Method for extracting metal copper from copper-containing sludge on circuit board

A technology for extracting metals and circuit boards, applied in the direction of improving process efficiency, etc., can solve problems such as limited sludge leaching effect, achieve good leaching effect, save costs, and reduce energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

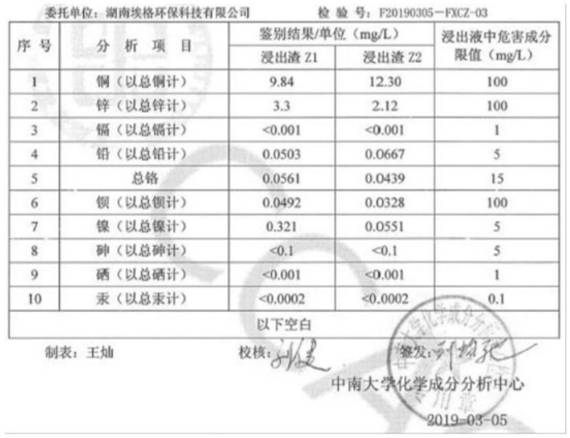

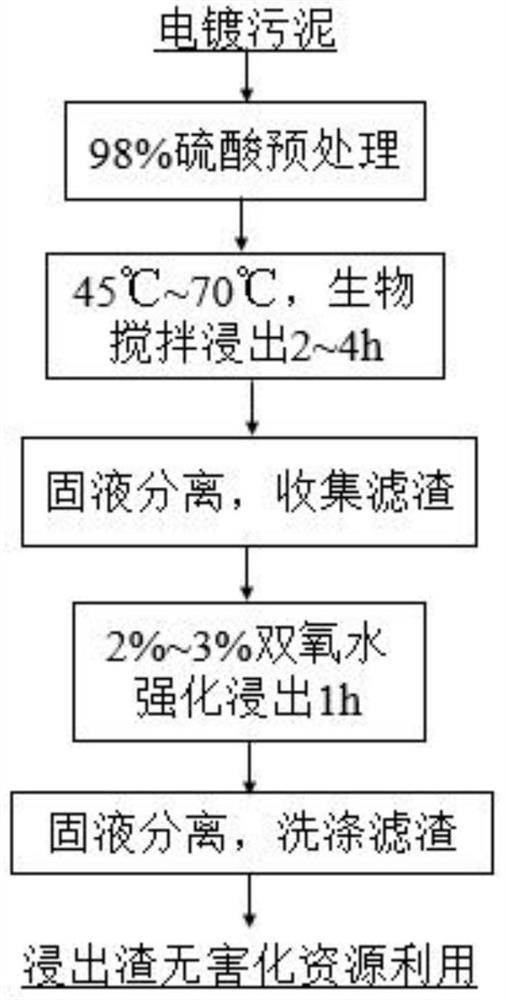

[0040] A method of extracting metallic copper from circuit board copper-containing sludge of the present invention, such as figure 1 As shown, the circuit board copper-containing sludge produced by a circuit board factory is used as raw material, the copper content is 14-20%, and the iron grade is 25-35%. The specific steps are as follows:

[0041] (1) Determination of acid consumption: Carry out relevant measurement to raw material, its water content is 55.34%, and copper content is 12.97%, after taking part raw material and drying under the condition of 105 ℃, take 10g dry basis and add 100mL distilled water, slowly, Continue to add 98% concentrated sulfuric acid until the slurry pH value is stable at about 1.5, record the addition of 98% concentrated sulfuric acid (mass concentration), which is the acid consumption of the raw material; record the 98% concentrated sulfuric acid acid consumption per 10g dry basis The volume is 3.7mL;

[0042] (2) Pretreatment: Weigh 44.78g o...

Embodiment 2

[0052] A method for extracting metallic copper from circuit board copper-containing sludge according to the present invention uses the circuit board copper-containing sludge produced by a circuit board factory as raw material, the copper content is 14-20%, and the iron grade is 25-35% , including the following steps:

[0053] (1) Determination of acid consumption: Carry out relevant determination to raw material, its water content is 60%, copper content is 12.60%, after taking part raw material and drying under the condition of 105 ℃, take 10g dry basis and add 100mL distilled water, slowly, Continue to add 98% concentrated sulfuric acid until the slurry pH value is stable at about 1.5, record the addition of 98% concentrated sulfuric acid (mass concentration), which is the acid consumption of the raw material; record the 98% concentrated sulfuric acid acid consumption per 10g dry basis The volume is 4.0mL;

[0054] (2) Pretreatment: Weigh 25kg of raw materials on a wet basis...

Embodiment 3

[0064] A method for extracting metallic copper from circuit board copper-containing sludge according to the present invention uses the circuit board copper-containing sludge produced by a circuit board factory as raw material, the copper content is 14-20%, and the iron grade is 25-35% , including the following steps:

[0065] (1) Determination of acid consumption: Carry out relevant measurement to raw material, its water content is 58%, and copper content is 14.80%, after taking part raw material and drying under the condition of 105 ℃, take 10g dry basis and add 100mL distilled water, slowly, Continue to add 98% concentrated sulfuric acid until the slurry pH value is stable at about 1.5, record the addition of 98% concentrated sulfuric acid (mass concentration), which is the acid consumption of the raw material; record the 98% concentrated sulfuric acid acid consumption per 10g dry basis The amount is 4.2g;

[0066] (2) Pretreatment: Weigh 5t of raw materials on a wet basis,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com