Simple beneficiation method for chalcocite-containing coarse-grain disseminated copper sulphide ore

A technology of copper sulfide ore and beneficiation method, which is applied in the direction of solid separation, etc., can solve the problems of accelerating the enrichment of copper minerals at the coarse and fine grain level, the difficulty of flotation recovery, and the loss of grinding and crushing, so as to improve the quality and recover copper efficiency, enhance selective adsorption capacity, and overcome the effect of overgrinding mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

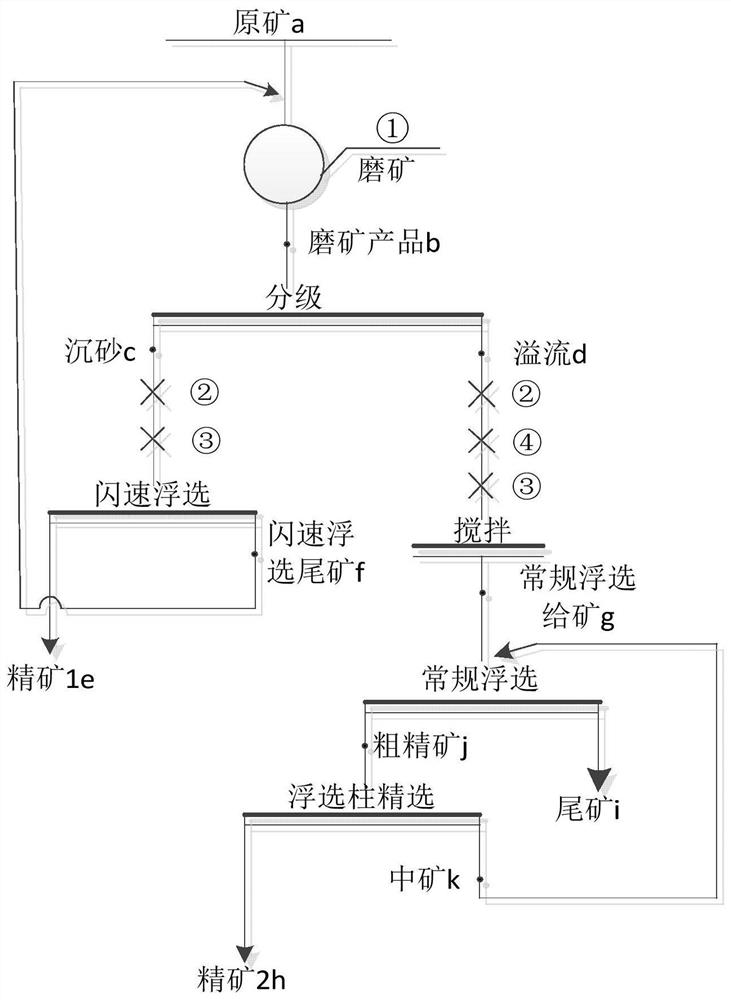

[0023] Such as figure 1 Shown, a kind of chalcocite-containing coarse-grain embedded type copper sulfide ore simple ore dressing method of the present invention is to replace copper collector with graphite in flash flotation and classification overflow flotation stage, improve the coarse-grained The selective adsorption capacity of minerals, changing the copper beneficiation flotation machine into a flotation column, shortening the process and reducing energy consumption, and including but not limited to the following process steps and conditions:

[0024] B. Grinding: adding calcium oxide (1) to the raw ore a of the ball mill at a rate of 1000-1500g / t for grinding to obtain the grinding product b;

[0025] B. Classification: Classify the grinding product b to obtain the pulp overflow d with a grinding fineness of -0.074mm and a content of 55 to 65% and the pulp sink with a grinding fineness of -0.074mm and a content of 8 to 15%. sand c;

[0026] C-1. Flash flotation: Put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com