Integrated self-reinforced and compact type one-time surface heat exchanging plate and flow channel structure formed by same

A compact, heat-exchanging plate technology, applied in the direction of heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of strengthening heat transfer components and the surface firmness of the substrate cannot be guaranteed, self-reinforced structural heat exchanger research Insufficient, poor contact between plates, etc., to achieve the effect of eliminating processing thermal resistance, preventing dust accumulation, and expanding the heat transfer surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and implementation, but the embodiments of the present invention are not limited thereto.

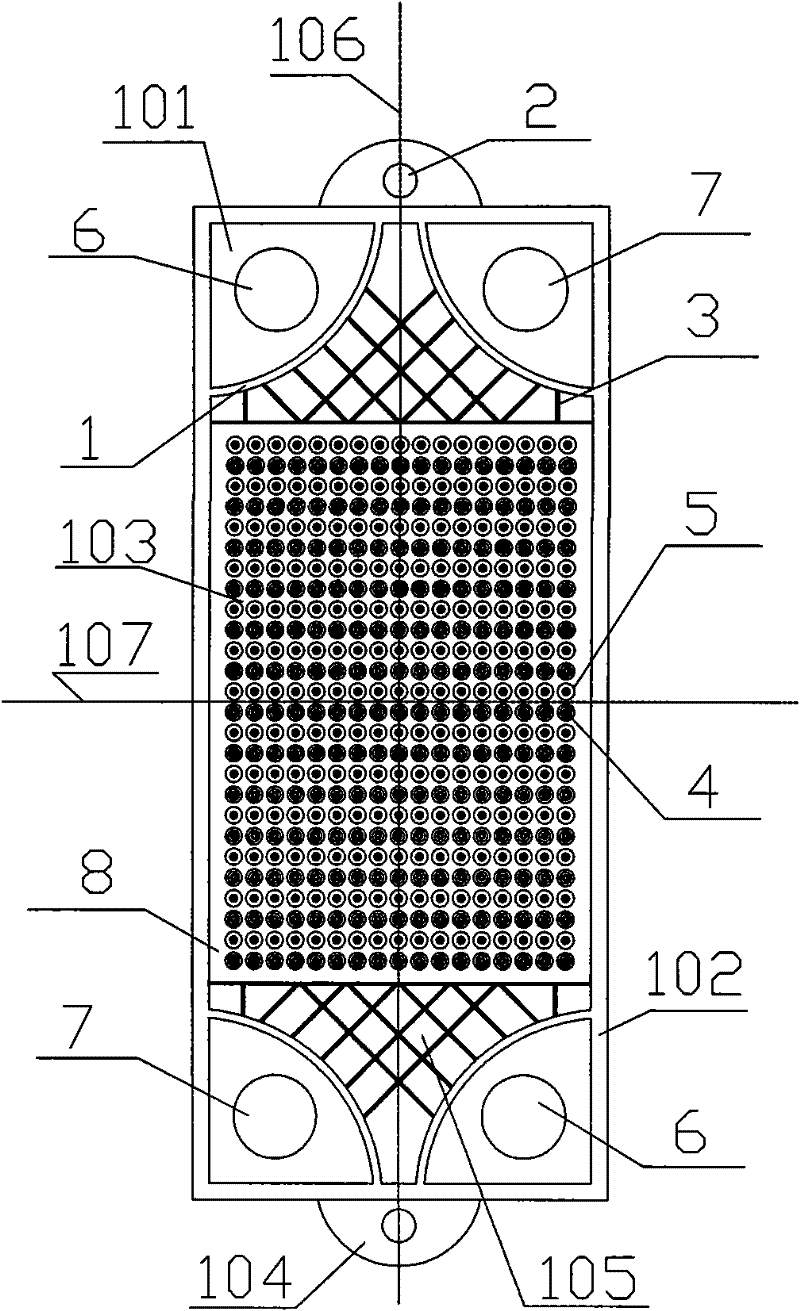

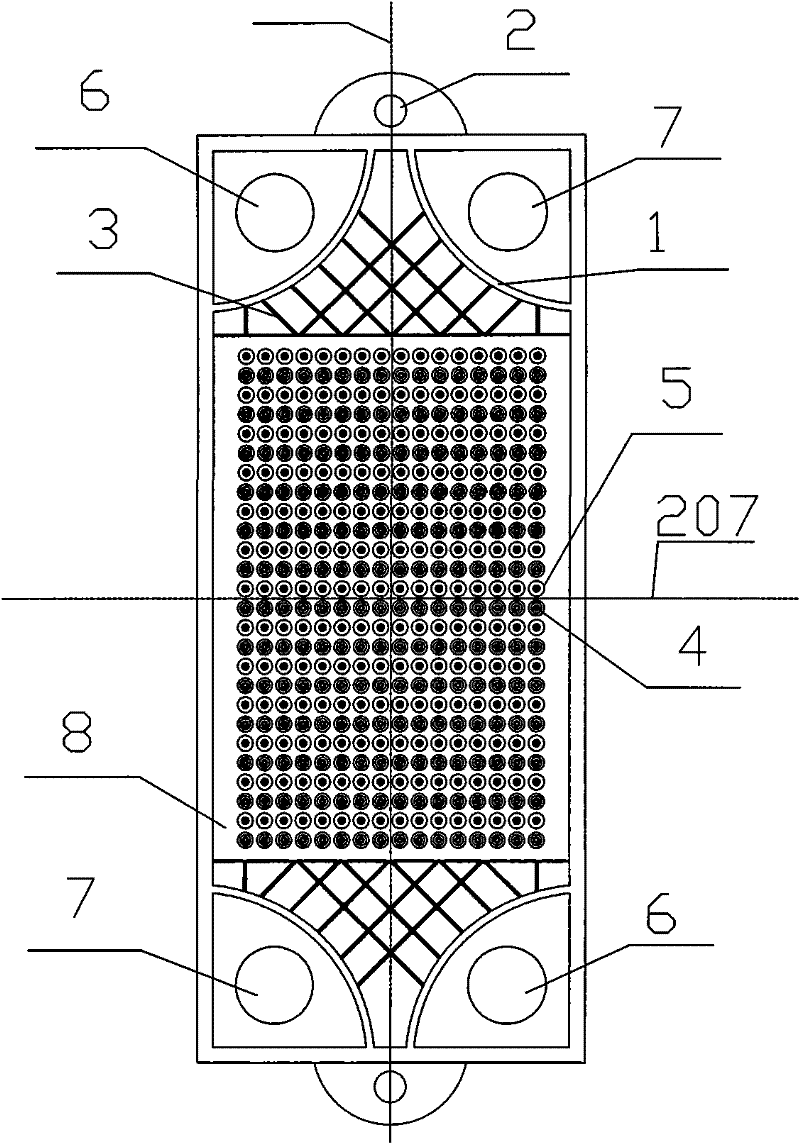

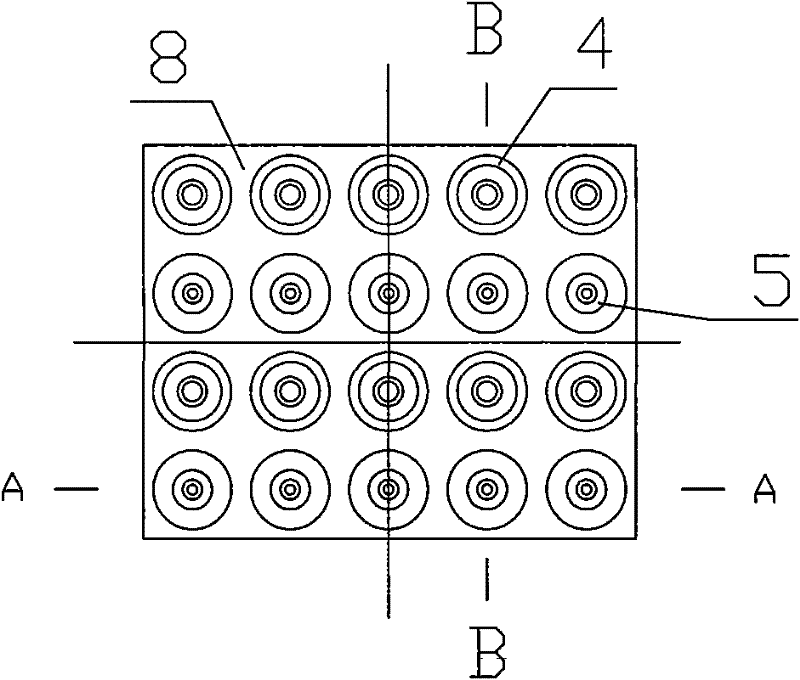

[0032] Such as figure 1 As shown, an integrated self-reinforcing compact primary surface heat exchange plate, its structure is: a through hole area 101 , an edge boss 102 , a heat exchange area 103 , a fixing area 104 and a flow guide area 105 . The edge of the rectangular heat exchange plate is provided with an edge boss 102, the thickness is 20-40mm, and the height is 1-15mm; the four corners of the rectangular heat exchange plate are provided with a through-hole area 101, and the ratio of the diameter of the through-hole to the short side of the rectangular plate The ratio is 1:3 to 1:5; a diversion area 105 is provided adjacent to the through hole area 101, and a semicircular boss 1 is provided between the through hole 6 and the through hole 7 and the diversion area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com