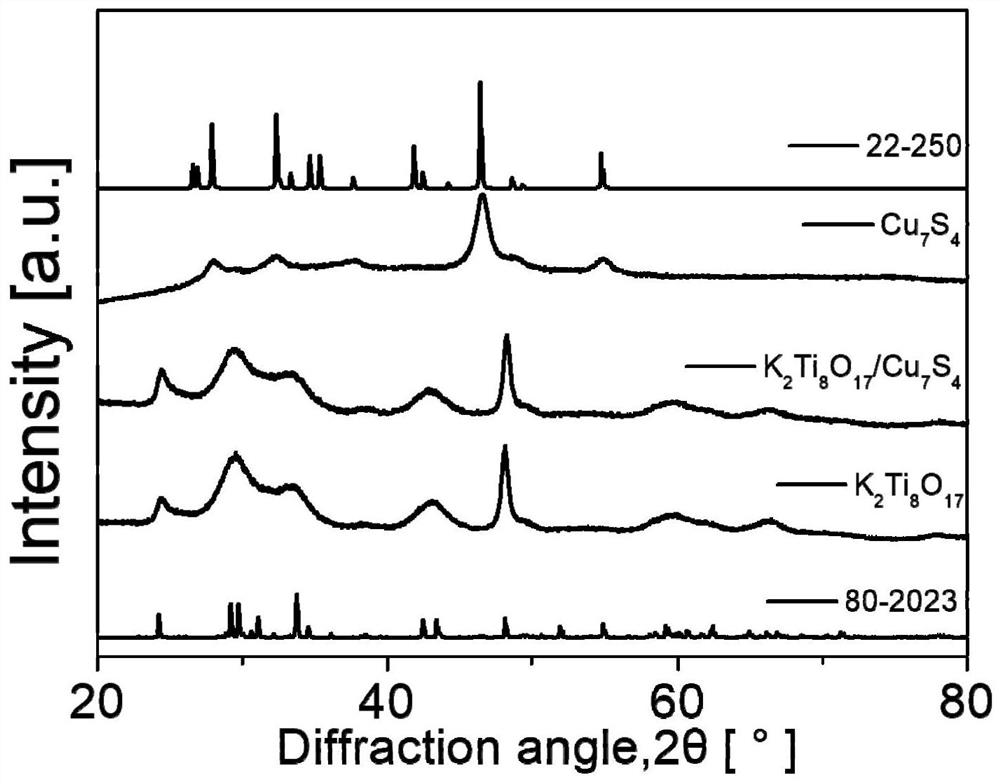

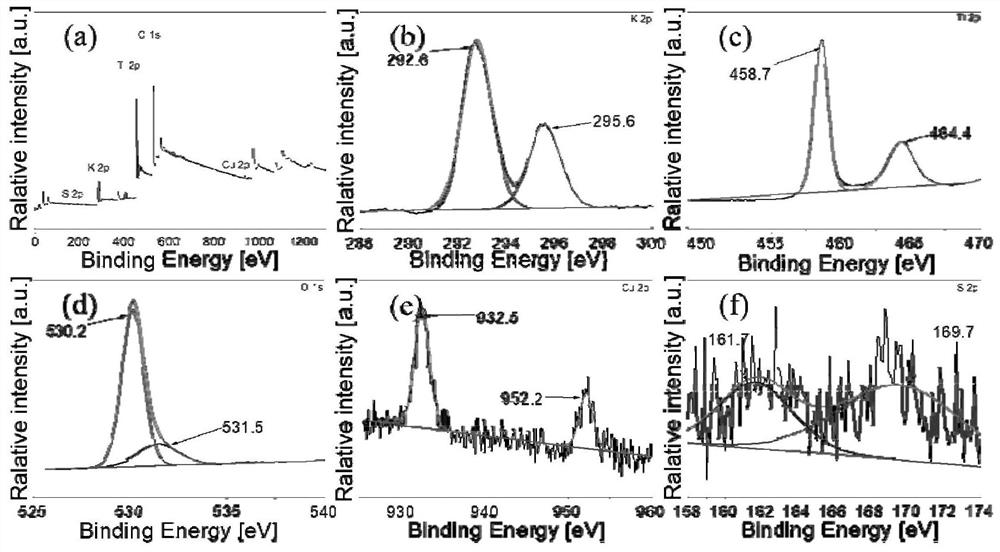

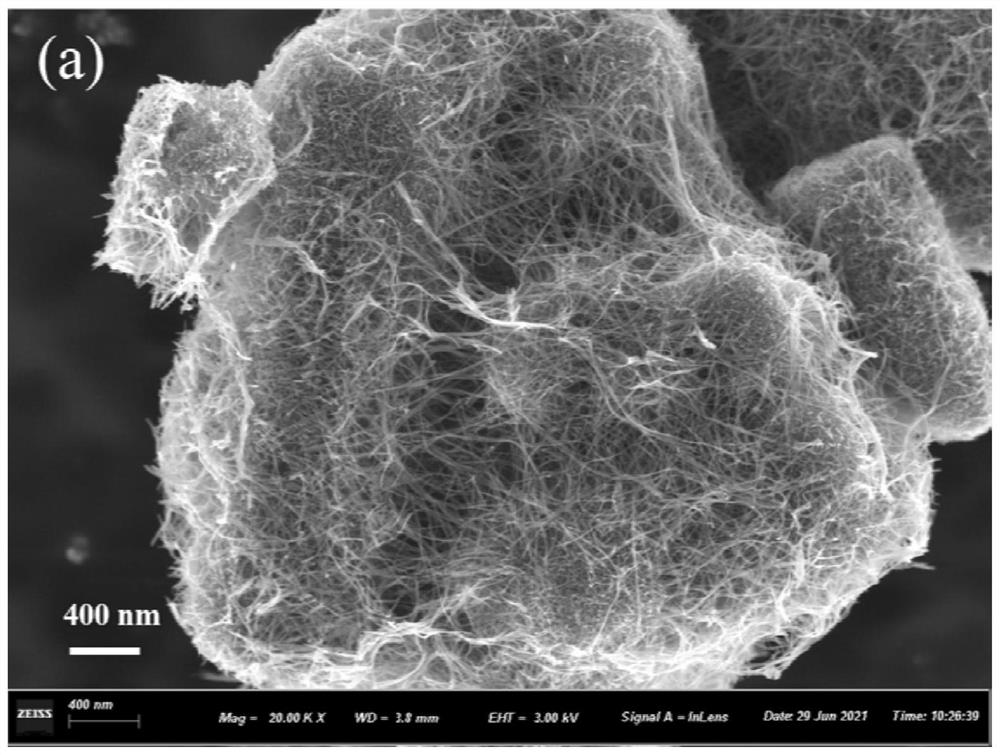

Potassium titanate-hepta-copper tetrasulfide composite material and preparation method and application thereof

A composite material, potassium titanate technology, applied in the field of materials, can solve the problems of weak reducibility, inhibition of carbon dioxide photocatalytic activity, etc., and achieve the effect of convenient operation, good application potential and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of potassium titanate-heptacopper tetrasulfide composite photocatalytic material, comprising the steps of:

[0032] Synthesis of potassium titanate nanowires: Add 2mmol of titanium dioxide and 10mL of KOH solution (8mmol / L) into 20mL of water and ultrasonically dissolve to obtain a homogeneous mixed solution; the above mixed solution is subjected to hydrothermal reaction at 180°C for 12h After the reaction is completed, the potassium titanate nanowires are obtained by centrifugal washing and drying;

[0033] Synthesis of potassium titanate-copper heptasulfide nanocomposites: Add 0.07-0.55 mmol of potassium titanate nanowires and 0.04 mmol of cadmium acetate dihydrate into 20 mL of ethanol, raise the temperature to 80 °C, and then add 0.04 mmol of thio Acetamide (dissolved in 5mL ethanol) was refluxed and stirred at 80°C for 4h, then added 0.08mmol cuprous chloride (dissolved in 5mL ethanol) and continued to refluxed for 2h, washed by centrifugation ...

Embodiment 2

[0040] Synthesis of potassium titanate-copper heptasulfide nanocomposites: Add 0.55 mmol of potassium titanate nanowires and 0.04 mmol of cadmium acetate dihydrate to 20 mL of ethanol, raise the temperature to 90 ° C, and then add 0.08 mmol of thioacetamide (dissolved in 5mL ethanol) at 90°C for 2h under reflux, then added 0.08mmol cuprous chloride (dissolved in 5mL ethanol) and continued to reflux for 2h, washed by centrifugation and dried to obtain potassium titanate-heptacopper tetrasulfide composite material ;

[0041] The prepared photocatalyst was used for photocatalytic reduction of CO 2 , the results show that CH 4 The formation rate is 1.86 μmol g -1 h -1 , the CO generation rate is 0.34 μmol g -1 h -1 .

Embodiment 3

[0043] Synthesis of potassium titanate-copper heptasulfide nanocomposites: Add 0.41 mmol of potassium titanate nanowires and 0.08 mmol of cadmium acetate dihydrate to 20 mL of ethanol, heat up to 100 ° C, and then add 0.04 mmol of thioacetamide (dissolved in 5mL ethanol) at 100°C for 2h under reflux, then added 0.16mmol cuprous chloride (dissolved in 5mL ethanol) and continued to reflux for 2h, washed by centrifugation and dried to obtain potassium titanate-heptacopper tetrasulfide composite material ;

[0044] The prepared photocatalyst was used for photocatalytic reduction of CO 2 , the results show that CH 4 The formation rate is 2.40 μmol g -1 h -1 , the CO generation rate is 0.15 μmol g -1 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com