Flotation column for sorting mineral

A mineral separation and flotation column technology, applied in flotation, solid separation, etc., can solve the problems of unsatisfactory equipment utilization, unbalanced feed and discharge, and inability to automatically control discharge, etc., to facilitate the industrialization of PLC Control, Versatile, Small Footprint Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

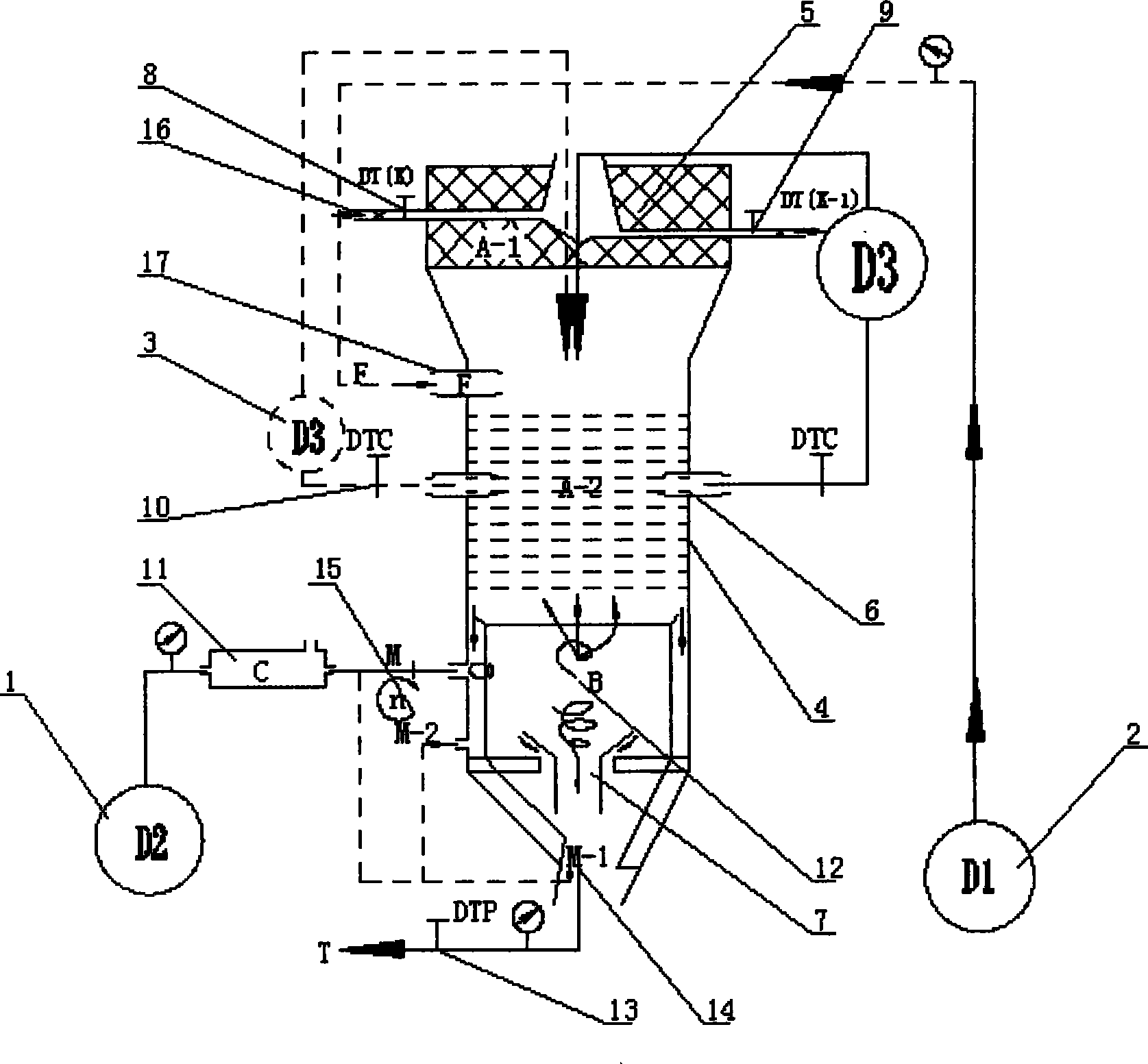

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] see figure 1 Shown, a kind of flotation column that is used for mineral separation of the present invention, it comprises column body 4, and described column body 4 is successively divided into concentrate collecting tank 5, sorting barrel and tailings discharge in the column body 4 Box 7, the concentrate collection tank 5 is provided with more than one concentrate discharge port 16, the concentrate discharge port 16 is provided with a concentrate discharge electric solenoid valve that can adjust the liquid level, and the sorting barrel includes The static micro-bubble sorting section in the middle and the swirling flow sorting section in the lower part, the sorting barrel is connected with the external air pump 1, the sorting barrel is equipped with a column inner cyclone 12, and the tailings discharge box 7 bottom tailings di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com