Heat dissipation device and control method thereof, medium, equipment and vehicle

A heat dissipation device and radiator technology, applied in the direction of power plant, vehicle components, vehicle energy storage, etc., can solve the problems of high weight requirements, energy loss, and high vehicle layout space requirements, so as to reduce the layout space requirements, Effect of improving life and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS It should be understood that the specific embodiments described herein are intended to illustrate and explain the present disclosure and is not intended to limit the disclosure.

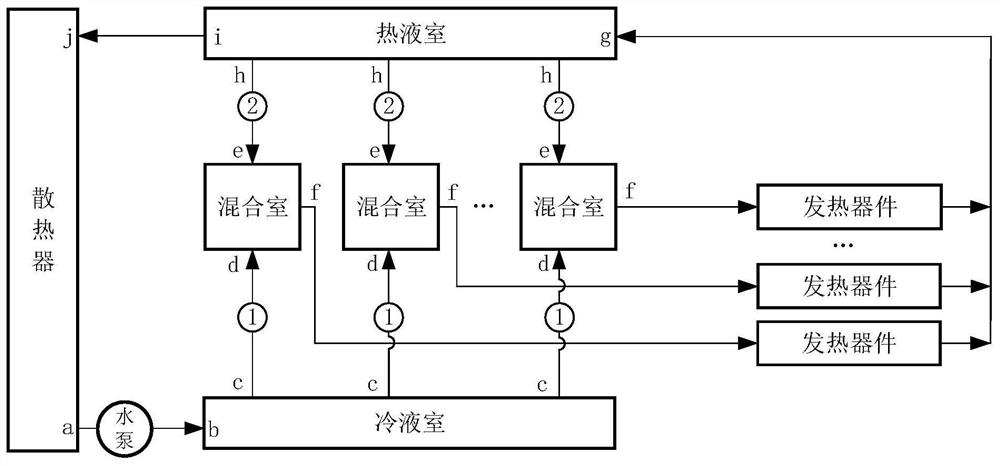

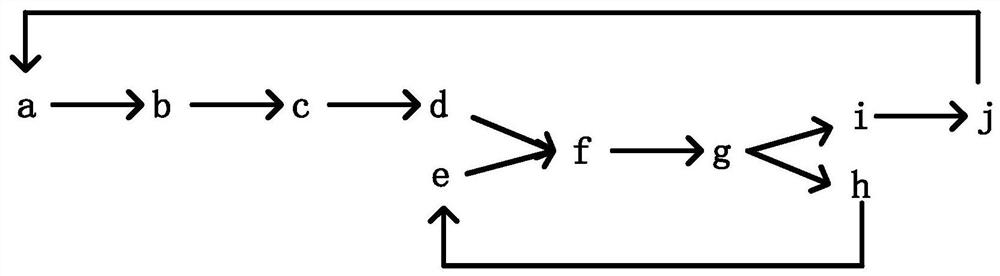

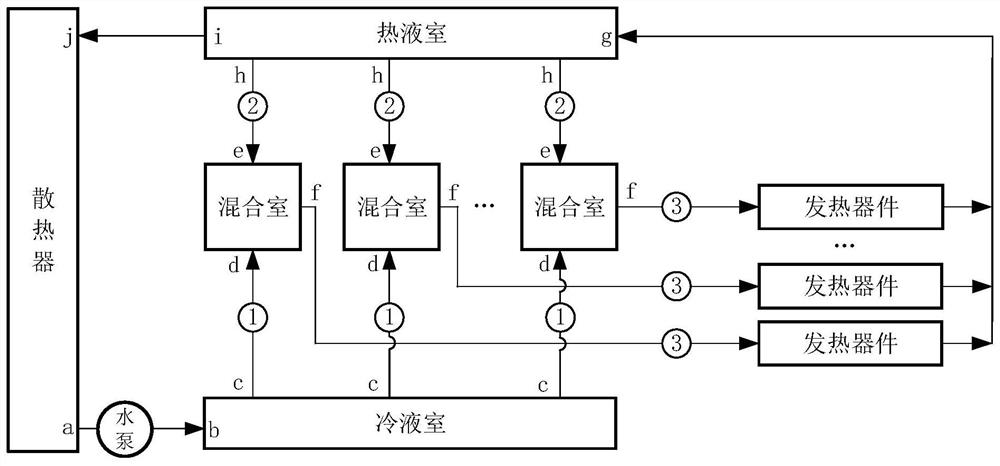

[0043] As shown above, the electric vehicle includes a plurality of heat generating devices such as a motor, an engine, an MCU, a PDU, and the like. figure 1 It is a schematic diagram of a heat sink for an electric vehicle provided by an exemplary embodiment. Such as figure 1 As shown, the heat sink can include a heat sink, a water pump, a cold liquid chamber, a hot liquid chamber, a plurality of mixing chambers corresponding to a plurality of heat generating devices.

[0044] Among them, the effluent port A of the heat sink is passed through the water pump in the inlet B, the radiator's inlet j contact the first water port 1 of the heat transfer chamber, and the first inlet D of each mixing chamber passes the corresponding first A valve 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com