Method for strengthening treatment of low-sulfur quartz vein type gold ore through centrifugal gravity concentration

An enhanced treatment, quartz technology, applied in the direction of solid separation, etc., can solve the problems of increasing the amount of leaching agent used in leaching time, incomplete dissociation of gold minerals, and reducing production efficiency, so as to reduce the grinding particle size requirements, save leaching time, reduce taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The low-sulfur quartz vein-type gold mine used is a quartz vein-type gold mine in Shandong, with a gold grade of 8.6g / t, containing 0.6% S by mass percentage, SiO 2 64.5%, the main gangue minerals are quartz and sericite, and the main metal minerals are pyrite.

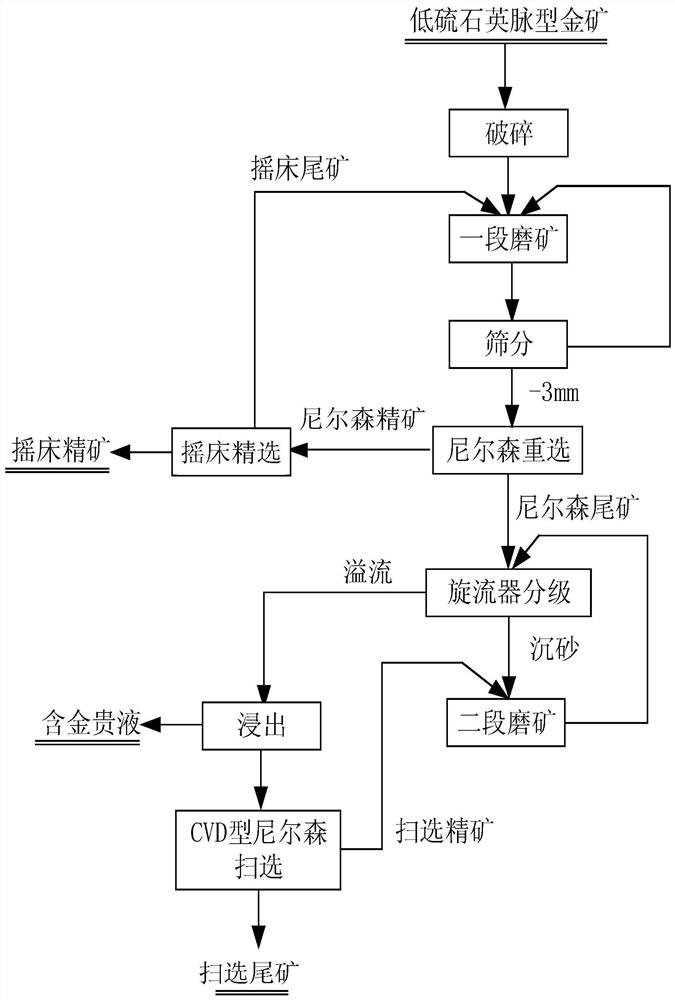

[0032] Process such as figure 1 shown;

[0033] Crush the low-sulfur quartz vein gold ore to a particle size of ≤16mm to make crushed ore; make the crushed ore into a primary slurry with a mass concentration of 70%, and then conduct a stage of grinding to make a finely ground pulp, which is a solid solid The part with a particle size of ≤74μm in the composition accounts for 40% of the total mass; the part with a particle size of ≤3mm is screened out of the ground pulp as fine ore slurry, and the rest is returned to the first stage of grinding;

[0034] The fine ore slurry is re-selected by intermittent discharge type Nelson concentrator, the gravity value of re-selection is 60G, the recoil water pressure is ...

Embodiment 2

[0048] The low-sulfur quartz vein-type gold mine used is a quartz vein-type gold mine in Gansu, with a gold grade of 2.2g / t. The gold in the ore mainly exists in the form of natural gold and silver-gold deposits, and the gold minerals are embedded in a wide range of particle sizes;

[0049] Method is with embodiment 1, and difference is:

[0050] (1) The crushed ore is made into a primary slurry with a mass concentration of 80%; in the solid component of the ground slurry, the part with a particle size ≤ 74 μm accounts for 60% of the total mass;

[0051] (2) The recoil hydraulic pressure of re-election is 5psi, and the ore discharge cycle is 40min; the yield of Nelson concentrate is 0.03%, the recovery rate of Au is 40%, and the gold grade of Nelson concentrate is 2700g / t;

[0052] (3) Nelson concentrate is made into a secondary slurry with a mass concentration of 30%; the gold recovery rate of shaker beneficiation is 35%, and the gold grade of shaker concentrate is 36600g / t; ...

Embodiment 3

[0057] Method is with embodiment 1, and difference is:

[0058] (1) The crushed ore is made into a primary pulp with a mass concentration of 75%; in the solid component of the ground pulp, the part with a particle size ≤ 74 μm accounts for 50% of the total mass;

[0059] (2) The recoil water pressure of re-election is 6psi, and the ore discharge cycle is 50min; the yield of Nelson concentrate is 0.01%, and the gold grade of Nelson concentrate is 6300g / t;

[0060] (3) Nelson concentrate is made into a secondary slurry with a mass concentration of 25%; the gold recovery rate of shaker beneficiation is 30%, and the gold grade of shaker concentrate is 82500g / t;

[0061] (4) Particle diameter ≤ 74 μm in the overflow solid component accounts for 80% of the total mass;

[0062] (5) Concentrate the overflow to make tertiary ore pulp with a mass concentration of 40%, add caustic soda to adjust the pH value to 11.5; the addition of the environmental protection gold extracting agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com