High-sodium low-fluorine continuous casting mould fluxes and preparation method thereof

A technology of continuous casting mold flux and mold flux, which is applied in the field of high-sodium and low-fluorine continuous casting flux and its preparation process, and in the field of mold flux for continuous casting of molten steel, which can solve the problems of high cost and reduce corrosion and pollution , the effect of reducing the fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

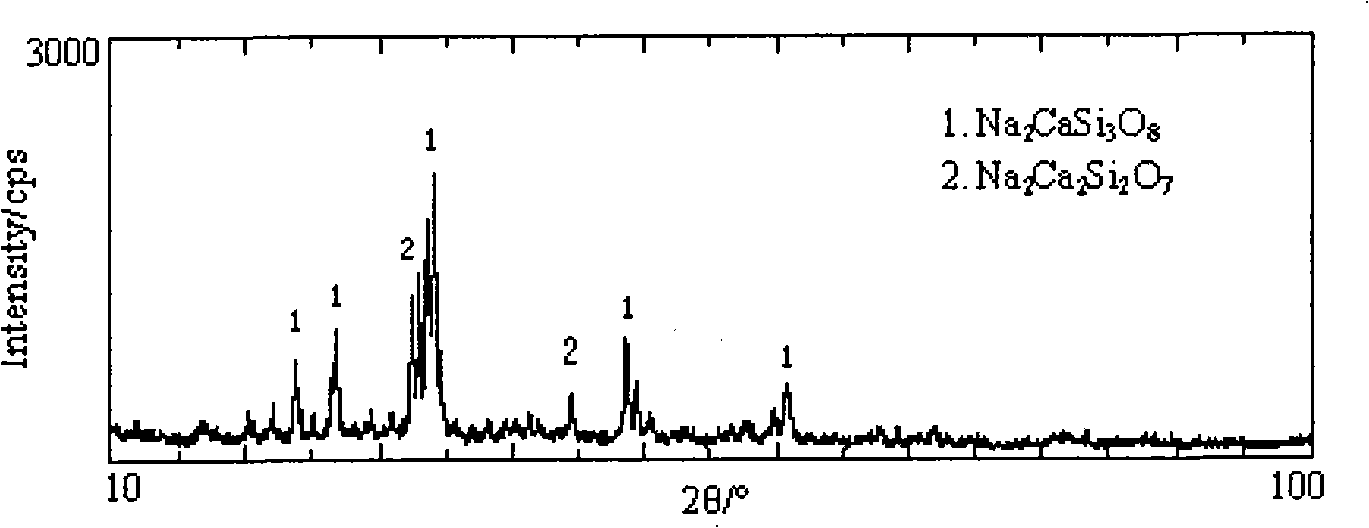

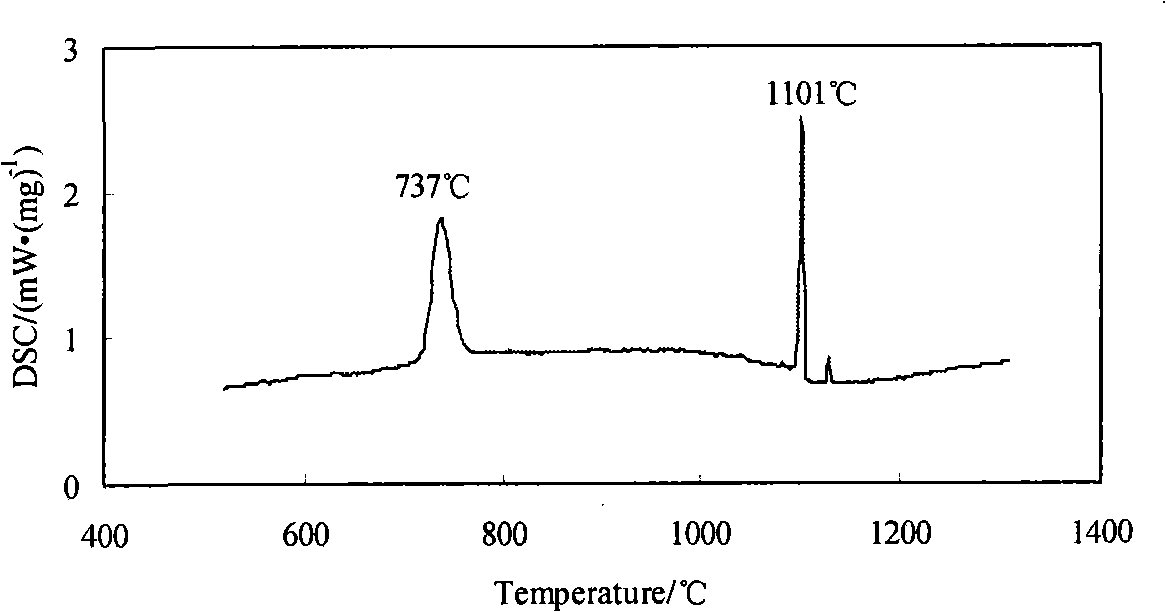

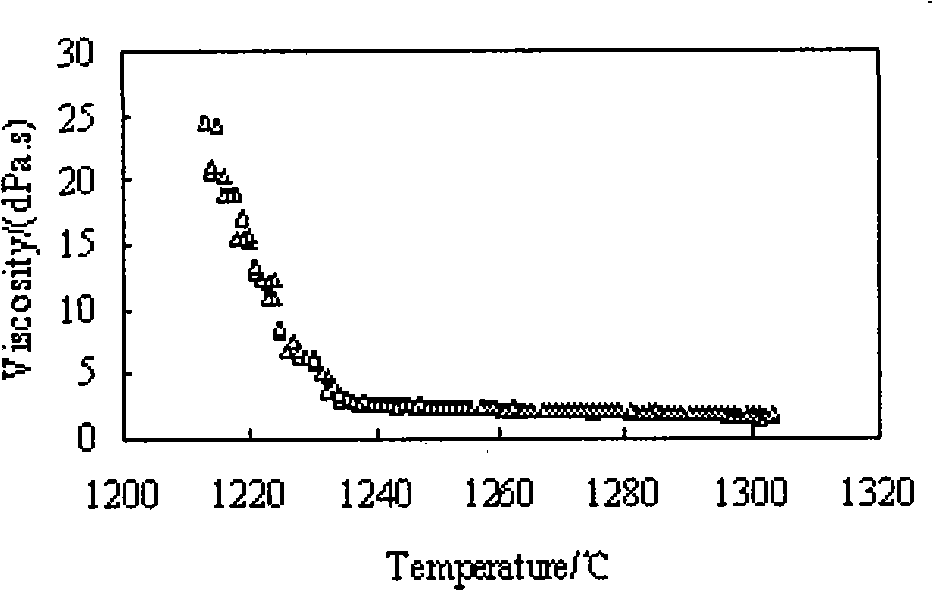

[0023] A high-sodium and low-fluorine continuous casting mold flux, characterized in that the mold flux is composed of wollastonite, limestone, quartz sand, fluorite, bauxite, manganese carbonate, magnesia, borax, industrial soda, lithium carbonate , Carbonaceous material raw material preparation, the chemical composition weight % of the mold flux is: 30%2 2 O2 o 3 2 O2 o 3 2The ratio of the ratio is controlled between 0.8-1.15 to ensure that the mold slag melt does not precipitate crystals at high temperatures, and the liquid slag in the slag film can play a role in lubricating the cast slab. Na in the mold flux 2 The content of O is 14-22%. When the mold slag of the present invention is used in the continuous casting process, the main mineral phase precipitated is xNa 2 O·yCaO·zSiO2, the specific mineral phase is Na 2 O·CaO·3SiO 2 、Na 2 O 2CaO 3SiO 2 or Na 2 O 2CaO 2SiO 2 , the crystallization temperature <1200°C, the proportion of air-cooled fracture crystals is 80-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com