High aluminum steel special continuous casting crystallizer casting powder

A continuous casting mold and mold flux technology, which is applied in the field of mold flux, can solve problems such as high production costs, surface quality problems of slabs, and unsmooth processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

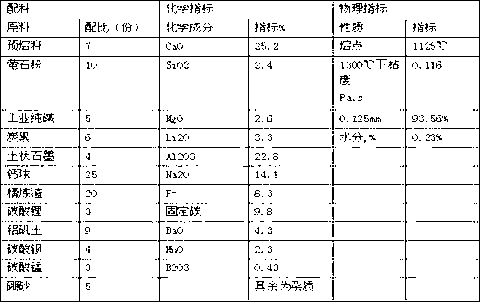

[0020] The continuous casting mold powder for high aluminum steel provided in this example is shown in the ingredient list 1

[0021]

[0022] Ingredients list 1

[0023] A steel plant continuous casting process: casting section 220*1600mm 2 , Pulling speed 0.8 ~ 1.2m / min.

[0024] When pouring starts, the mold slag of the present invention is evenly pushed into the crystallizer, and it is required to evenly cover the entire molten steel surface. Between 60mm, keep the black slag operation, and do not expose the molten steel surface.

[0025] After pouring, the liquid steel level fluctuates within 5mm, and the casting speed is stable at 0.95m / min. At this time, the thickness of the liquid slag layer is measured to be about 10mm. After that, measure the liquid slag layer every 20 minutes, and its thickness is 8-12mm. During the casting process, the mold slag spreads well in the crystallizer, there is no crusting and agglomeration, ...

Embodiment 2

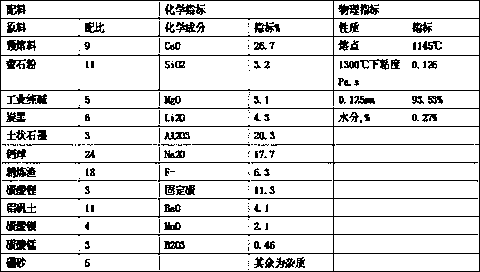

[0029] For the high-alumina continuous casting mold flux provided in this example, see ingredient list 2:

[0030]

[0031] Ingredients list 2

[0032] B steel plant continuous casting process: casting section 230*1600mm 2 , Pulling speed 0.9 ~ 1.3m / min.

[0033] When pouring starts, the mold slag of the present invention is evenly pushed into the crystallizer, and it is required to evenly cover the entire molten steel surface. Between 60mm, keep the black slag operation, and do not expose the molten steel surface.

[0034]After pouring, the liquid steel level fluctuated within 3mm, and the casting speed was stable at 1.2m / min. At this time, the thickness of the liquid slag layer was measured to be about 10mm. After that, measure the liquid slag layer every 20 minutes, and its thickness is between 9 and 12 mm. During the casting process, the mold slag spreads well in the crystallizer, there is no crusting and agglomeration, the flame is mode...

Embodiment 3

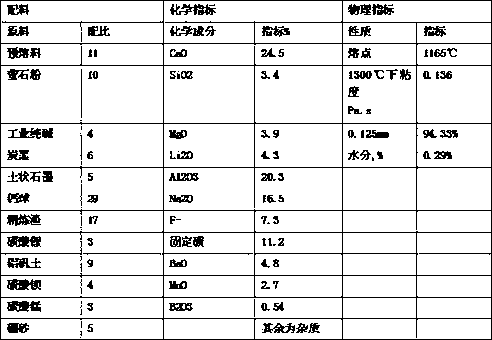

[0038] For the high-alumina continuous casting mold flux provided in this example, see ingredient list 3:

[0039]

[0040] Ingredients list 3

[0041] C steel plant continuous casting process: casting section 220*1600mm 2 , Pulling speed 0.8 ~ 1.4m / min.

[0042] When pouring starts, the mold slag of the present invention is evenly pushed into the crystallizer, and it is required to evenly cover the entire molten steel surface. Between 60mm, keep the black slag operation, and do not expose the molten steel surface.

[0043] After pouring, the fluctuation of liquid steel level is within 6mm, and the casting speed is stable at 1m / min. At this time, the thickness of liquid slag layer is measured to be about 10mm. After that, measure the liquid slag layer every 20 minutes, and its thickness is 10-12mm. During the casting process, the mold slag spreads well in the crystallizer, there is no crusting and agglomeration, the flame is moderate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com