Method for intensively extracting copper in high-grade chalcocite

A high-grade, chalcocite technology, applied in the direction of improving process efficiency, can solve the problems of long leaching cycle, low resource utilization rate, slow copper leaching, etc., and achieve the effect of shortening leaching cycle, accelerating copper leaching and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The purpose of the present invention is to provide a process for intensively extracting copper from high-grade chalcocite, which can not only shorten the leaching period but also speed up copper leaching, efficiently utilize high-grade chalcocite, and realize resource utilization maximization.

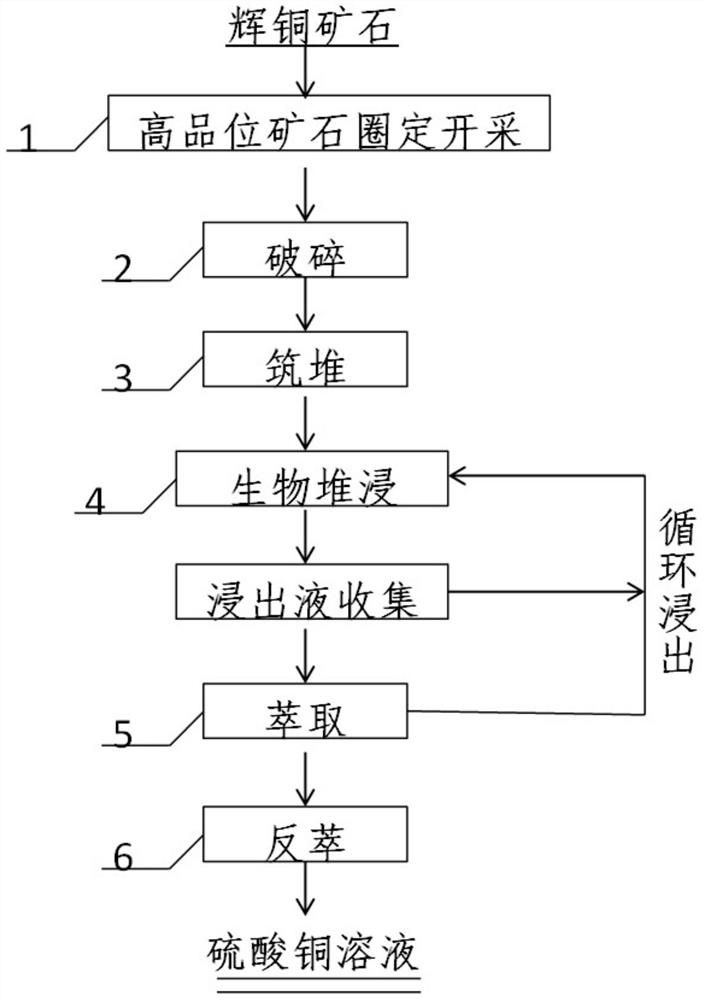

[0026] A process for intensively extracting copper from high-grade chalcocite ore. Firstly, the high-grade chalcocite ore is crushed and piled up, and then after the pile is completed, the bacteria-containing raffinate with high acid and high iron is used for cyclic leaching operation. The leachate is regularly Sampling is carried out to analyze the copper concentration. When the copper concentration of the leaching soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com