Patents

Literature

44results about How to "Shorten the leaching cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moderate thermophilic enriched substance used for mineral leaching of copper pyrites

InactiveCN101560485APromote leachingReduce inhibitionBacteriaMicroorganism based processesHigh concentrationFerroplasma thermophilum

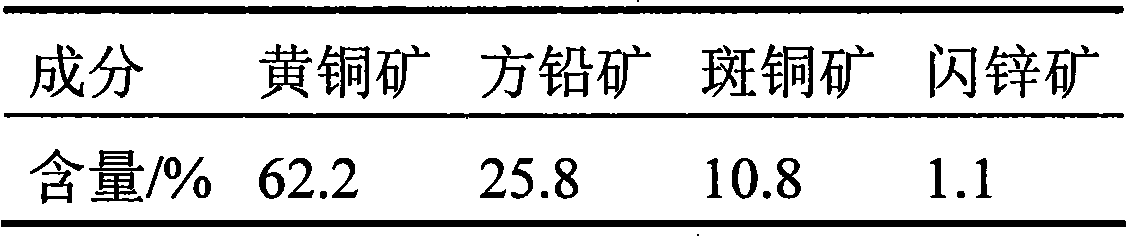

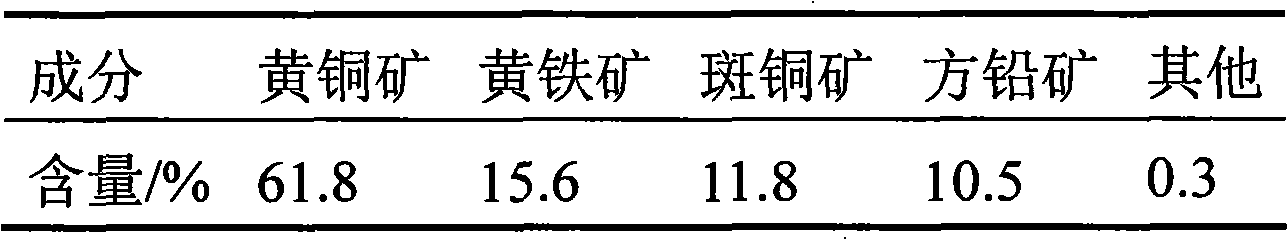

The invention discloses a moderate thermophilic enriched substance used for mineral leaching of copper pyrites, comprising five mineral leaching microorganisms: acidithiobacillus caldus S2, leptospirillum ferriphilum YSK, sulfobacillus acidophilus ZW-1, sulfobacillus thermosulfidooxidans YN22 and ferroplasma thermophilum L1; the pH value and the temperature which are most suitable for the growth of the enriched substance are respectively 1.4-2.0 and 45-48 DEG C. Compared with the existing microorganisms used for brass bio-heap leaching, the enriched substance not only improves the leaching reaction kinetics and shortens the leaching period, but also reduces the passivation inhibition phenomenon and increases the bioleaching speed and the leaching rate of the copper pyrites; furthermore, the enriched substance can endure high concentration metallic ion at the late stage of bioleaching.

Owner:CENT SOUTH UNIV

Microwave processing device for dump leaching uranium ores

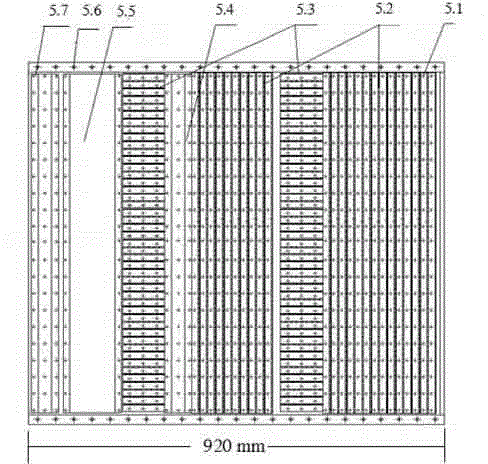

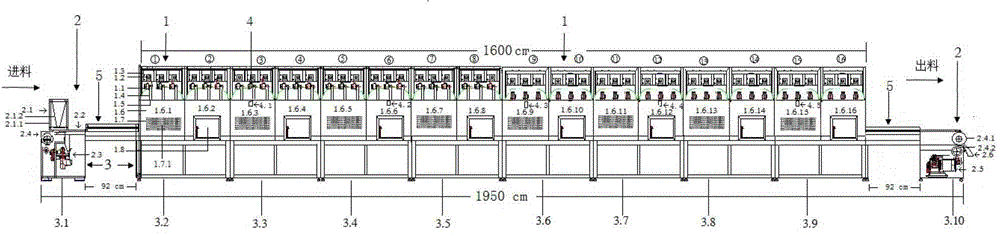

The invention discloses a microwave processing device for the dump leaching uranium ores. The device uses microwave to carry out irradiation to dump leaching uranium ores, due to the fact that differences exist among the microwave temperature rising effects of different minerals inside the uranium ore particles, heat stress differences are generated among the different minerals inside the uranium ore particles, the grain boundaries of the different minerals inside uranium ore particles break and the cracks inside the particles extend, therefore the poriness of the uranium ore particles is increased, the permeability of the inner portions of the uranium ore particles is improved, the dissociation degree of the uranium ores is improved, the leaching efficiency of the dump leaching of the uranium ores is improved, and a leaching period is shortened. The whole equipment comprises 16 microwave units, a material conveying system, a support, a temperature detecting and controlling system and a microwave suppressor. When the microwave processing device for the dump leaching uranium ores is used to process the dump leaching uranium ores, the microwave processing device has the advantages of being good in the matching of microwave power and the uranium ores, low in processing energy consumption, large in processing quantity, stable in material conveying, and small in microwave leakage, the poriness of the uranium ores and the dissociation degree of the uranium ores are further improved, the leaching efficiency is further improved, and the leaching period is further shortened and the like. The microwave processing device for the dump leaching uranium ores is also suitable for the processing of dump leaching gold ores, dump leaching copper ores and other dump leaching ores, and has obvious effect in increasing poriness of ore particles, improving the permeability of the inner portion of the ore particles, improving the dissociation degree of useful ores, improving leaching efficiency, and shortening leaching efficiency.

Owner:NANHUA UNIV

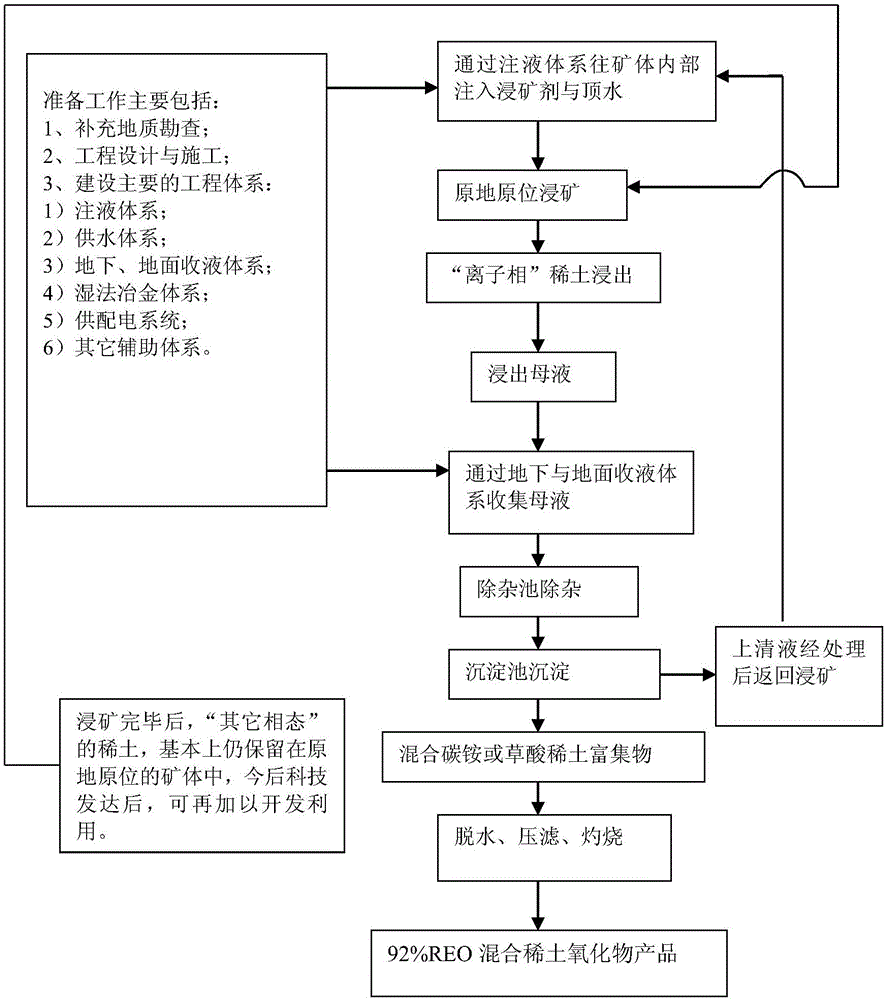

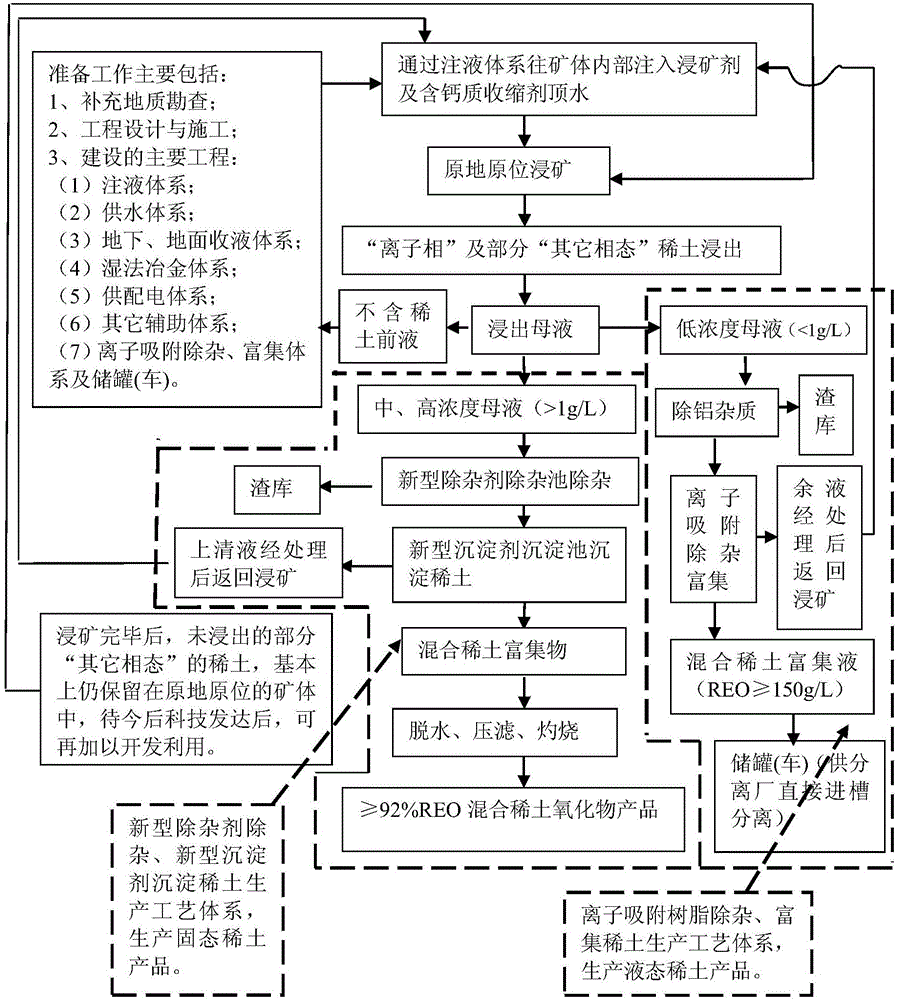

Rare earth in-situ leaching and enriching process for ionic rare earth ore

The invention discloses a rare earth in-situ leaching and enriching process for ionic rare earth ore. The rare earth in-situ leaching and enriching process comprises the following steps: step 1, injection an ore leaching agent and a shrinkage agent into ore body, and performing sited and in-situ ore leaching to enable 'ion-phase' and part of 'other-phase' rare earth to leach out to obtain a mother liquor; step 2, pumping an impurity removal agent I into the medium and high-concentration mother liquor for impurity removal, precipitating through a precipitator, washing with clear water, filtering, and firing to obtain a solid rare earth product, wherein the impurity removal agent I is a mixed solution of a sodium bicarbonate solution and a sodium carbonate solution, and the precipitator is a sodium bicarbonate solution; and pumping an impurity removal agent II into the low-concentration mother liquid for neutralization to remove aluminum impurities, pumping ion exchange columns into the mother liquor from which aluminum is removed for adsorptive enrichment of rare earth ions, and desorbing with acid to obtain a liquid rare earth product, wherein the impurity removal agent II is lime cream. The independently researched and developed brand-new agents are used together with the whole set of innovative technology to achieve the purposes of significant change of the ionic rare earth extraction process, comprehensive optimization of technical-economic indicators and friendly ecological environment.

Owner:赣州弘茂稀土工程有限公司

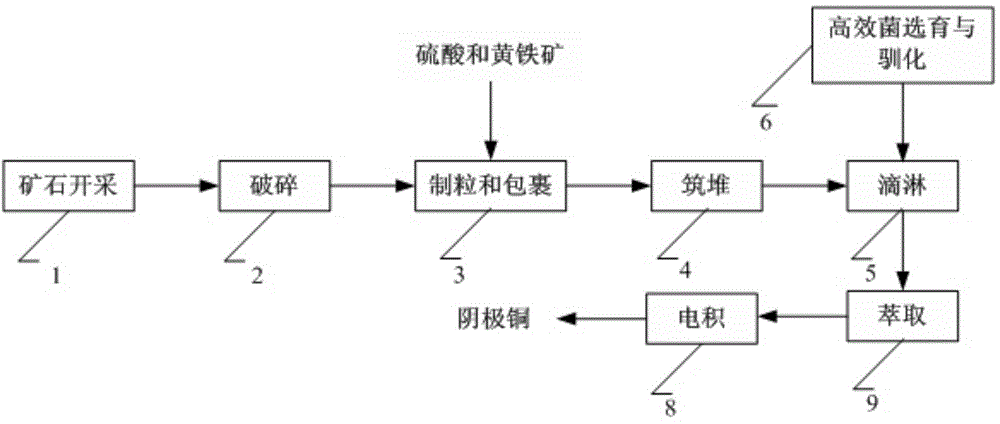

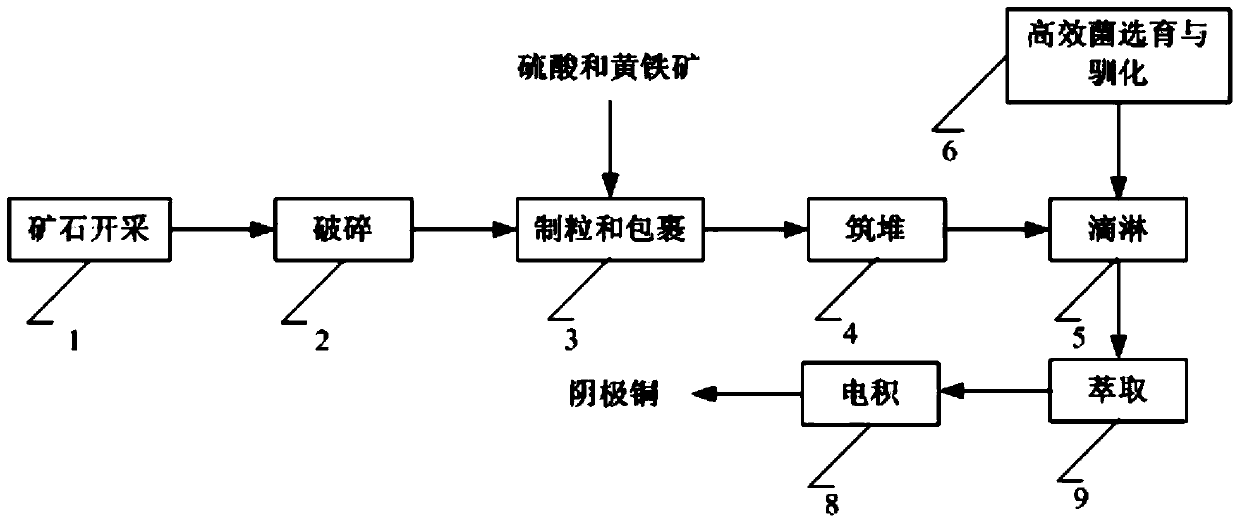

Efficient sulfur-oxidizing bacteria and rapid heating method for low-sulfur copper mine leaching process in Alpine region

ActiveCN105779324AImprove permeabilityIncrease oxidation rateBacteriaMicroorganism based processesSulfurInitial rate

The invention discloses an efficient sulfur-oxidizing bacteria with a strain name of Acidithiobacillus thiooxidans Retech DW-II. The strain is preserved in China General Microbiological Culture Collection Center, Institute of Microbiology of the Chinese Academy of Sciences, No.3, Court No.1, Beichen West Road, Chaoyang District, Beijing on September 10, 2014, and has accession number of CGMCCNo. 9625. The invention also provides a rapid heating method for low-sulfur copper mine leaching process in Alpine region. The method comprises the steps of: crushing ore to -50mm, mixing with pyrite powder, conducting sulfuric acid slaking and granulation to improve the permeability of the stock heap and provide sufficient energy for bacteria; and finally adding the efficient sulfur-oxidizing bacteria CGMCC No. 9625. The method speeds up the initial rate of oxidation of the pyrite ore heap, and provides sufficient heat for the stock heap, so that temperature of the stock heap rapidly increases to above 40 DEG C.

Owner:有研资源环境技术研究院(北京)有限公司

Autotrophic and heterotrophic compound ore-leaching flora FIM-Z4 and application thereof

ActiveCN105199990AImprove leaching rateImprove leaching reaction kineticsBacteriaMicroorganism based processesLeaching rateAcidithiobacillus thiooxidans

The invention discloses autotrophic and heterotrophic compound ore-leaching flora FIM-Z4 and application thereof and provides a mixed culture FIM-Z4 of acidithiobacillus ferrooxidans, acidithiobacillus thiooxidans and acidiphiliu acidophilum; the preservation number of the mixed culture FIM-Z4 is CGMCC No.11190. Through synergistic effect, the leaching reaction kinetics is improved obviously, the reaction speed is increased, the leaching period is shortened, and the leaching rate and leaching yield of metal (copper and nickel) ions in target ore are increased. The heterotrophic compound ore-leaching flora FIM-Z4 is a compatible whole, and the population ecology keeps relatively stable in a long-term domestication process. The heterotrophic compound ore-leaching flora FIM-Z4 is applied to biological metallurgy and has a better leaching effect on copper ions in low-grade copper sulphide ore and nickel ions in low-grade nickel ore.

Owner:FUJIAN INST OF MICROBIOLOGY

Bioleaching process of sulfide mineral ore or concentrate or tailing containing alkaline veinstone

InactiveCN100422358CHigh activitySpeed up leachingProcess efficiency improvementThiobacillus ferrooxidansMetal leaching

A biological extracting technology for the ore or ore comcentrate or tailings of sulfide containing alkaline vein rock includes separating and culturing the bacterial mixture of thiobacillus ferrooxidan and microspirillum ferrooxidan in 9K culture medium, naturalizing culture in the water in which said ore to be extracted and pyrite ore or sulfur are immersed, enlarge culture, mixing the ore tobe extracted with pyrite ore and sulfur powder, stacking, and showing the bacteria contained high-Fe liquid for extracting metal. Its advantages are short period, high extracting speed and rate, and low cost.

Owner:有研资源环境技术研究院(北京)有限公司

Method for bath leaching and extracting nickel and cobalt from garnierite

InactiveCN102061381AImprove permeabilityLow priceProcess efficiency improvementPregnant leach solutionCobalt

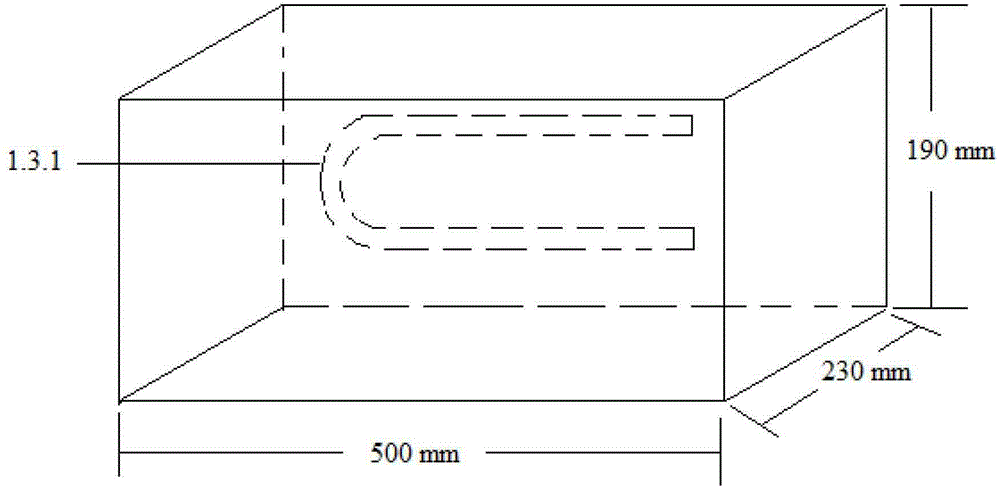

The invention discloses a method for bath leaching and extracting nickel and cobalt from garnierite, comprising the following steps of: (1) crushing the garnierite into ore particles; (2) placing the ore particles in a leaching bath; (3) throwing a leaching agent from a liquid inlet at the top of the leaching bath for soaking the ore particles, wherein the ore particles must be immersed in the liquid level of the leaching agent; (4) discharging a leaching liquid from a liquid outlet at the bottom of the leaching bath; and (5) preparing a novel leaching agent and repeating the step (3) and the step (4) until the nickel content in the ore is lower than a preset value. The method is short in process and simplicity in operation, involves less equipment, and can be used for making the leaching period shortened to about 30 days, leading the nickel leaching rate to reach over 80 percent, and enabling the leaching liquid to have a good permeability. Moreover, the prices of used related materials, the acid consumption and the production cost are low.

Owner:广西银亿新材料有限公司

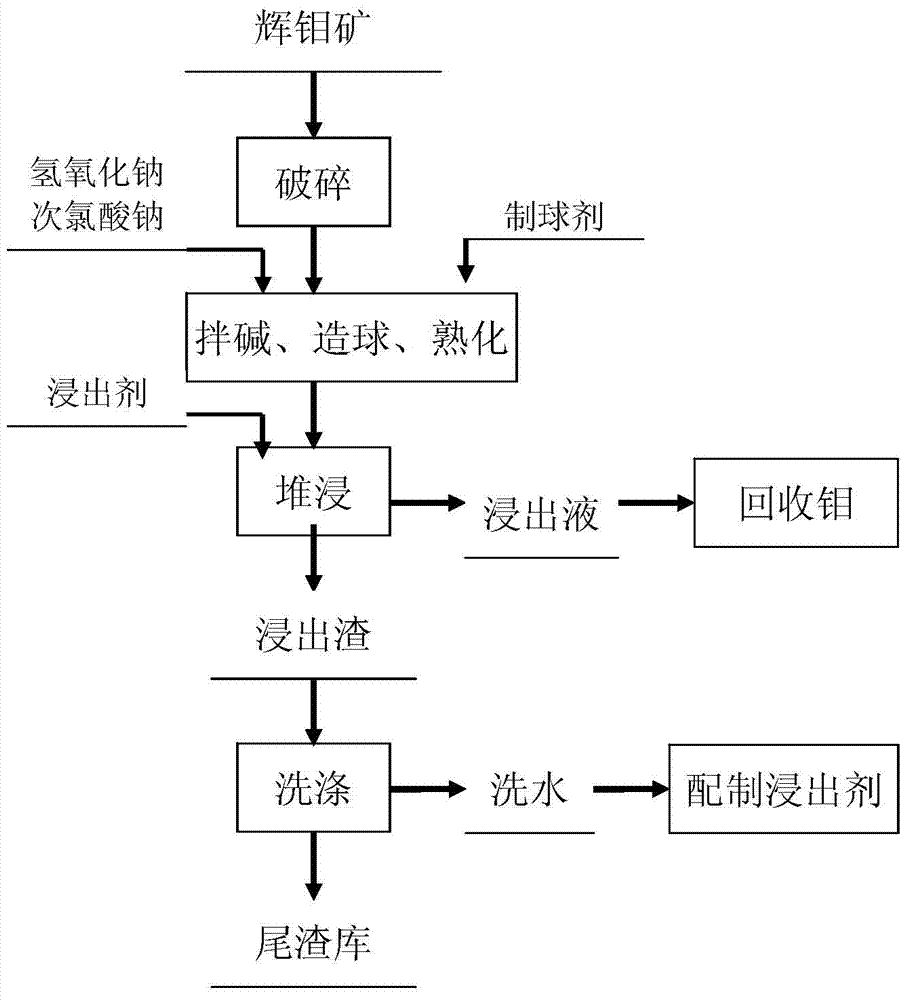

Reinforced dump leaching method of low grade molybdenite

InactiveCN104726704AImprove leaching rateShorten the leaching cycleProcess efficiency improvementResource recoveryLower grade

A method is disclosed against the technical problems of long pump leaching period and low molybdenum leaching rate of low grade molybdenite. A granulation pelletizing technology is used to fully expose molybdenum in molybdenite and realize ultrafine particle molybdenite pump leaching, and an alkali mixing slaking reinforcement technology is used to increase the reaction speed and rate of a leaching agent with the target element in order to shorten the leaching period and improve the leaching rate of the target product. The method simplifies the floating-roasting-stirring leaching grinding process of traditional methods, avoids pollution of SO2 to air, optimizes Method for Recovering Molybdenum through Dump Leaching of Low Grade Molybdenite, and realizes further improvement of the resource recovery rate, reduction of the running cost and improvement of the economic exploitation values of the low grade molybdenite through the granulation pelletizing technology and the alkali mixing slaking reinforcement technology.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

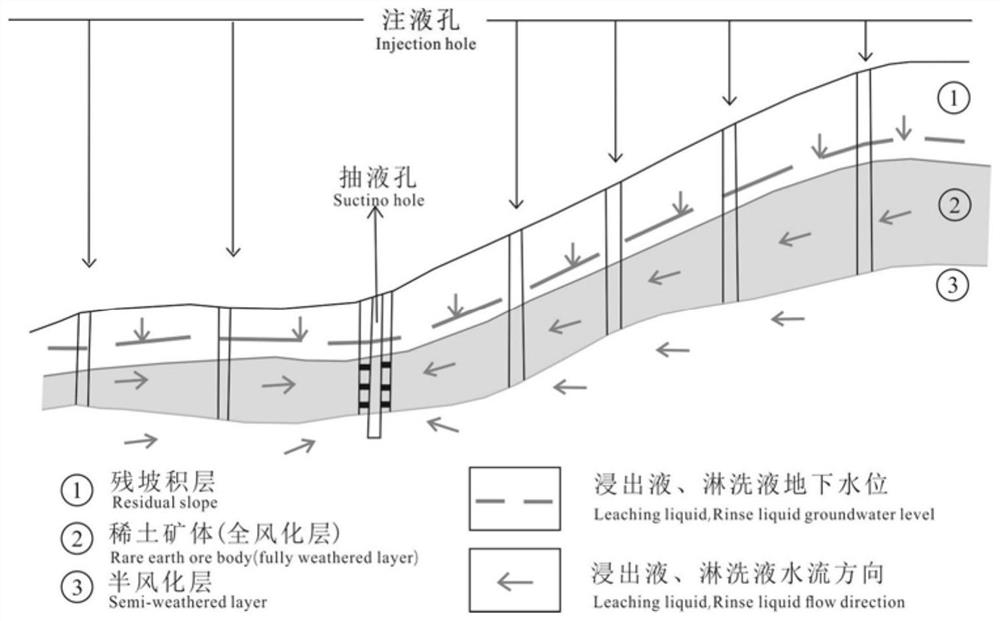

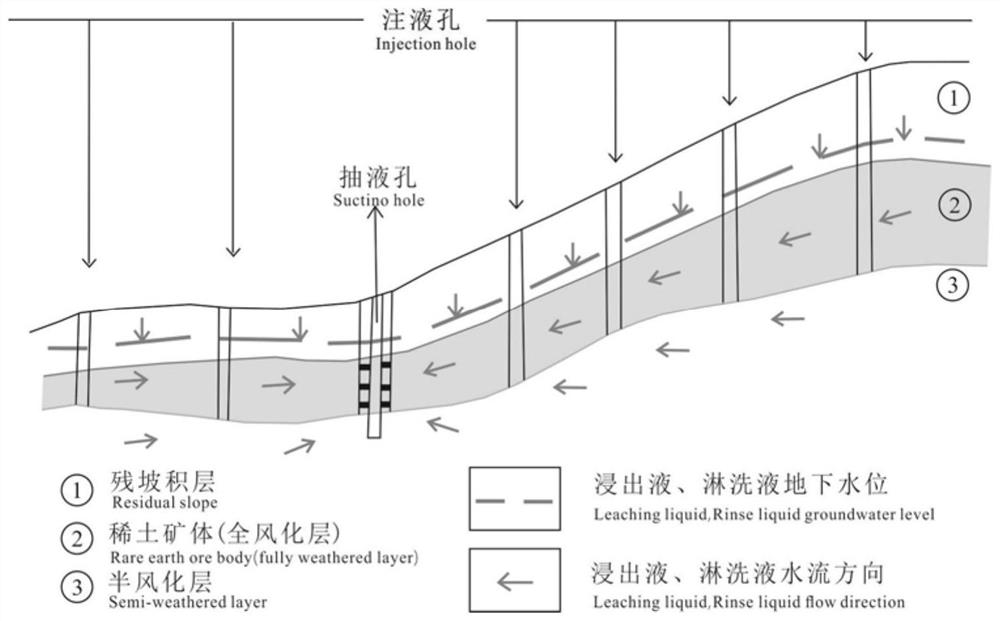

Ion adsorption type rare earth ore mining and environmental governance integrated method

ActiveCN112921192AImprove the ecological environmentLow costProcess efficiency improvementHydrometryMining engineering

The invention discloses an ion adsorption type rare earth ore mining and environmental governance integrated method which comprises the following steps: an underground water level control technology: in combination with a hydrological cycle process of a mining area, forming liquid injection holes for injecting a leaching agent in a rare earth ore body distribution section, and forming liquid extraction holes for extracting rare earth leaching liquid in an underground water collection area; a rare earth mining technology from bottom to top: punching the liquid injection holes to penetrate through the ore body, leaching the middle lower part of the rare earth ore body, and then leaching the upper part of the ore body; a mining area elution technology: injecting eluent through the liquid injection holes, conducting circular elution on the residual leaching agent in underground water, and recycling low-grade rare earth; and a monitoring technology: after the elution technology is completed, reserving and converting part of the liquid extraction holes into long-term monitoring holes for environment monitoring so that the local environment can be monitored for a long time. According to the ion adsorption type rare earth ore mining and environmental governance integrated method, rare earth ore mining and ecological environmental governance are integrated into a unified technology system, mining and environmental governance can be completed at the same time, and the phenomenon that governance is conducted after pollution occurs is avoided.

Owner:广东省地质调查院

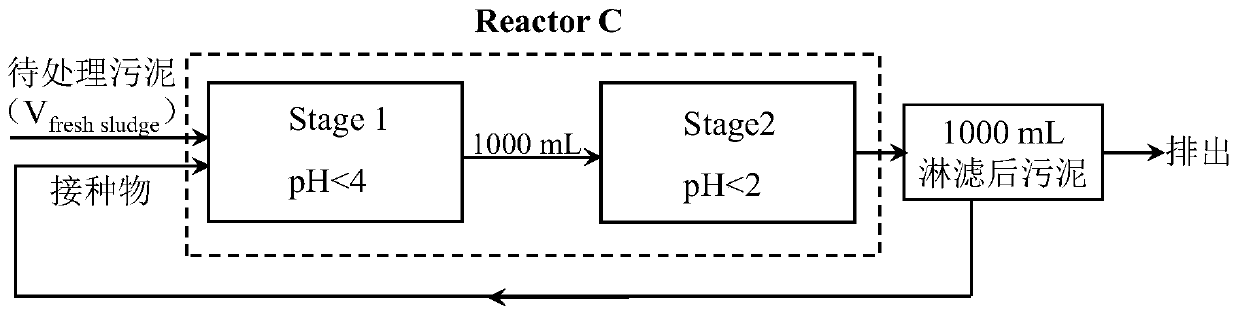

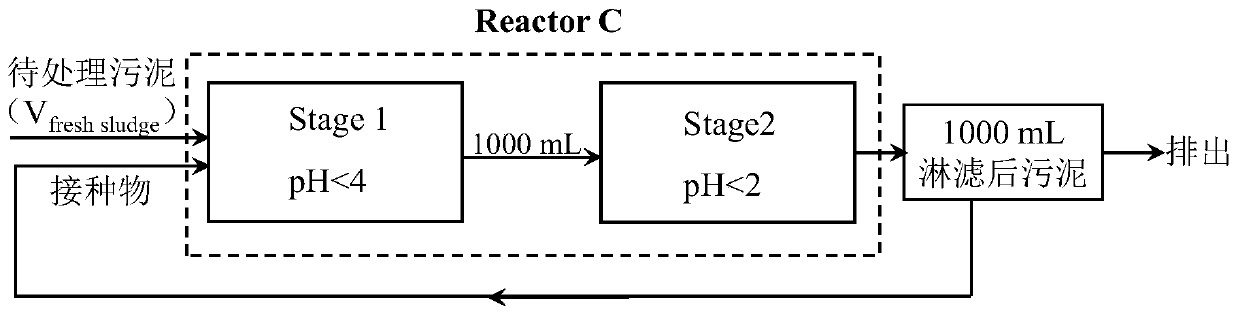

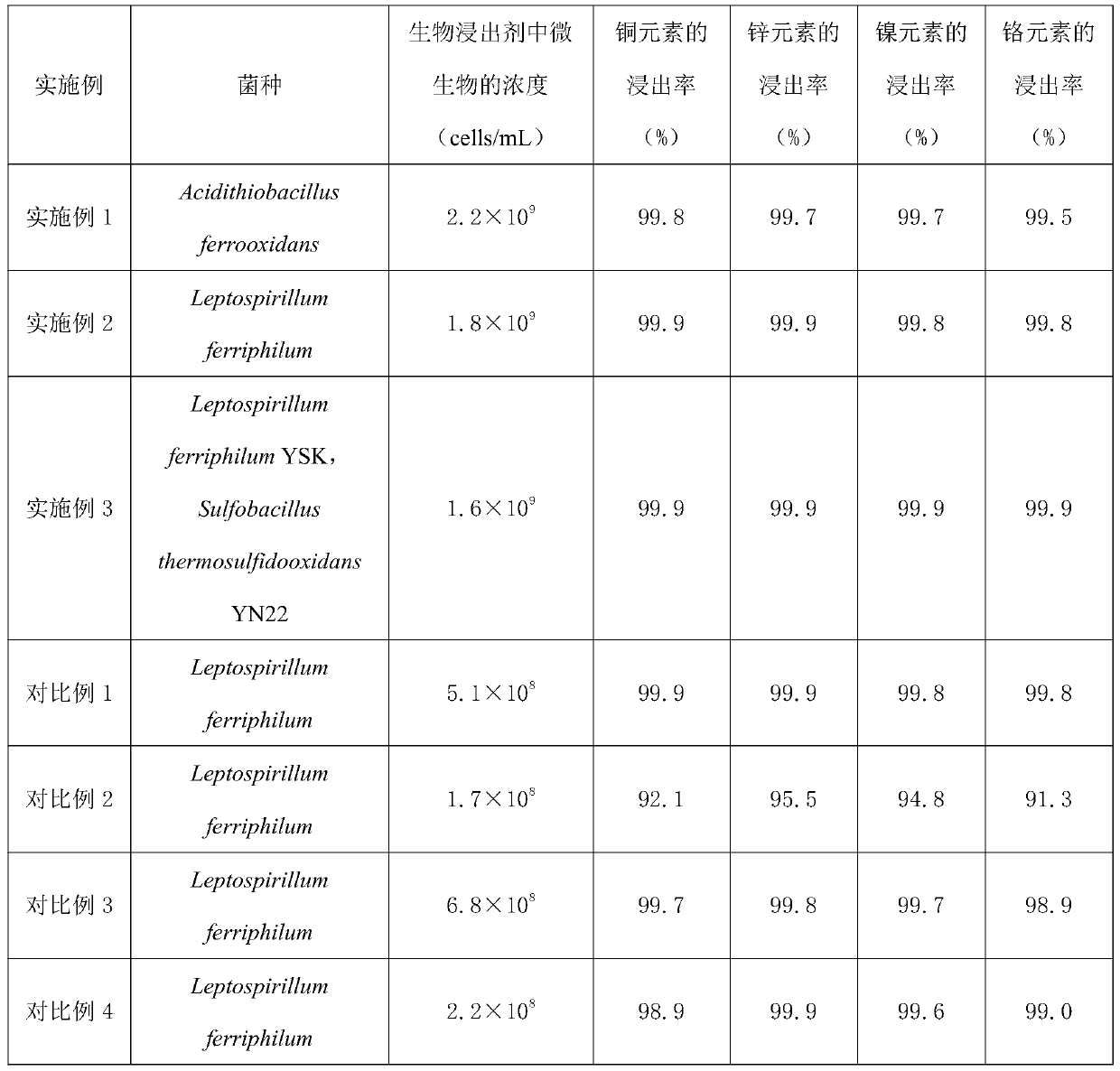

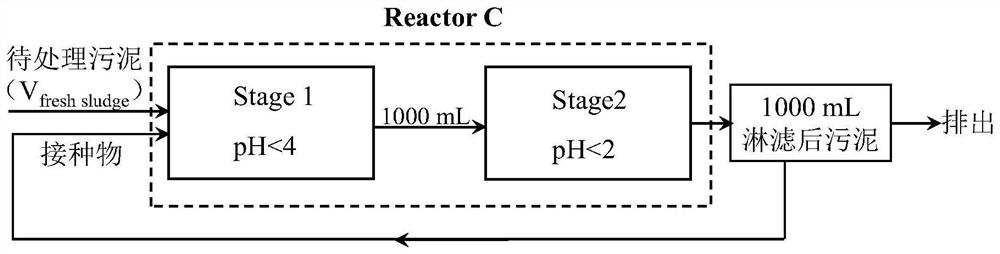

Secondary bioleaching continuous process for efficiently removing heavy metal chromium from leather making sludge

ActiveCN110040926AImprove bioleaching performanceIncrease concentrationWater contaminantsWaste water treatment from animal processingSludgeBioleaching

The invention discloses a secondary bioleaching continuous process for efficiently removing heavy metal chromium from leather making sludge. The secondary bioleaching continuous process comprises thefollowing steps: adding microflora, a microorganism energy substance and sludge to be treated into a first-level reactor and a second-level reactor respectively, supplementing to working volume with water, and meanwhile starting the first-level reactor and the second-level reactor; carrying out a bioleaching reaction on the first-level reactor and the second-level reactor; when the pH values of the first-level reactor and the second-level reactor are lower than a set value, draining the sludge bleached in the second-level reactor by a certain volume, and supplementing sludge in the first-levelreactor for reacting continually; supplementing the sludge bleached in the second-level reactor and the sludge to be treated containing the bioenergy substrate into the first-level reactor for reacting continually; repeating the step 3 and the step 4 to realize continuous bioleaching reaction for removing chromium. By adopting the secondary bioleaching continuous process, corresponding reaction environments can be provided for different microorganisms, the long-term continuous running of the bioleaching reaction is promoted, and the engineering application of the bioleaching process is realized.

Owner:SICHUAN UNIV

Sulfur and arsenic containing difficult-to-treat gold mine gold extraction method

InactiveCN106148693AShorten the leaching cycleImprove leaching rateProcess efficiency improvementBiological oxidationGranularity

The invention provides a sulfur and arsenic containing difficult-to-treat gold mine gold extraction method. According to the method, firstly, solid active carbon is added for enhancing bacterial oxidation pretreatment; then, after the ore pulp concentration and the pH are regulated, active carbon adsorption is performed for leaching gold. At the biological oxidation stage, the dosage of the solid active carbon is 6g / L to 10g / L; the granularity range is 1mm to 5mm; under the effect of the solid active carbon, the oxidation time of sulfur and arsenic containing difficult-to-treat gold mine biological leaching is greatly shortened; the leaching rate is greatly improved; after the pre-oxidation is completed, the ore pulp concentration and the pH are regulated, and the gold leaching is directly performed; gold and arsenic are recovered through analysis after the gold leaching. The method provides important theoretical and technical guidance for sulfur and arsenic containing difficult-to-treat gold mine biological pre-oxidation and gold leaching.

Owner:CENT SOUTH UNIV

A method for dephosphorizing high-phosphorus iron ore by utilizing fermented liquid of Aspergillus niger strain

ActiveCN108004401BReduce phosphorus contentShorten the leaching cycleProcess efficiency improvementMicroorganismSlurry

The invention relates to a method for performing high-phosphorus iron ore dephosphorization utilizing aspergillus niger strain fermentation liquor. The method comprises the following steps of: cultivating and fermenting an aspergillus niger strain in a biological reactor, separating, and enabling the separated aspergillus niger strain fermentation liquor to perform mineral leaching and dephosphorization on crushed high-phosphorus iron ores at a constant temperature in a mineral leaching reactor; and performing solid-liquid separation to obtain dephosphorized iron ores. The aspergillus niger strain fermentation liquor disclosed by the invention has a remarkable dephosphorization effect in treating high-phosphorus iron ores, is good in dephosphorization effect in a high-phosphorus iron ore dephosphorization technology, can shorten a microorganism mineral leaching period, and improves slurry concentration; and aspergillus niger hyphae can be repeatedly used for many times, and mineral-leached liquid also can be re-added with energy resource substances for being recycled for many times, so that realizable science and technology basis is provided for development and utilization of richhigh phosphorous iron ores of China.

Owner:WUHAN UNIV OF TECH

Using method of organic chlorine oxidant in neutral in-situ leaching uranium mining

The invention belongs to the technical field of in-situ leaching uranium mining, and particularly relates to a using method of an organic chlorine oxidant in neutral in-situ leaching uranium mining. Carbon dioxide and oxygen are injected into groundwater to prepare a leaching agent, and the pH value of the leaching agent is controlled to be 6.8-7.5; the concentration of the leach liquor uranium does not increase any more when reaching a peak value, and the oxygen stops being added; sodium dichloroisocyanurate is added as an oxidant, the prepared sodium dichloroisocyanurate solution is added into a liquid injection main pipe through a metering pump, and the mass concentration is 200-300 mg / L; the free chlorine concentration of a leach liquor is monitored, and when the free chlorine concentration is greater than 20 mg / L, the mass concentration of the oxidant sodium dichloroisocyanurate is reduced to 30-40% of the original concentration, namely, 60-120 mg / L; when the leaching rate of a block section is greater than 70%, the oxidant stops being added until the leaching process is finished. The using method can overcome the defect that the neutral leaching uranium mining adopts the oxygen as the oxidant, the tetravalent uranium in the ore is effectively oxidized, the concentration of the leach liquor uranium is improved, and the leaching period of the ore is shortened

Owner:BEIJING RES INST OF CHEM ENG & METALLURGY

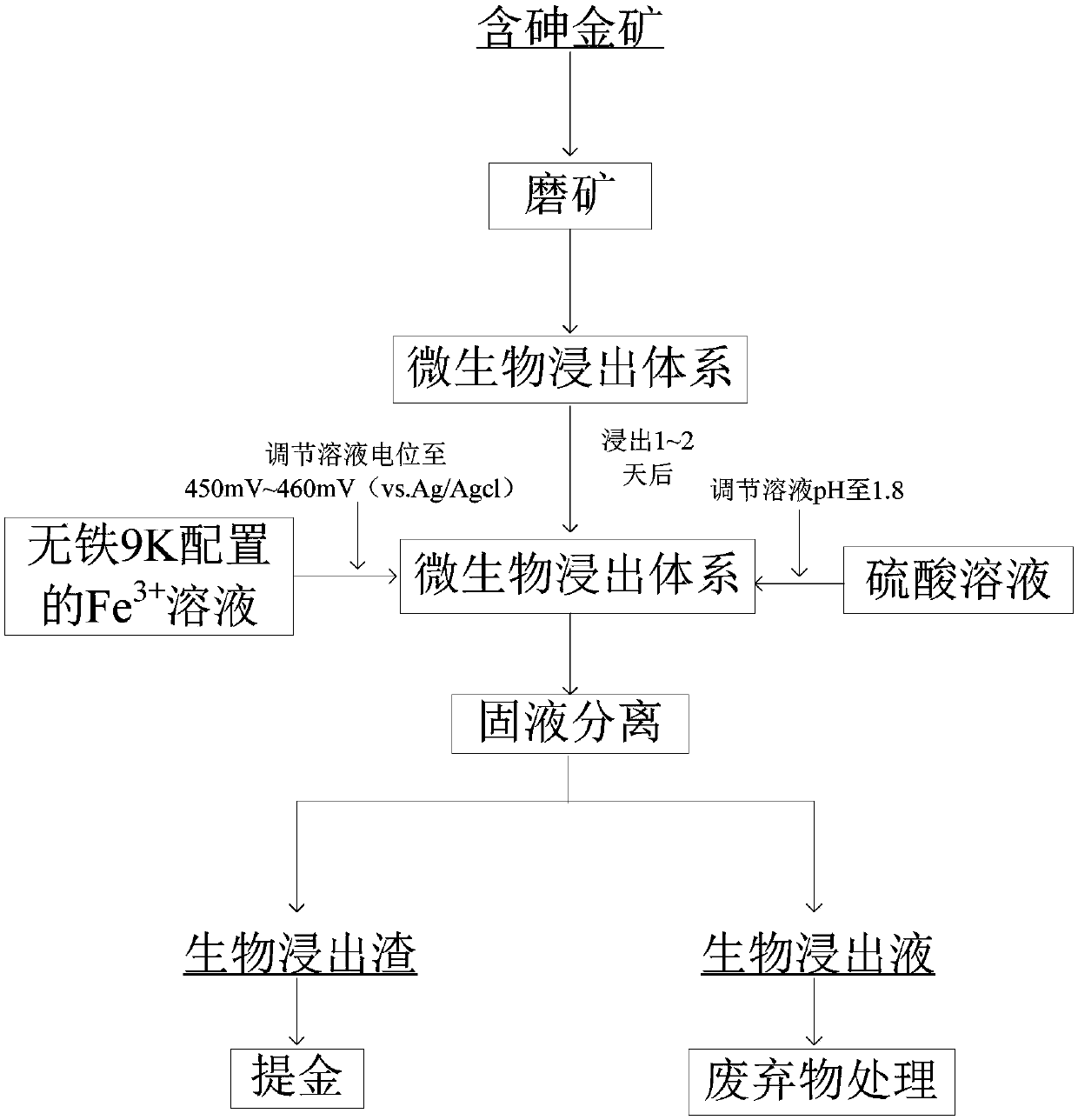

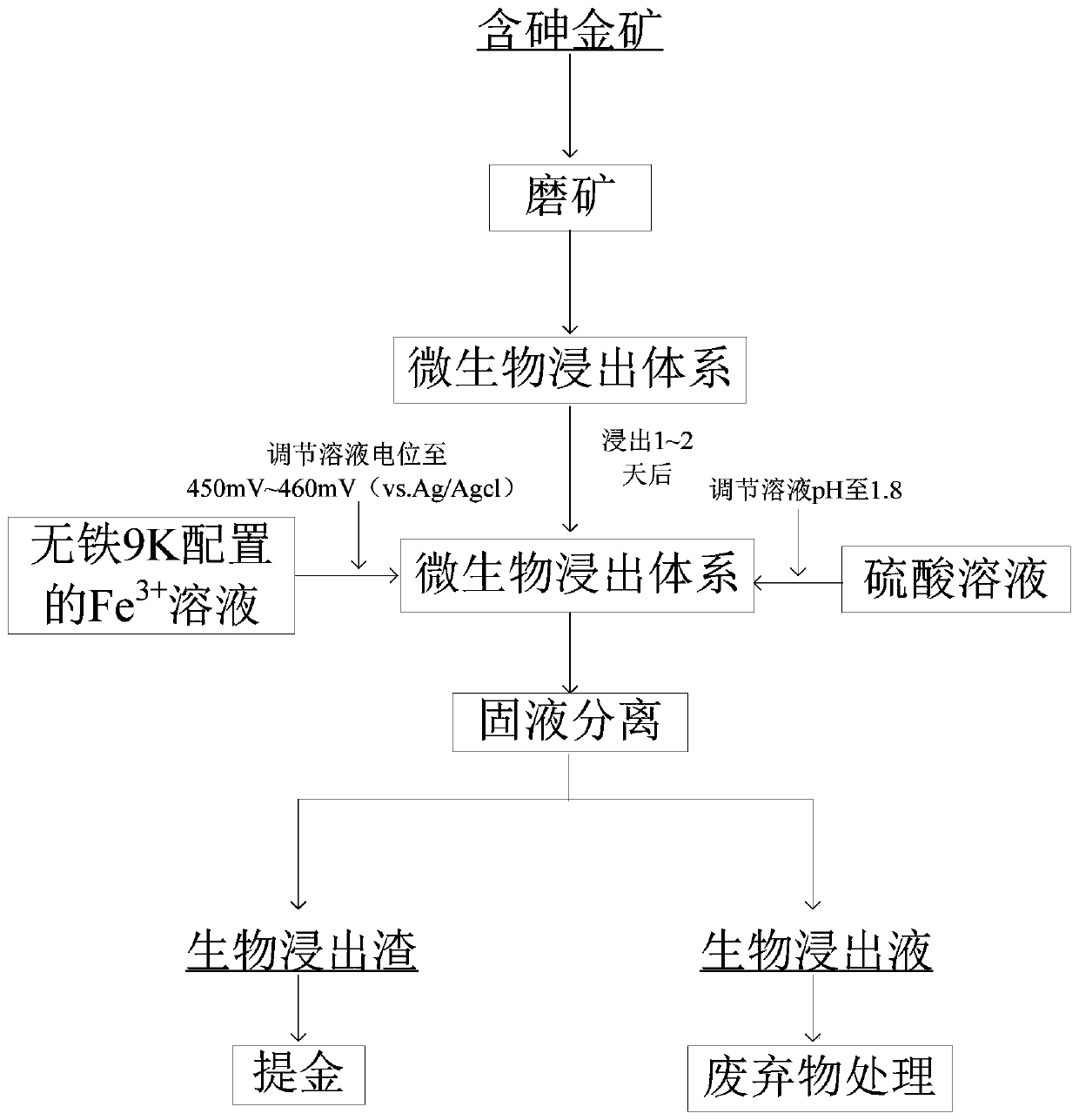

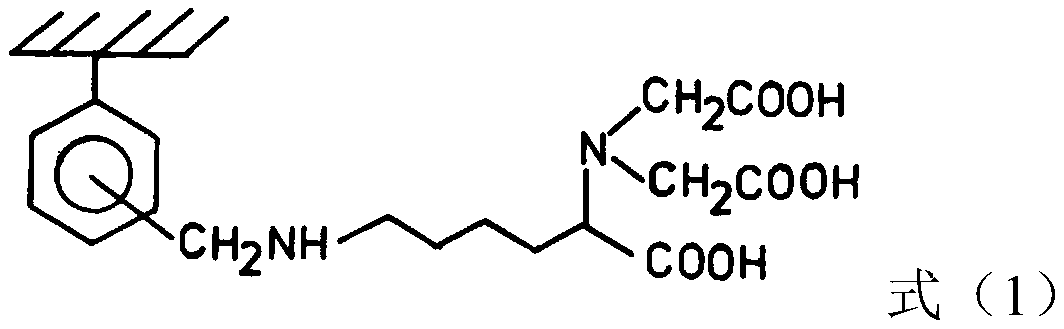

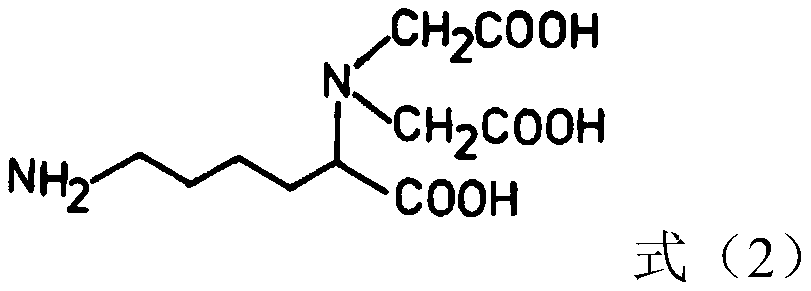

A method for enhancing biological oxidation of arsenic-containing gold ore through potential regulation and control

ActiveCN107746950AAffect growthFacilitate oxidation rateProcess efficiency improvementThiobacillus ferrooxidansSlag

A method for enhancing biological oxidation of arsenic-containing gold ore through potential regulation and control is disclosed. The method includes (1) subjecting the arsenic-containing gold ore tofine grinding to obtain ore powder; (2) preparing a 9K medium; (3) adding the ore powder obtained in the step (1) and thiobacillus ferrooxidans into the 9K medium prepared in the step (2), performingprimary biological leaching to obtain primary ore pulp, then adding a Fe<3+> solution to adjust the potential of the primary ore pulp, adjusting the pH of the primary ore pulp at the same time, and performing secondary biological leaching to obtain secondary ore pulp; and (4) after the secondary biological leaching in the step (3) is finished, subjecting the secondary ore pulp to solid liquid separation to obtain gold leaching slag. The method can significantly shorten the leaching period, is high in treatment efficiency and simple to operate, and can be widely used in ore enterprises of various sizes.

Owner:CENT SOUTH UNIV

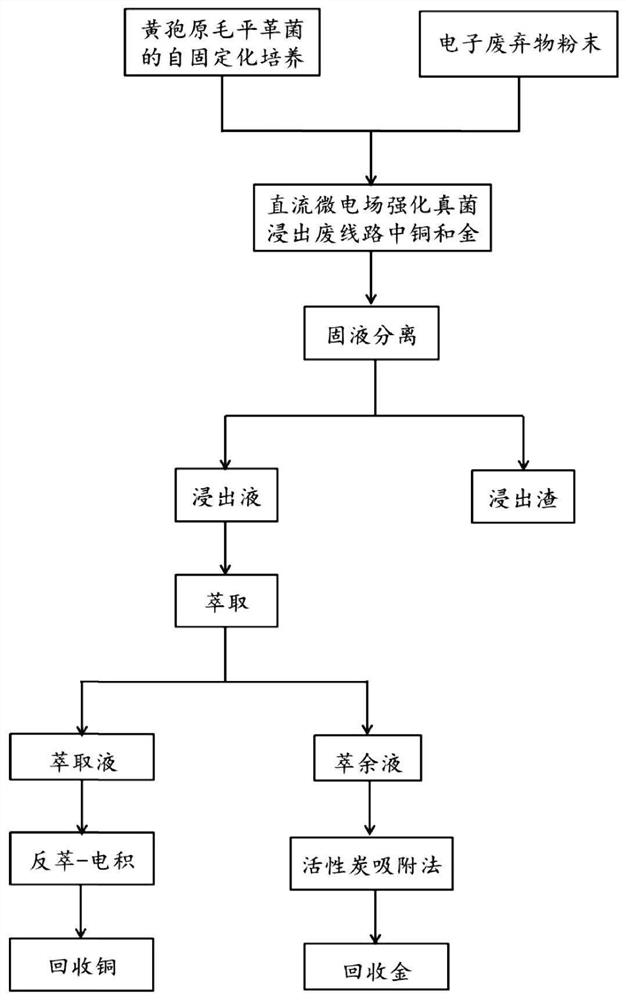

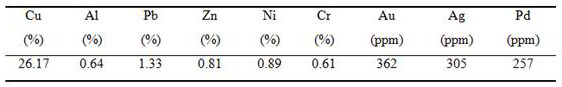

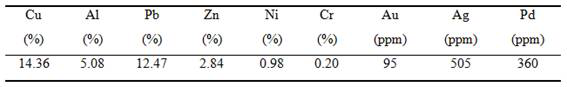

Method for leaching copper and gold in waste circuit board by utilizing micro-electric field to strengthen phanerochaete chrysosporium

ActiveCN113308605APromote growthLower pHFungiPhotography auxillary processesPhanerochaeteElectrolysis

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for leaching copper and gold in a waste circuit board by utilizing a micro-electric field to strengthen phanerochaete chrysosporium. The method comprises the following steps: firstly, carrying out self-immobilization culture on phanerochaete chrysosporium; then adding the sterilized waste circuit board powder into an electrolysis container containing cultured fungus liquid, and performing direct-current micro-electric field enhanced leaching for 6-10 days; and finally, recycling copper and gold from the microbiological leaching liquid through an extraction-reverse extraction-electrodeposition method and an activated carbon adsorption method. After the combined action of the micro-electric field and the phanerochaete chrysosporium, the average leaching rates of copper and gold in the waste circuit board are 70.90% and 38.64% correspondingly. In a fungus leaching system without applying the micro-electric field, the average leaching rates of copper and gold of the waste circuit board are 44.54% and 27.53% correspondingly. The method has the advantages that the leaching rate of copper and gold is obviously improved after micro-electric field strengthening, and the leaching period is shortened by at least 4 days.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

A method of regulating potential to enhance biooxidation of arsenic-containing gold ore

ActiveCN107746950BAffect growthFacilitate oxidation rateProcess efficiency improvementThiobacillus ferrooxidansIron(II) oxide

A method for enhancing biological oxidation of arsenic-containing gold ore through potential regulation and control is disclosed. The method includes (1) subjecting the arsenic-containing gold ore tofine grinding to obtain ore powder; (2) preparing a 9K medium; (3) adding the ore powder obtained in the step (1) and thiobacillus ferrooxidans into the 9K medium prepared in the step (2), performingprimary biological leaching to obtain primary ore pulp, then adding a Fe<3+> solution to adjust the potential of the primary ore pulp, adjusting the pH of the primary ore pulp at the same time, and performing secondary biological leaching to obtain secondary ore pulp; and (4) after the secondary biological leaching in the step (3) is finished, subjecting the secondary ore pulp to solid liquid separation to obtain gold leaching slag. The method can significantly shorten the leaching period, is high in treatment efficiency and simple to operate, and can be widely used in ore enterprises of various sizes.

Owner:CENT SOUTH UNIV

Whole utilizing method of arsenious gold fine mine

InactiveCN111560519AReduce concentrationReduce pollutionIon-exchange process apparatusOther chemical processesSorbentGold ore

The invention provides a whole utilizing method of an arsenious gold fine mine. The whole utilizing method comprises the following steps of (1) performing crushing, milling and acidification on a goldmine; (2) performing bacteria preoxidation on the gold mine subjected to crushing, milling and acidification, and adding an arsenic adsorbing agent to the bacteria preoxidation system; (3) performingthickening treatment to obtain an upper floating layer, clear liquid and an underflow; (4) performing neutralizing, cyanation and lixiviating on the underflow for recovery of gold; and (5) recoveringarsenic from the upper floating layer. Through the adoption of the whole utilizing method disclosed by the invention, arsenic in the arsenious gold fine mine can be subjected to selective adsorption,and besides, the behavior of low gold leaching efficiency due to gold adsorption and taking away can be avoided.

Owner:JIANGXI YIYUAN REGENERATION RESOURCE CO LTD

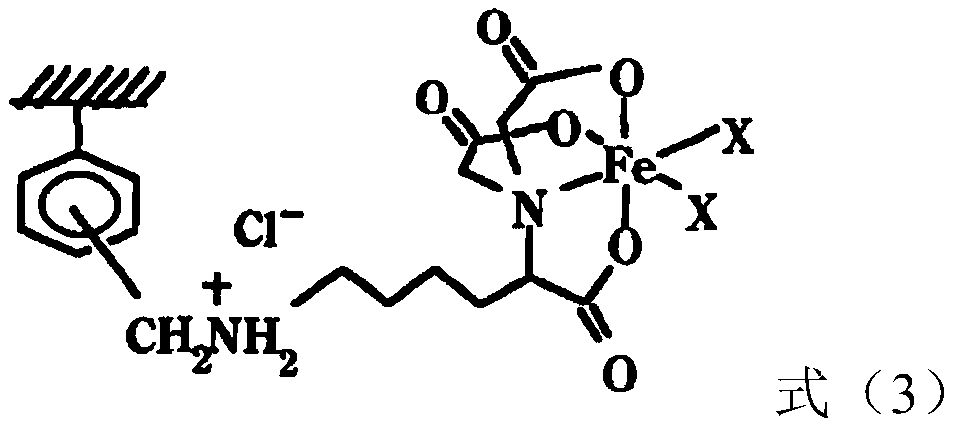

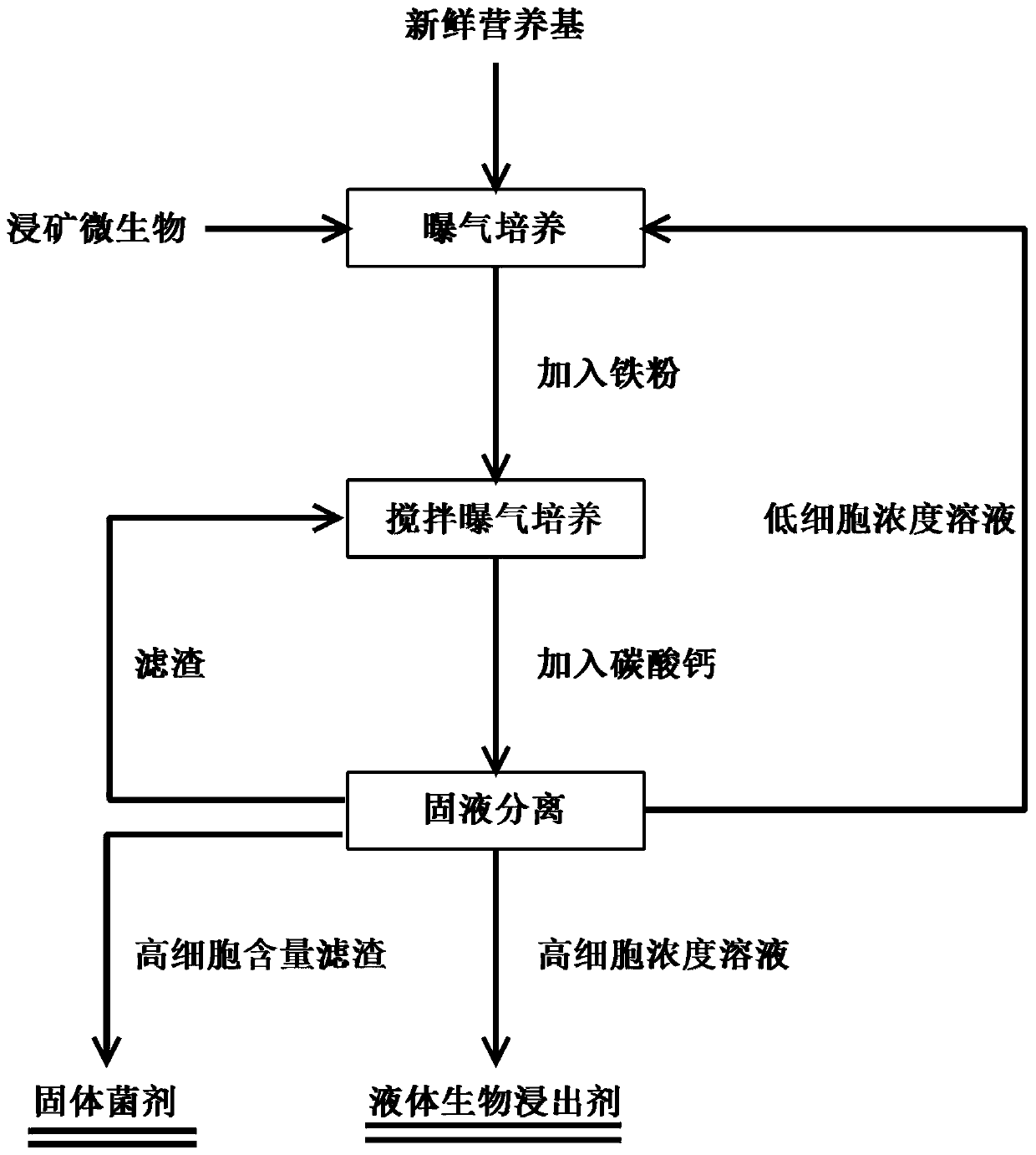

A kind of culture method of iron oxidation leaching microorganism

ActiveCN108998396BImprove cultivation efficiencyReduce incubation timeBacteriaMicroorganism based processesMicroorganismIron powder

Owner:CENT SOUTH UNIV

Clean nickel ore pretreatment process

PendingCN112011683AImprove leaching rateImprove and solve the passivation problem where the leaching rate obviously changes from fast to slowProcess efficiency improvementMicrowave sinteringMetal

The invention belongs to the technical field of nickel ore pretreatment, and particularly relates to a clean nickel ore pretreatment process. Aiming at the problems of long treatment period, low nickel leaching rate, low yield, serious environmental pollution and obvious passivation of the later nickel leaching rate from fast to slow in the existing process, the invention provides the following scheme: (1) ore dressing: removing large bedrock with a weak weathering degree and low nickel content in nickel ore in advance by adopting the procedures of crushing, screening and the like; and (2) microwave sintering and pressure leaching: carrying out microwave sintering on the nickel ore treated in the step (1) to destroy mineral lattices, then carrying out pressure leaching in a low-temperatureenvironment, separating out iron ions, precipitating to obtain hematite, and filtering out the hematite. According to the method, the characteristics of the nickel ore can be well adapted, the ore leaching performance is excellent, the biological column leaching effect is excellent, and the biological leaching period is short; the metal yield is high; no pollution is caused to the environment; and the passivation problem that the nickel leaching rate obviously changes from high to low in the later leaching period can be solved, and the nickel leaching rate is high.

Owner:JIANGSU DELONG NICKEL IND CO LTD

Use method of organochlorine oxidant in acid-process in-situ leaching uranium mining

ActiveCN112853127AShorten the leaching cycleGood oxidation effectProcess efficiency improvementEnvironmental chemistryDichloroisocyanuric acid

The invention belongs to the technical field of in-situ leaching uranium mining, and particularly relates to a use method of an organochlorine oxidant in acid-process in-situ leaching uranium mining. H2SO4 is added into underground water to prepare a leaching agent, and acidification is started; a mixed solution of dichloroisocyanuric acid and trichloroisocyanuric acid is added as an oxidizing agent, the mass concentration ranges from 150 mg / L to 300 mg / L, the mass ratio of dichloroisocyanuric acid ranges from 20% to 30%, and the mass ratio of trichloroisocyanuric acid ranges from 70% to 80%; the Eh value of lixivium is monitored, when the Eh value of the lixivium is stabilized to be 550 mV or above, the mass concentration of the oxidizing agent is not changed, the mass ratio of dichloroisocyanuric acid is 60%-70%, and the mass ratio of trichloroisocyanuric acid is 30%-40%; the free chlorine concentration of the lixivium is monitored, and when the free chlorine concentration is larger than 8 mg / L, the concentration is reduced to 40%-60% of the original concentration; and when the leaching rate of blocks is greater than 80%, oxidizing agent adding is stopped, and the concentration of H2SO4 is reduced to 3.0-5.0 g / L until the leaching process is finished. According to the use method, tetravalent uranium in the ore can be effectively oxidized, the uranium concentration of the lixivium is improved, the reagent cost of the oxidizing agent is reduced, and the leaching period of the ore is shortened.

Owner:BEIJING RES INST OF CHEM ENG & METALLURGY

An integrated method of ion adsorption type rare earth ore mining and environmental treatment

ActiveCN112921192BImprove the ecological environmentLow costProcess efficiency improvementEcological environmentMining engineering

The invention discloses an integrated method for ion adsorption type rare earth ore mining and environmental treatment. , in the groundwater catchment area, a liquid pumping hole for extracting rare earth leaching liquid is arranged; bottom-up rare earth mining process: the liquid injection hole penetrates the ore body, and the middle and lower parts of the rare earth ore body are first leached, and then the ore body is leached. Upper part; mining area leaching process: inject the leaching liquid through the liquid injection hole, circulate the leaching agent remaining in the groundwater, and recover low-grade rare earth; monitoring process: after the leaching process is completed, part of the liquid pumping holes are reserved for conversion It is a long-term monitoring hole for environmental monitoring, and conducts long-term monitoring of the local environment. The invention integrates rare earth ore mining and ecological environment treatment into a unified process system, can simultaneously complete the two links of mining and environmental treatment, and avoids the phenomenon of "pollution first and treatment later".

Owner:广东省地质调查院

Method for removing uranium through oxidation

ActiveCN111924956AHigh deuranium removal rateSimple processWaste water treatment from quariesWater contaminantsPyriteProcess engineering

The invention provides a method for removing uranium by oxidation. The method comprises the following steps: mixing uranium-containing wastewater, pyrite and a buffer agent, regulating the pH value tobe neutral, introducing oxygen into the obtained mixed solution, and reacting. According to the method, the uranium is fixed to the surface of the pyrite through the adsorption or reduction effect ofthe pyrite, meanwhile, the uranium can also be fixed into the precipitate through iron oxide formed by oxidizing the pyrite, and therefore the purpose of removing the uranium in the uranium-containing wastewater is achieved. The method has the advantages of being simple in process, easy and convenient to operate, low in cost and capable of efficiently removing uranium, and has important theoretical guiding significance for repairing and treating the high-uranium underground water in the retired mining area of the neutral in-situ leaching uranium mining.

Owner:NANHUA UNIV

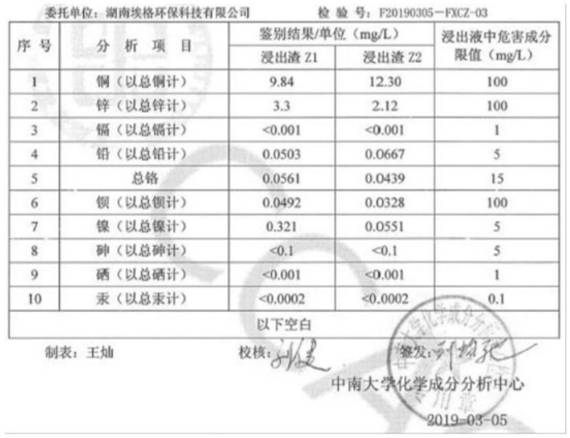

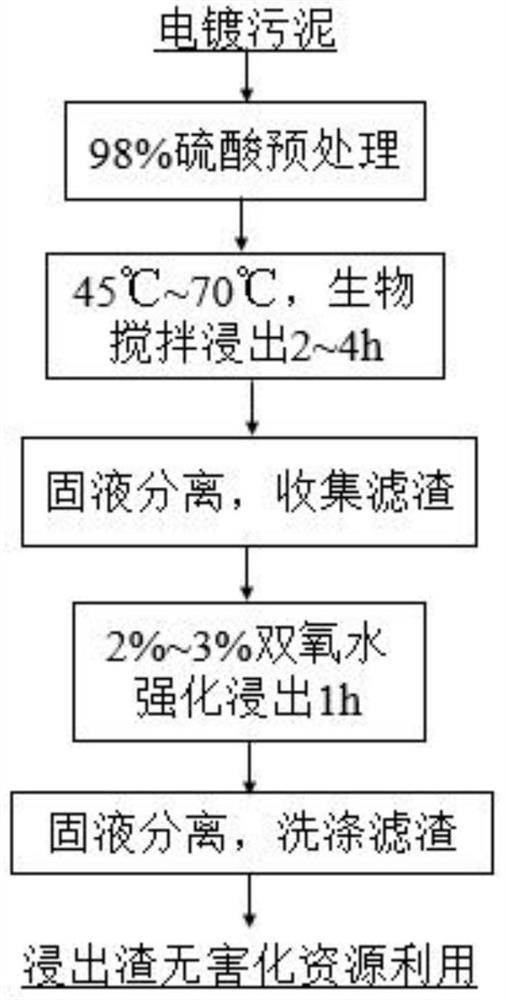

Method for extracting metal copper from copper-containing sludge on circuit board

InactiveCN112210670AImprove leaching effectShorten the leaching cycleProcess efficiency improvementPregnant leach solutionSludge

The invention discloses a method for extracting metal copper from copper-containing sludge on a circuit board. The method comprises the steps of adding concentrated sulfuric acid into the copper-containing sludge on the circuit board for pretreatment; adding biological bacteria liquid into the pretreated copper-containing sludge on the circuit board, and carrying out stirring and leaching to finish the solid-liquid separation; sequentially adding clear water and hydrogen peroxide into obtained leaching residue, carrying out the enhanced stirring and leaching, and then carrying out the solid-liquid separation and the washing; and extracting copper from an obtained leaching solution, and carrying out cyclone electrodeposition after back extraction to extract the metal copper. According to the method, firstly, the copper in the copper-containing sludge on the circuit board is leached by adopting a biological wet method, and then the hydrogen peroxide is added in the process for the secondary enhanced leaching, so that a leaching effect better than the single biological leaching is obtained, the maximum recovery of the copper in the copper-containing sludge on the circuit board is achieved, and meanwhile, the leaching residue reaches a harmless discharge standard and can be discharged or utilized as a harmless resource.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for monitoring leaching state of in-situ leaching uranium mining

ActiveCN112816276AImprove leaching rateAccurately judge the leaching effectPreparing sample for investigationSurface/boundary effectMining engineeringUranium mine

The invention belongs to the technical field of uranium mining, and particularly relates to a method for monitoring the leaching state of in-situ leaching uranium mining. The invention discloses a method for monitoring the uranium leaching state in an underground ore bed in the in-situ leaching uranium mining process. The method is mainly characterized in that monitoring holes are constructed in different positions in an in-situ leaching uranium mining well site, a certain number of sample bags filled with ore samples are hung in the monitoring holes, one sample bag is taken out every certain monitoring period for sample analysis, and the leaching states of uranium in ore beds at different positions at different leaching times of the in-situ leaching uranium mining well site are obtained through calculation. And the next production mining area is accurately guided to adjust process parameters.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

A two-stage bioleaching continuous process for efficient removal of heavy metal chromium from tannery sludge

ActiveCN110040926BImprove bioleaching performanceIncrease concentrationWater contaminantsWaste water treatment from animal processingMicroorganismBioelectric Energy Sources

The invention discloses a two-stage bioleaching continuous process for efficiently removing heavy metal chromium from tannery sludge. Microbial communities, microbial energy substances, and sludge to be treated are respectively added to the first-stage reactor and the second-stage reactor. Make up to the set working volume with water, and start the first and second reactors at the same time; the first reactor and the second reactor respectively carry out the bioleaching reaction; when the pH of the first reactor and the second reactor If the value is lower than the set value, discharge a certain volume of sludge from the second-stage reactor after leaching and then use the sludge in the first-stage reactor to make up for the reaction; take the sludge from the second-stage reactor after leaching The mud and the untreated sludge containing bioenergy substances are added to the first-stage reactor to continue the reaction; repeating steps 3 and 4 to achieve continuous bioleaching reaction dechrome. The invention is beneficial to provide corresponding reaction environment for different microorganisms, promotes long-term continuous operation of biological leaching reaction, and realizes engineering application of biological leaching process.

Owner:SICHUAN UNIV

A kind of biological and chemical synergistic leaching method of weathering crust leaching type rare earth ore

ActiveCN113046579BReduce dosageImprove leaching rateProcess efficiency improvementMicroorganismSoil science

The invention discloses a biological and chemical synergistic method for leaching weathering crust leaching type rare earth ore, which comprises the following steps: 1) preparation of microbial leaching agent; 2) chemical cationic salt leaching agent; 3) leaching. In the bioleaching process, the chemical leaching agent is used in combination, and the synergistic effect of the biological and chemical leaching agents is used to realize the high-efficiency extraction of rare earths, which effectively overcomes the problem of low bioleaching efficiency; the microorganisms used in the present invention exist widely in nature and have green The advantages of environmental protection and low cost, microorganisms and leaching agent components are conducive to ecological restoration and improvement; the method of biological and chemical synergistic leaching of weathering crust leaching type rare earth ores of the present invention reduces the amount of chemical leaching agents used, and is effective in alleviating environmental pollution. The clean and efficient extraction of rare earths has been realized under the premise.

Owner:CENT SOUTH UNIV

High-efficiency sulfur-oxidizing bacteria and a process for rapid heating of low-sulfur copper ore leaching in alpine regions

ActiveCN105779324BImprove permeabilityIncrease oxidation rateBacteriaMicroorganism based processesMicroorganismSulfur

The invention discloses an efficient sulfur-oxidizing bacteria with a strain name of Acidithiobacillus thiooxidans Retech DW-II. The strain is preserved in China General Microbiological Culture Collection Center, Institute of Microbiology of the Chinese Academy of Sciences, No.3, Court No.1, Beichen West Road, Chaoyang District, Beijing on September 10, 2014, and has accession number of CGMCCNo. 9625. The invention also provides a rapid heating method for low-sulfur copper mine leaching process in Alpine region. The method comprises the steps of: crushing ore to -50mm, mixing with pyrite powder, conducting sulfuric acid slaking and granulation to improve the permeability of the stock heap and provide sufficient energy for bacteria; and finally adding the efficient sulfur-oxidizing bacteria CGMCC No. 9625. The method speeds up the initial rate of oxidation of the pyrite ore heap, and provides sufficient heat for the stock heap, so that temperature of the stock heap rapidly increases to above 40 DEG C.

Owner:有研资源环境技术研究院(北京)有限公司

A kind of bacterial stirring leaching method of uranium ore

Owner:NORTHEASTERN UNIV LIAONING

A kind of autotrophic and heterotrophic compound leaching bacteria group fim-z4 and its application

ActiveCN105199990BImprove leaching rateImprove leaching reaction kineticsBacteriaMicroorganism based processesIron sulphurCopper sulfide

The invention discloses autotrophic and heterotrophic compound ore-leaching flora FIM-Z4 and application thereof and provides a mixed culture FIM-Z4 of acidithiobacillus ferrooxidans, acidithiobacillus thiooxidans and acidiphiliu acidophilum; the preservation number of the mixed culture FIM-Z4 is CGMCC No.11190. Through synergistic effect, the leaching reaction kinetics is improved obviously, the reaction speed is increased, the leaching period is shortened, and the leaching rate and leaching yield of metal (copper and nickel) ions in target ore are increased. The heterotrophic compound ore-leaching flora FIM-Z4 is a compatible whole, and the population ecology keeps relatively stable in a long-term domestication process. The heterotrophic compound ore-leaching flora FIM-Z4 is applied to biological metallurgy and has a better leaching effect on copper ions in low-grade copper sulphide ore and nickel ions in low-grade nickel ore.

Owner:FUJIAN INST OF MICROBIOLOGY

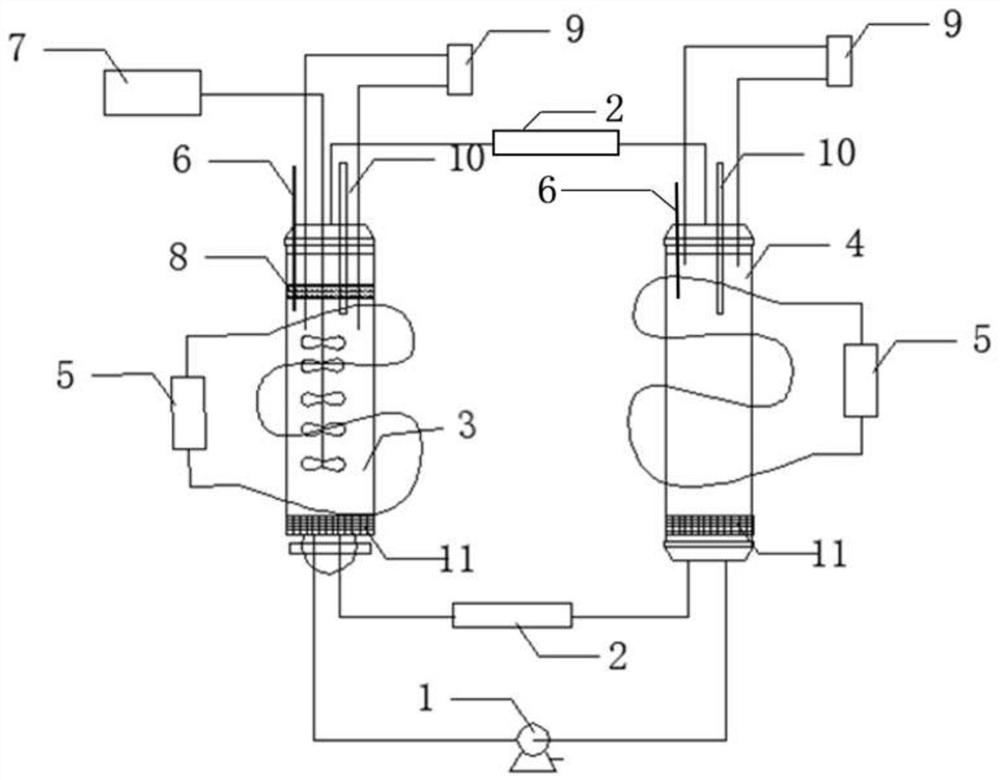

Biological-chemical two-stage circulating reactor for pretreatment of refractory gold ore

PendingCN114107658AImprove leaching efficiencyShorten the leaching cycleProcess efficiency improvementElectrochemical responsePeristaltic pump

The invention discloses a biological-chemical two-stage circulating reactor for pretreatment of refractory gold ores, which is used for enhancing pretreatment of refractory gold ores by simultaneously using an electrochemical method and a biological leaching method and is used for improving the gold extraction rate of the refractory gold ores. Comprising a double-head air pump, two constant-current peristaltic pumps, an electrochemical reactor, an electrical stimulation bioreactor, two electric heating systems, two external electric fields, two pH and oxidation-reduction potentiometers, two thermometers, a stirrer and a filter. According to the device, biological reaction and chemical reaction in the ore leaching process are carried out separately, strengthening measures are taken for bacterial reproduction and biological leaching through direct current stimulation, the leaching period is shortened, the cost is reduced, microbiological leaching of the chemical reactor is strengthened through the electric field potential, the oxidation rate of refractory gold ore can be remarkably increased, and the leaching efficiency of the refractory gold ore is improved. And the leaching rate of gold is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com