A method for preparing sphericity manganic acid lithium cell anode active material

A spherical lithium manganate, battery cathode technology, applied in battery electrodes, manganate/permanganate, circuits, etc., can solve problems such as poor battery performance, and achieve stable battery performance, uniform particle size, and good cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

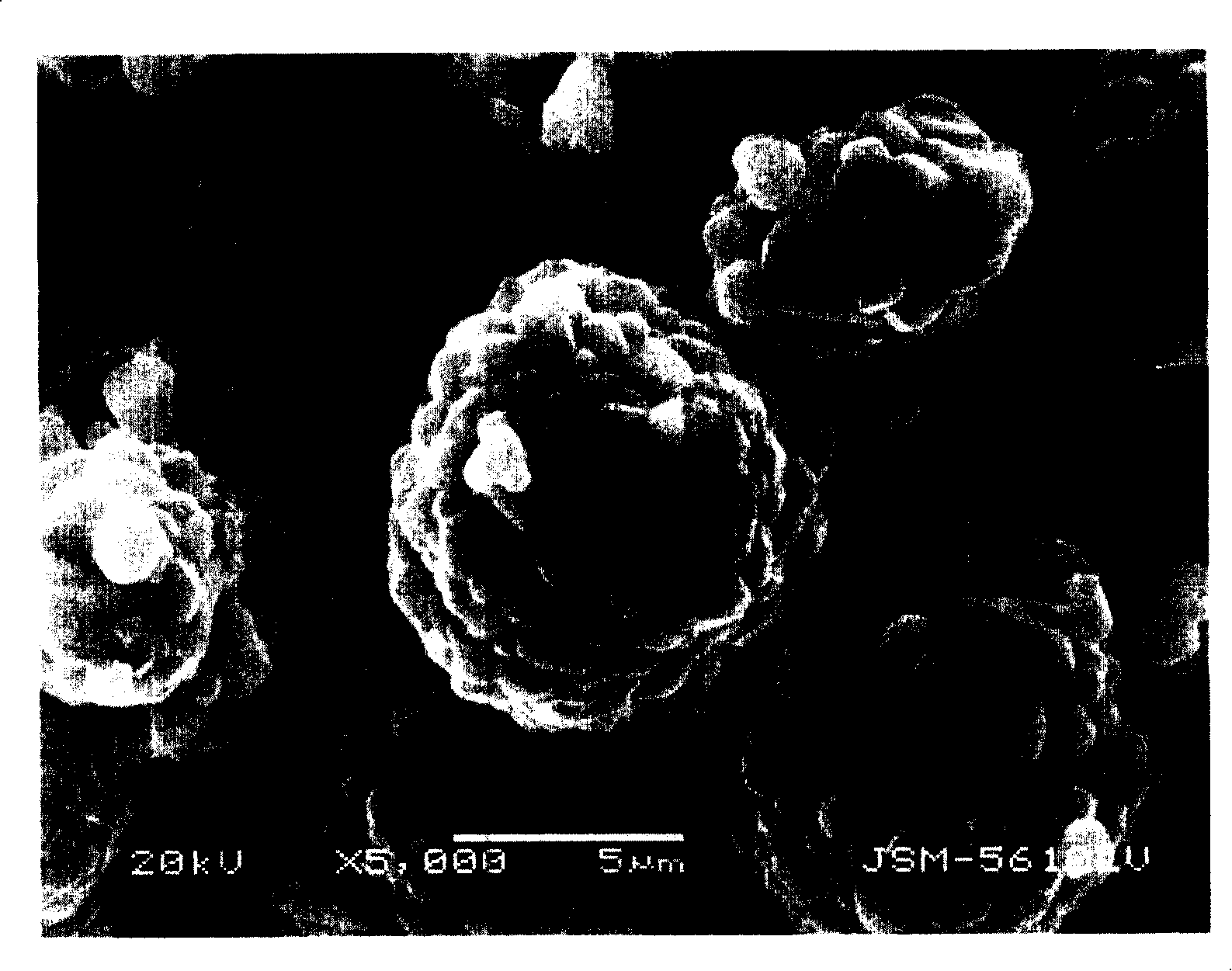

[0009] According to the preparation method of lithium manganese oxide battery positive electrode material of the present invention, the method comprises that spherical manganese carbonate is calcined at 300-800 DEG C for 2-15 hours in the presence of oxidizing gas, then mixed with lithium source, and calcined in the presence of oxidizing gas .

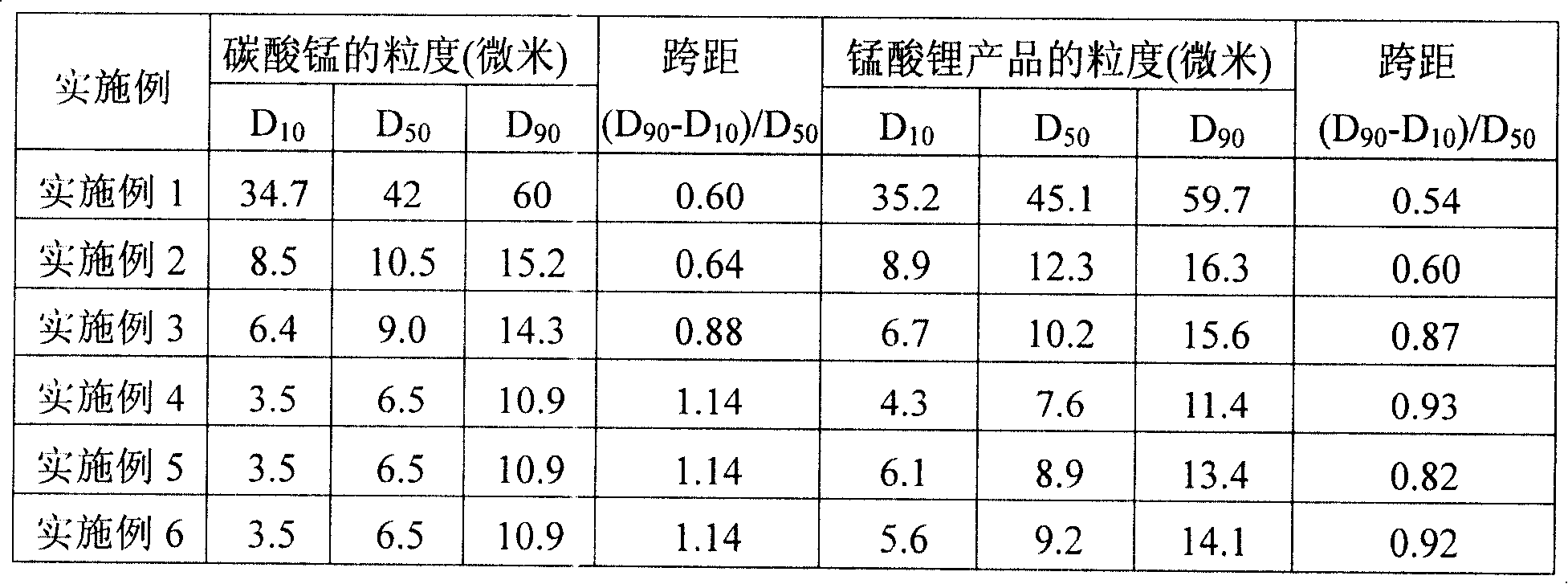

[0010] According to the preparation method of the present invention, the particle size of the spherical lithium manganate depends on the preparation particle size of its precursor. Therefore, if one wants to obtain spherical lithium manganese oxide with uniform particle size, the particle size of spherical manganese carbonate particles needs to be uniform, so the particle size span (D 90 -D 10 ) / D 50 Be below 1.5, preferably (D 90 -D 10 ) / D 50 1 or less, more preferably (D 90 -D 10 ) / D 50 0.8 or less.

[0011] According to the preparation method of the present invention, before the manganese carbonate is calcined and mixed wit...

Embodiment 1

[0035] Prepare MnSO with a concentration of 1.6 mol / L 4 And 0.08 mol / liter cobalt sulfate mixed salt solution, 0.96 mol / liter sodium carbonate, 0.02 mol / liter sodium hydroxide and 0.55 mol / liter ammonia water mixed alkali solution. Add 20 liters of water in a 100-liter reactor as the bottom liquid, control the temperature at 30°C, stir vigorously, and add mixed salt solution, sodium carbonate solution and mixed alkali solution. Control MnSO 4 The flow rate of the aqueous solution is 40 ml / min, the flow rate of the sodium carbonate solution is 80 ml / min, and the flow rate of the mixed alkali solution is controlled to stabilize the pH value at 7.8±0.1. Reaction began to overflow after 7 hours, and the manganese carbonate product was discharged into the receiving tank from the overflow port. The manganese carbonate product obtained after reacting for 40 hours has a stable composition, and the same manganese carbonate product can be obtained by continuing the reaction afterwards...

Embodiment 2

[0054] First prepare Mn(NO 3 ) 2 And 0.05 mol / liter cobalt sulfate, 0.05 mol / liter nickel sulfate mixed salt solution, prepare 0.85 mol / liter sodium carbonate, prepare 0.12 mol / liter sodium hydroxide and 0.05 mol / liter ammonia water mixed alkali solution. Add 20 liters of water in a 100-liter reactor as the bottom liquid, control the temperature at 50°C, stir vigorously, and add mixed salt solution, sodium carbonate solution and mixed alkali solution. Control MnSO 4 The flow rate of the aqueous solution is 40 ml / min, the flow rate of the sodium carbonate solution is 80 ml / min, and the flow rate of the mixed alkali solution is controlled to stabilize the pH value at 9.0±0.1. Reaction began to overflow after 7 hours, and the manganese carbonate product was discharged into the receiving tank from the overflow port. The product obtained after reacting for 40 hours has a stable composition, and the same manganese carbonate product can be obtained by continuing the reaction after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com