Whole utilizing method of arsenious gold fine mine

A gold concentrate and gold ore technology, applied in chemical instruments and methods, improvement of process efficiency, ion exchange, etc., can solve problems such as gold robbery, high processing cost, environmental pollution, and reduced gold leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

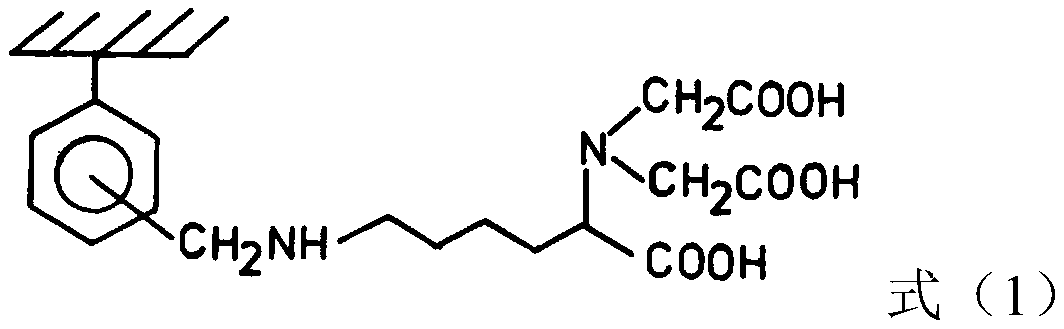

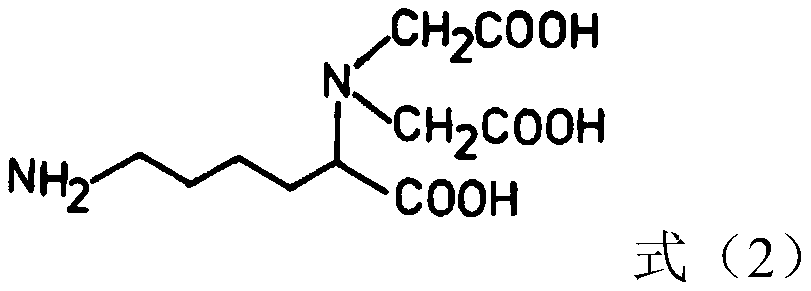

[0053] The arsenic-containing polymetallic gold ore (from a gold mine in Northwest Gansu, the chemical composition analysis of the raw ore showed 2.12wt% gold and 1.51wt% arsenic) was mainly composed of sulfide-wrapped gold and semi-exposed gold, mainly composed of arsenic sulfide and It exists in the form of arsenopyrite. Add 200mL of medium solution in the pre-oxidation container, then add the arsenic-containing polymetallic gold ore to sterilize, inoculate 12ml acidophilic Thiobacillus ferrooxidans after sterilization, then add 12g / L of the formula (1) The adsorbent is shown, the pre-oxidation temperature is normal temperature (28-30°C), the rotation speed of the agitator is 80-100r / min, the liquid-solid ratio of biological oxidation is 5-25ml / g, and the solution potential of the bacterial pre-oxidation system is controlled to be 500-550mv. The time range for pre-oxidation is 5-9 days. After the bacterial pre-oxidation is completed, adjust the pulp concentration and pH val...

Embodiment 2

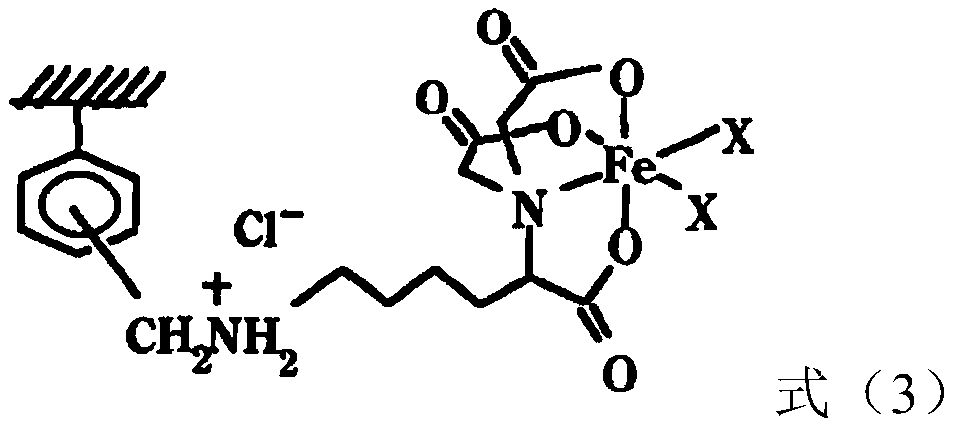

[0056] Repeat the example, the only difference from Example 1 is that the adsorbent is replaced by the adsorbent shown in formula (3). After detection and calculation, the leaching rate of arsenic is 88.6%, and the recovery rate of gold is 89.7%.

[0057] As can be seen from Examples 1 and 2, when the adsorbent shown in formula (3) is used, it can be more beneficial to the adsorption of arsenic, the adsorption mechanism may be more effective, and the fallen Fe 3+ Can promote the proliferation of bacteria.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com