A kind of monodisperse blue chalcocite semiconductor nanocrystal and preparation method thereof

A blue chalcocite, semiconductor technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as complex operation, and achieve the effect of safe and simple operation, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 15 milliliters of octadecene and 5 milliliters of dodecanethiol in a 50 milliliter round-bottomed flask, then add 4.5 millimoles of copper acetylacetonate and 0.75 millimoles of zinc acetylacetonate, purify nitrogen for 15 minutes, and then react The solution was slowly heated to 240°C, and reacted for 120 minutes under magnetic stirring. After the reaction was completed, it was naturally cooled to room temperature, and ethanol was added to the reaction solution for precipitation. After aging and centrifugation, the obtained sample was vacuum-dried at 70°C. After 6 hours, the final product was obtained.

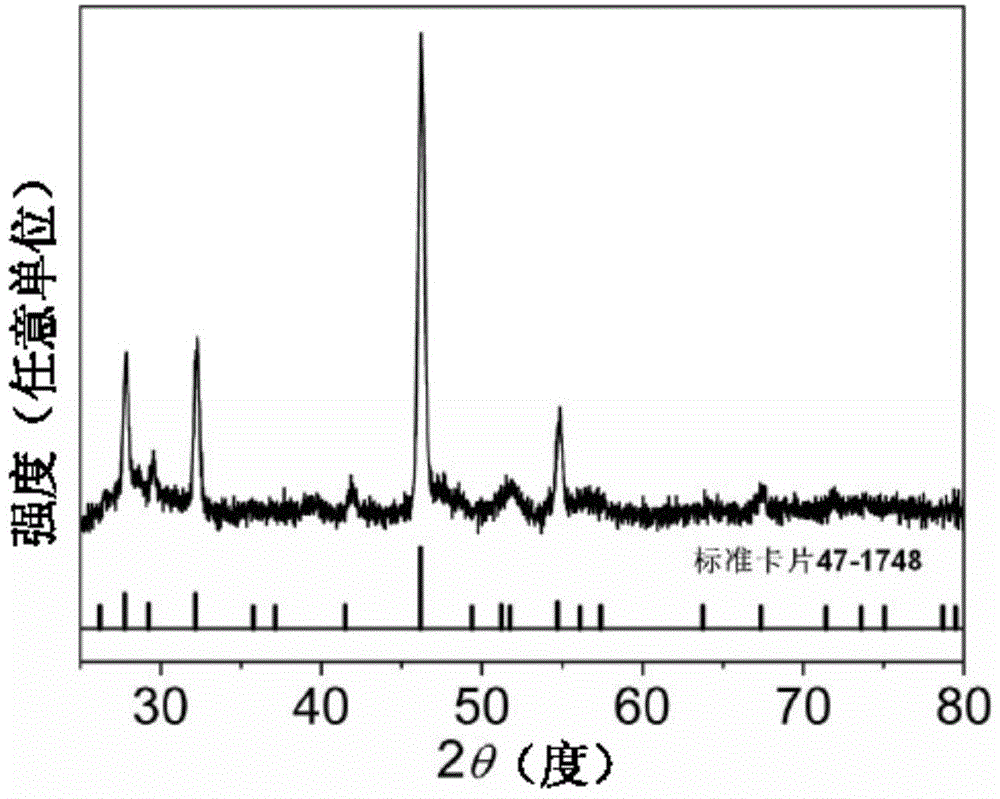

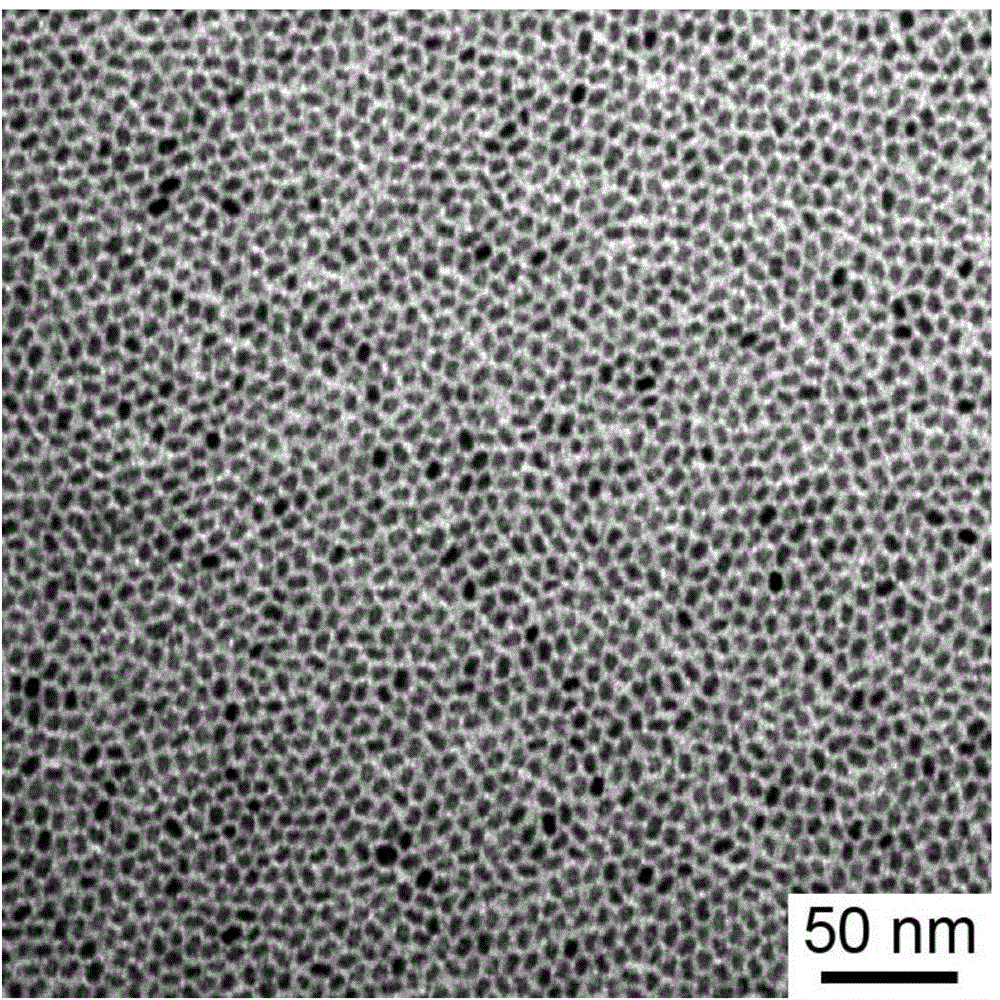

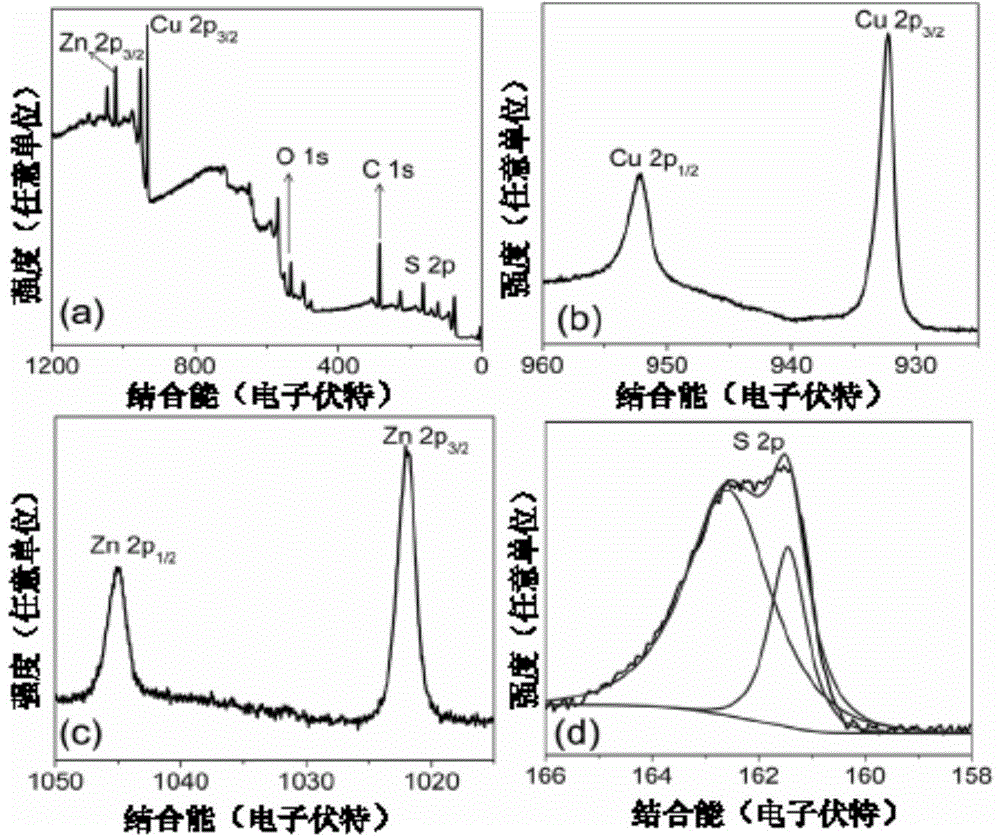

[0026] figure 1 It is the blue chalcocite (Cu 9 S 5 ) X-ray powder diffraction pattern of nanocrystals, which proves that the prepared product is chalcopyrite structure with rhombic lattice (JCPDS47-1748), and the crystal form is better; figure 2 It is the blue chalcocite (Cu 9 S 5 ) The transmission electron micrograph of the nanocrystal, which proves that t...

Embodiment 2

[0028] Add 15 milliliters of octadecene and 5 milliliters of dodecanethiol in a 50 milliliter round bottom flask, then add 4.5 millimoles of copper acetylacetonate and 0.5 millimoles of cadmium acetate, and all the other operations are the same as in Example 1.

[0029] Figure 4 and Figure 5 Respectively the blue chalcocite (Cu 9 S 5 ) X-ray powder diffraction patterns and transmission electron microscope photographs of the nanocrystals, indicating that the crystal structure is good, does not contain other impurities, and the prepared blue chalcocite nanocrystals are uniform spherical nanocrystals.

Embodiment 3

[0031] Add 15 milliliters of octadecene and 5 milliliters of dodecanethiol in a 50 milliliter round bottom flask, then add 4.5 millimoles of copper acetylacetonate and 0.5 millimoles of aluminum acetylacetonate, all the other operations are the same as in Example 1.

[0032] Figure 6 For the prepared blue chalcocite (Cu 9 S 5 ) X-ray powder diffraction pattern of nanocrystals, the sample is a rhombic chalcopyrite structure with good crystallinity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com