Collophane quaternary ammonium salt cationic collector, synthesis method and application of collophane quaternary ammonium salt cationic collector

A technology of quaternary ammonium salt cation and synthesis method, which is applied in the field of collophanite quaternary ammonium salt cation collector and its synthesis, can solve the problems of particularly sensitive ore slime, poor water solubility, poor selectivity, etc., and achieve improved separation Sexuality, wide range of raw material sources, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

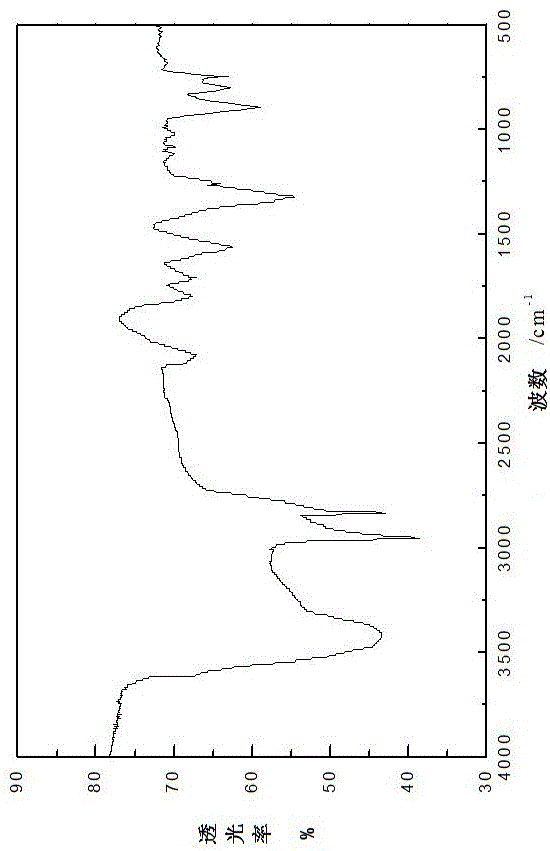

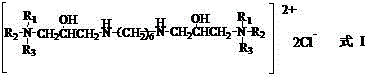

[0023] Embodiment 1, a kind of quaternary ammonium salt cationic collector, structural formula such as formula Shown:

[0024]

[0025] In formula I: R 1 , R 2 and R 3 selected from methyl, ethyl, propyl, butyl, hydroxymethyl, hydroxyethyl, hydroxypropyl or hydroxybutyl.

[0026] The quaternary ammonium salt cationic collector is composed of C 1 -C 4 It is prepared from tertiary amine, hydrochloric acid, epichlorohydrin, hexamethylenediamine and strong alkali solution. The molar ratio of each raw material is, hexamethylenediamine: C 1 -C 4 Tertiary amine: hydrochloric acid: epichlorohydrin: strong base=1:1.8: 2.5:1.8: 2.5.

[0027] The synthetic method comprises the steps:

[0028] (1) Preparation of intermediate: Slowly add concentrated hydrochloric acid to C 1 -C 4 In the tertiary amine solution, control the temperature of the reaction system, stir at room temperature for 10 minutes, add epichlorohydrin dropwise, and stir and react at 40°C for 2 hours after the...

Embodiment 2

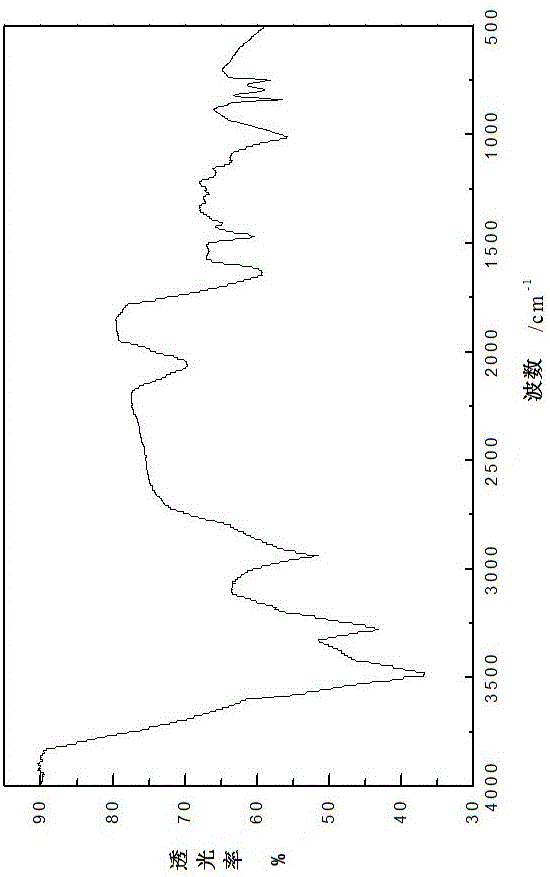

[0031] Embodiment 2, a kind of quaternary ammonium salt cationic collector, structural formula such as formula Shown:

[0032]

[0033] In formula I: R 1 , R 2 and R 3 selected from methyl, ethyl, propyl, butyl, hydroxymethyl, hydroxyethyl, hydroxypropyl or hydroxybutyl.

[0034] The quaternary ammonium salt cationic collector is composed of C 1 -C 4 It is prepared from tertiary amine, hydrochloric acid, epichlorohydrin, hexamethylenediamine and strong alkali solution. The molar ratio of each raw material is, hexamethylenediamine: C 1 -C 4 Tertiary amine: hydrochloric acid: epichlorohydrin: strong base = 1: 2.5: 1.8: 2.5: 1.8.

[0035] The synthetic method comprises the steps:

[0036] (1) Preparation of intermediate: Slowly add concentrated hydrochloric acid to C 1 -C 4 In the tertiary amine solution, control the temperature of the reaction system, stir at room temperature for 20 minutes, add epichlorohydrin dropwise, and stir and react at 60°C for 4 hours after...

Embodiment 3

[0039] Embodiment 3, a kind of quaternary ammonium salt cationic collector, structural formula such as formula Shown:

[0040]

[0041] In formula I: R 1 , R 2 and R 3 selected from methyl, ethyl, propyl, butyl, hydroxymethyl, hydroxyethyl, hydroxypropyl or hydroxybutyl.

[0042] The quaternary ammonium salt cationic collector is composed of C 1 -C 4 It is prepared from tertiary amine, hydrochloric acid, epichlorohydrin, hexamethylenediamine and strong alkali solution. The molar ratio of each raw material is, hexamethylenediamine: C 1 -C 4Tertiary amine: hydrochloric acid: epichlorohydrin: strong base=1:2.1: 2.1:2: 2.1.

[0043] The synthetic method comprises the steps:

[0044] (1) Preparation of intermediate: Slowly add concentrated hydrochloric acid to C 1 -C 4 In the tertiary amine solution, control the temperature of the reaction system, stir at room temperature for 15 minutes, add epichlorohydrin dropwise, and stir and react at 40~60°C for 3 hours after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com