Ion adsorption type rare earth ore mining and environmental governance integrated method

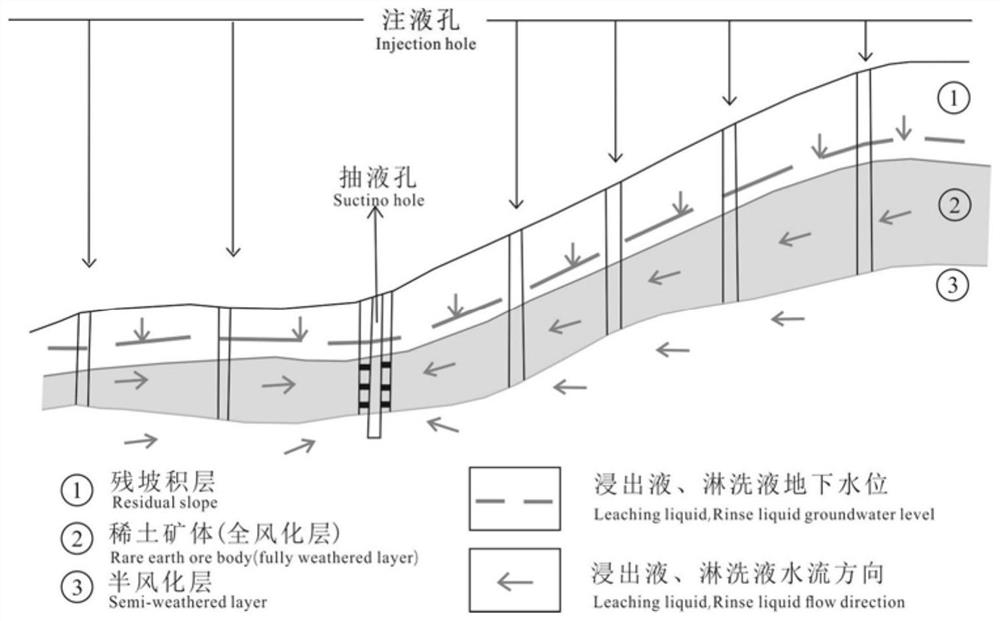

An ion adsorption type, environmental treatment technology, applied in the fields of mining, mine geological environment treatment and mine ecological restoration, can solve the problems of leaking polluted plant growth layer, low flow rate of leachate, and low recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The technical solution of the present invention will be further elaborated below through specific examples.

[0047] An integrated method for ion-adsorption rare earth mining and environmental governance in this embodiment specifically includes the following aspects:

[0048] (1) Survey and layout

[0049] Carry out 1:5000~1:2000 mineral geological surveys in mining areas to find out the rock type, lithofacies, lithology, evolution characteristics of ore-forming parent rocks and their relationship with ore-forming; find out the distribution range, quantity, scale, production Parameters such as shape, spatial position and shape, mutual relationship, range of weathering crust, grade of rare earth ore, leaching rate, etc.

[0050] Carry out 1:5000 hydraulic and environmental geological surveys in mining areas, investigate the supply, runoff, and discharge conditions of groundwater in mining areas, and determine the catchment boundaries; find out the distribution of (inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com