Flotation promoter of coal slime and method for preparing flotation reagent

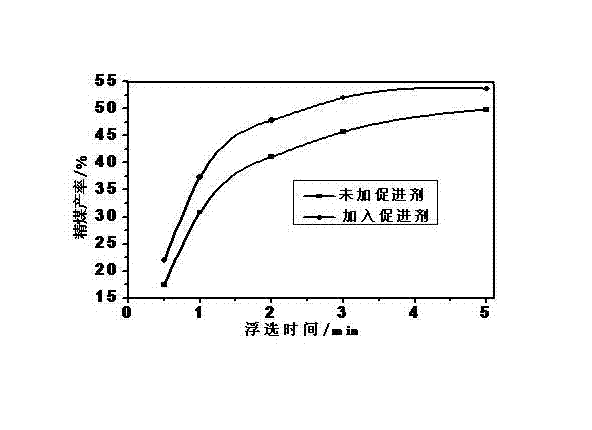

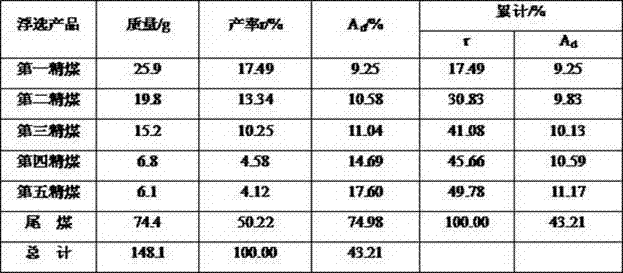

A coal slime flotation and accelerator technology, which is applied in flotation, solid separation and other directions, can solve the problems of increased production cost of coal preparation, unreported, and high production cost, so as to reduce the time required for flotation and improve flotation. Efficiency and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The flotation accelerator consists of the following substances in mass percentage:

[0032] Bisamide diester-based nonionic gemini surfactant: 60%, OP-10: 20%, O-20: 10%, Span-60: 10%.

[0033] Among them, in the general formula of bisamide diester-based nonionic gemini surfactant, m=1, n=1, R 1 is an alkyl group with 0 carbon atoms, R 2 is an alkyl group with 5 carbon atoms, R 3 is an alkyl group with 1 carbon atom; R 4 is an alkyl group having 5 carbon atoms.

[0034] The method for preparing flotation agent with coal slime flotation accelerator, its steps are as follows:

[0035] Prepare the flotation agent according to the ratio of accelerator: collector or compound agent = 0.5:100,

[0036] The first step: Add the collector or compound agent to the bisamide diester-based nonionic gemini surfactant under heating conditions, and stir until the bisamide diester-based nonionic gemini surfactant is completely dissolved. Controlled at 25°C;

[0037] Step 2: Add Sp...

Embodiment 2

[0045]1. The composition of the flotation accelerator is: bisamide diester-based nonionic gemini surfactant: 40%, OP-20: 20%, O-10: 20%, Span-80: 10%, Tween -60: 10%.

[0046] Among them, in the general formula of bisamide diester-based nonionic gemini surfactant, m=2, n=2, R 1 is an alkyl group with 5 carbon atoms, R 2 is an alkyl group with 1 carbon atom, R 3 is an alkyl group with 5 carbon atoms; R 4 is an alkyl group having 1 carbon atom.

[0047] 2. Preparation of flotation agents:

[0048] Prepare the flotation agent according to the ratio of accelerator: collector or compound agent=0.5:100, and the method for preparing the flotation agent is as follows:

[0049] The first step: Add the collector or compound agent to the bisamide diester-based nonionic gemini surfactant under heating conditions, and stir until the bisamide diester-based nonionic gemini surfactant is completely dissolved. Controlled at 85°C;

[0050] Step 2: Add Span-80 to the collector or composit...

Embodiment 3

[0058] 1. The composition of the flotation accelerator is: bisamide diester-based nonionic gemini surfactant: 70%, OP-30: 15%, O-15: 15%.

[0059] Among them, in the general formula of bisamide diester-based nonionic gemini surfactant, m=2, n=2, R 1 is an alkyl group with 3 carbon atoms, R 2 is an alkyl group with 3 carbon atoms, R 3 is an alkyl group with 3 carbon atoms; R 4 is an alkyl group having 3 carbon atoms.

[0060] 2. Preparation of flotation agents:

[0061] Prepare the flotation agent according to the ratio of accelerator: collector or compound agent=0.5:100, and the method for preparing the flotation agent is as follows:

[0062] The first step: Add the collector or compound agent to the bisamide diester-based nonionic gemini surfactant under heating conditions, and stir until the bisamide diester-based nonionic gemini surfactant is completely dissolved. Controlled at 55°C;

[0063] Step 2: Add OP-30 and O-15 directly to water in proportion and mix well.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com