Catalytic chemical coolant for hot aerosol and preparation method thereof

A chemical cooling and catalytic technology, applied in the direction of fire prevention equipment, etc., can solve the problems of poor vibration resistance, easy pulverization of coolant, and unfriendly environment, so as to improve the strength and surface finish, increase the content of active ingredients, and improve the environment. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

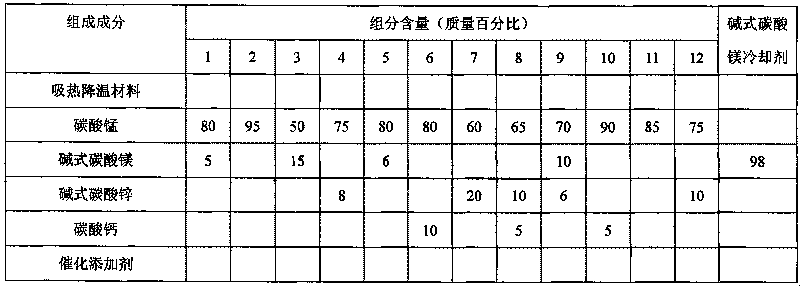

[0053] Prepare the coolant with the following ratio

[0054] Manganese carbonate 80% by mass

[0056] Iron oxide 5% by mass

[0057] Basic magnesium carbonate 5% by mass

[0058] Sodium silicate 2.5% by mass

[0059] Polyvinyl alcohol 1% by mass

[0060] Hydroxyethylcellulose 1% by mass

[0061] Zinc stearate 0.5% by mass

[0062] The production process is as follows: firstly weigh manganese carbonate, zinc oxide, iron oxide, and basic magnesium carbonate according to the proportion, then add them to a high-speed mixing granulator and mix them at high speed for 15 minutes; then add the weighed sodium silicate and polyvinyl alcohol to prepare The aqueous solution was first stirred at low speed for 5 minutes, and then granulated with high-speed shearing and stirring for 10 minutes; the prepared mixture was dried in an oven at 60°C for 4 hours, and after taking it out, it was placed in a tank mixer and stirred by adding zinc stearate. 5min; p...

Embodiment 2

[0065] Prepare the coolant with the following ratio

[0066] Manganese carbonate 95% by mass

[0067] Sodium silicate 2.5% by mass

[0068] Polyvinyl alcohol 1% by mass

[0069] Hydroxyethylcellulose 1% by mass

[0070] Graphite 0.5% by mass

[0071] The production process is as follows: first weigh the manganese carbonate and add it to a high-speed mixing granulator, then add the aqueous solution prepared by weighed sodium silicate and polyvinyl alcohol, first stir at a low speed for 5 minutes, and then granulate with high-speed shearing for 10 minutes; Dry the prepared mixture in an oven at 60°C for 4 hours, take it out, put it in a tank mixer, add weighed zinc stearate and stir for 5 minutes; put the above mixture into a rotary tablet press, pass through a non-penetrating die Pressed under the pressure of 200 MPa to form a tablet with a diameter of 8 mm; the prepared tablet was placed in a water chestnut type sugar coating machine, and the surface was coated with a weig...

Embodiment 3

[0074] Prepare the coolant with the following ratio

[0075] Manganese carbonate 50% by mass

[0076] Zinc oxide 15% by mass

[0077] Copper oxide 15% by mass

[0078] Basic magnesium carbonate 15% by mass

[0079] Sodium silicate 2.5% by mass

[0080] Polyvinyl alcohol 1% by mass

[0081] Hydroxyethylcellulose 1% by mass

[0082] Zinc stearate 0.5% by mass

[0083] The production process is as follows: firstly weigh manganese carbonate, zinc oxide, iron oxide, and basic magnesium carbonate according to the proportion, then add them to a high-speed mixing granulator and mix them at high speed for 15 minutes; then add the weighed sodium silicate and polyvinyl alcohol to prepare The aqueous solution was first stirred at low speed for 5 minutes, and then granulated with high-speed shearing and stirring for 10 minutes; the prepared mixture was dried in an oven at 60°C for 4 hours, and after taking it out, it was placed in a tank mixer and stirred by adding zinc stearate. 5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com