, dissolved in 33 mL of ethylene glycol solution, and then added dropwise 1.5─2.0 g of polyethylene glycol 2000, at 50 oC Under the condition of heating in a water bath, slowly add 2.70 g of urea (the molar ratio of manganese dichloride: urea is 1:3) while stirring, and continue stirring for 1 hour while maintaining the temperature. The mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined reactor and reacted at 120°C for 12 hours. After the reactor was cooled to room temperature, the resulting precipitate was separated by filtration, washed three times with deionized water and absolute ethanol, and dried in vacuum at 80°C for 12 hours to obtain white spherical MnCO 3 Precursor.

[0047] The eutectic lithium salt 0.38LiOH·H 2 O─0.62LiNO 3 With the above product MnCO 3 After fully mixing according to the ratio of 1: 2, heat preservation at 200 °C for 3 h, and then calcined at 700 °C for 8 h to obtain a black product....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com