Beneficiation method for step-by-step classified comprehensive recovery of valuable elements from primary vein platinum ore tailings

A technology of valuable elements and beneficiation method, which is applied in the comprehensive recovery of chromite, the beneficiation of primary vein platinum ore tailings for comprehensive recovery of valuable elements, and the platinum and palladium fields in primary vein platinum ore tailings. Solve the problems of excessive chromium content in platinum and palladium concentrates, increase the difficulty of production management, and have no impurity removal process, so as to facilitate subsequent sorting, improve the utilization rate of tailings resources, and achieve early harvest and fast harvest.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

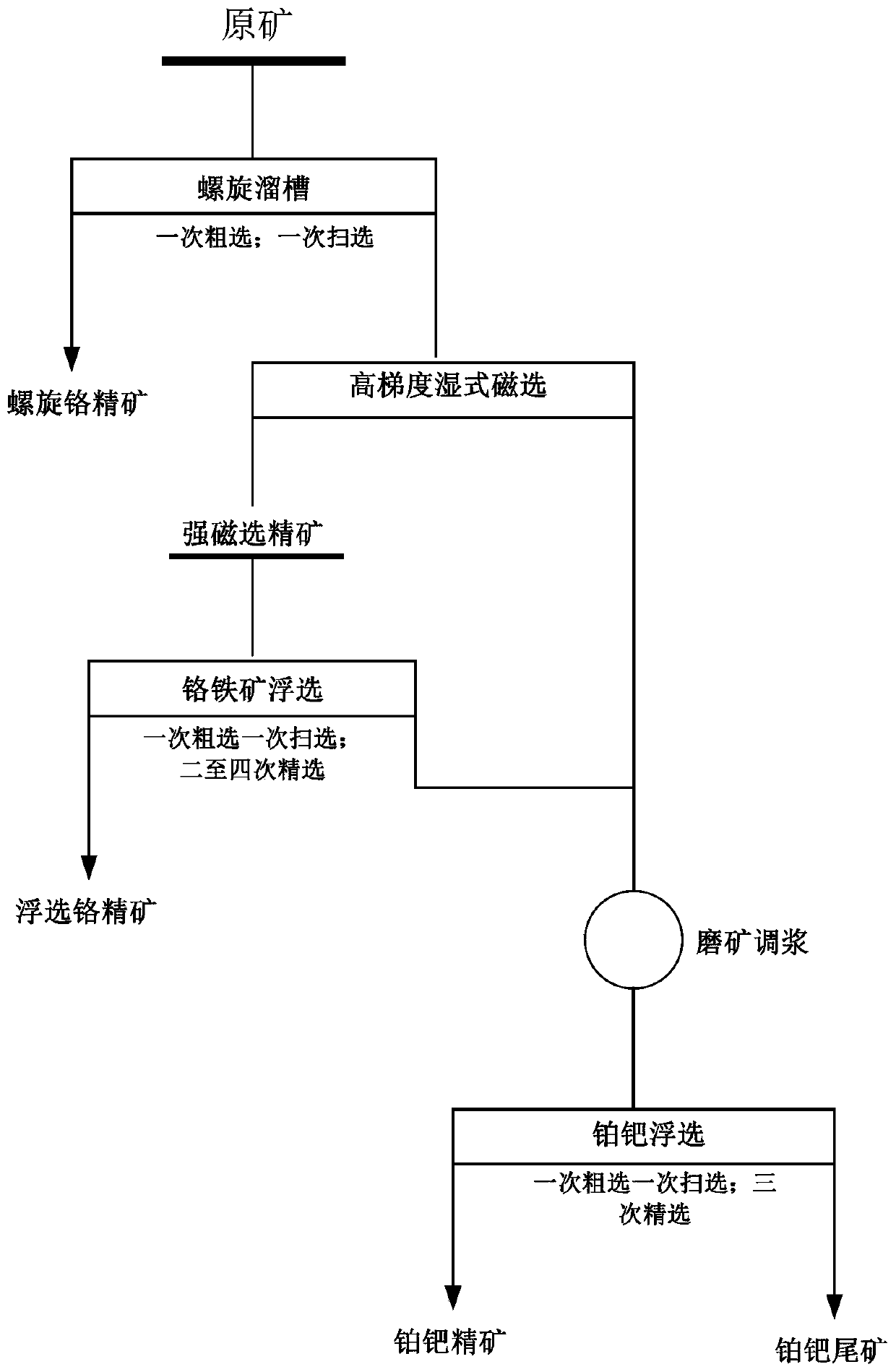

[0043] This embodiment provides a beneficiation method for step-by-step classification and comprehensive recovery of valuable elements from primary vein platinum ore tailings.

[0044] The tailings of a platinum mine in a vein in China are selected. The valuable metal elements in the tailings are platinum, palladium and chromium, the content of platinum is 0.70g / t, the content of palladium is 0.44g / t, Cr 2 o 3 The content is 19.53%. The main metal oxide is chromite, which contains a small amount of magnetite. The gangue minerals are mainly talc, serpentine and quartz, followed by tremolite, copper pyroxene, diopside, brucite and other minerals. Tailings -0.074mm accounted for 74.56% (-0.043mm accounted for 51.83%).

[0045] Such as figure 1 , the primary vein platinum ore tailings samples were adopted After one roughing and one sweeping in the spiral chute, the yield was 15.64%. Cr 2 o 3 The product is 41.92%, and the recovery rate is 33.56% of spiral chrome concentrate...

Embodiment 2

[0047] This embodiment provides a beneficiation method for step-by-step classification and comprehensive recovery of valuable elements from primary vein platinum ore tailings.

[0048] The tailings of a platinum mine in South Africa are selected. The valuable metal elements in the tailings are platinum, palladium and chromium. The platinum content is 0.55g / t, the palladium content is 0.31g / t, and the Cr 2 o 3 The content is 22.55%. The main metal oxide is chromite, which contains a small amount of magnetite. The gangue minerals are mainly enstatite, serpentine and quartz, followed by tremolite, diopside, talc, brucite and other minerals. Tailings -0.074mm accounted for 50.45% (-0.043mm accounted for 41.07%).

[0049] Primary vein platinum ore tailings sample collection After one roughing and one sweeping in the spiral chute, the yield was 26.67%, Cr 2 o 3 The product is 42.32%, and the recovery rate is 50.06% of the spiral chrome concentrate and spiral tailings; the spir...

Embodiment 3

[0051] This embodiment provides a beneficiation method for step-by-step classification and comprehensive recovery of valuable elements from primary vein platinum ore tailings.

[0052] The tailings of a platinum mine in a vein in Russia are selected. The valuable metal elements in the tailings are platinum, palladium and chromium, the content of platinum is 0.60g / t, the content of palladium is 0.34g / t, Cr 2 o 3 The content is 18.56%. The main metal oxide is chromite, which contains a small amount of magnetite. The gangue minerals are mainly talc, serpentine and quartz, followed by tremolite, copper pyroxene, diopside, brucite and other minerals. Tailings -0.074mm accounted for 86.77% (-0.043mm accounted for 701.87%).

[0053] Primary vein platinum ore tailings sample collection After one roughing and one sweeping in the spiral chute, the yield was 4.54%. Cr 2 o 3 The product is 42.28%, and the recovery rate is 10.34% of spiral chromium concentrate and spiral tailings; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com