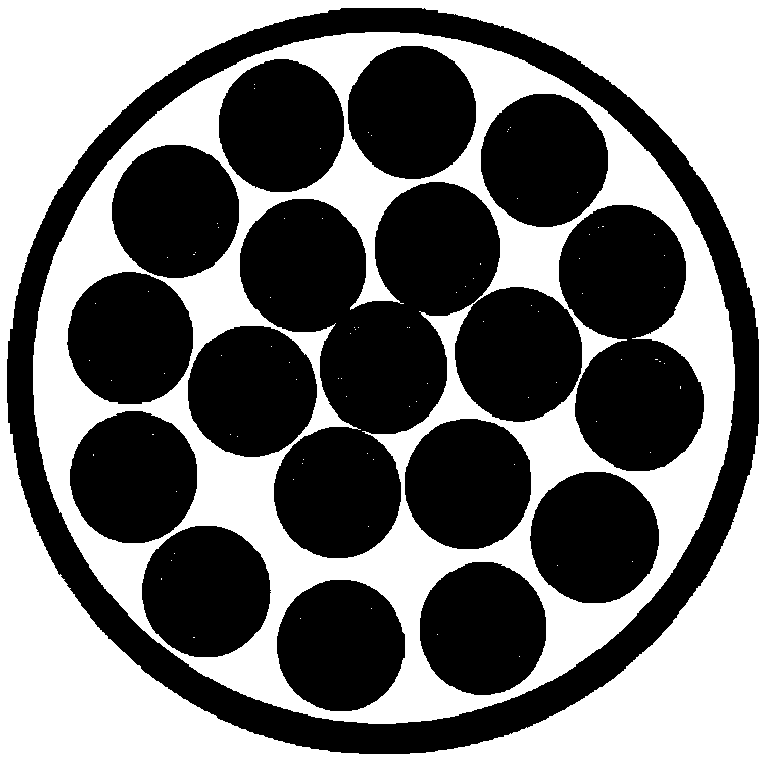

A preparation method of a double-carbon layer coated manganese oxide composite material

A technology of composite materials and manganese oxide, which is applied in nanotechnology, electrochemical generators, electrical components, etc. for materials and surface science. The effect of loss of active substances, wide range of raw material sources, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

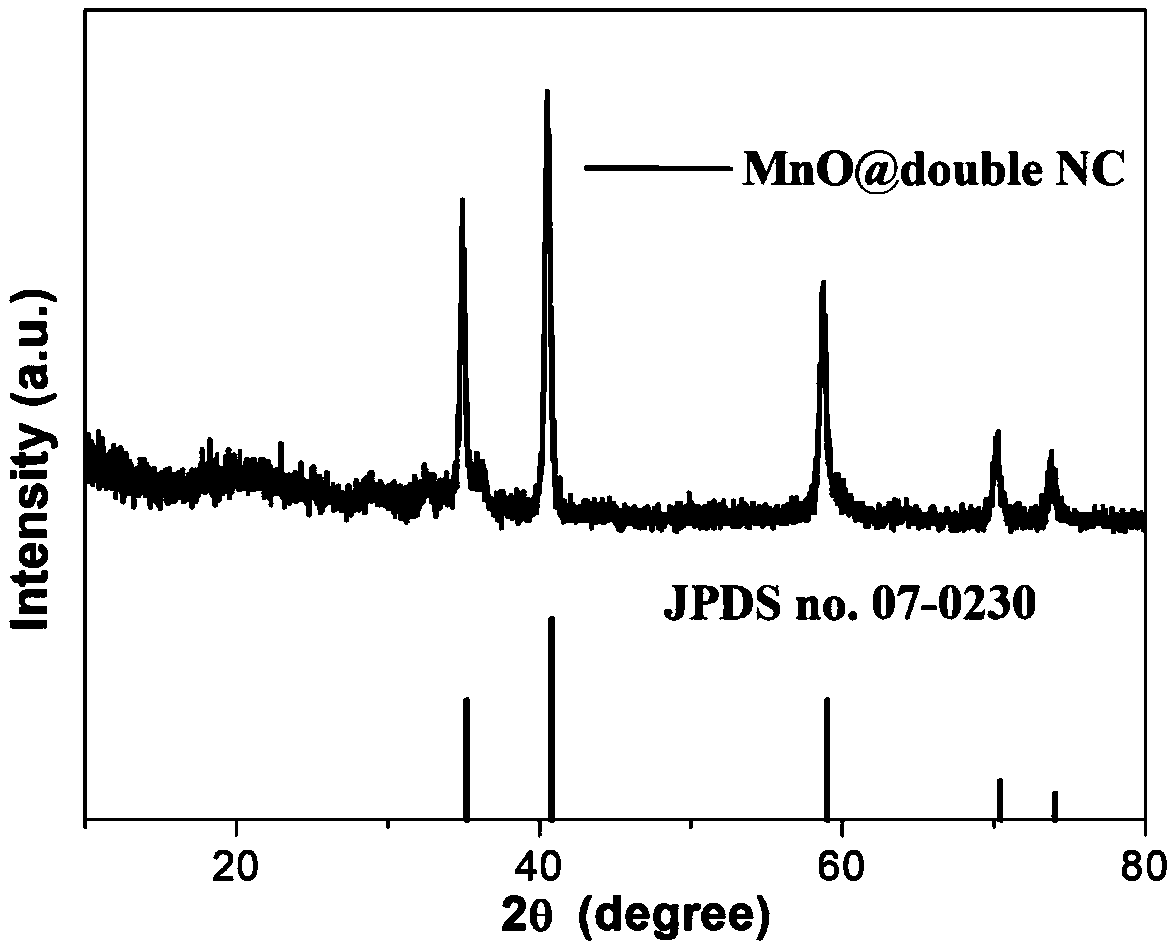

Image

Examples

Embodiment 1

[0048] A kind of preparation method of double carbon layer coated manganese oxide composite material of the present invention, comprises the following steps:

[0049] (1) Take 2mmol MnSO 4 Add 40ml ethanol and 40ml deionized water mixed solution, 10mmol NH 4 HCO 3 Add 40ml of deionized water, mix the two together and stir for 3 hours to carry out co-precipitation reaction. The reaction product is filtered, washed, and dried in a vacuum oven at 120°C for 6 hours to obtain spherical manganese carbonate;

[0050] (2) Take 1g of spherical manganese carbonate and put it into a mixed solution of 100ml of deionized water and 100ml of absolute ethanol. After being uniformly dispersed by ultrasonic waves, add 5g of glucose, stir for 10h, dry in a vacuum oven at 120°C for 10h, and place In a tube furnace, raise the temperature to 400°C at a rate of 2°C / min in an argon atmosphere and keep it warm for 10 hours, and take it out after cooling to room temperature to obtain a precursor;

...

Embodiment 2

[0055] A kind of preparation method of double carbon layer coated manganese oxide composite material of the present invention, comprises the following steps:

[0056] (1) Take 2mmol MnSO 4 Add 40ml ethanol and 40ml deionized water mixed solution, 20mmol NH 4 HCO 3 Add 40ml of deionized water, mix the two together and stir for 8 hours to carry out co-precipitation reaction. The reaction product is filtered, washed, and dried in a vacuum oven at 105°C for 12 hours to obtain spherical manganese carbonate;

[0057] (2) Take 1g of spherical manganese carbonate and put it into a mixed solution of 100ml of deionized water and 100ml of absolute ethanol. After being uniformly dispersed by ultrasonic waves, add 1g of glucose, stir for 24h, dry in a vacuum oven at 105°C for 20h, and place In a tube furnace, raise the temperature up to 500°C at a rate of 5°C / min in an argon atmosphere and keep it warm for 6 hours, and take it out after cooling to room temperature to obtain a precursor; ...

Embodiment 3

[0062] A kind of preparation method of double carbon layer coated manganese oxide composite material of the present invention, comprises the following steps:

[0063] (1) Take 2mmol MnSO 4 Add 40ml ethanol and 40ml deionized water mixed solution, 16mmol NH 4 HCO 3 Add 40ml of deionized water, mix the two together and stir for 5 hours to carry out co-precipitation reaction. The reaction product is filtered, washed, and dried in a vacuum oven at 110°C for 8 hours to obtain spherical manganese carbonate;

[0064] (2) Take 1g of spherical manganese carbonate and put it into a mixed solution of 100ml of deionized water and 100ml of absolute ethanol. After being dispersed evenly by ultrasonic waves, add 3g of glucose, stir for 18h, dry in a vacuum oven at 110°C for 15h, and place In a tube furnace, raise the temperature to 450°C at a rate of 3°C / min in an argon atmosphere and keep it for 8 hours, and take it out after cooling to room temperature to obtain a precursor;

[0065] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com