Phosphorite double-reverse flotation process

A double reverse flotation and reverse flotation magnesium removal technology, applied in flotation, solid separation, etc., can solve problems such as high viscosity, difficult engineering practice, and interference with normal flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

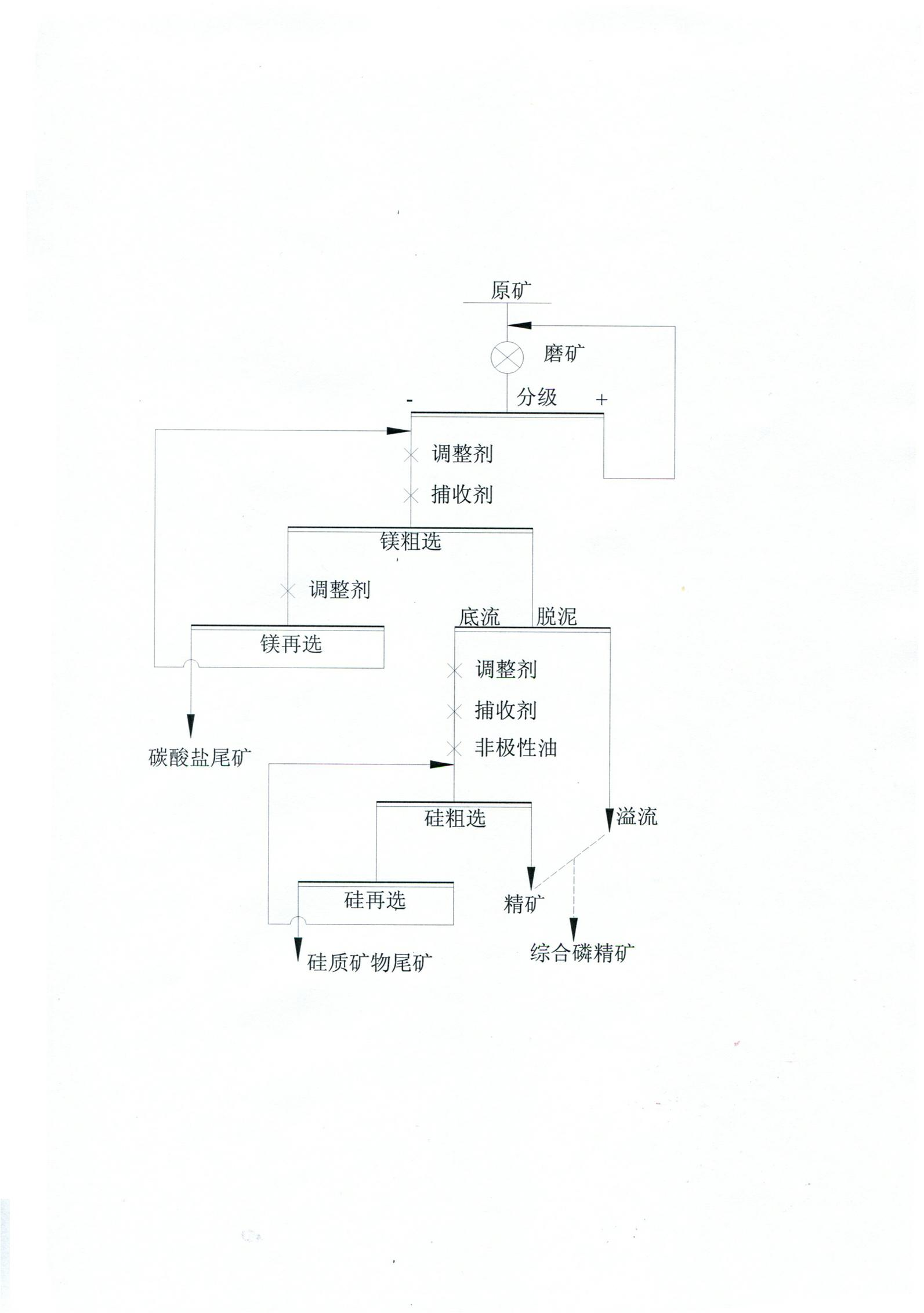

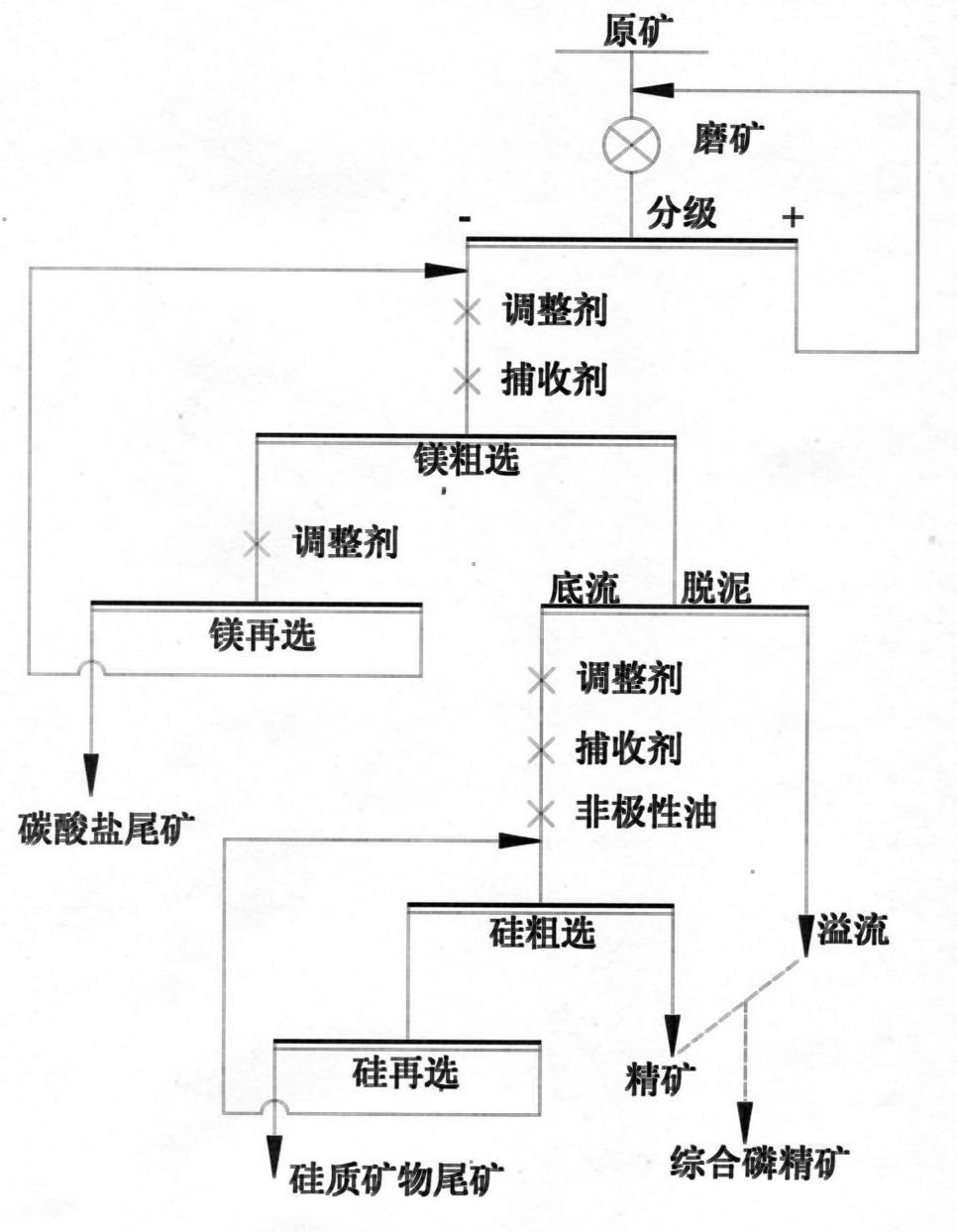

[0021] Embodiment 1, with reference to figure 1 , a double reverse flotation process for phosphate rock, its steps are as follows:

[0022] (1) Reverse flotation magnesium removal: After the phosphate rock is ground to the particle size required by flotation, add reverse flotation magnesium removal regulator 5kg / t raw ore and magnesium removal collector 0.8kg / t raw ore to carry out magnesium roughing operation , the magnesium roughing tank is the demagnesium coarse concentrate; the magnesium roughing foam is added with 3 kg / t raw ore demagnesium regulator, and then the magnesium re-election operation is carried out, and the magnesium re-selection tank is the demagnesium medium ore, Mine returns to magnesium roughing, magnesium re-selection foam is carbonate tailings;

[0023] (2) Desliming and pulping of the demagnesium coarse concentrate: The demagnesium coarse concentrate enters the desliming device to remove the particles smaller than 10 microns. The mass concentration of ...

Embodiment 2

[0027] Embodiment 2, with reference to figure 1 , a double reverse flotation process for phosphate rock, its steps are as follows:

[0028] (1) Reverse flotation magnesium removal: After the phosphate rock is ground to the particle size required by flotation, add reverse flotation magnesium removal regulator 20kg / t raw ore and magnesium removal collector 3.5kg / t raw ore to carry out magnesium roughing operation , the magnesium roughing tank is the demagnesium coarse concentrate; after the magnesium roughing foam is added with 2 kg / t raw ore demagnesium regulator, the magnesium re-election operation is carried out, and the magnesium re-selection tank is the demagnesium medium ore, Mine returns to magnesium roughing, magnesium re-selection foam is carbonate tailings;

[0029] (2) Desliming and pulping of the demagnesium coarse concentrate: The demagnesium coarse concentrate enters the desliming device to remove the particles smaller than 38 microns. More than 25%; the sand ent...

Embodiment 3

[0034] Embodiment 3, with reference to figure 1 , a double reverse flotation process for phosphate rock, its steps are as follows:

[0035](1) Reverse flotation magnesium removal: After the phosphate rock is ground to the particle size required by flotation, add reverse flotation magnesium removal regulator 10kg / t raw ore and magnesium removal collector 2.5kg / t raw ore to carry out magnesium roughing operation , the magnesium roughing tank is demagnesium coarse concentrate; after the magnesium roughing foam is added with 0.5 kg / t raw ore demagnesium regulator, the magnesium re-election operation is carried out, and the magnesium re-selection tank is the demagnesium medium ore, Mine returns to magnesium roughing, magnesium re-selection foam is carbonate tailings;

[0036] (2) Desliming and pulping of the demagnesium coarse concentrate: The demagnesium coarse concentrate enters the desliming device to remove the particles smaller than 20 microns. More than 25%; the sand enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com