An integrated method of ion adsorption type rare earth ore mining and environmental treatment

An ion adsorption type and environmental treatment technology, applied in mine geological environment treatment, mine ecological restoration, and mining mining, can solve the problems of increasing the difficulty and cost of environmental treatment, long rare earth leaching cycle, leakage of rare earth leachate, etc., and achieve environmental conservation cost, achieve sustainable development, and shorten the effect of leaching cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The technical solutions of the present invention will be further elaborated below through specific embodiments.

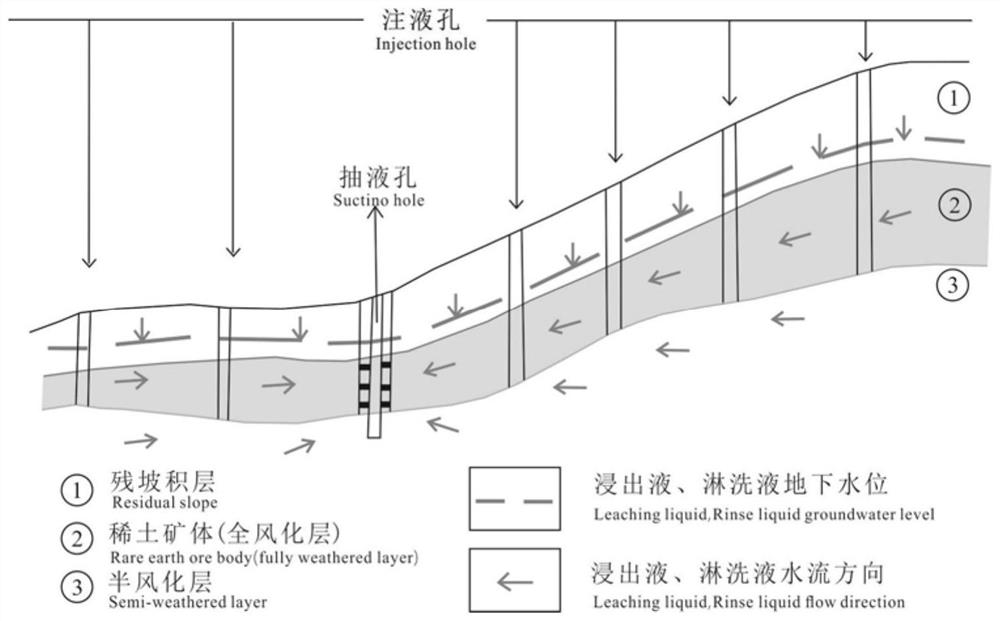

[0047] An integrated method for ion adsorption type rare earth ore mining and environmental treatment of the present embodiment specifically includes the following aspects:

[0048] (1) Investigation and deployment

[0049] Carry out a geological survey of mineral resources in the mining area from 1:5000 to 1:2000 to find out the ore-forming parent rock, lithofacies, lithology, evolution characteristics and their relationship with metallogenic; find out the distribution range, quantity, scale and production of ore bodies parameters such as shape, spatial location and form, relationship between each other and the extent of weathering crust, grade of rare earth ore, and leaching rate.

[0050] Carry out a 1:5000 geological survey of the hydraulic environment in the mining area, investigate the recharge, runoff, and discharge conditions of groundwater in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com