Technological method for leaching manganese ore with high spent acid

A process method and manganese ore technology, applied in the field of manganese salts, can solve the problems of reducing resource utilization, increasing neutralization costs, and low manganese ore leaching rate, achieving obvious economic benefits, improving utilization, and reducing neutralization costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

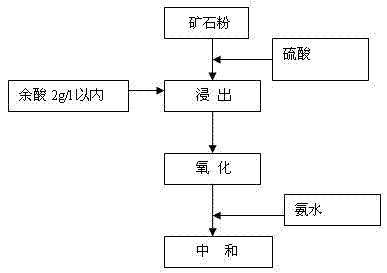

Image

Examples

Embodiment Construction

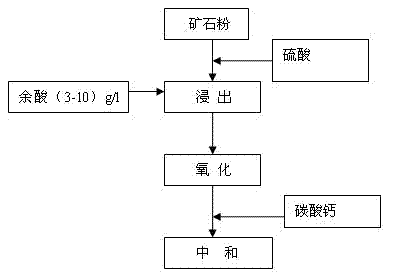

[0022] Such as figure 2 , the process method for leaching manganese ore with high residual acid of the present invention is characterized in that it comprises the following steps:

[0023] 1. According to the process requirements, add sulfuric acid to manganese ore powder, and react to obtain manganese sulfate leaching solution; in the leaching solution, keep the concentration of sulfuric acid above 3g / l, generally in the range of (3-10) g / l ; This concentration is the residual concentration of sulfuric acid in the manganese sulfate solution, so as to ensure excessive sulfuric acid in the leaching solution, the reaction of manganese ore and acid is more thorough, so that manganese ions can be dissolved to the maximum extent, so as to improve the leaching rate and reduce the content of manganese in the slag.

[0024] 2. According to the process requirements, add an oxidizing agent to the leaching solution for oxidation treatment; the added oxidizing agent is mainly manganese d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com