Preparation method of high-voltage cathode material Lil+xMn3/2-yNil/2-zMy+zO4 of lithium ion battery with long service life

A technology of positive electrode material and precipitation method, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of cumbersome process and achieve the effects of simple process, improved cycle performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

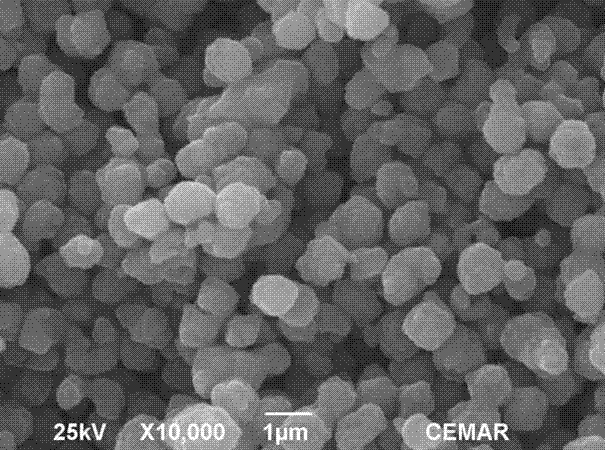

[0028] Weigh 2.969 g of MnCl 2 ·H 2 O, dissolved in 33 mL of ethylene glycol solution, and then added dropwise 1.5─2.0 g of polyethylene glycol 2000, at 50 oC Under the condition of heating in a water bath, slowly add 2.70 g of urea (the molar ratio of manganese dichloride: urea is 1:3) while stirring, and keep stirring for 1 hour at this temperature. The mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined reactor and reacted at 200°C for 12 hours. After the reactor was cooled to room temperature, the resulting precipitate was separated by filtration, washed three times with deionized water and absolute ethanol, and dried under vacuum at 80°C for 12 hours to obtain white spherical MnCO 3 Precursor.

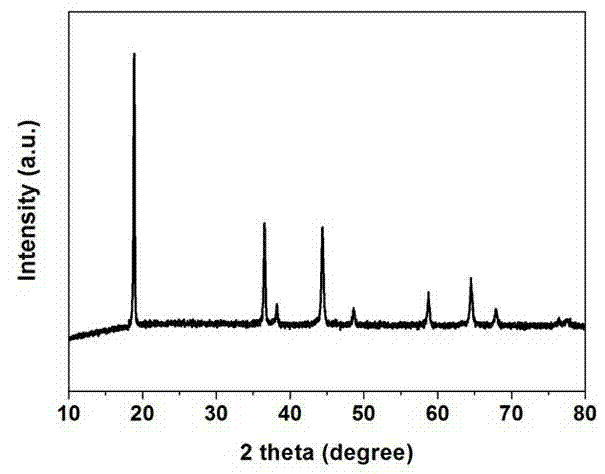

[0029] The eutectic lithium salt 0.38Li(OH) . h 2 O─0.62LiNO 3 , Spherical MnCO 3 with Ni(NO 3 ) 2 . 6H 2 O was fully mixed according to the ratio of 1.02:1.5:0.5, and kept at 200 °C for 4 h, and then calcined at 800 °C for 12 h to obtain a black pro...

Embodiment 2

[0032] The eutectic lithium salt 0.38Li(OH) . h 2 O─0.62LiNO 3 , the spherical MnCO prepared by Example 1 3 with Ni(NO 3 ) 2 . 6H 2 O was fully mixed according to the ratio of 1.05:1.5:0.5, then kept at 200 °C for 4 h, and then calcined at 800 °C for 12 h to obtain a black product, which was analyzed by elemental analysis and XRD respectively. It shows that the product is lithium nickel manganese oxide (Li 1.05 mn 1.5 Ni 0。5 o 4 ).

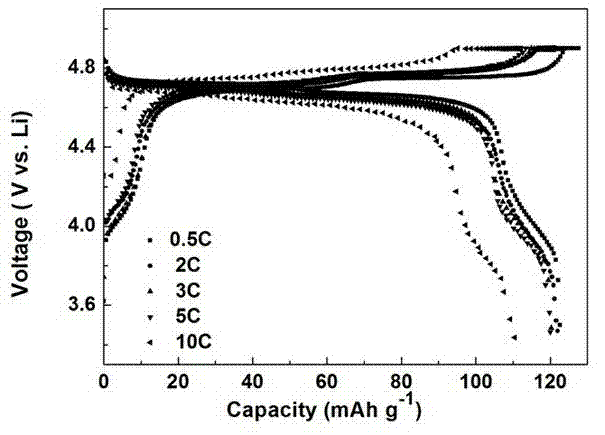

[0033] The spherical lithium nickel manganese oxide prepared under the above conditions was used as the positive electrode active material and matched with the appropriate electrolyte and separator to assemble a CR2025 battery. Under the charge and discharge conditions of 3.5─4.9 V, 2 C, the first cycle discharge specific capacity of this material is 120.0 mAh g -1 , the capacity retention after 300 cycles was 94%.

Embodiment 3

[0035] The eutectic lithium salt 0.74LiOH·H 2 O─0.26Li 2 CO 3 , the spherical MnCO prepared by Example 1 3 with Ni(NO 3 ) 2 . 6H 2 O was fully mixed according to the ratio of 1.02:1.5:0.5, and kept at 420 °C for 4 h, and then calcined at 700 °C for 12 h to obtain a black product, which was analyzed by elemental analysis and XRD respectively. It shows that the product is lithium nickel manganese oxide (Li 1.02 mn 0.5 Ni 0.5 o 4 -700 o C).

[0036] The spherical lithium nickel manganese oxide prepared under the above conditions was used as the positive electrode active material and matched with the appropriate electrolyte and separator to assemble a CR2025 battery. Under the charge and discharge conditions of 3.5─4.9 V, 2 C, the first cycle discharge capacity of this material is 111 mAh g -1 , with a capacity of 105 mAh g after 100 cycles -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com