Nanometer manganese carbonate/graphene hydrogel complex and preparation method thereof

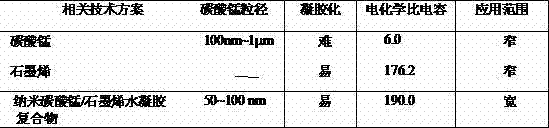

A graphene hydrogel, nano-carbonic acid technology, applied in nano-carbon, graphene, manganese compounds and other directions, can solve problems such as affecting the purity of manganese carbonate, instability of melamine, easy decomposition reaction, etc., and achieves a simple and reliable preparation method. Good electrochemical performance, effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

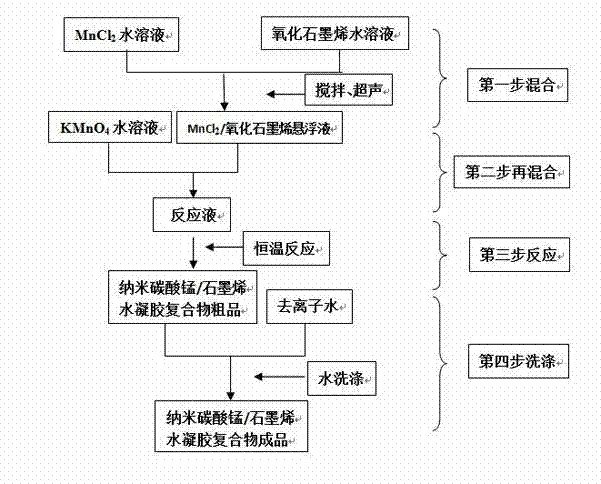

[0020] combine figure 1 , the preparation method of a kind of nano-manganese carbonate / graphene hydrogel compound that the present invention proposes, it is characterized in that comprising the following steps:

[0021] The first step of mixing: the MnCl 2 The aqueous solution was added to the graphene oxide aqueous solution, and under the conditions of stirring and ultrasonic oscillation, a uniform MnCl 2 / graphene oxide suspension;

[0022] The second step is to mix again: KMnO 4 Add the aqueous solution to the MnCl obtained in the first step 2 / Graphene oxide suspension forms a reaction liquid with it;

[0023] The third step reaction: the reaction solution obtained in the second step is placed in a closed reaction kettle for constant temperature reaction, and the chemical equation is:

[0024] , , , to obtain the crude product of nano-manganese carbonate / graphene hydrogel composite;

[0025] The fourth step of washing: adding deionized water to the crude nano...

Embodiment 1

[0030] Mixing step 1: Mix 40 μl MnCl 2 Aqueous solution (100 mg / ml) was added to 2 ml graphene oxide aqueous solution (5 mg / ml), under the conditions of stirring and ultrasonic oscillation for 45 min, a uniform MnCl 2 / graphene oxide suspension;

[0031] Second step remixing: 4 mg KMnO 4 Dissolve in 0.4 ml water to form KMnO 4 aqueous solution, 0.4 ml KMnO 4 Add the MnCl obtained in the first step to the aqueous solution 2 / Graphene oxide suspension forms a reaction liquid with it;

[0032] The third step reaction: the reaction solution obtained in the second step is placed in a closed reaction kettle for constant temperature reaction, the reaction temperature is 180 o C, the reaction time is 48 h, and the crude product of nano-manganese carbonate / graphene hydrogel composite is obtained;

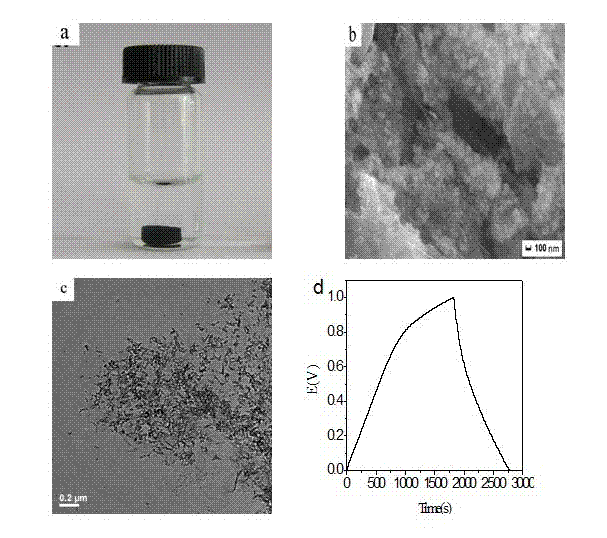

[0033] The fourth step of washing: the crude nano-manganese carbonate / graphene hydrogel composite obtained in the third step is washed with 100 ml of deionized water to obtain the fi...

Embodiment 2

[0036] Mixing step 1: Mix 20 μl MnCl 2 Aqueous solution (100 mg / ml) was added to 2ml graphene oxide aqueous solution (5 mg / ml), under the conditions of stirring and ultrasonic oscillation for 45 min, a uniform MnCl 2 / graphene oxide suspension;

[0037] The second step is to mix again: mix 2mg KMnO 4 Dissolve in 0.4 ml water to form KMnO 4 aqueous solution, 0.4 ml KMnO 4 Add the MnCl obtained in the first step to the aqueous solution 2 / Graphene oxide suspension forms a reaction liquid with it;

[0038] The third step reaction: the reaction solution obtained in the second step is placed in a closed reaction kettle for constant temperature reaction, the reaction temperature is 180 o C, the reaction time is 48 h, and the crude product of nano-manganese carbonate / graphene hydrogel composite is obtained;

[0039] The fourth step of washing: wash the crude nano-manganese carbonate / graphene hydrogel composite obtained in the third step with 120 ml of deionized water to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com