Patents

Literature

43results about How to "Reduce microwave leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

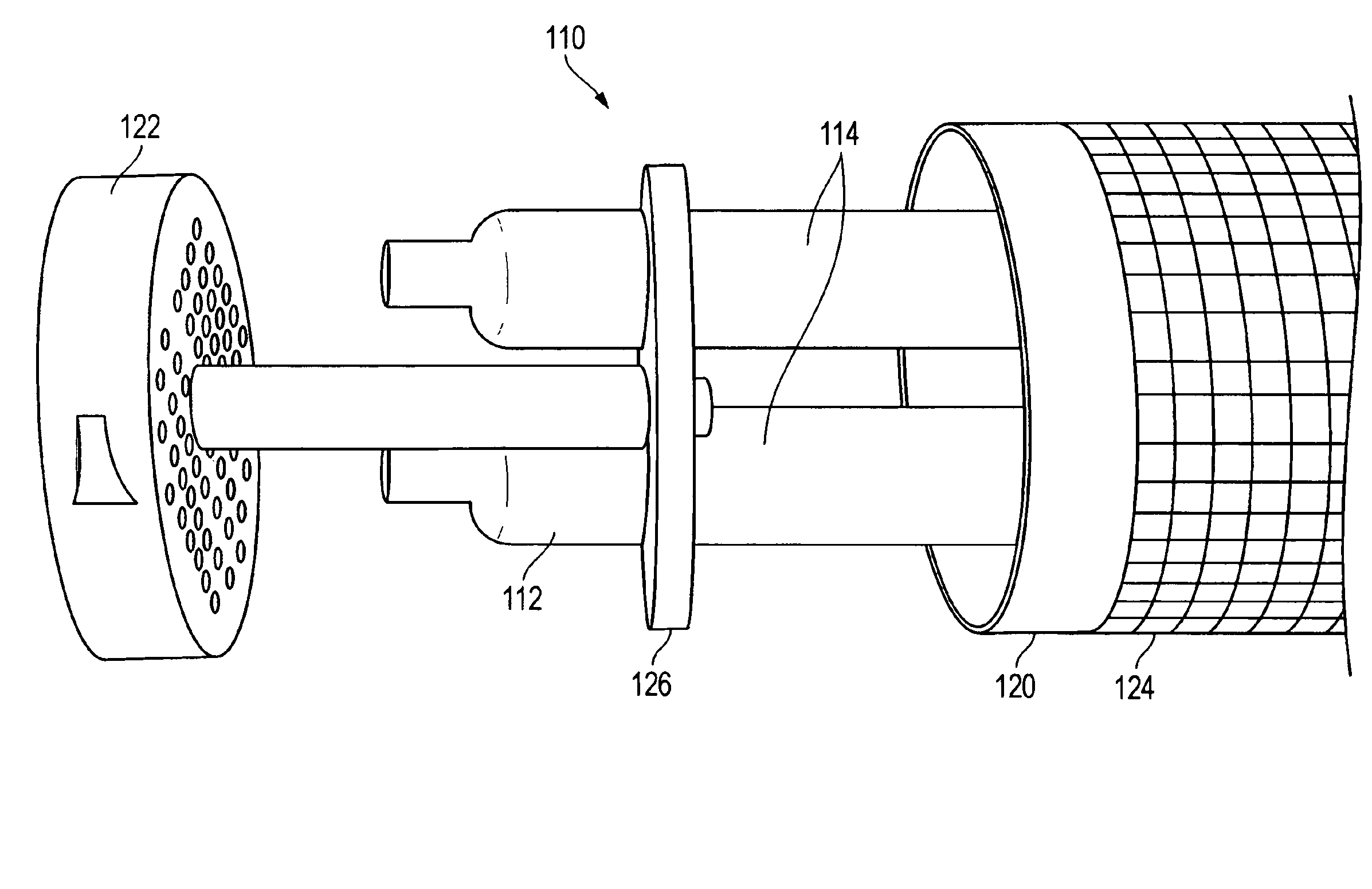

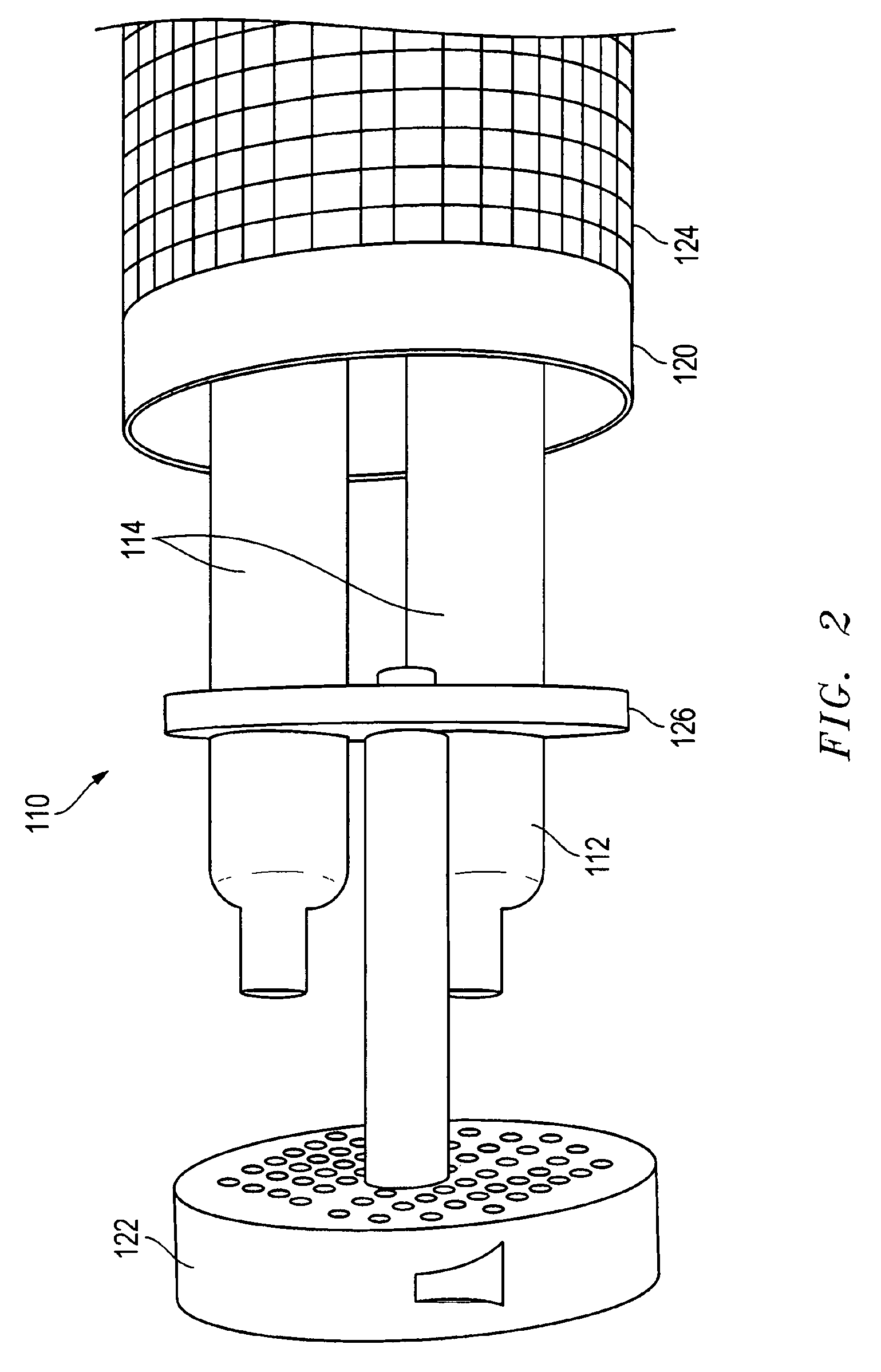

Sterilizer

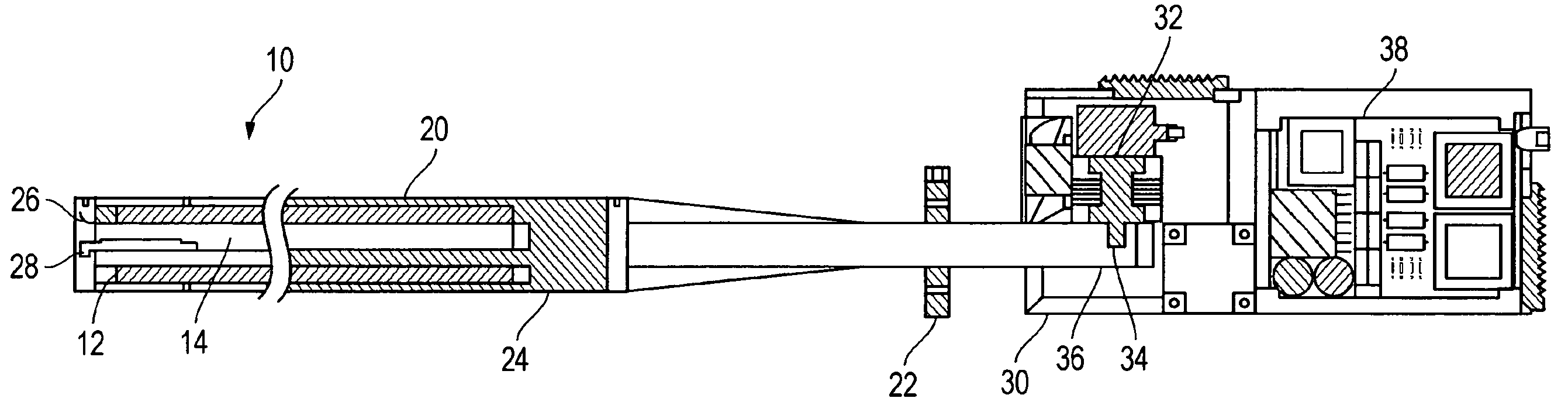

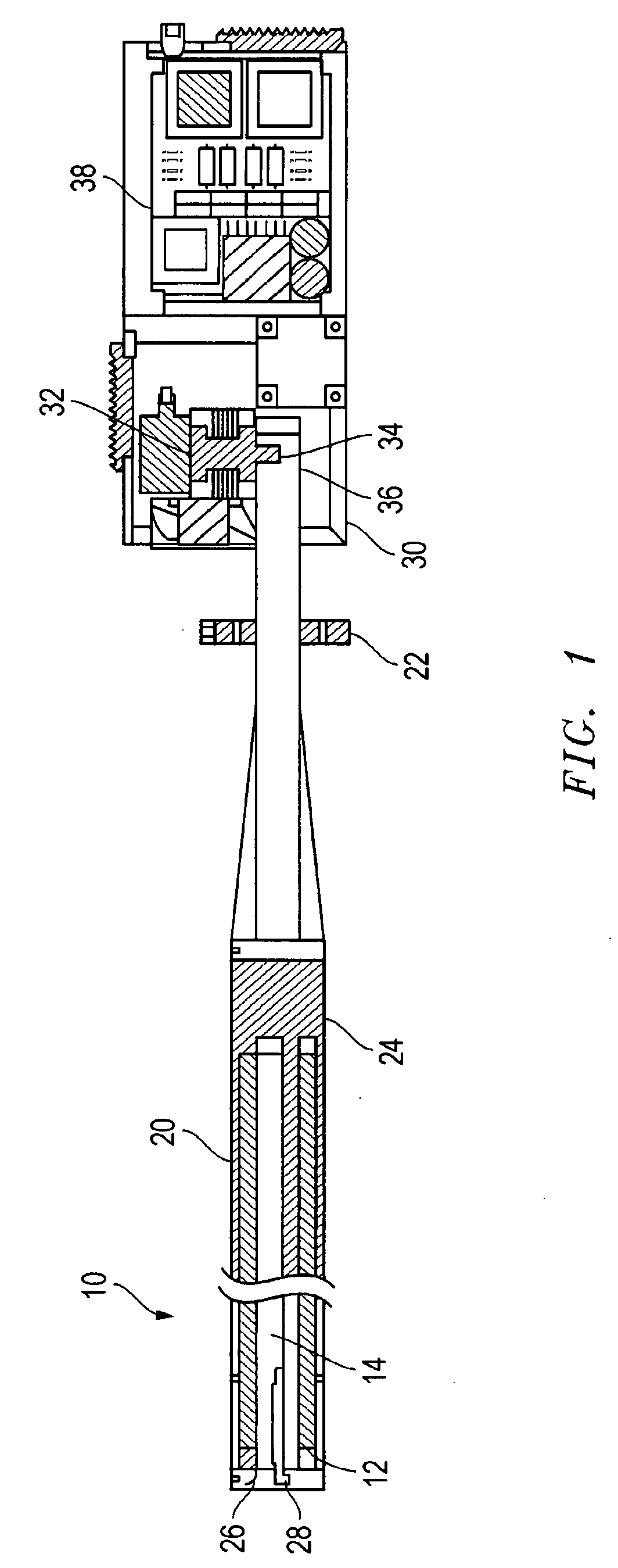

InactiveUS20080131337A1Facilitate energy savingFacilitate control flow pacingMaterial analysis using wave/particle radiationWater/sewage treatment by irradiationMicrowaveEngineering

A lamp assembly comprising one or more lamp clusters. Each lamp cluster comprises one or more electrodeless UV lamps which are excited by microwaves emitted from a microwave generator. The microwave generator and power supply are enclosed within a housing that is integral with the lamp clusters. The lamp clusters are wholly surrounded by a waveguide. The waveguide, comprising a flange and a distal end cap connected by a mesh, forms an enclosure. The waveguide is essentially UV transparent to allow UV light to pass through but effectively opaque to microwaves in order to substantially contain the microwaves within the waveguide enclosure.

Owner:SEVEN TRENT WATER PURIFICATION INC

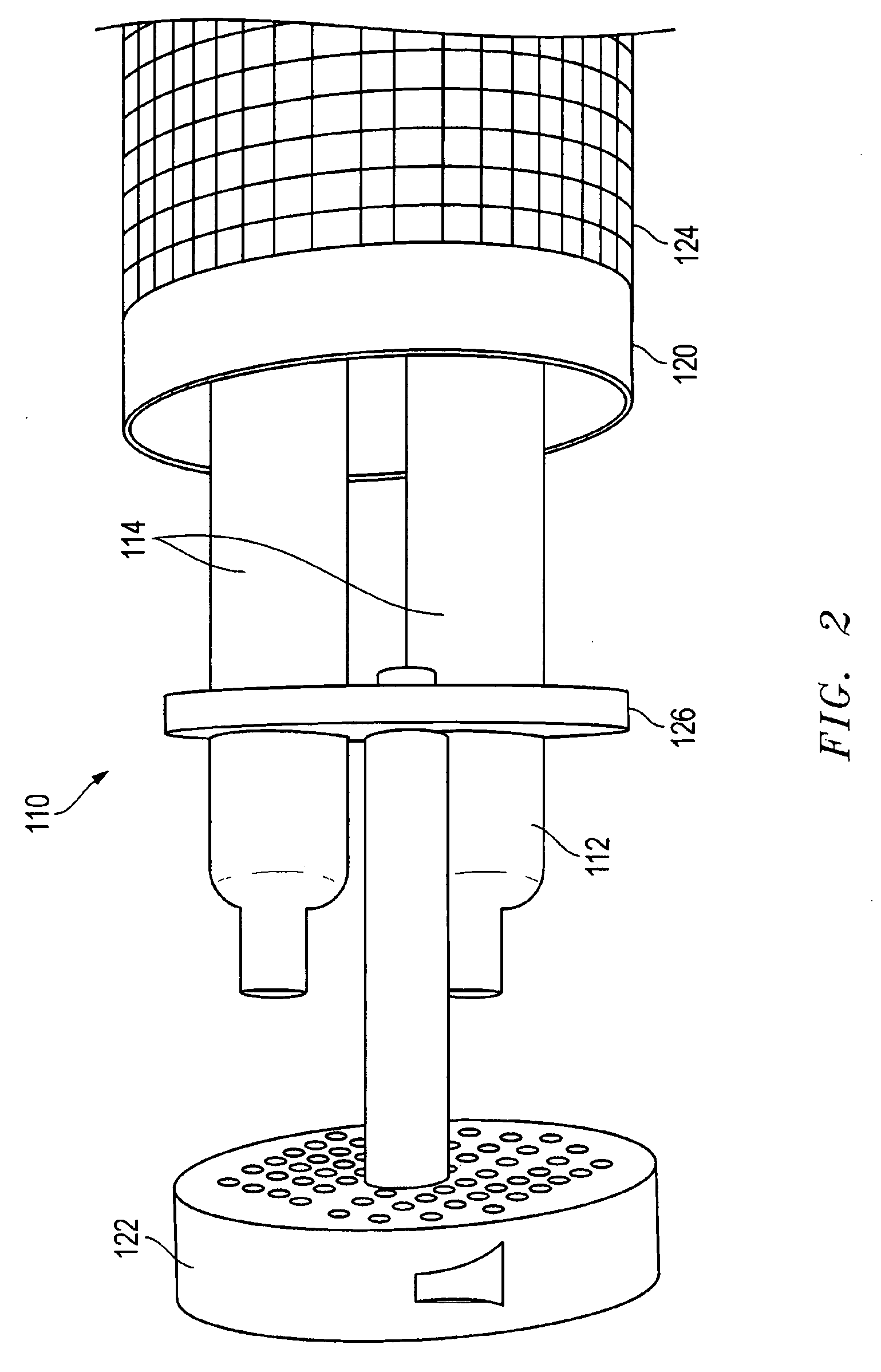

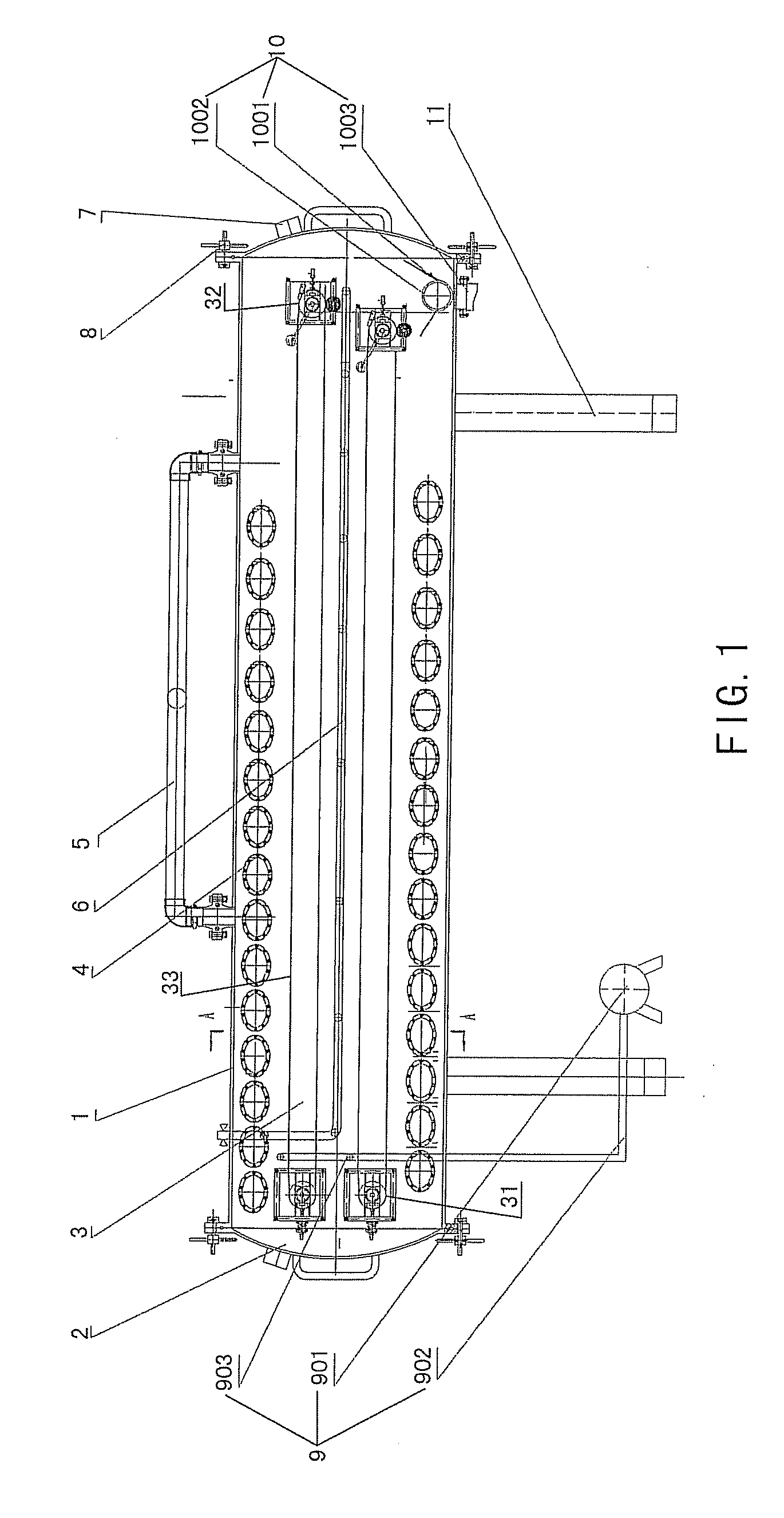

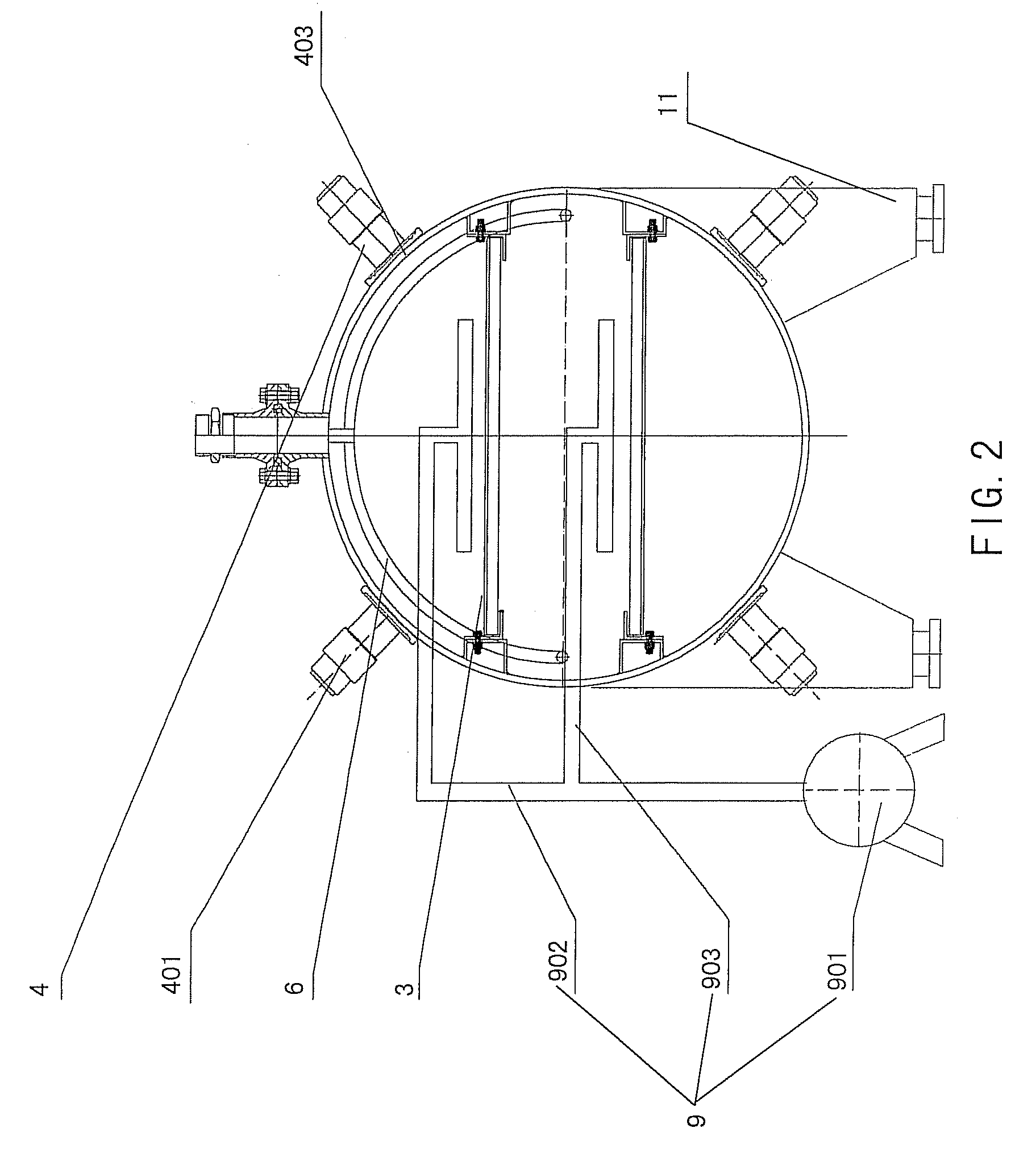

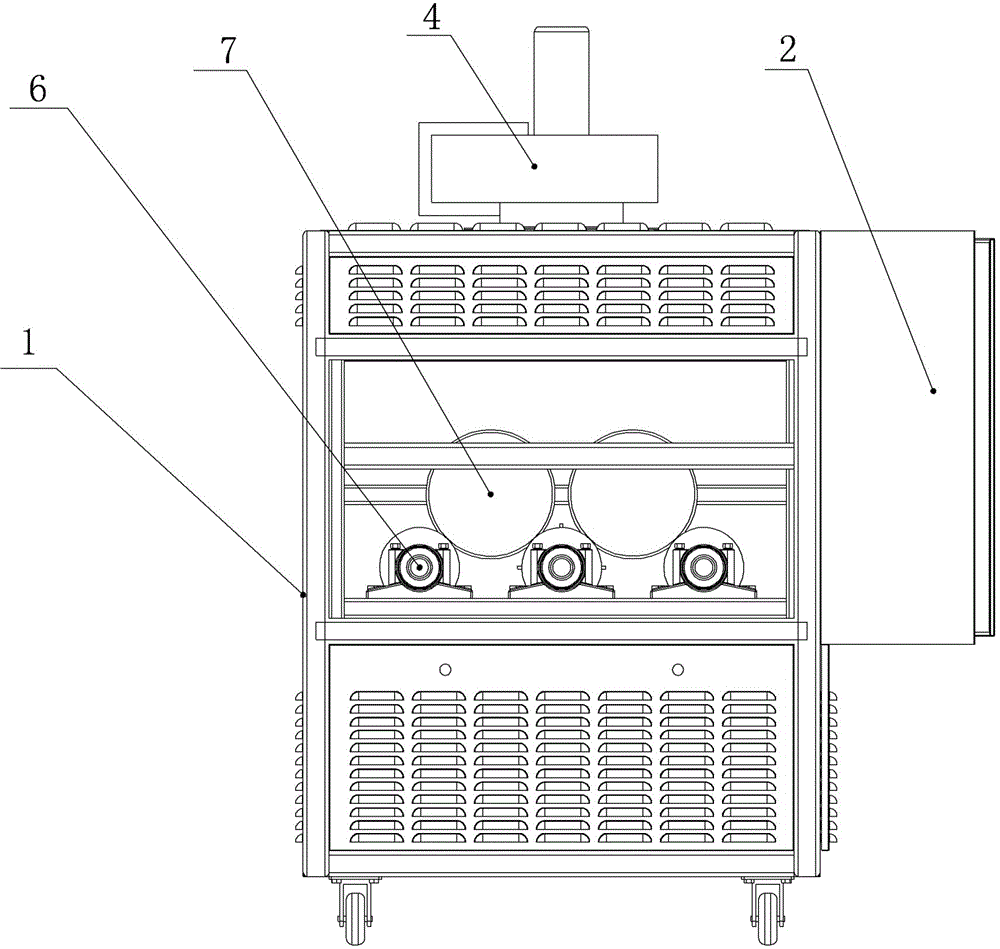

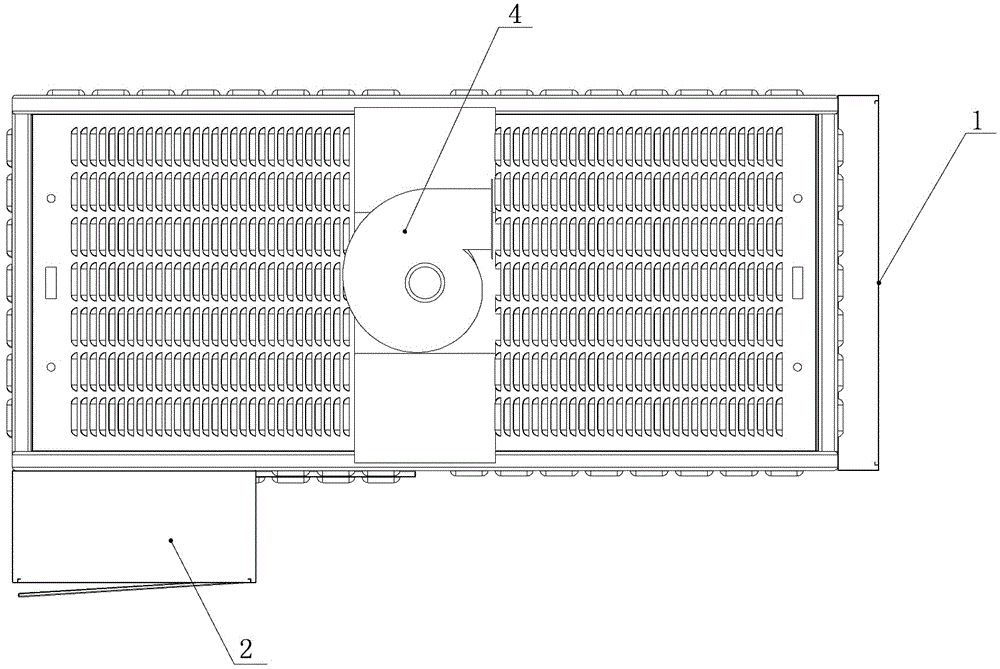

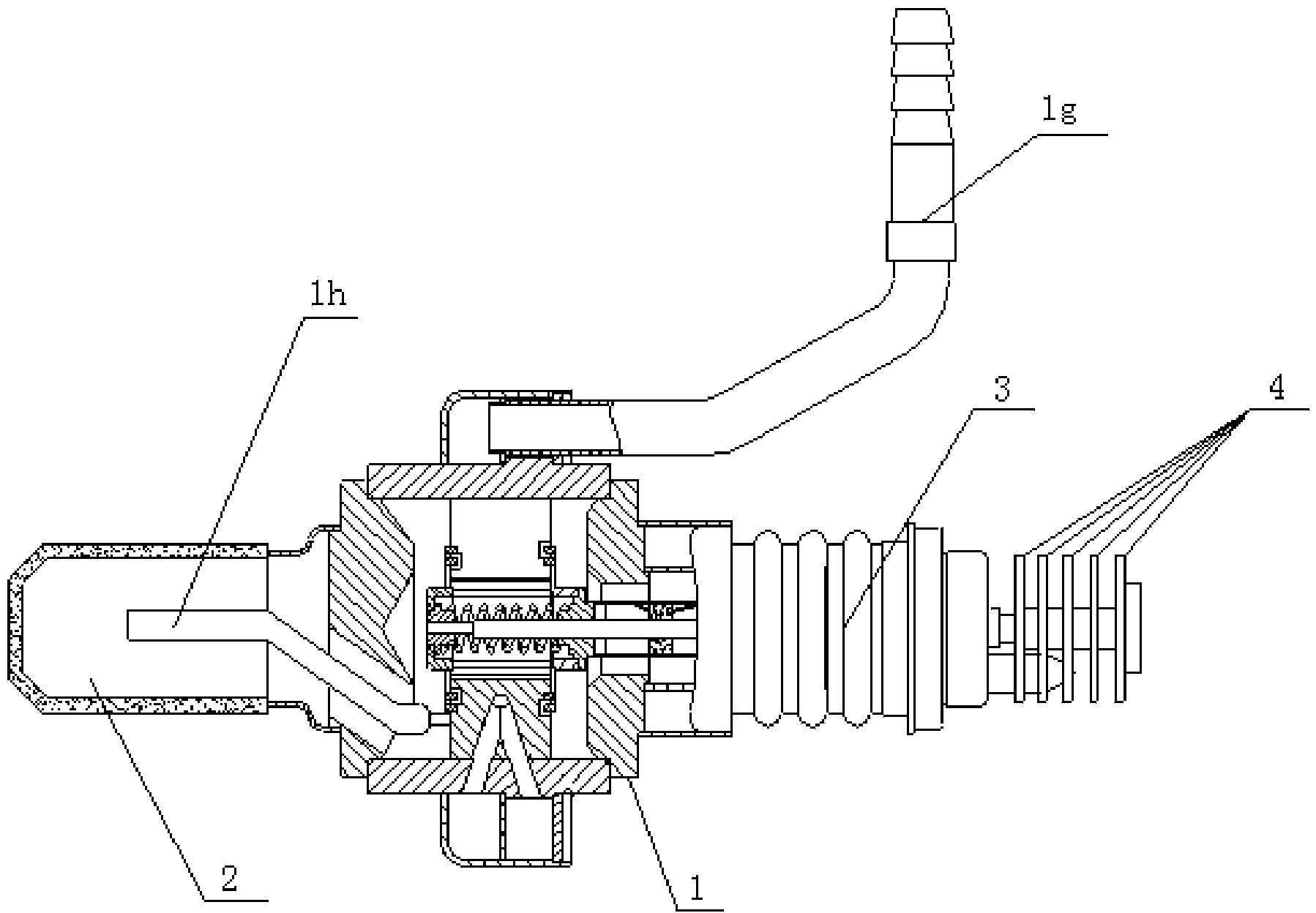

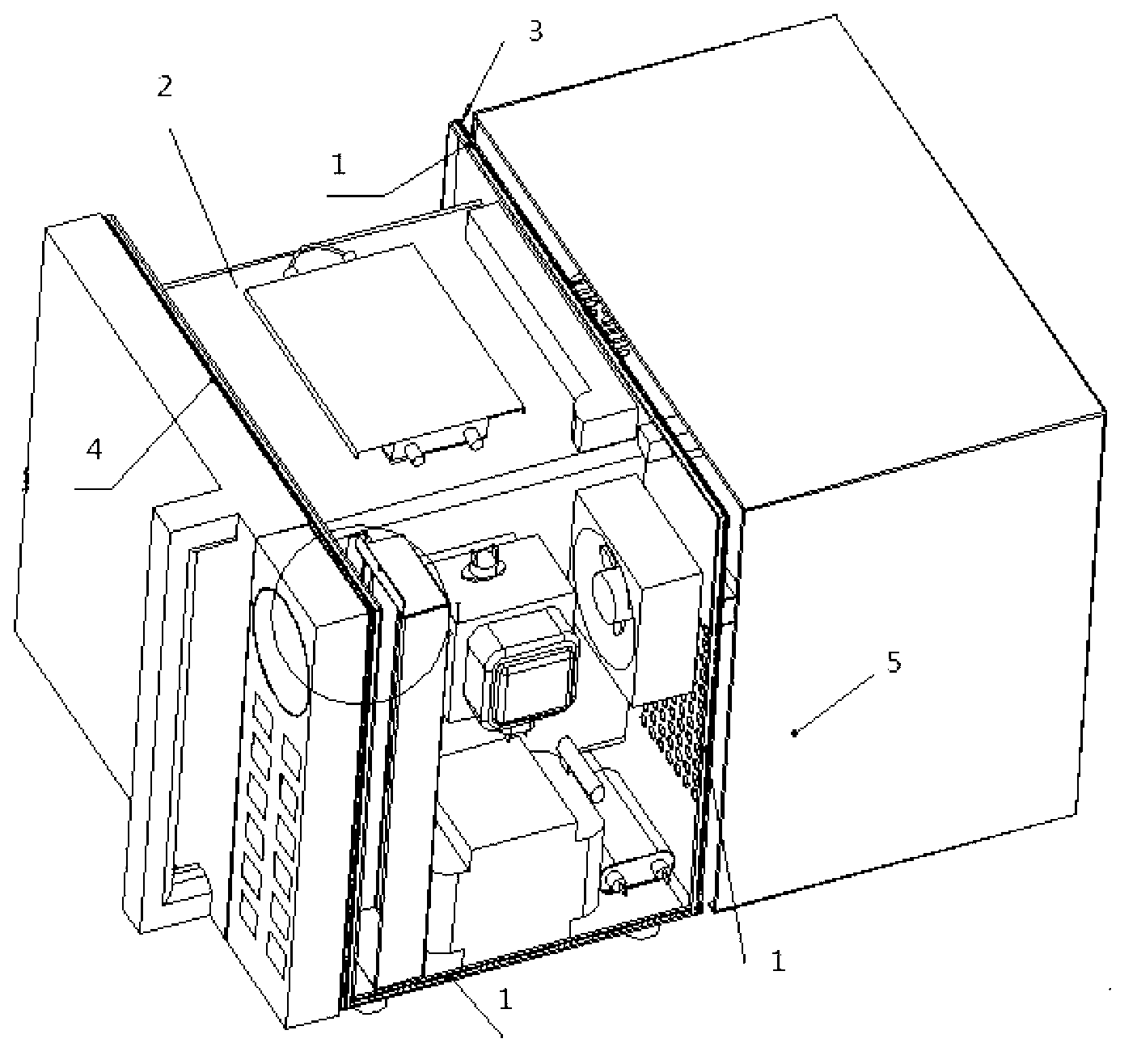

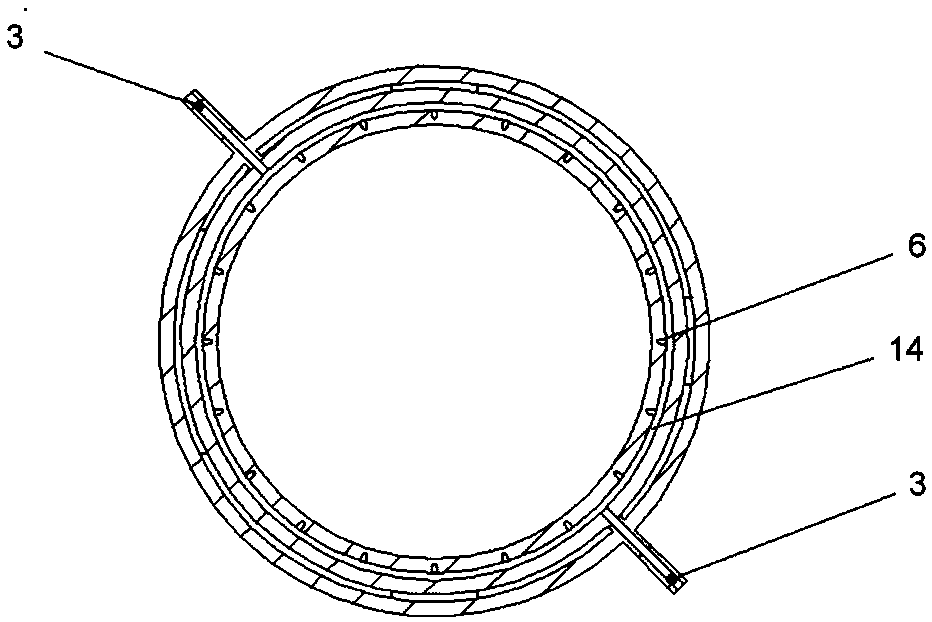

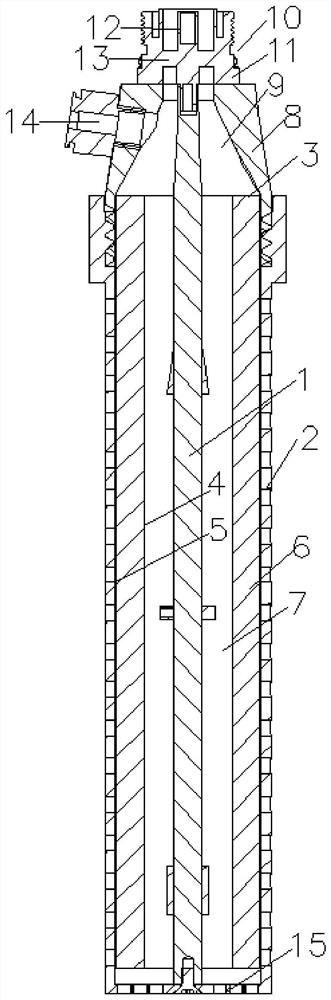

Vacuum microwave drying apparatus

InactiveUS20100000110A1Increase profitTemperature gradientDrying solid materials with heatDrying solid materials without heatMicrowaveFuel tank

A vacuum microwave drying apparatus, includes: a tank (1); a tank enclosure (2), which defines an accommodate space with the tank; a vacuum system, which is communicated with the accommodate space through a vacuum pipe (5); a continuous feed-in mechanism (9), including a feed-in pipe (902) communicated with the accommodate space, the continuous feed-in mechanism (9) sending materials into the accommodate space through the feed-in pipe (902) continuously; a continuous feed-out mechanism (10), which sends the materials out of the accommodate space continuously; at least two layers of material sending mechanisms (3), each of which is arranged in the accommodate space in parallel along the longitudinal direction of the tank, to send the materials from the continuous feed-in mechanism (9) into the continuous feed-out mechanism (10); and a plurality of microwave heating devices (4), each of which has a microwave feed-in port (403), which is located in the accommodate space, to send microwave to the accommodate space, the microwave being used to dry the materials which is sent by the material sending mechanism (3). The vacuum microwave drying apparatus can reduce the occupied space, and can perform a continuous drying operation.

Owner:LI SHENG

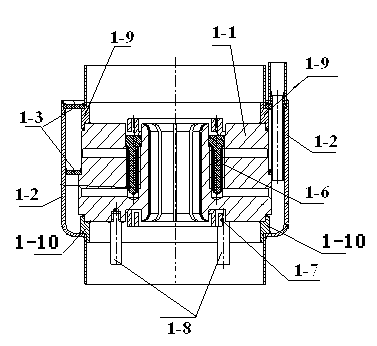

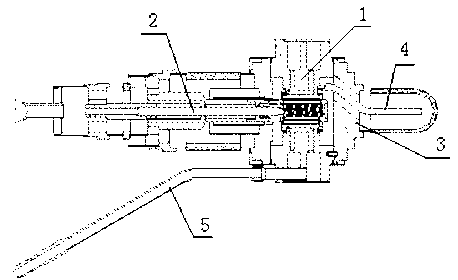

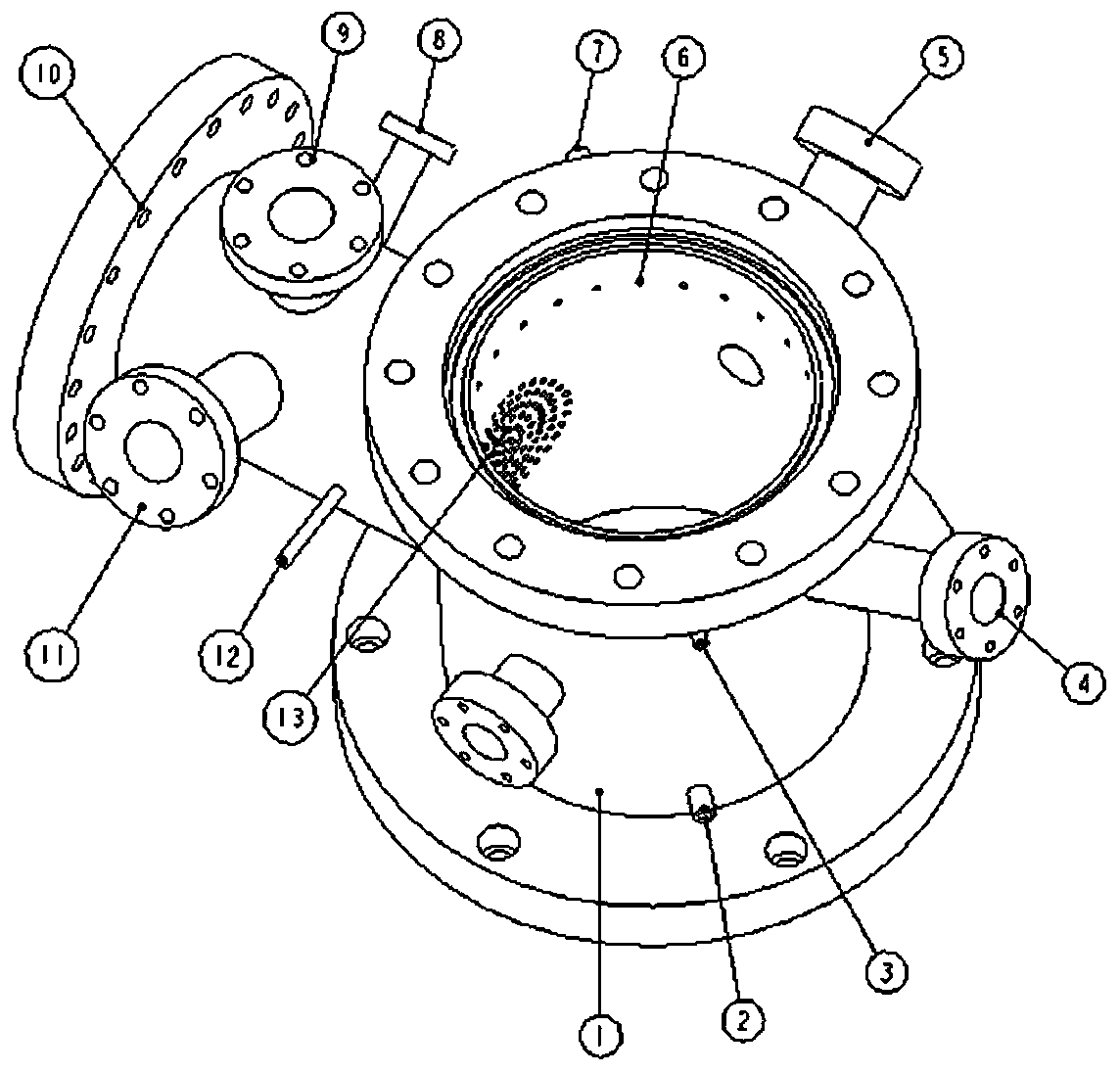

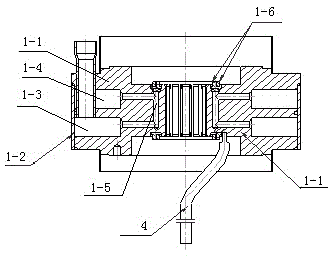

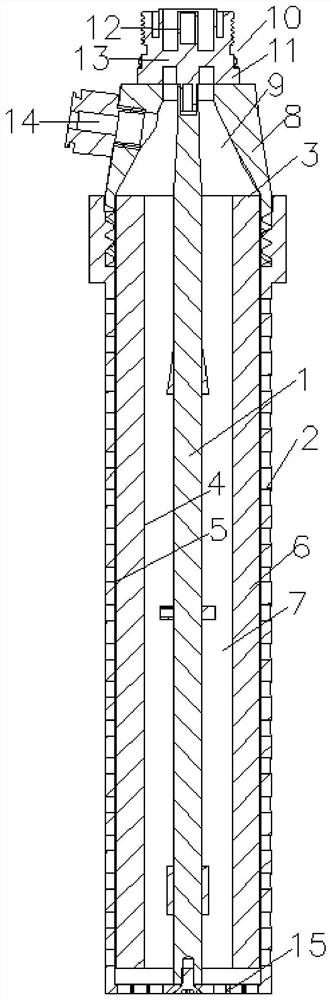

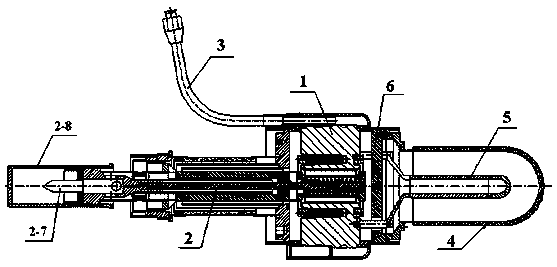

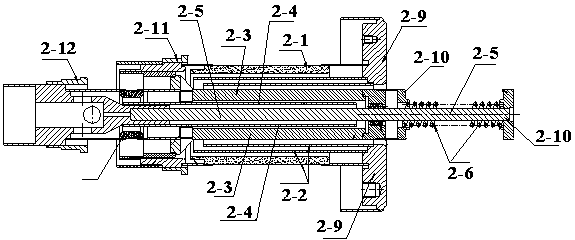

75 kw / 915 mhz high-power continuous wave magnetron

ActiveCN103258704ASimple structureNovel structureMagnetronsTransit-tube collectorsMicrowaveContinuous wave

The invention discloses a 75 kW continuous wave magnetron. The 75 kW continuous wave magnetron comprises a positive pole cavity combination (1), a negative pole lead wire combination (2), a water pipe (3) which is connected with the positive pole cavity (1), an output window combination (4) which is connected with the negative pole cavity combination (1), an antenna combination (5) which is fixed on the negative pole cavity combination (1), and an inner pole shoe (6) which is fixed at one end of the positive pole cavity combination (1), wherein the antenna combination (5) is located inside the output window combination (4). The continuous wave magnetron is reasonable in structural design, high in power, high in output efficiency, less in microwave leakage, and high in safety performance. Particularly, due to the fact that a negative pole structure of a fan-shaped resonator system structure with high characteristic impedance is adopted and an n-shaped water line cooling structure is adopted on a negative pole, heat dissipation effect is better, light striking probability is less, working is stable, structure is novel, and the magnetron is suitable for being used in a high-power microwave heating device in industries.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP +1

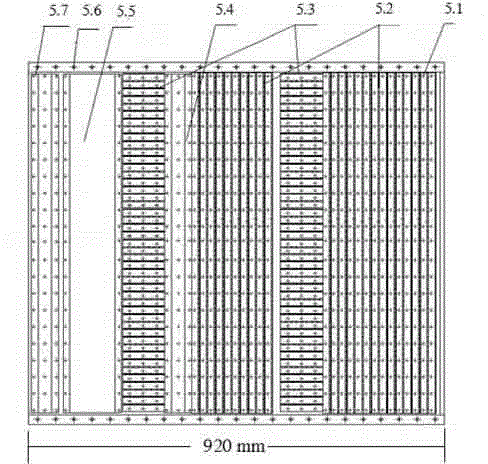

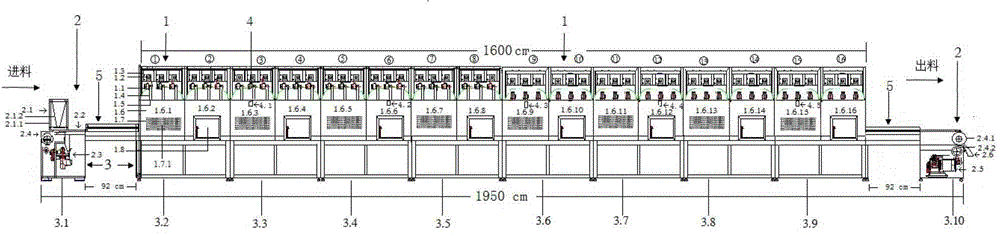

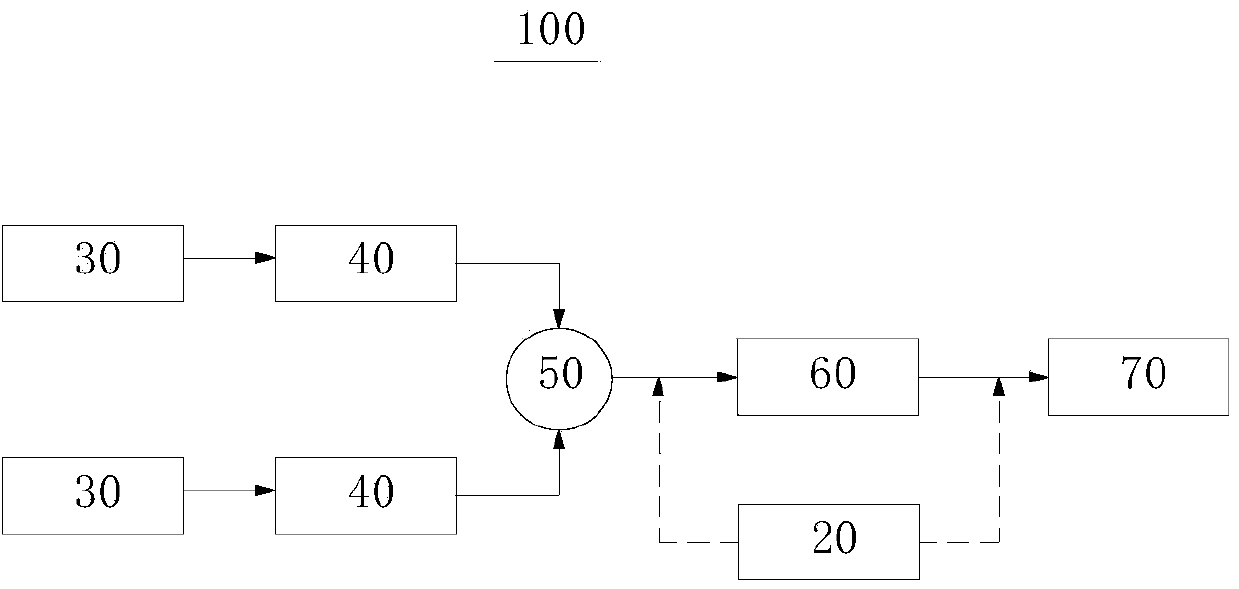

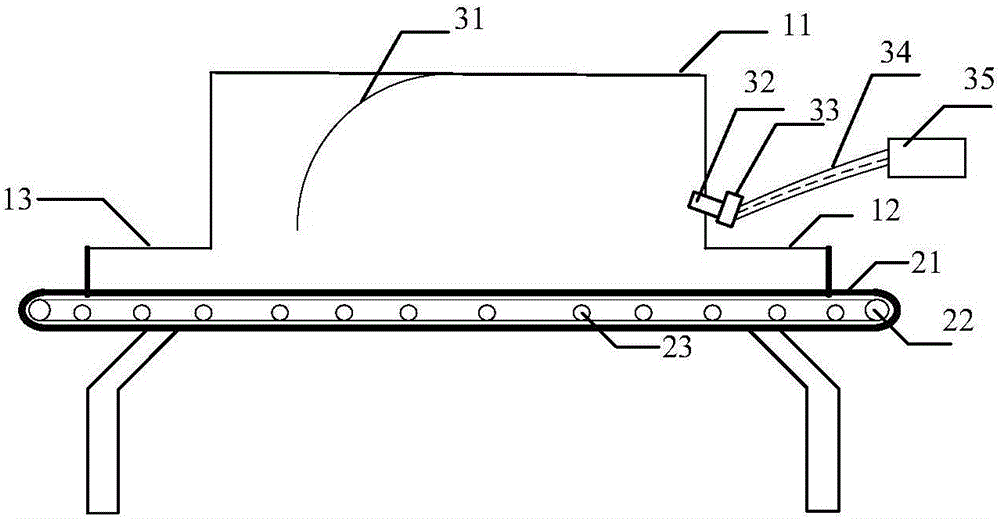

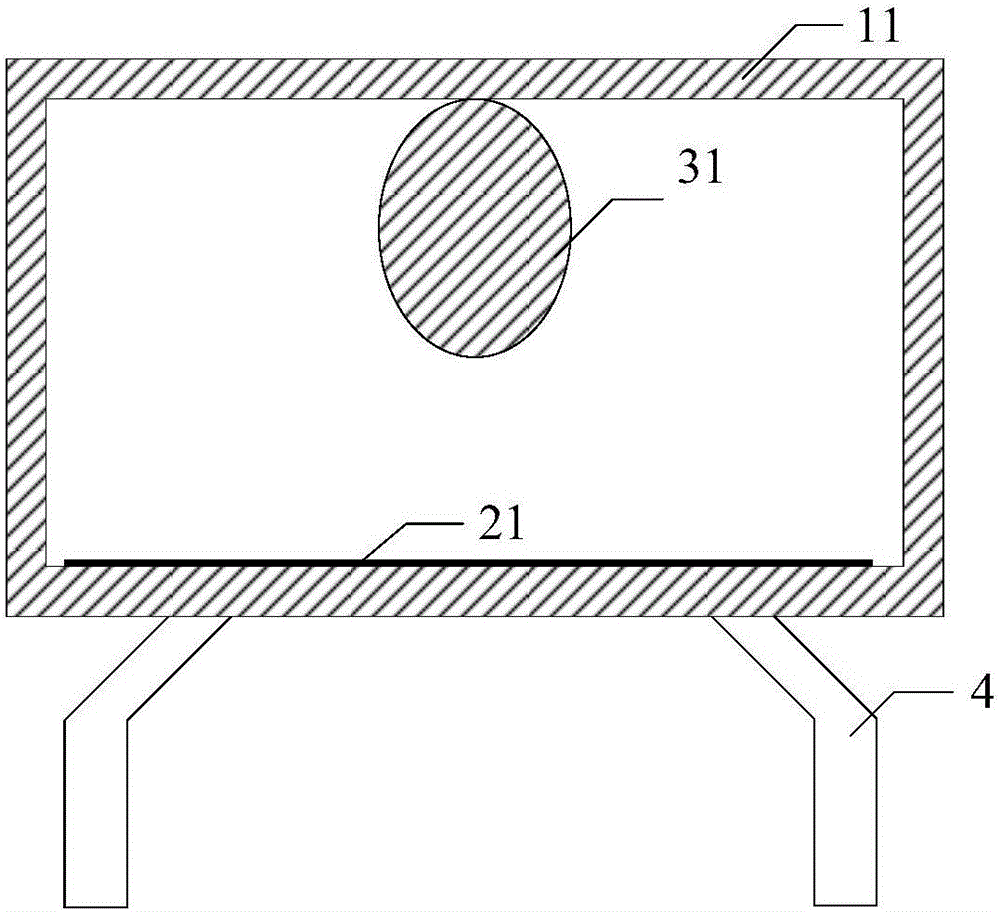

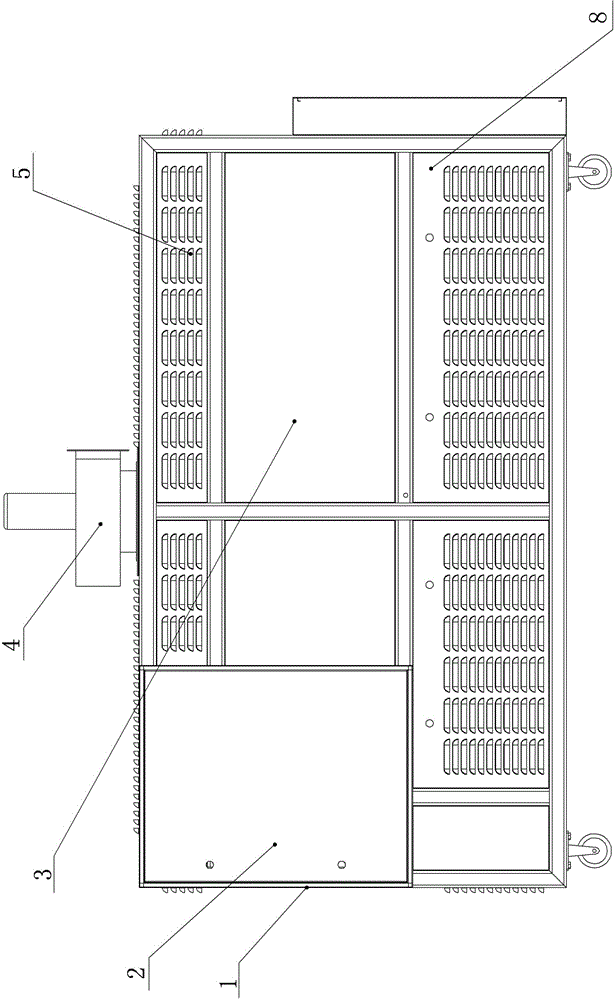

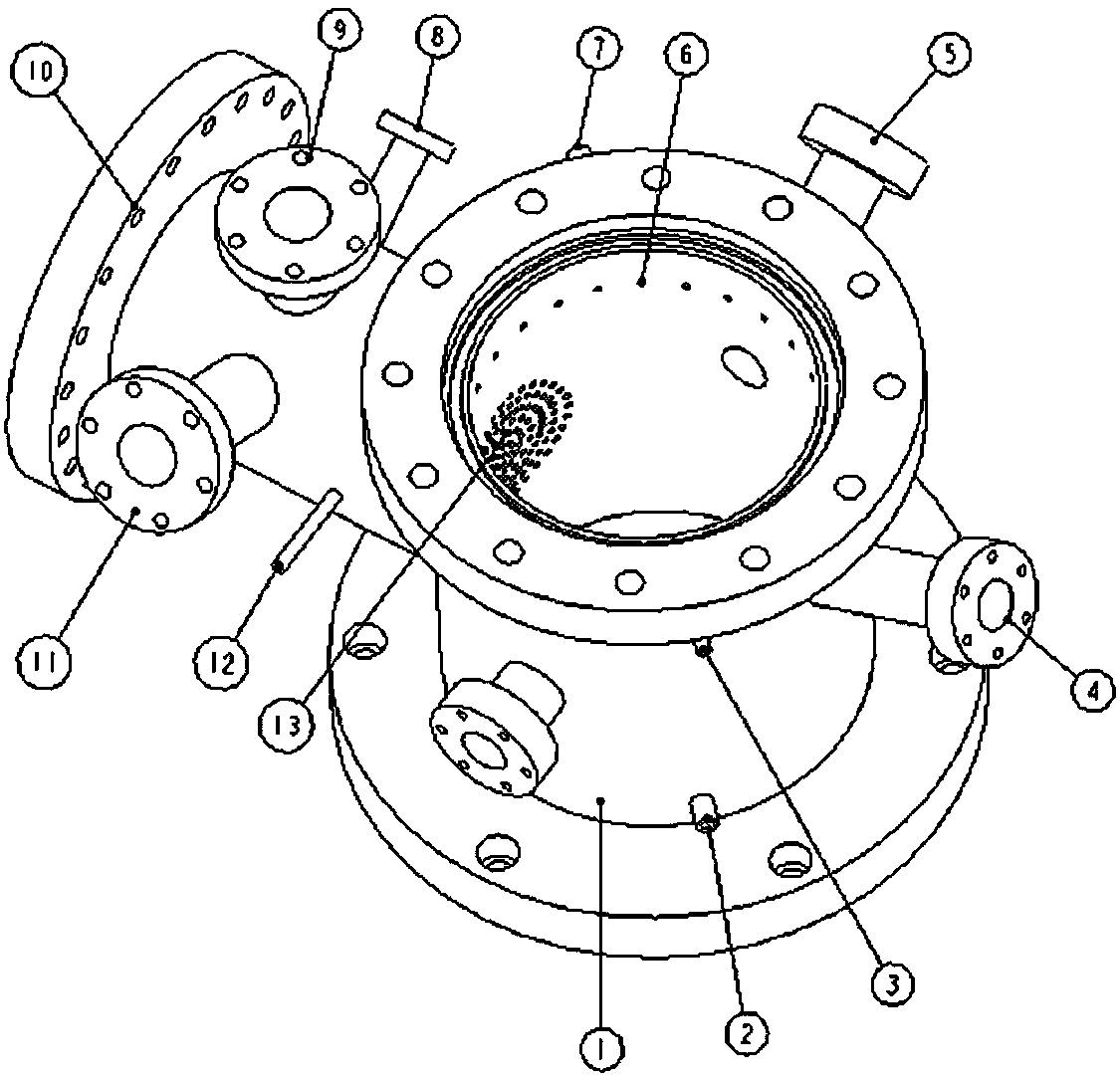

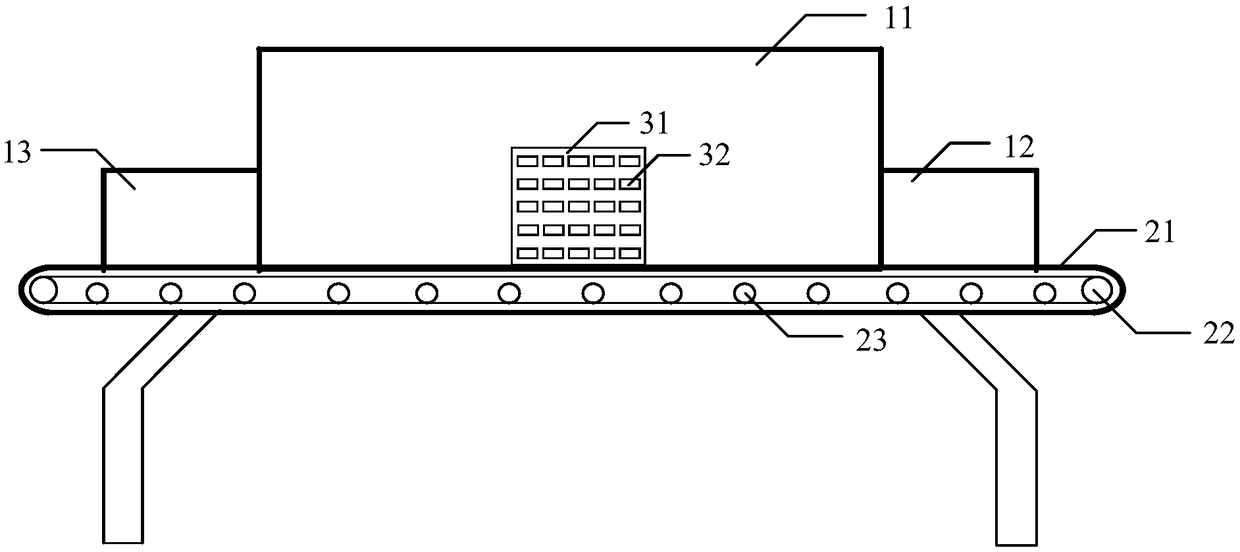

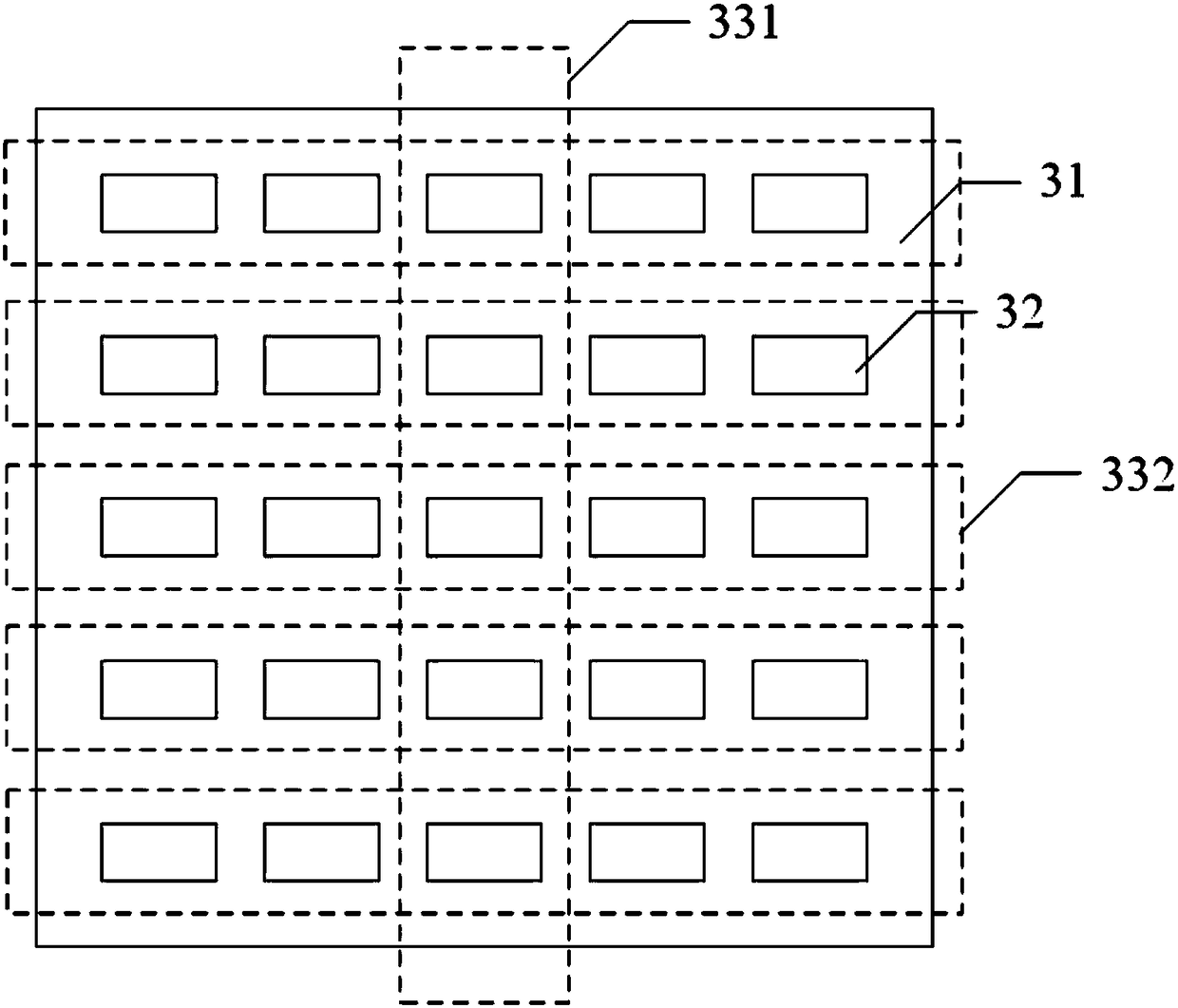

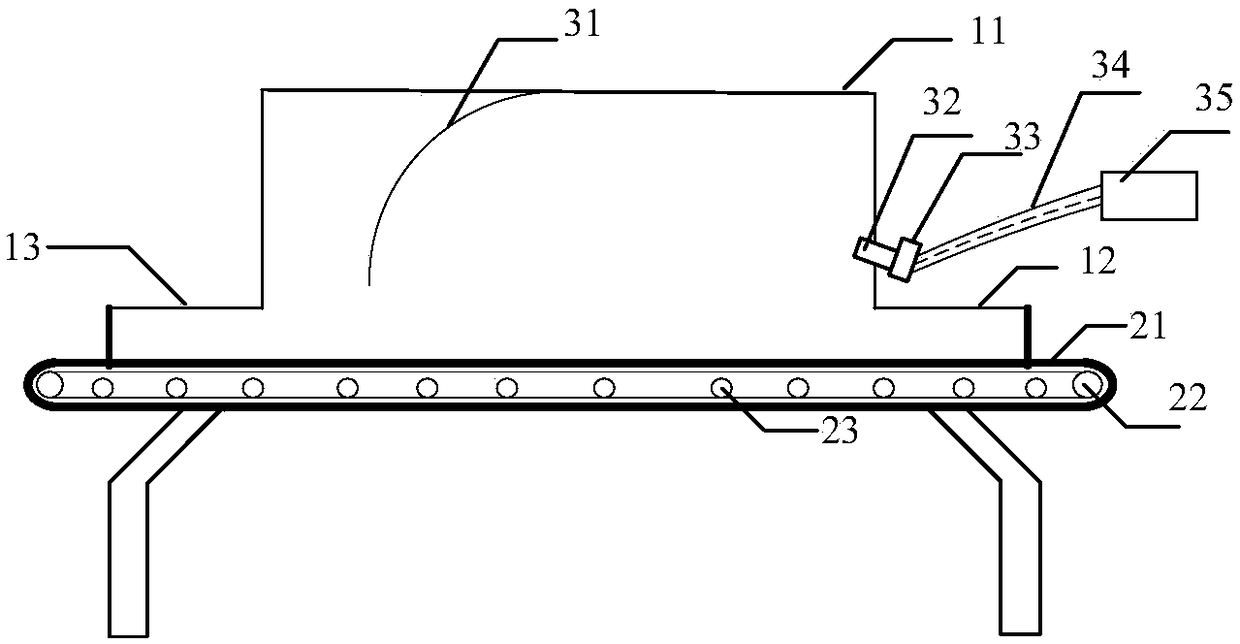

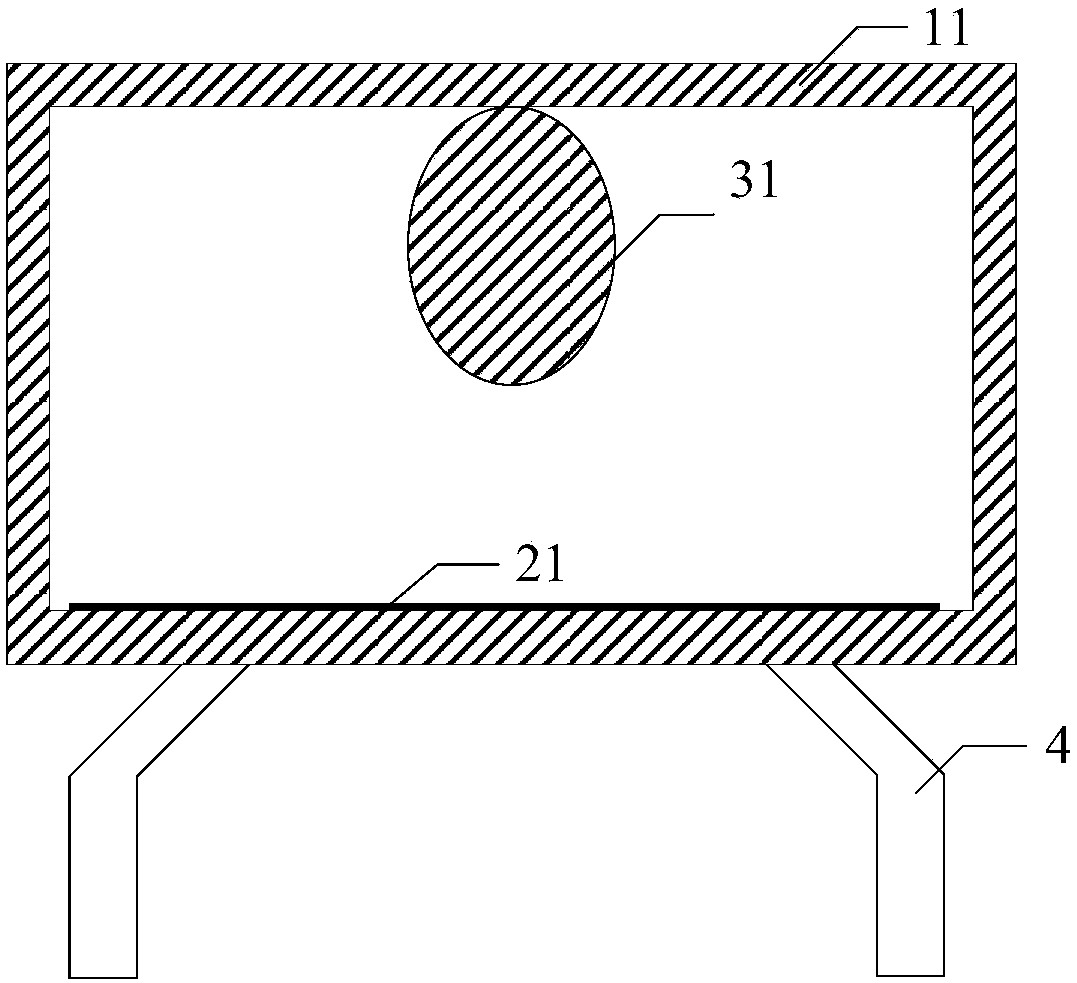

Microwave processing device for dump leaching uranium ores

The invention discloses a microwave processing device for the dump leaching uranium ores. The device uses microwave to carry out irradiation to dump leaching uranium ores, due to the fact that differences exist among the microwave temperature rising effects of different minerals inside the uranium ore particles, heat stress differences are generated among the different minerals inside the uranium ore particles, the grain boundaries of the different minerals inside uranium ore particles break and the cracks inside the particles extend, therefore the poriness of the uranium ore particles is increased, the permeability of the inner portions of the uranium ore particles is improved, the dissociation degree of the uranium ores is improved, the leaching efficiency of the dump leaching of the uranium ores is improved, and a leaching period is shortened. The whole equipment comprises 16 microwave units, a material conveying system, a support, a temperature detecting and controlling system and a microwave suppressor. When the microwave processing device for the dump leaching uranium ores is used to process the dump leaching uranium ores, the microwave processing device has the advantages of being good in the matching of microwave power and the uranium ores, low in processing energy consumption, large in processing quantity, stable in material conveying, and small in microwave leakage, the poriness of the uranium ores and the dissociation degree of the uranium ores are further improved, the leaching efficiency is further improved, and the leaching period is further shortened and the like. The microwave processing device for the dump leaching uranium ores is also suitable for the processing of dump leaching gold ores, dump leaching copper ores and other dump leaching ores, and has obvious effect in increasing poriness of ore particles, improving the permeability of the inner portion of the ore particles, improving the dissociation degree of useful ores, improving leaching efficiency, and shortening leaching efficiency.

Owner:NANHUA UNIV

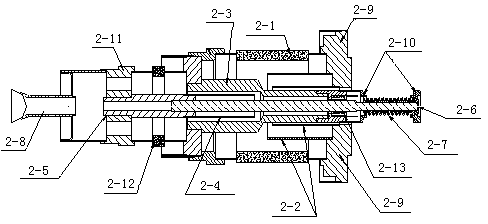

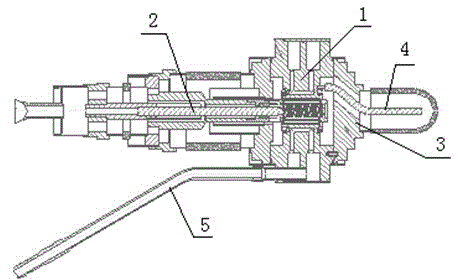

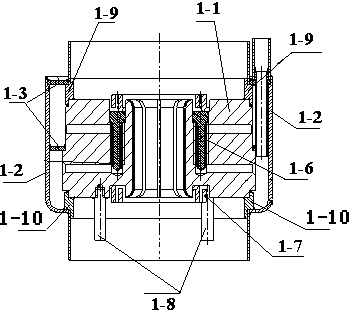

2450-MHz high-power continuous-wave magnetron and preparation method thereof

ActiveCN103346053AImprove pressure resistanceExtended service lifeMagnetronsTransit-tube collectorsCavity magnetronMicrowave

The invention discloses a 2450-MHz high-power continuous-wave magnetron and a preparation method thereof. The 2450-MHz high-power continuous-wave magnetron comprises an anode cavity combination unit (1), a cathode outgoing line combination unit (2), an output window combination unit (3) connected with the anode cavity combination unit (1), and an output antenna (4) fixed at the anode cavity combination unit (1); the other end of the output antenna (4) is arranged inside the output window combination unit (3); and the anode cavity combination unit (1) is connected with a cavity cooling water inlet-outlet pipe (5). The structure of the provided continuous-wave magnetron is designed reasonably; the power of the magnetron is high and the output power can reach over 30 KW; the service life can reach more than 5000 hours; the microwave leakage is less; and the security performance is high. Besides, according to the preparation method of the continuous-wave magnetron, lots of experiment screening is carried out; and the method has the advantages of reasonable process design and high operability. Moreover, the prepared magnetron with characteristics of high gas tightness, a high vacuum degree, low sparking probability and stable performance enables various defects existing in the prior art to be overcome.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP +1

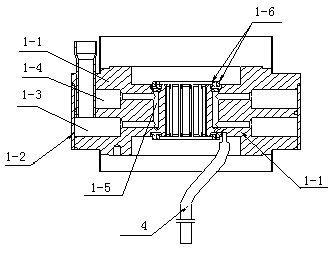

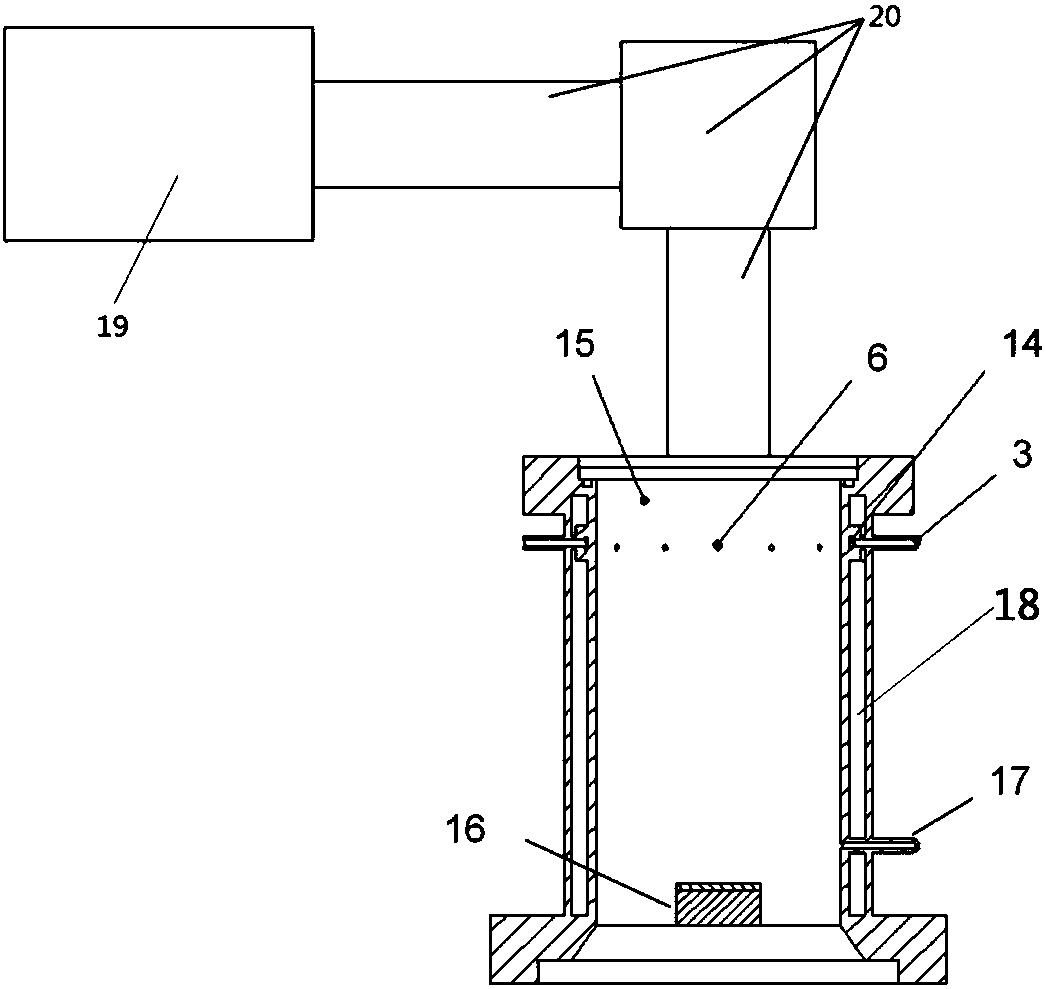

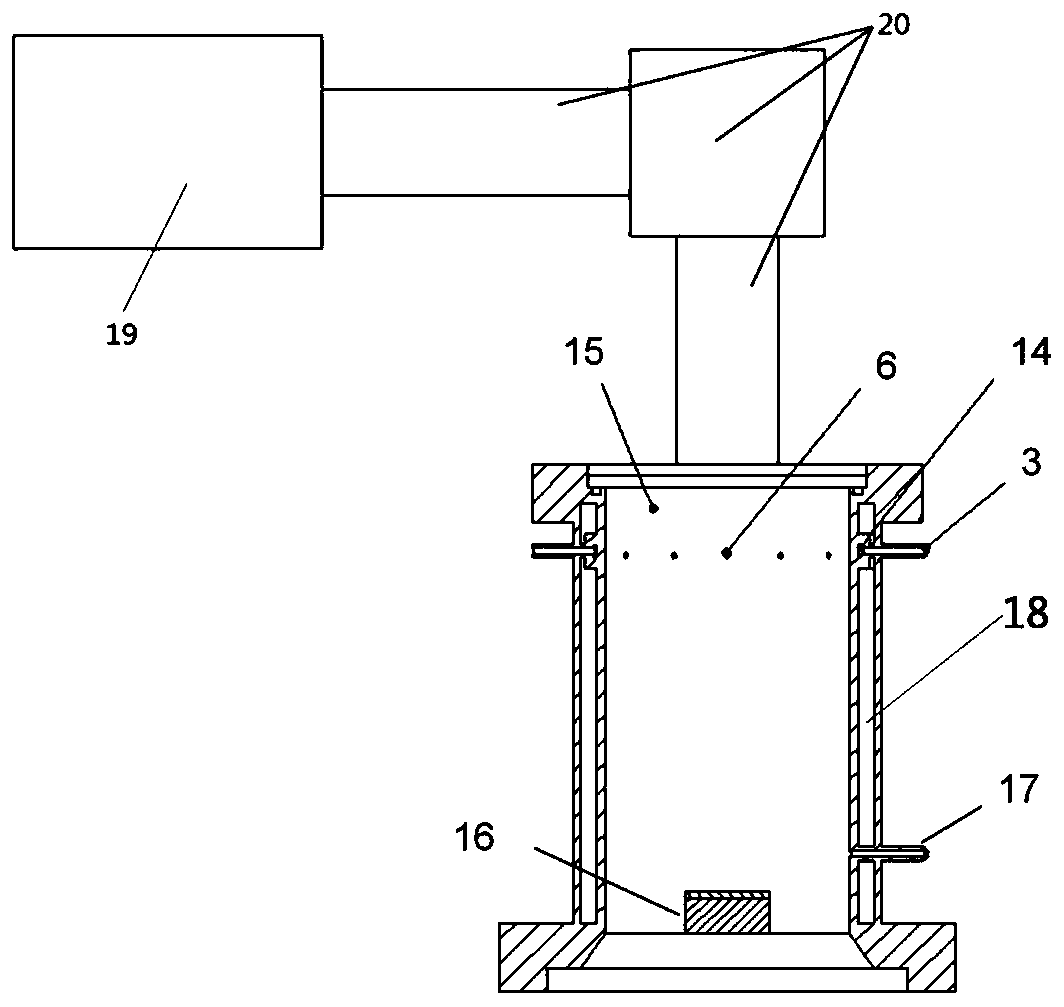

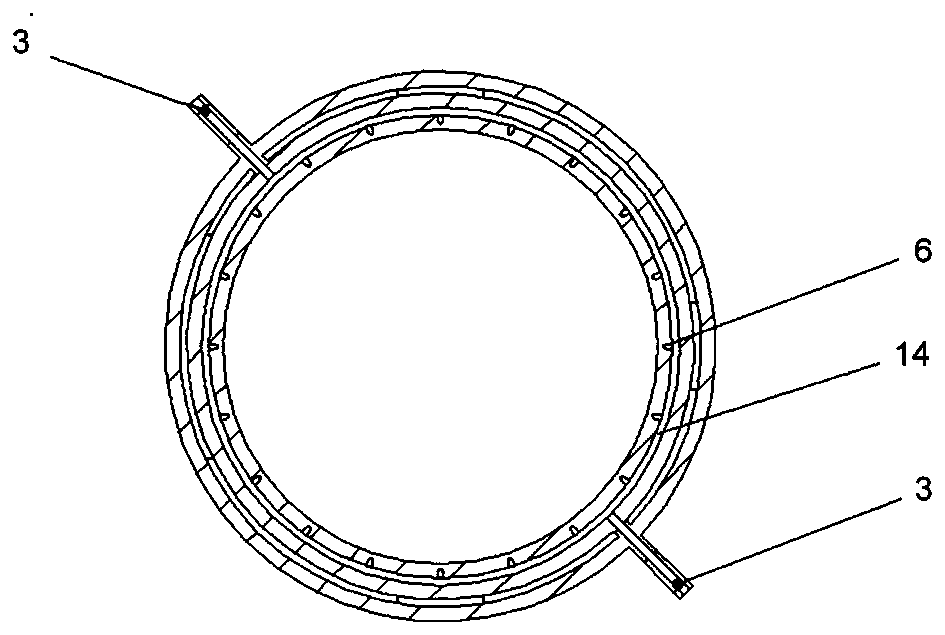

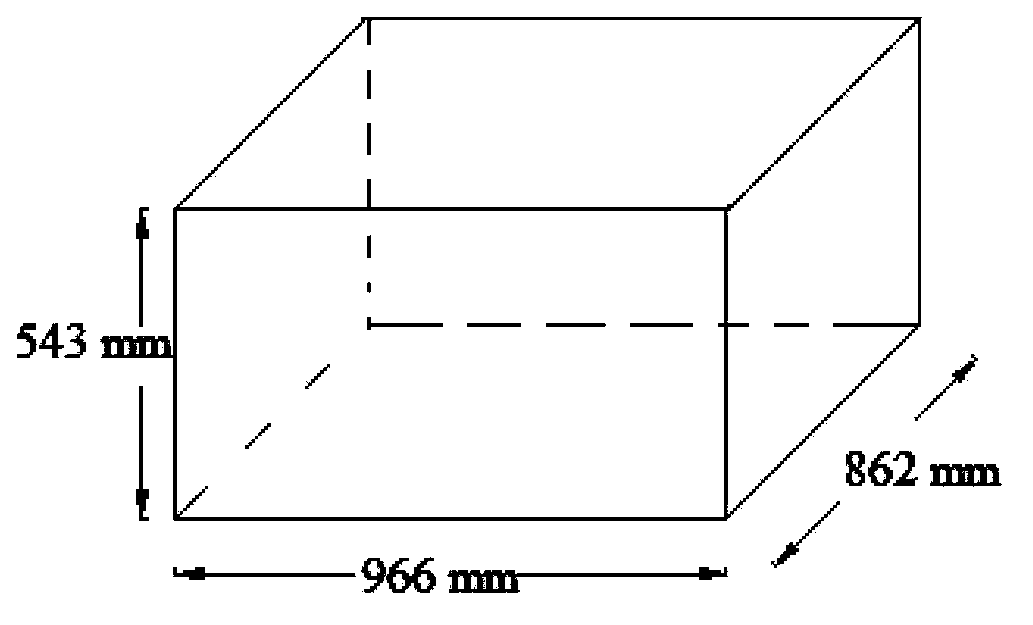

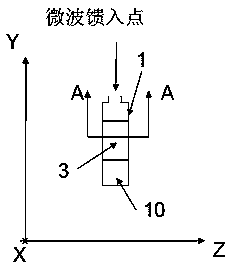

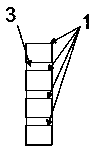

Microwave irradiation chamber, microwave irradiation system and microwave irradiation and real-time observation method

ActiveCN103776682AReal-time biological indicator observationReduce microwave leakageMaterial analysis using microwave meansPreparing sample for investigationEngineeringIrradiation

The invention provides a microwave irradiation chamber, a microwave irradiation system and a microwave irradiation and real-time observation method. The microwave irradiation chamber comprises a shell and a shielding component, wherein a cuboid-shaped cavity is formed in the shell, a microwave receiving interface and a microwave absorption interface are arranged in the central positions of the two end walls of the shell, respectively, a first opening is formed in the central position of the top wall of the shell, and a second opening is formed in the central position of the bottom wall; the shielding component covers the first opening of the shell, and the center of the shielding component is provided with a through hole. According to the technical scheme of the invention, the microwave irradiation chamber can be directly connected into a real-time observation and analysis instrument to carry out biological index observation in real time, so that the microwave leakage is slight, and the cross-sectional area of the microwave irradiation chamber is adjustable, and therefore, the compound irradiation of microwaves with different frequencies can be realized.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

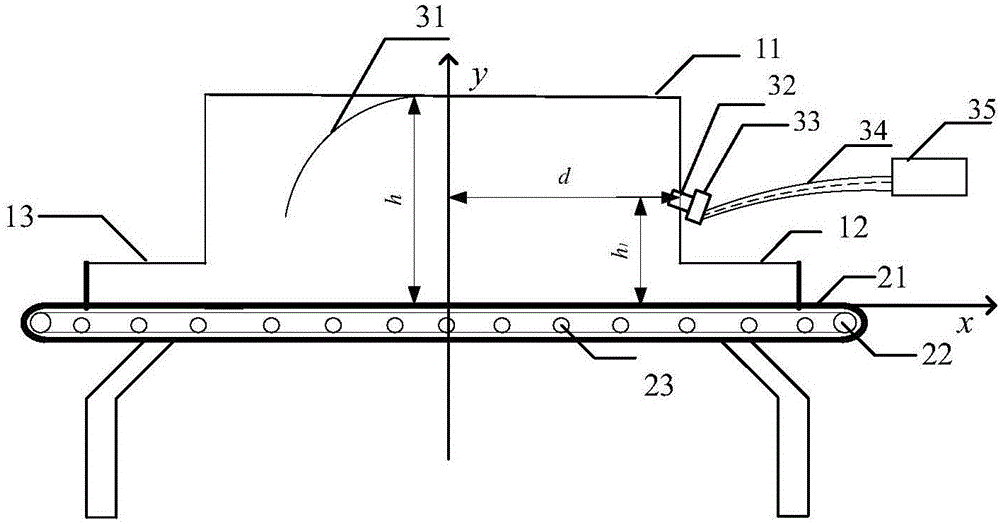

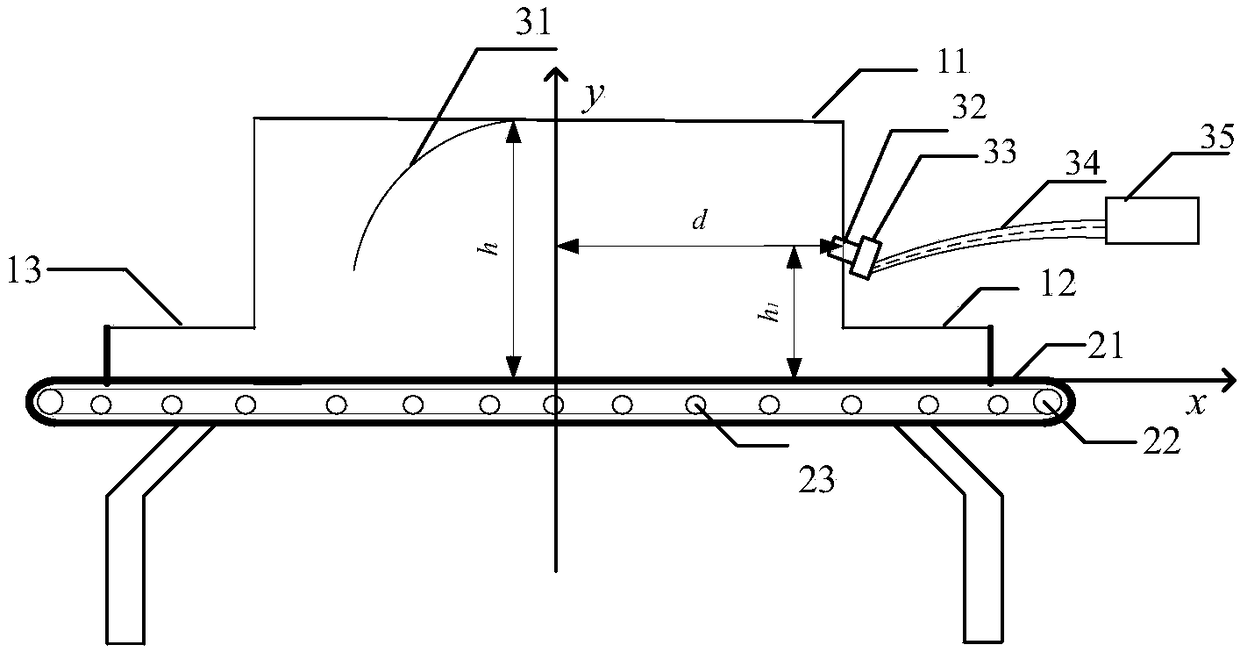

Continuous transmission type focusing microwave reactor

ActiveCN106334508AAvoid the effects of extensionUniform effectMicrowave heatingEnergy based chemical/physical/physico-chemical processesProduction lineMicrowave

The invention belongs to the field of microwave energy utilizing devices, and provides a continuous transmission type focusing microwave reactor. The continuous transmission type focusing microwave reactor comprises a reaction device, a transmission device, a feed device and a supporting device, and is characterized in that the feed device comprises a metal reflecting surface, a radiating trumpet, a coaxial transmission line, a waveguide coaxial converter and a microwave source, wherein the metal reflecting surface is arranged on the inner wall of the top surface of a metal cavity; the microwave source is connected with the radiating trumpet through the coaxial transmission line and the waveguide coaxial converter; the radiating trumpet is fixed to the side wall of the metal cavity, runs through the metal cavity, and irradiates at a certain inclination angle relative to the wall of the metal cavity, so that the focus of the metal reflecting surface is positioned in the direction of a main lobe of the radiating trumpet. In a way of irradiating a detected object at a maximum field strength point by feeding the side end of a waveguide into the metal wall, reflecting and focusing, the continuous transmission type focusing microwave reactor improves the reaction efficiency, speeds up the reaction, improves the reaction uniformity and saves the energy; the continuous transmission type focusing microwave reactor is combined with a continuous transmission type production line, and is applied to large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Sterilizer

InactiveUS7794673B2Improve disinfection qualityPrevent escapeMaterial analysis by optical meansDeodrantsMicrowaveEngineering

A lamp assembly comprising one or more lamp clusters. Each lamp cluster comprises one or more electrodeless UV lamps which are excited by microwaves emitted from a microwave generator. The microwave generator and power supply are enclosed within a housing that is integral with the lamp clusters. The lamp clusters are wholly surrounded by a waveguide. The waveguide, comprising a flange and a distal end cap connected by a mesh, forms an enclosure. The waveguide is essentially UV transparent to allow UV light to pass through but effectively opaque to microwaves in order to substantially contain the microwaves within the waveguide enclosure.

Owner:SEVEN TRENT WATER PURIFICATION INC

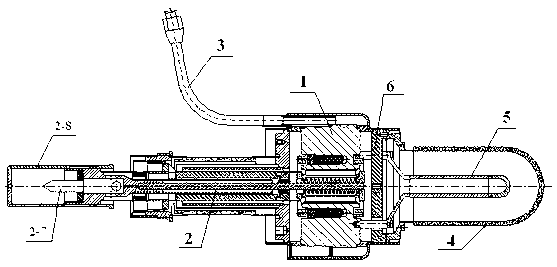

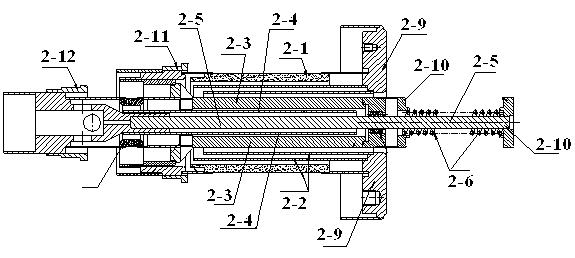

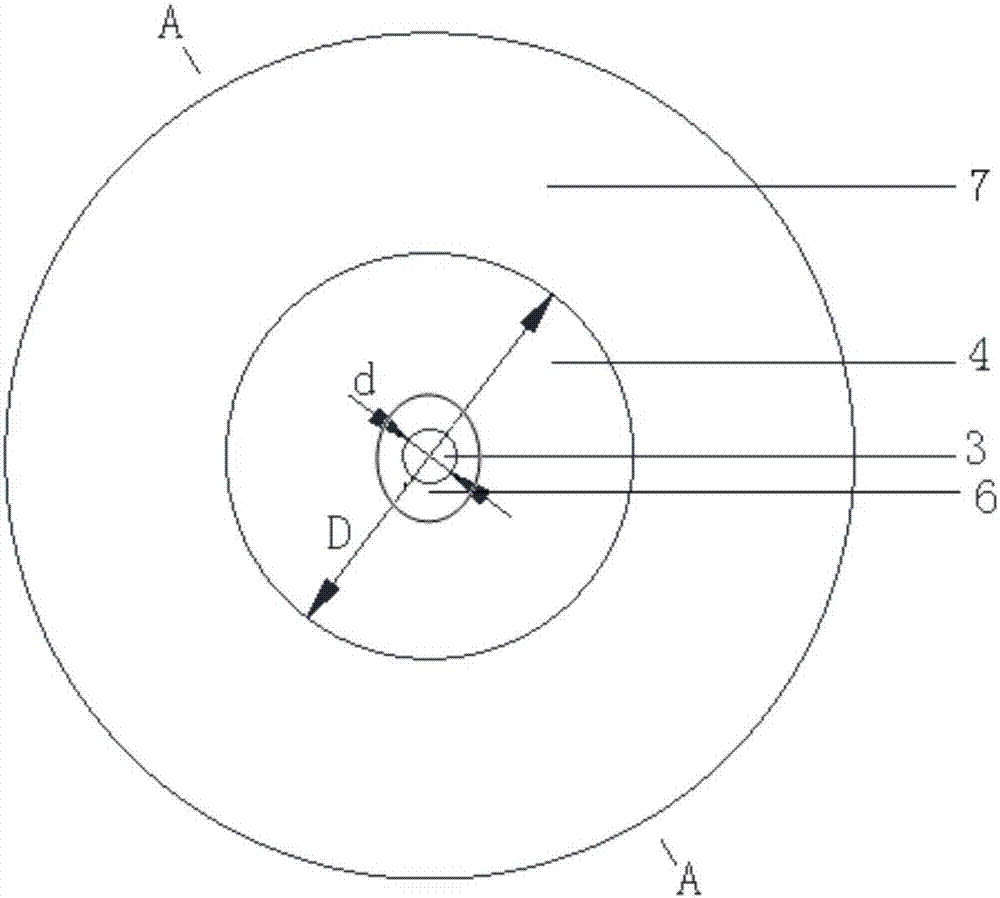

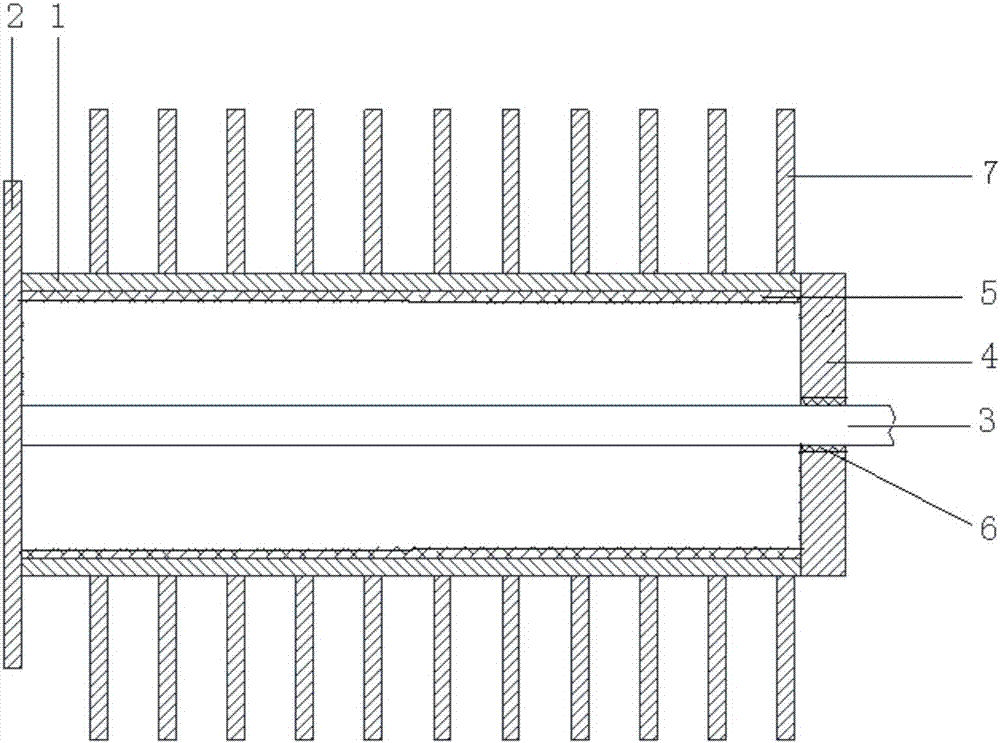

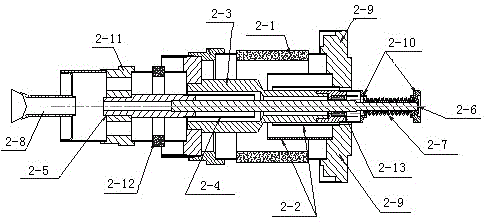

Magnetron cathode cable microwave leakage protective device

The invention relates to a magnetron and discloses a magnetron cathode cable microwave leakage protective device for preventing microwave leakage by use a coaxial structure and a wave-absorbing material. The magnetron cathode cable microwave leakage protective device comprises a junction surface, a cathode cable, a sleeve and a short-circuit plate; the junction surface is mounted at the starting end of the sleeve, while the short-circuit plate is mounted at the tail end of the sleeve; the cross section of the sleeve is circular; a cooling fin is mounted on the sleeve; the cathode cable penetrates through the short-circuit plate along the central axis of the sleeve to be connected with the junction surface; the wave-absorbing material is arranged between the sleeve and the cathode cable. The magnetron and discloses a magnetron cathode cable microwave leakage protective device has the beneficial effects that the microwave energy leaked by the magnetron cathode cable is absorbed thoroughly by the wave-absorbing material arranged between the sleeve and the cathode cable in the transmission process of the coaxial transmission line, the converted heat is dissipated to the surrounding space by the cooling fin, and therefore, the normal work of the coaxial line transmission system is guaranteed, the reliability of the protective device is improved and the microwave leakage is stopped.

Owner:SOUTHWEST JIAOTONG UNIV

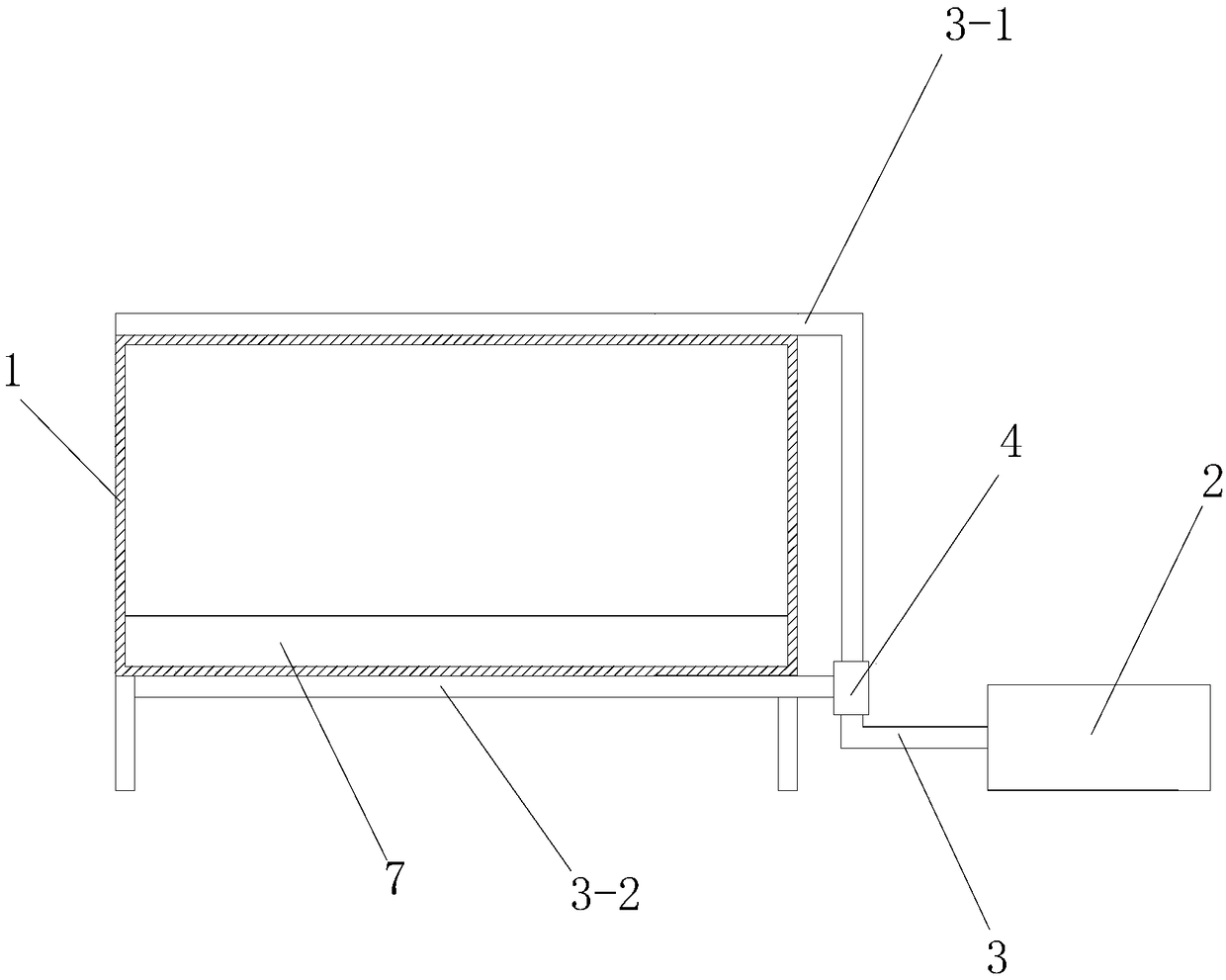

Microwave log-drying device

InactiveCN102980383AHeating evenlyImprove efficiencyDrying solid materials with heatDrying machines with progressive movementsThermodynamicsMicrowave - action

The invention discloses a microwave log-drying device, which comprises a box body, a power machine, a control system and an electrical control cabinet. The inner top part of the box body is provided with a microwave generating source, the lower part of the microwave generating source is provided with a microwave acting cavity, the microwave acting cavity is internally provided with a plurality of rows of rollers in the vertical direction, and the rollers can rotate forwards and reversely. A power machine chamber is arranged under the rollers, and the power machine used for driving the rollers to rotate is arranged in the power machine chamber; and the upper side of the box body is provided with a fan, and an induced air port of the fan is communicated with the microwave acting cavity. Microwave energy is adopted to dry logs, the microwave log-drying device has the advantages of uniform heating and high efficiency, the thermal efficiency is high, power consumption can be minimized, and automated control can be realized easily. Since the logs can be rotated forwards and reversely, every side face of the logs can be heated uniformly, and good heating effects can be achieved.

Owner:HENAN BODA MICROWAVE EQUIP

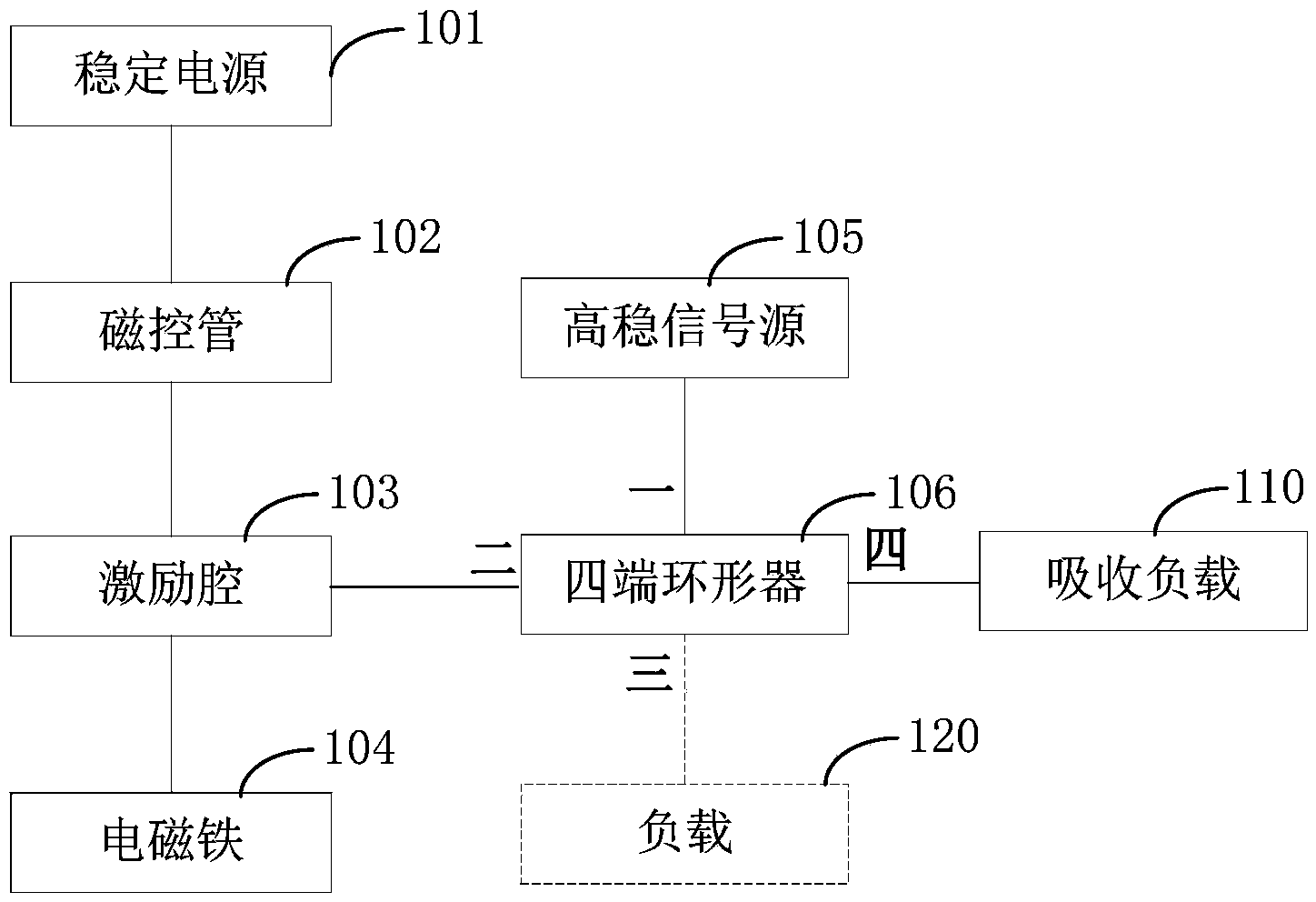

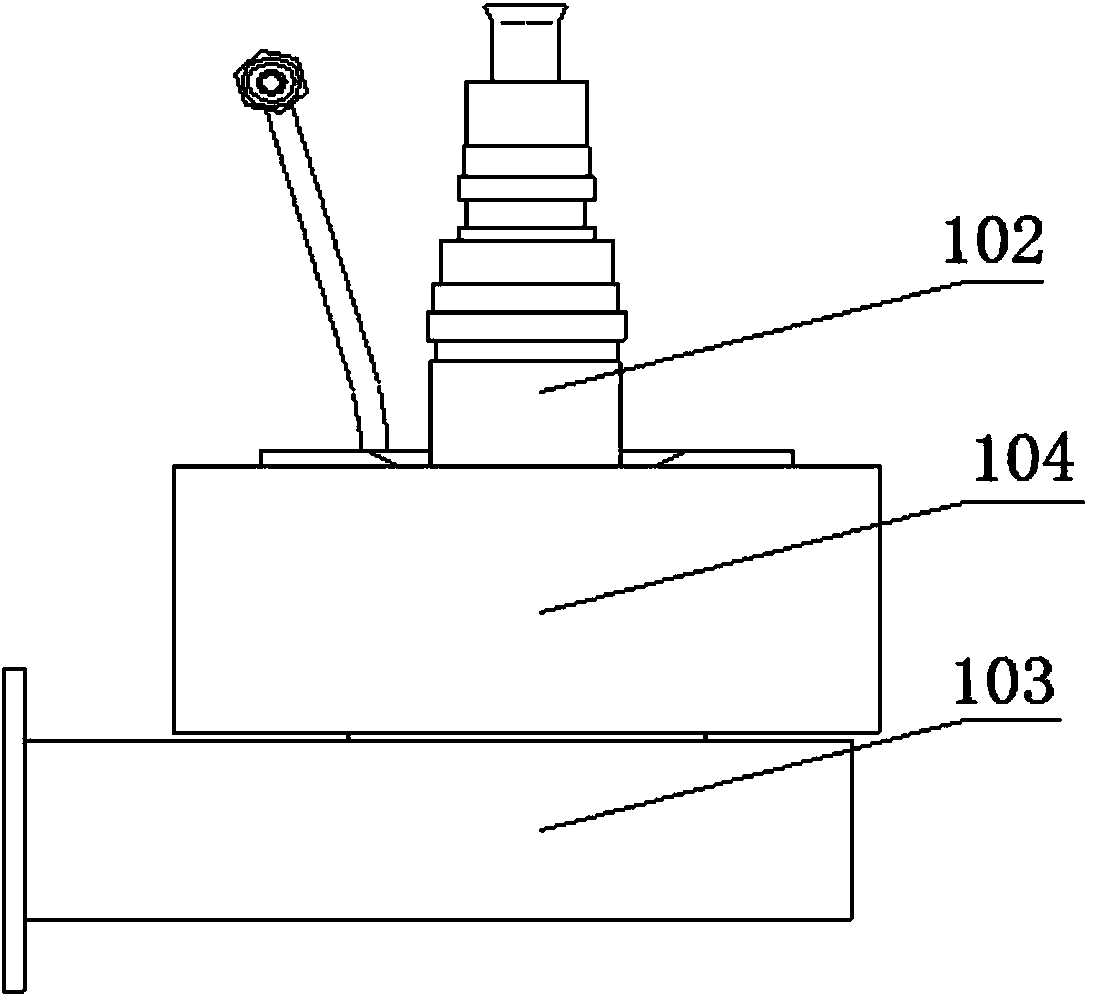

Magnetron with injected locking frequency of 20 kW/2450 MHz

InactiveCN104241064AImprove securityImprove frequency stabilityMagnetronsTransit-tube coupling devicesMicrowave powerEngineering

The invention discloses a magnetron with the injected locking frequency of 20 kW / 2450 MHz. The magnetron comprises a stabilized power supply, a magnetron body, an excitation cavity, an electromagnet, a high-stability signal source, a four-port circulator and an absorbing load. The stabilized power supply is a microwave power supply and is connected with the magnetron body. The magnetron body and the electromagnet are fixed to the excitation cavity. The stabilized power supply, the magnetron body, the electromagnet and the excitation cavity form a microwave energy generator which provides microwave power. The four-port circulator is provided with four ports, the first port is connected with the high-stability signal source, the second port is connected with the excitation cavity, the third port is connected with a load and used for outputting the microwave power to the load, and the fourth port is connected with the absorbing load. The high-stability signal source is used for providing stable 2450 MHz microwave signals, and the 2450 MHz microwave signals are injected into the magnetron body through the four-port circulator. The oscillation frequency of the magnetron body is controlled by the injected signal frequency, and the microwave energy is output through the third port. The magnetron body has the low exterior quality factor.

Owner:NANJING SANLE MICROWAVE TECH DEV

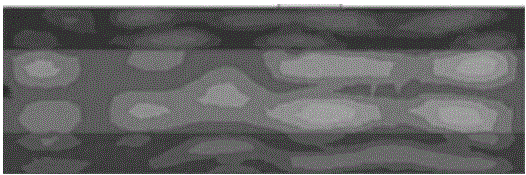

Tunnel type multi-mode microwave resonant cavity with rotation function

ActiveCN106211405AUniform Microwave Energy DistributionGood microwave irradiation uniformityOhmic-resistance heatingMicrowave heatingEnvironmental resistanceRotation function

The invention relates to a tunnel type multi-mode microwave resonant cavity with a rotation function. The microwave resonant cavity consists of a hollow hexagonal prism, HFSS (High Frequency Structure Simulation Software) is used for simulating and positioning the positions of four microwave energy feedback holes, four microwave tubes with total 4KW independently feed microwave energy from different directions, the energy distribution of the microwave resonant cavity is improved through electromagnetic wave energy feedback simulation, and microwave energy focus points in the resonant cavity are obviously reduced; meanwhile, a pipeline installation position is designed on the middle position of the resonant cavity, pipelines made of low-microwave adsorption materials including ceramics and glass can be assembled; and the pipeline which finishes being installed can rotate under the driving of a rotation device, and materials in the pipeline can be subjected to even microwave radiation. In the field of environment protection, the microwave resonant cavity is suitable for processing agriculture and forestry waste materials, waste rubber, waste plastics, waste printing circuits and the like, can carry out intermittent batch processing, can be combined with other piece of conveying processing equipment to realize fluidization operation, has the advantages of simple structure and high practical application value and is favorable for industrial popularization.

Owner:TONGJI UNIV

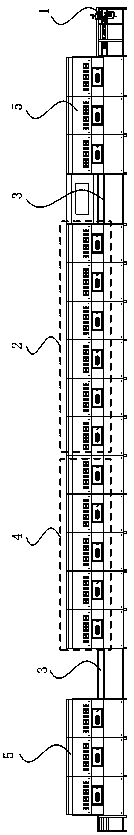

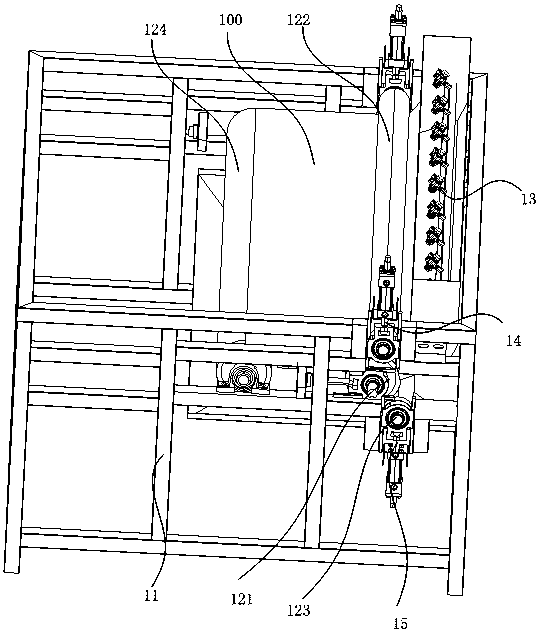

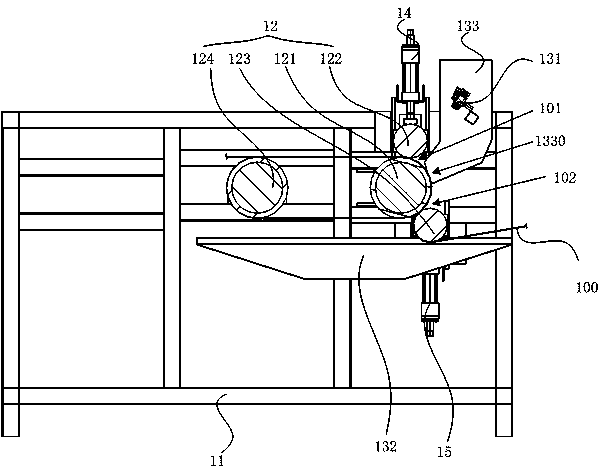

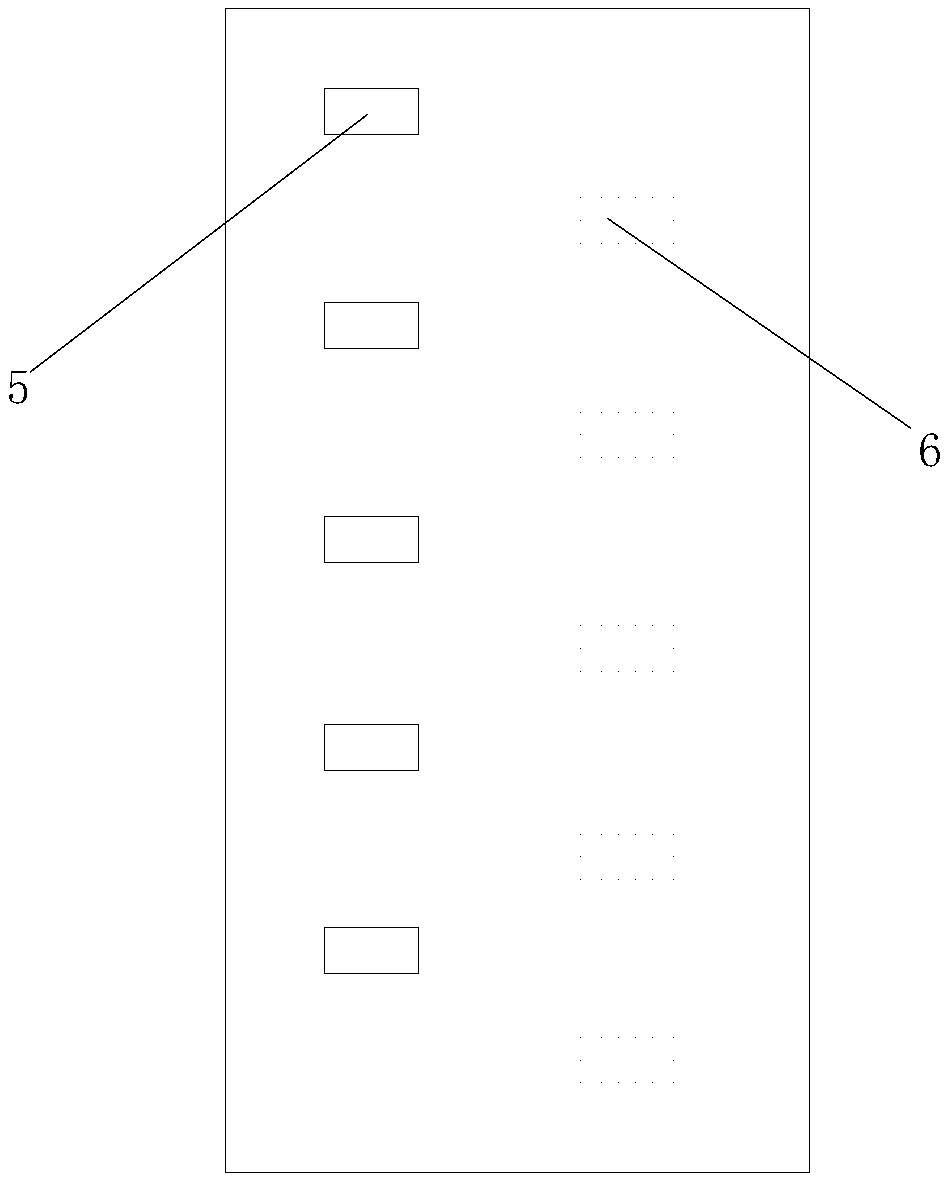

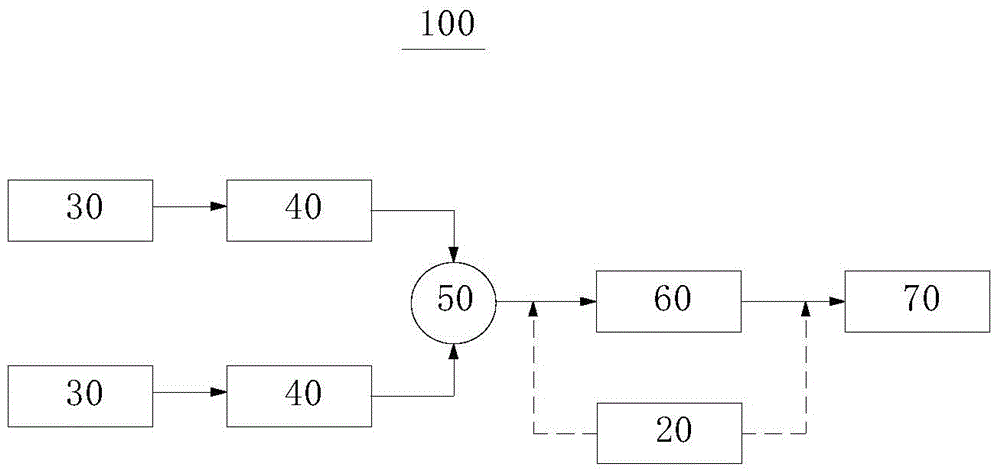

Tunnel type nonwoven fabric processing system and control method thereof

InactiveCN110387647AReduce usageReduce microwave leakageDomestic cooling apparatusDrying solid materials without heatMicrowaveEngineering

The invention provides a tunnel type nonwoven fabric processing system and a control method thereof. The tunnel type nonwoven fabric processing system comprises an unwinding machine, a spraying mechanism, a microwave heating tunnel and a conveying belt, wherein the unwinding machine, the spraying mechanism and the microwave heating tunnel are sequentially arranged, microwave inhibitors are arranged at two ends of the microwave heating tunnel respectively, and a microwave generator is arranged in the microwave heating tunnel; the unwinding machine is used for automatically unwinding to-be-processed nonwoven fabric, the spraying mechanism is sued for spraying a solution to the unwound nonwoven fabric, and the conveying belt penetrates through the microwave heating tunnel and the microwave inhibitors and is used for conveying the nonwoven fabric. The solution is sprayed to the nonwoven fabric to reduce the dosage of the solution, meanwhile, the microwave inhibitors are used for reducing the microwave leakage to meet the continuous production requirement, the production cost is reduced and the production safety is improved.

Owner:孙晓宇 +1

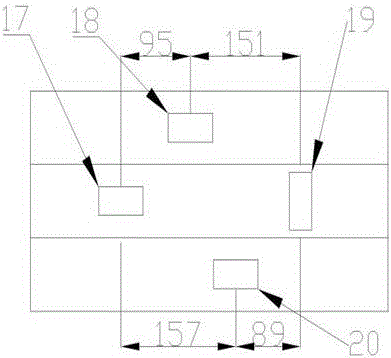

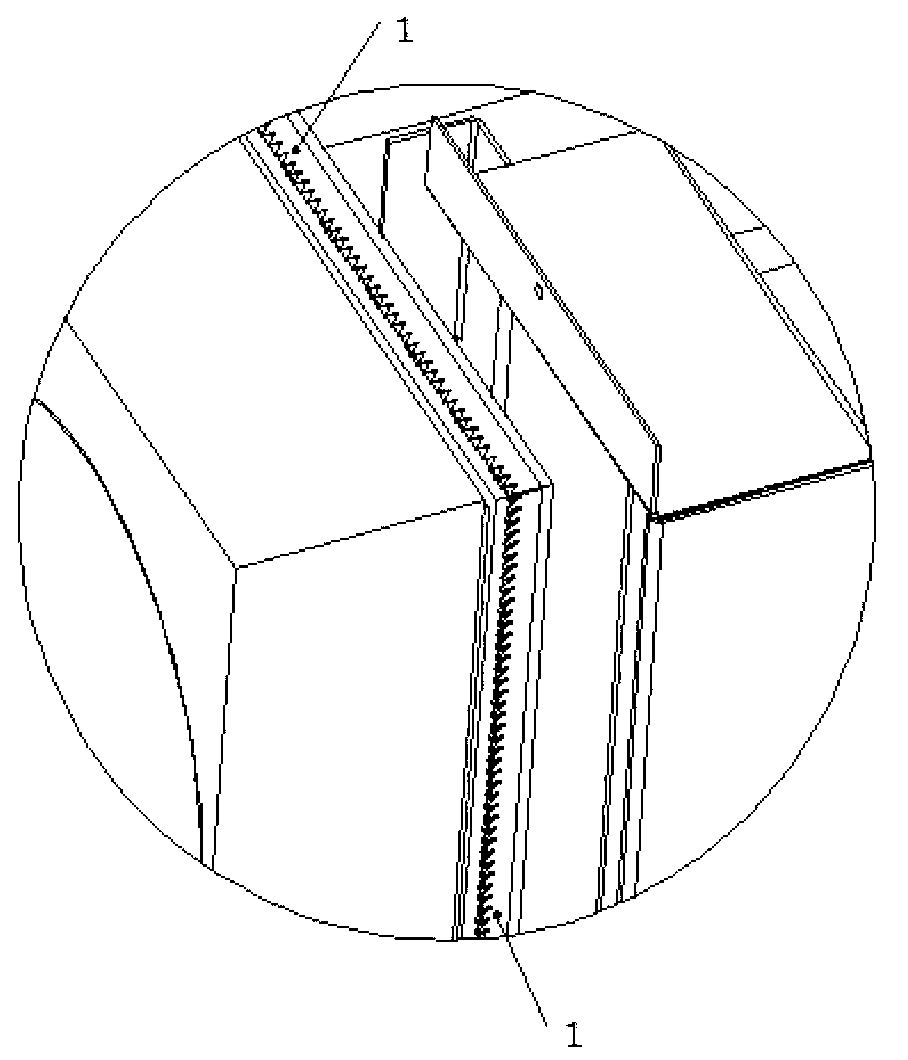

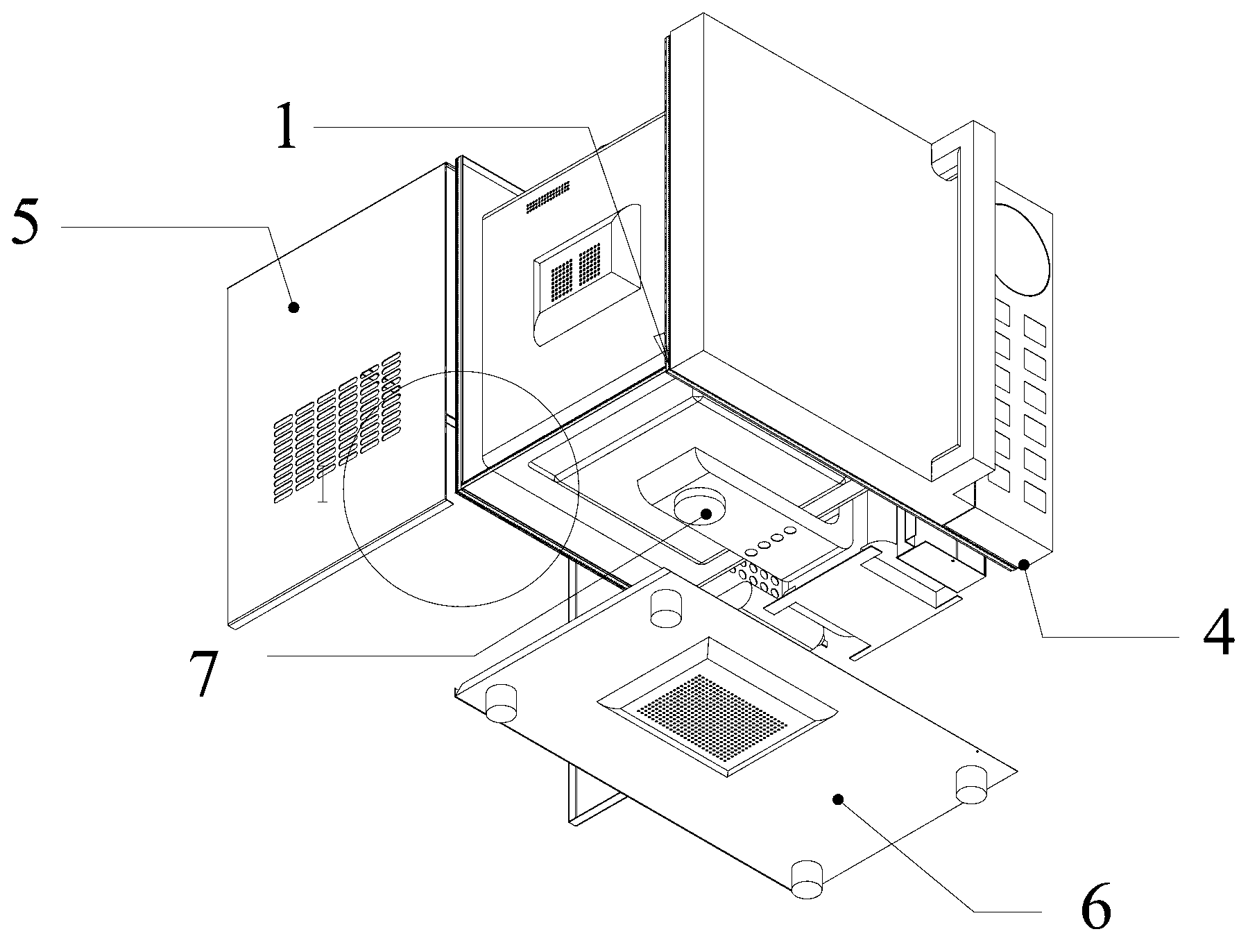

Device and method for suppressing electromagnetic leakage of microwave oven

ActiveCN102843799AImprove securityAvoid couplingDomestic stoves or rangesLighting and heating apparatusLow voltage circuitsMicrowave oven

The invention relates to a device for suppressing the electromagnetic leakage of a microwave oven, which is characterized by comprising a box-gap shielding component, a box-hole shielding metal wire mesh, a metal isolating cover (15) and a metal isolating wall (19). The box-gap shielding component is a one-sided sawtooth-shaped beryllium copper reed (1); the box-hole shielding metal wire mesh is arranged on the round-hole areas on two sides of the wall of the microwave oven; the metal isolating cover (15) is assembled together with assembling box of a low-voltage circuit unit through two screw holes at the upper end and the bottom and hereby covers the low-voltage circuit unit; and the metal isolating wall (19) is arranged at the bottom of a microwave stirrer (7) at the tail end of a microwave launching and transmitting channel (18). Due to the adoption of the device, the difficulty of shielding the gap of the shell of the microwave oven is reduced, 90% of high-frequency electromagnetic waves are suppressed from leaking outside, and the purpose of preventing the electromagnetic leakage is achieved.

Owner:ANFANG HI TECH ELECTROMAGNETIC SAFETY TECHN BEIJING

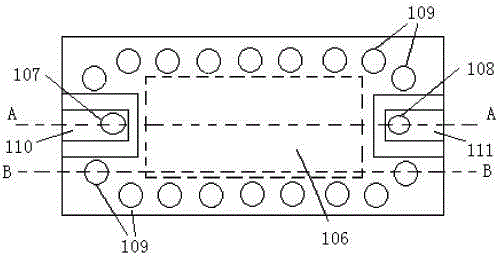

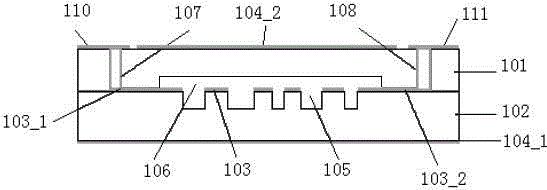

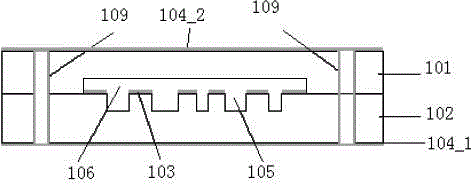

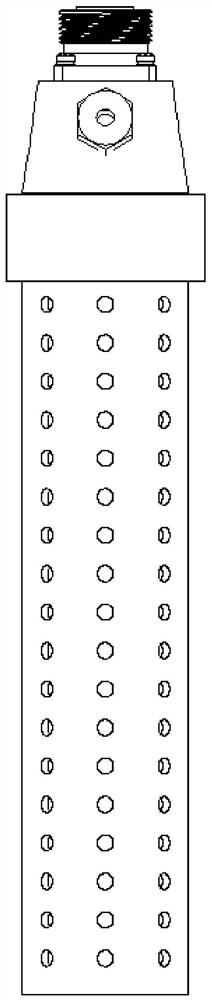

MPCVD cavity structure and MPCVD device

The invention relates to a MPCVD cavity structure and a MPCVD device. The MPCVD cavity structure and the MPCVD device comprise a hollow body. The body is provided with an air inlet pipe. The inner wall of the body is provided with a plurality of air inlets, and the air inlets are in communication with the air inlet pipe. The air inlets are at least divided into a layer. The air inlets of the samelayer evenly distributes at the same height of the inner wall of the body. The body is provided with an air outlet, and the air outlet is in communication with an inner cavity of the body. A gas in the cavity structure penetrates through the air inlet pipe and the air inlets, and uniformly enters the cavity. At the same time, the size of the air inlets is different, it is ensured that air flow ofeach air inlet is basically the same, and the uniformity of air intake is ensured. The MPCVD cavity structure and the MPCVD device are compact in design, reasonable in structure, and convenient to operate. The plasma is stable and distributes evenly, is suitable for the preparation of uniform MPCVD deposition products with large areas.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Three-dimensional integrated multi-layer stacked micro-shielded mems filter bank

ActiveCN103779642BOvercome the cavity effectImproved clutter suppression performanceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMicrowaveEngineering

The present invention provides a three-dimensionally integrated multi-layer stacked structure micro-shielding MEMS filter group, which includes the following features: the filter group includes two filters, respectively A filter and B filter, and 4 layers of substrate materials, A filter structure includes bottom-up A substrate and B substrate, B filter structure includes bottom-up C substrate and D substrate; the metal surface between B substrate and C substrate is a filter group Provide signal input and output; the signals of the two filters are separately drawn out. Advantages: Two independent MEMS filters are integrated in a three-dimensional monolithic chip using MEMS technology, which reduces the area of traditional filter components and is easy to achieve integration. It adopts a fully sealed cavity structure, which reduces microwave leakage and avoids on-chip Pollution of the internal structure of the chip by water flow, debris, etc. in subsequent processes such as separation; provides a solution for vertically integrating two filters, which can be extended to the integration of multiple filter banks.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

A kind of mpcvd cavity structure and mpcvd equipment

ActiveCN108149223BGuaranteed uniformitySame air flowChemical vapor deposition coatingEngineeringMechanical engineering

The invention relates to a MPCVD cavity structure and a MPCVD device. The MPCVD cavity structure and the MPCVD device comprise a hollow body. The body is provided with an air inlet pipe. The inner wall of the body is provided with a plurality of air inlets, and the air inlets are in communication with the air inlet pipe. The air inlets are at least divided into a layer. The air inlets of the samelayer evenly distributes at the same height of the inner wall of the body. The body is provided with an air outlet, and the air outlet is in communication with an inner cavity of the body. A gas in the cavity structure penetrates through the air inlet pipe and the air inlets, and uniformly enters the cavity. At the same time, the size of the air inlets is different, it is ensured that air flow ofeach air inlet is basically the same, and the uniformity of air intake is ensured. The MPCVD cavity structure and the MPCVD device are compact in design, reasonable in structure, and convenient to operate. The plasma is stable and distributes evenly, is suitable for the preparation of uniform MPCVD deposition products with large areas.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

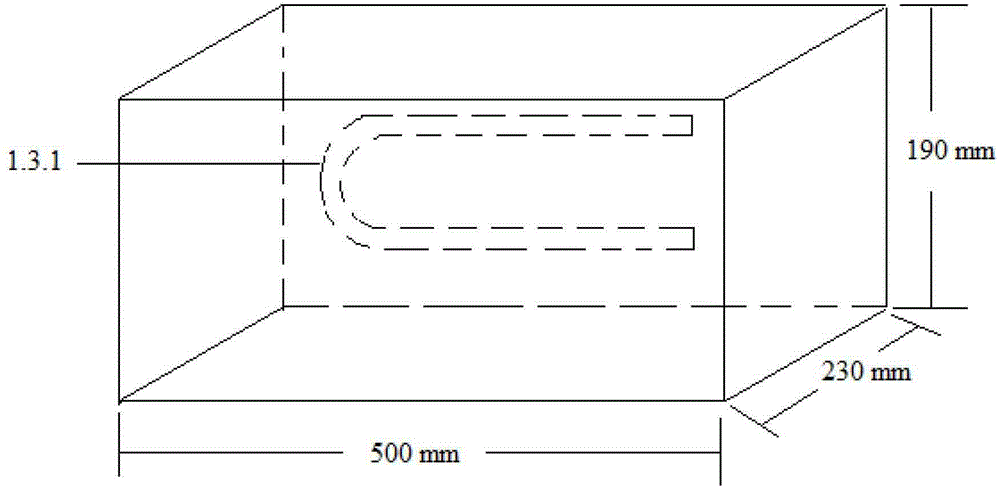

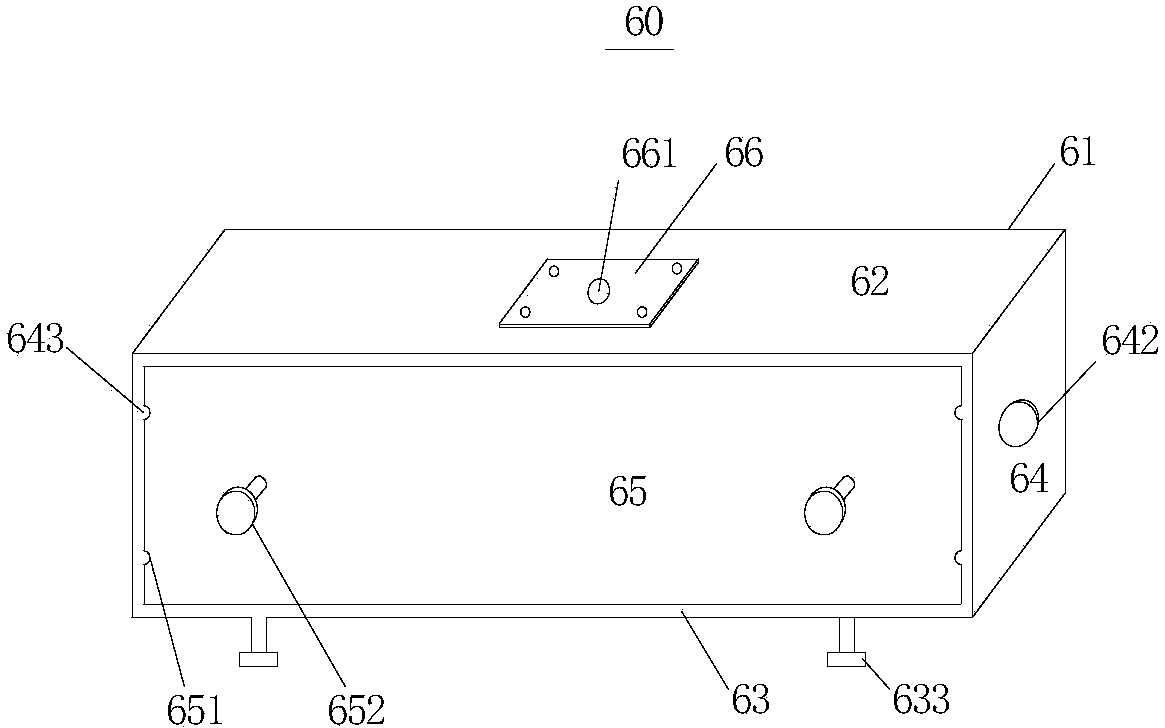

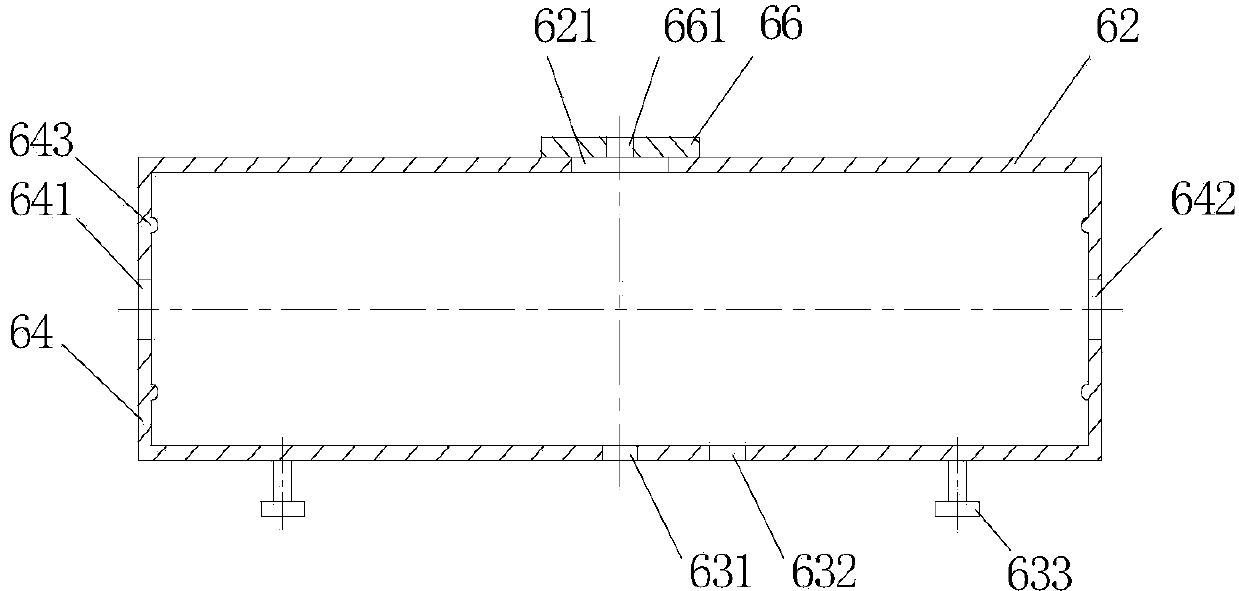

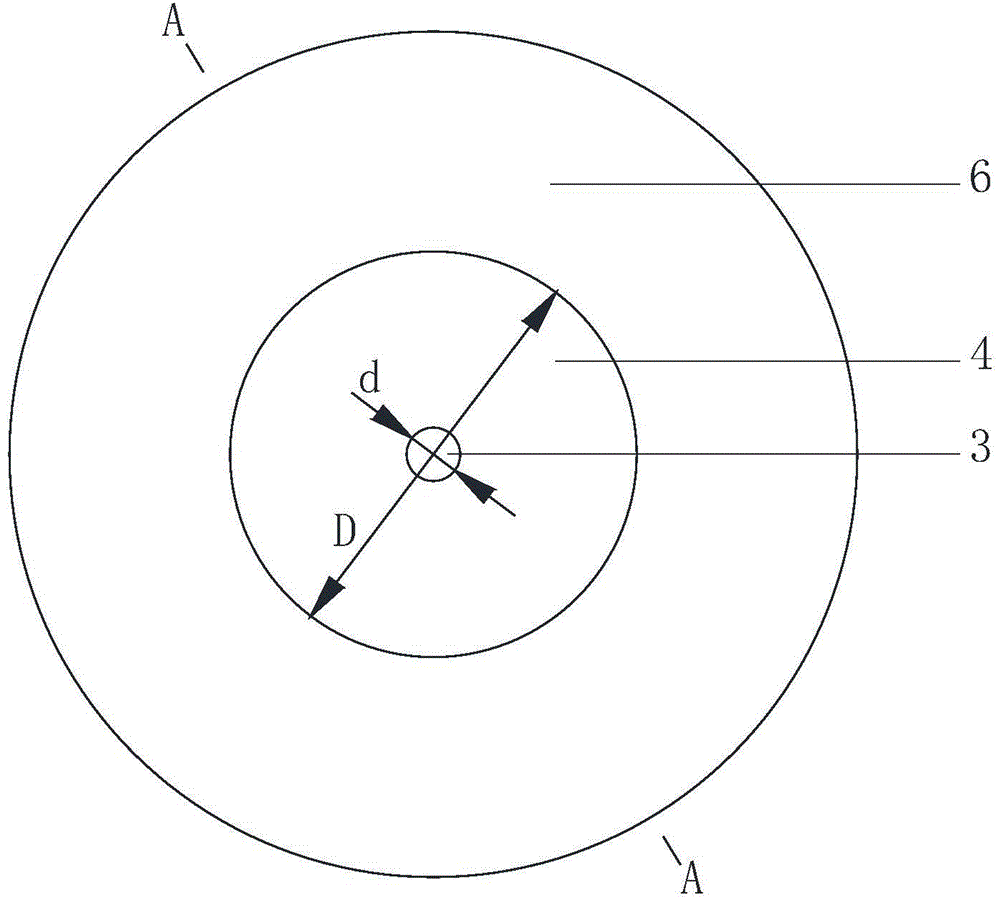

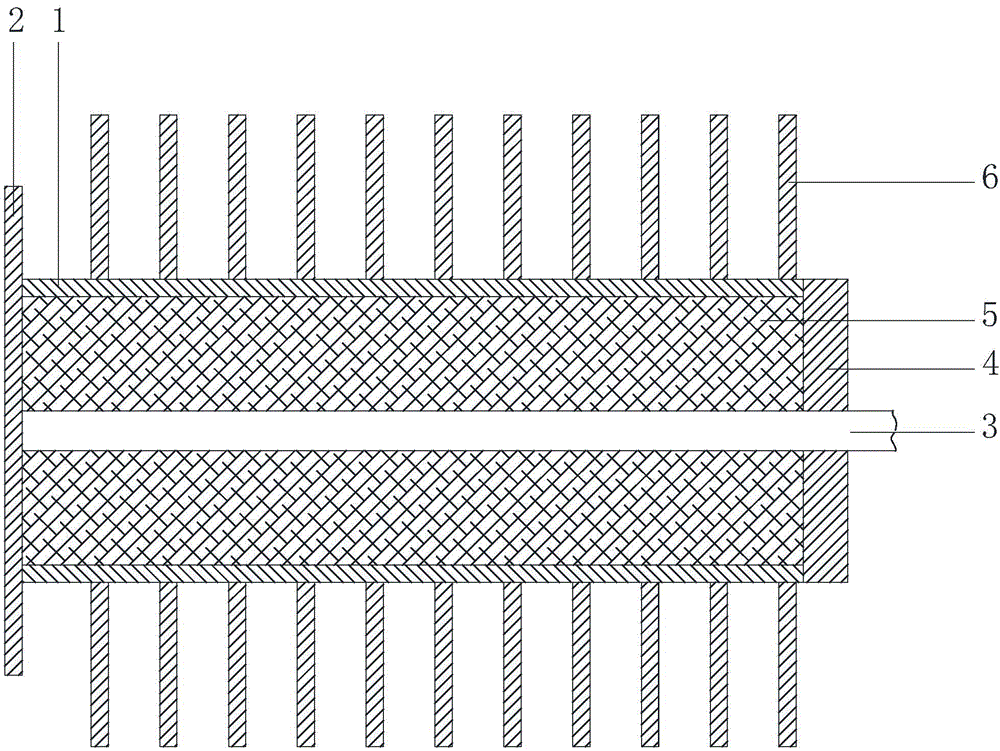

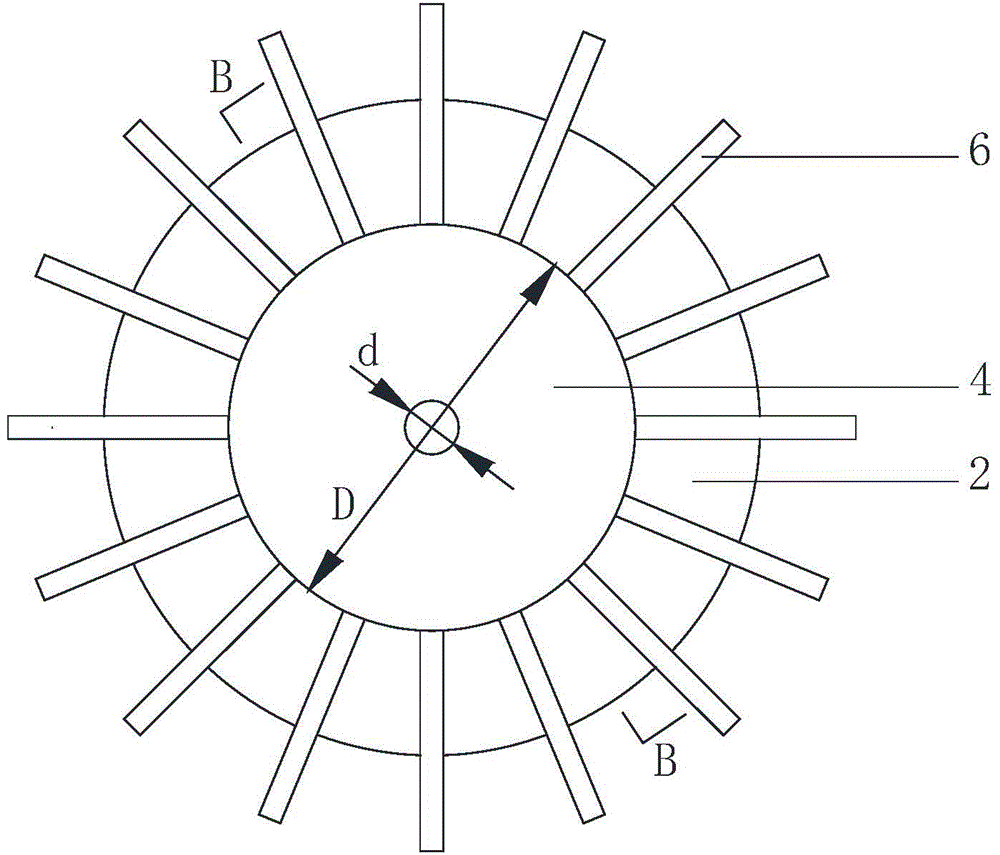

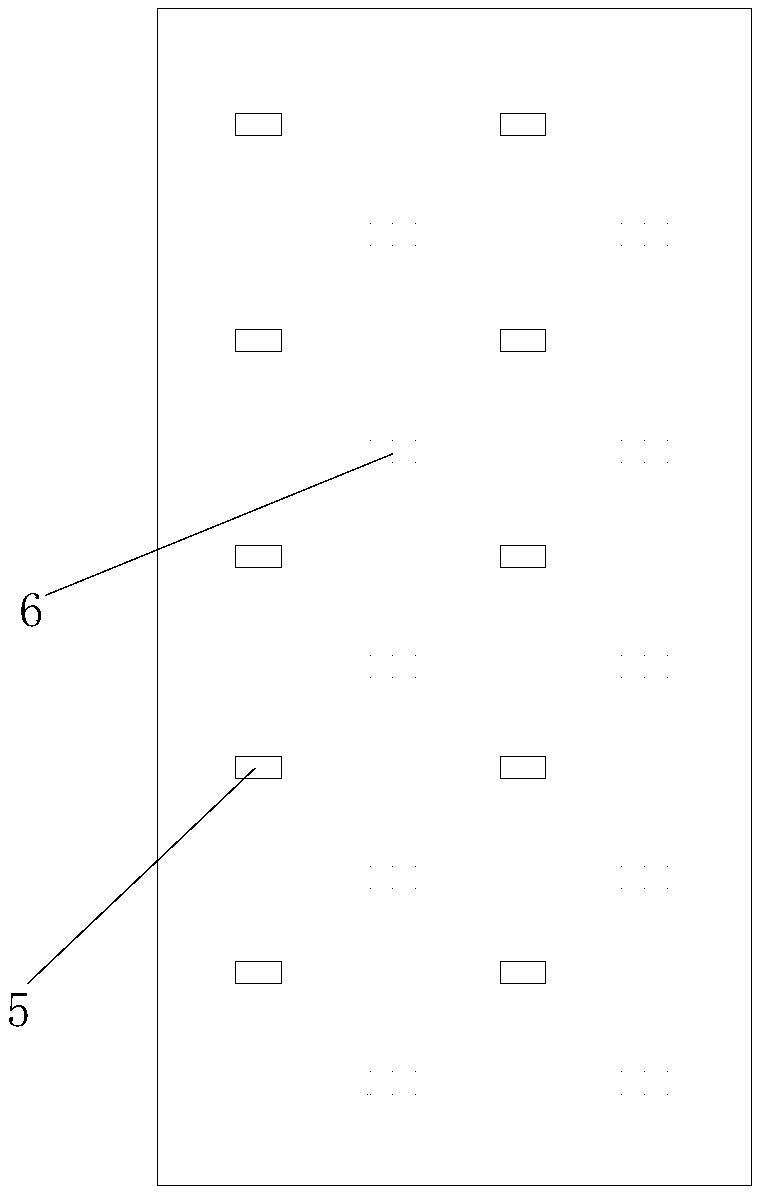

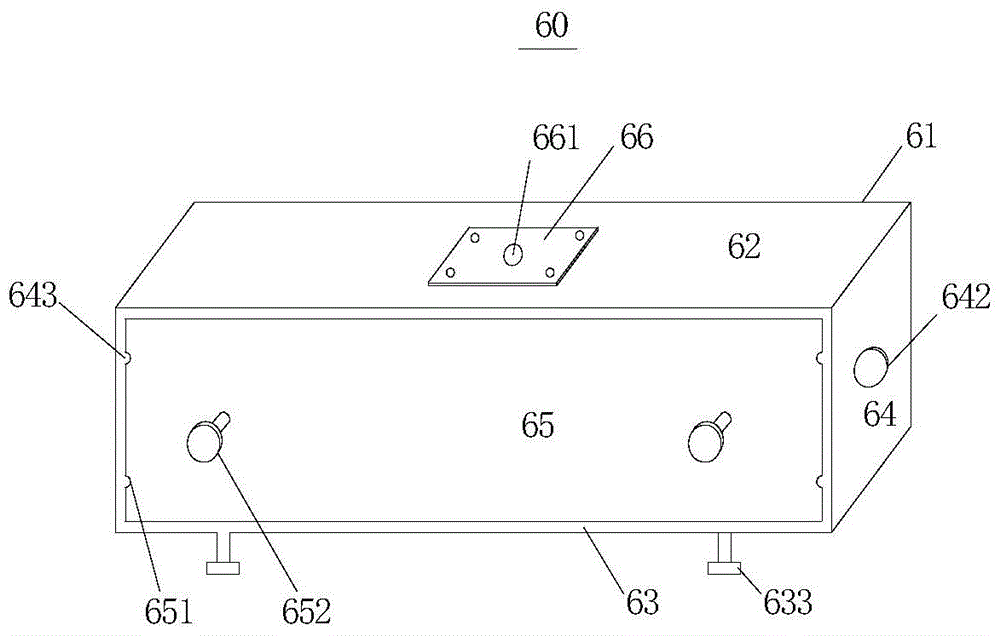

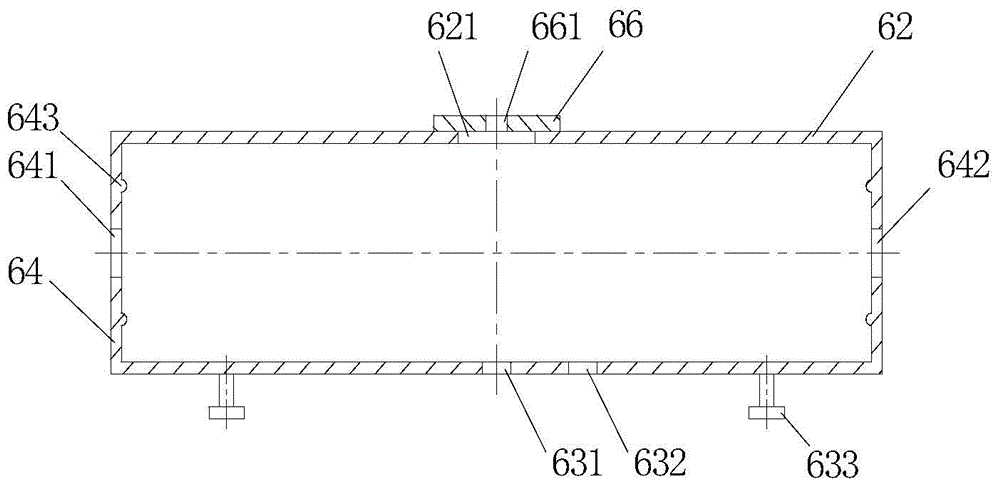

A multi-mode microwave heating chamber for processing heap leached uranium ore

The invention discloses a multi-mode microwave heating cavity for treating dump leaching uranium ore. The multi-mode microwave heating cavity comprises fifteen microwave power feeding ports and waveguides, two illuminating ports, a humidity-discharging port and an openable operating window. Energy is fed back by adopting a plurality of ports, the ports are isolated from one another by appropriate distances, microwave power enters a box body at different phases, distribution of each path in maximum modes is formed in the box body after repeated reflection for obtaining higher field uniformity, and meanwhile, sufficient microwave power density can be achieved in the box body in a power synthesis way. The multi-mode microwave heating cavity is further characterized in that energy is fed back through two paths of waveguide ports in a 90-degree orthogonal polarization way, so that power coupling among the ports is reduced. The multi-mode microwave heating cavity can be applied to a microwave treatment system for dump leaching uranium ore, and is also suitable for microwave drying equipment, microwave sterilizing equipment and microwave high-temperature baking equipment of various types. The multi-mode microwave heating cavity has the advantages of high matching property among power feeding ports, low microwave reflectivity, uniform energy density, high coupling property with materials, high heating efficiency, small microwave leakage, use safety and the like.

Owner:NANHUA UNIV

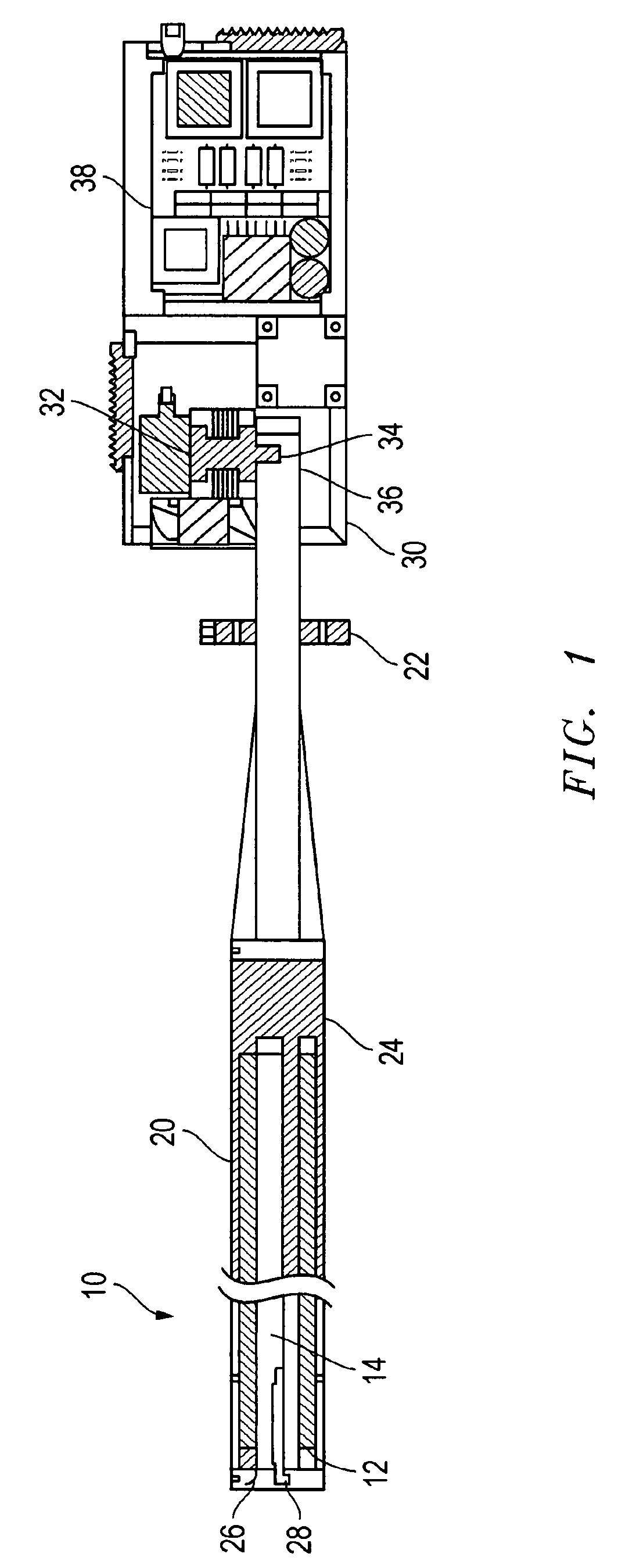

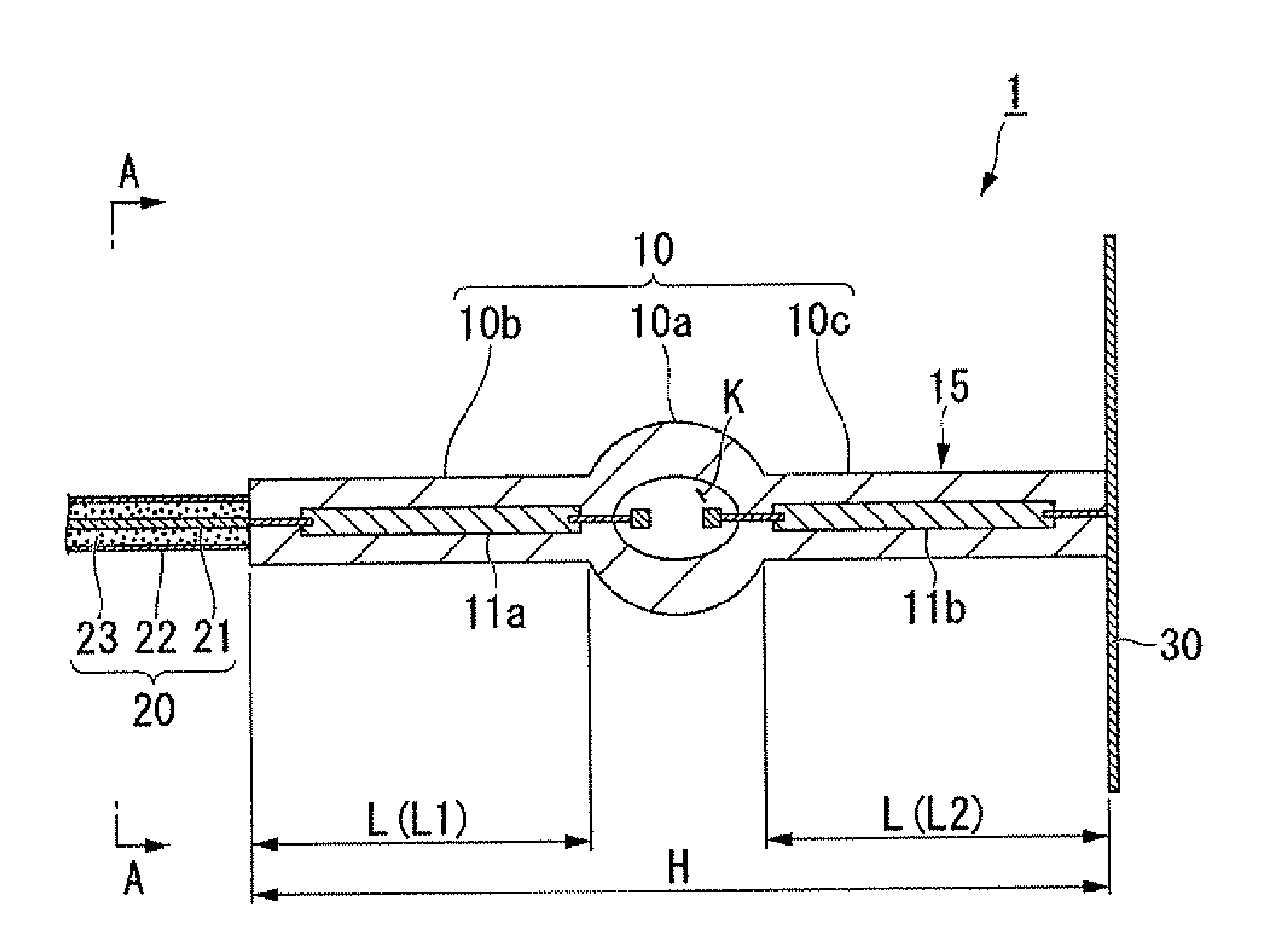

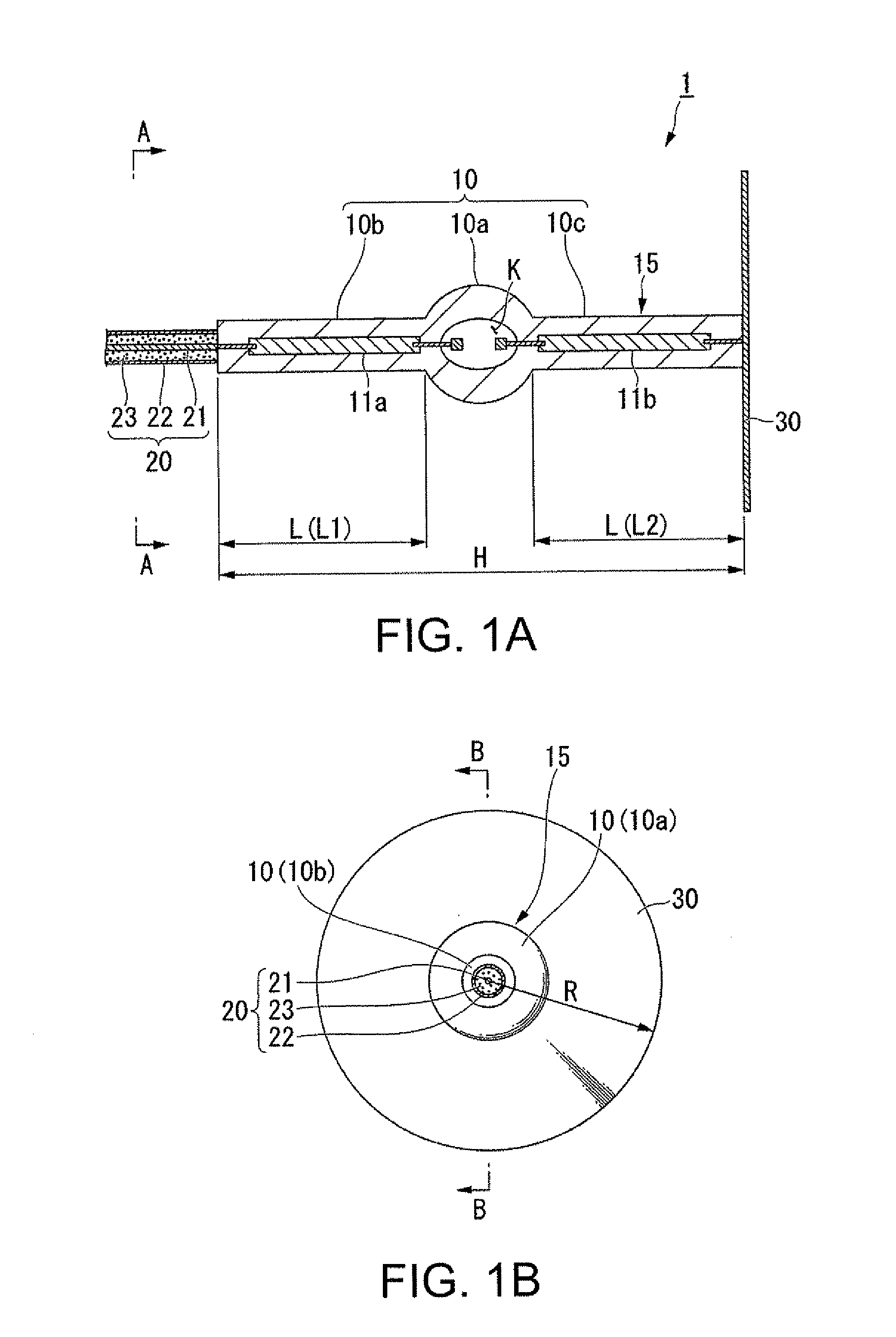

Light source device and projector

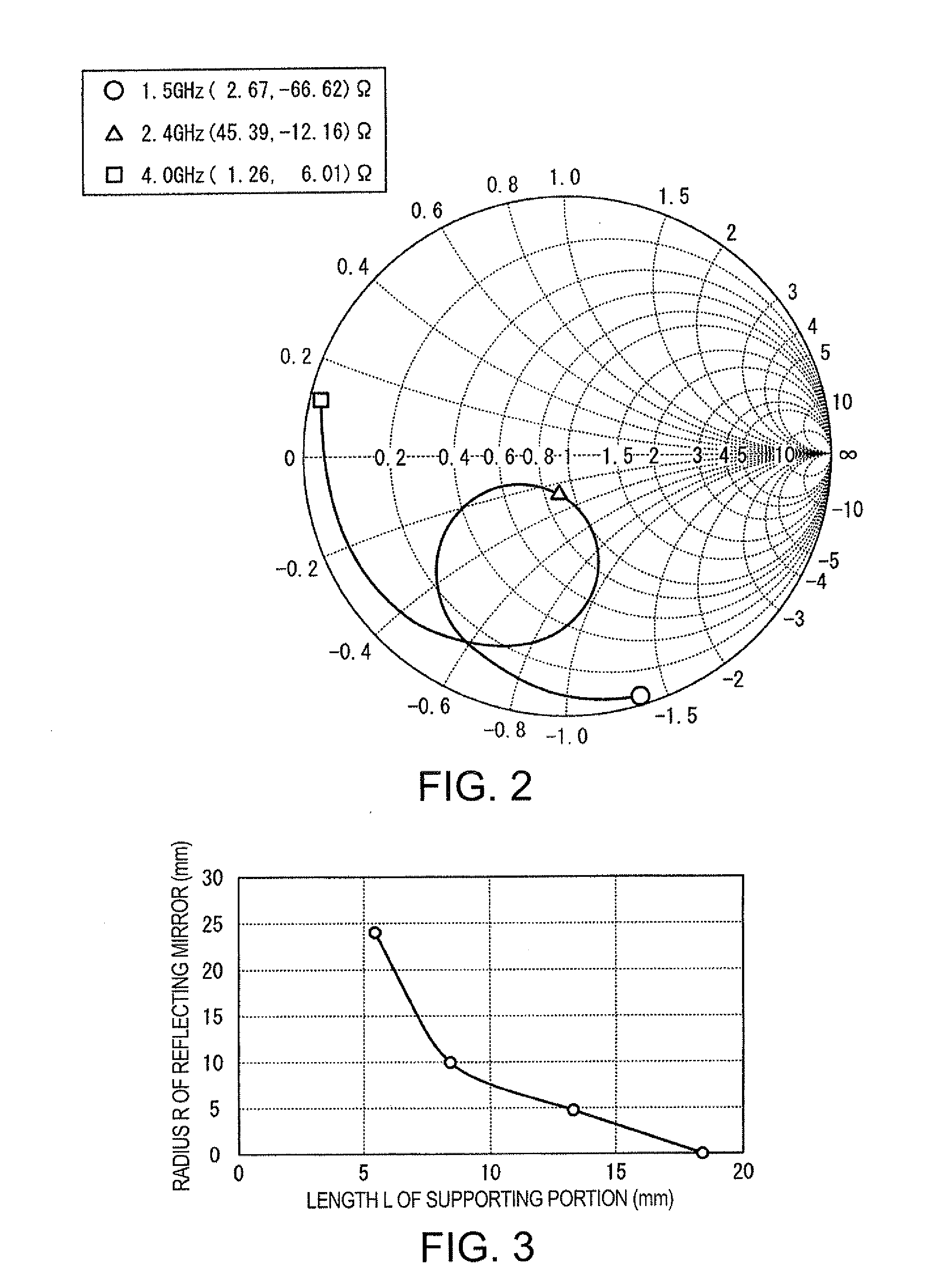

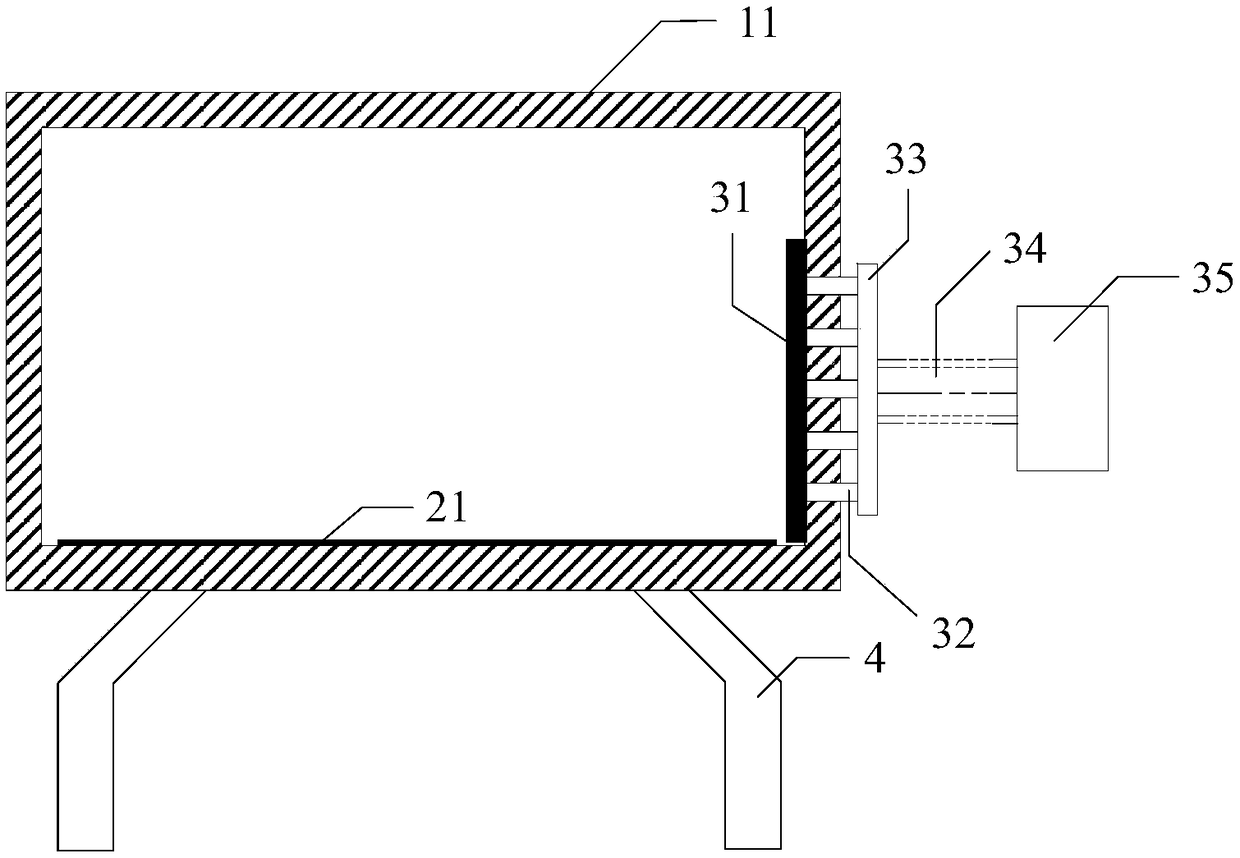

InactiveUS20100188010A1Reduce microwave leakageImprove luminous efficiencyPoint-like light sourceElectric lighting sourcesElectricityMicrowave power

A light source device includes: a microwave power source which outputs a microwave; a light-emitting tube with an emission space where a light-emitting material, which emits light by input of the microwave, is filled; a first electrode which is provided at one side of the light-emitting tube and is electrically connected to the microwave power source; a second electrode which is provided at the other side of the light-emitting tube, the emission space being interposed between the first and second electrodes; and a reflecting plate which is electrically connected to the second electrode and which reflects the microwave such that an antinode of the amplitude of a standing wave of a high-frequency current is positioned in the emission space by making the microwave resonate.

Owner:SEIKO EPSON CORP

A continuous transmission quasi-non-diffracting wave microwave reactor

ActiveCN106237957BAvoid the Effects of Diffractive SpreadUniform effectMicrowave heatingEnergy based chemical/physical/physico-chemical processesProduction lineMicrowave

The invention belongs to the field of microwave energy application devices, and provides a continuous transmission type quasi-non-diffraction wave microwave reactor, including a reaction device, a transmission device, a feeding device and a supporting device; the feeding device includes a radiator, a feeding waveguide, and a power distribution device. and phase shifter, coaxial transmission line and microwave source; the microwave source is connected to the input end of the power distribution and phase shifter through the coaxial transmission line, and the output end of the power distribution and phase shifter is connected to several feeder waveguides, and the feeder waveguide passes through The radiator is connected to the radiator through the metal cavity. The radiator is located at the middle and lower part of the back of the metal cavity. The radiator is provided with a rectangular radiation port of the same size as the feed waveguide. The present invention adopts the way of multi-feeder feed-in to generate non-diffraction wave to irradiate the reactant, so as to improve the reaction efficiency, speed up the reaction speed, improve the uniformity of the reaction and save energy, and combine it with the continuous transmission production line, and apply it on a large scale In industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

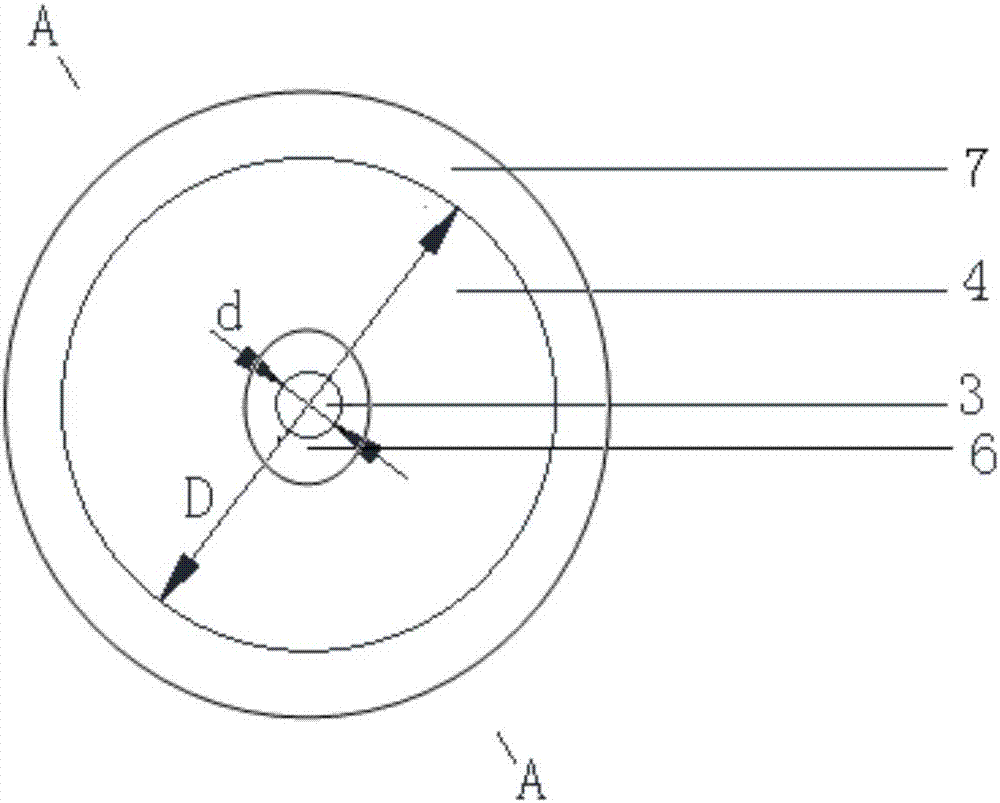

High Power Magnetron Cathode Cable Microwave Leakage Protection Device

InactiveCN106206220BStrong enoughGood electrical and thermal conductivityTransit-tube coupling devicesCoaxial lineCoaxial transmission line

Owner:SOUTHWEST JIAOTONG UNIV

Melamine foam uniform foaming device

The invention discloses a melamine foam uniform foaming device and belongs to the field of microwave foaming. The foaming device includes an oven body and multiple sets of microwave devices, wherein the front and rear side walls of the oven body are separately provided with a feeding door and a discharging door. Each set of microwave device includes a microwave source and a wave conduit, wherein the microwave source is arranged at one end of the wave conduit, the wave conduit is divided into a first branch pipe and a second branch pipe by a power splitter, the first branch pipe is arranged onthe top wall of the oven body, the second branch pipe is arranged outside the bottom wall of the oven body, top microwave feeding mouths are arranged on the connection surface between the first branchpipe and the oven body, bottom microwave feeding mouths are arranged on the connection surface between the second branch pipe and the oven body, and the top microwave feeding mouths and the bottom microwave feeding mouths are staggered in the length and width directions of the oven body. The melamine foam uniform foaming device has the advantages of good matching between the microwave feeding mouths, low microwave reflection rate, uniform energy density, good coupling with materials, high heating efficiency, small microwave leakage, safe use and the like.

Owner:郑州峰泰纳米材料有限公司

A 2450mhz high-power continuous wave magnetron and its preparation method

ActiveCN103346053BEasy to processImprove characteristic impedanceMagnetronsTransit-tube collectorsCavity magnetronMicrowave

The invention discloses a 2450-MHz high-power continuous-wave magnetron and a preparation method thereof. The 2450-MHz high-power continuous-wave magnetron comprises an anode cavity combination unit (1), a cathode outgoing line combination unit (2), an output window combination unit (3) connected with the anode cavity combination unit (1), and an output antenna (4) fixed at the anode cavity combination unit (1); the other end of the output antenna (4) is arranged inside the output window combination unit (3); and the anode cavity combination unit (1) is connected with a cavity cooling water inlet-outlet pipe (5). The structure of the provided continuous-wave magnetron is designed reasonably; the power of the magnetron is high and the output power can reach over 30 KW; the service life can reach more than 5000 hours; the microwave leakage is less; and the security performance is high. Besides, according to the preparation method of the continuous-wave magnetron, lots of experiment screening is carried out; and the method has the advantages of reasonable process design and high operability. Moreover, the prepared magnetron with characteristics of high gas tightness, a high vacuum degree, low sparking probability and stable performance enables various defects existing in the prior art to be overcome.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP +1

Microwave irradiation cavity, microwave irradiation system, microwave irradiation and real-time observation method

ActiveCN103776682BReal-time biological indicator observationReduce microwave leakageMaterial analysis using microwave meansPreparing sample for investigationObservation methodMicrowave irradiation

The invention provides a microwave irradiation chamber, a microwave irradiation system and a microwave irradiation and real-time observation method. The microwave irradiation chamber comprises a shell and a shielding component, wherein a cuboid-shaped cavity is formed in the shell, a microwave receiving interface and a microwave absorption interface are arranged in the central positions of the two end walls of the shell, respectively, a first opening is formed in the central position of the top wall of the shell, and a second opening is formed in the central position of the bottom wall; the shielding component covers the first opening of the shell, and the center of the shielding component is provided with a through hole. According to the technical scheme of the invention, the microwave irradiation chamber can be directly connected into a real-time observation and analysis instrument to carry out biological index observation in real time, so that the microwave leakage is slight, and the cross-sectional area of the microwave irradiation chamber is adjustable, and therefore, the compound irradiation of microwaves with different frequencies can be realized.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

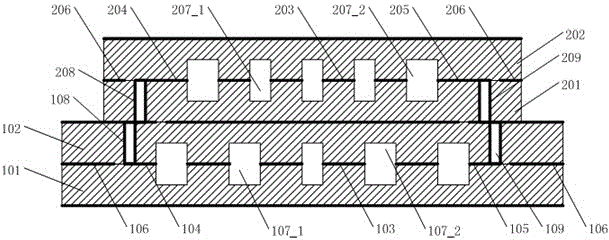

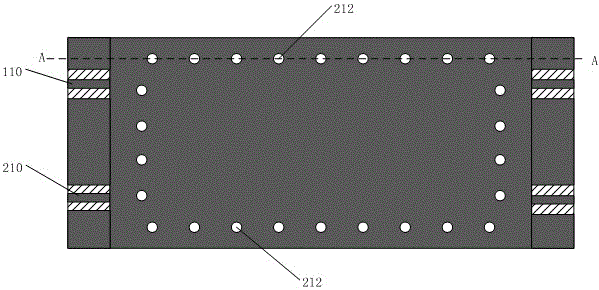

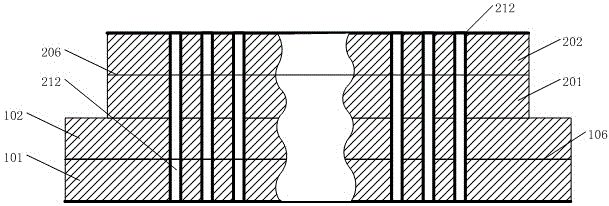

Full-closed cascading micro mechanical filter of micro shielding structure

ActiveCN103050748BReduce microwave leakageImproved clutter suppression performanceWaveguide type devicesGraphicsWater flow

The invention relates to a full-closed cascading micro mechanical filter of a micro shielding structure, and the filter structurally comprises an upper layered substrate and a lower layered substrate, wherein the upper layered substrate and the lower layered substrate are integrated through a micro mechanical alignment bonding process. A microwave signal is transmitted to the transmission wire of an input signal interface of the lower layered substrate from the input end of the filter of the upper layered substrate; the signal output end of the lower layered substrate is connected to the output end of the filter of the upper layered substrate through an output through hole; the lower surface of the lower layered substrate of the filter is a lower layered grounding surface; parts on the upper surface of the upper layered substrate other than graphics on the input end and the output end of the filter form an upper layered grounding surface; and the upper layered grounding surface and the lower layered grounding surface are electrically connected through a metal through hole array. The full-closed cascading micro mechanical filter of the micro shielding structure has the advantages that an upper wafer and a lower wafer are connected by the signal through a three-dimensional through hole, the sizes of the upper layered substrate and the lower layered substrate are the same, so that the physical sizes of input and output interfaces are reduced; a full-closed structure is adopted, so that microwave leakage is reduced; and pollution of water flow, chips and the like in chip separation and other post processes to the internal structure of a chip is avoided.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

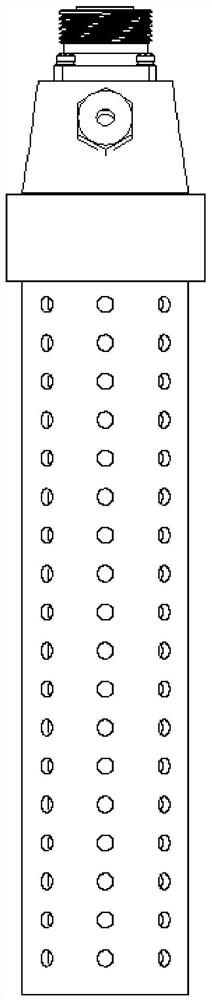

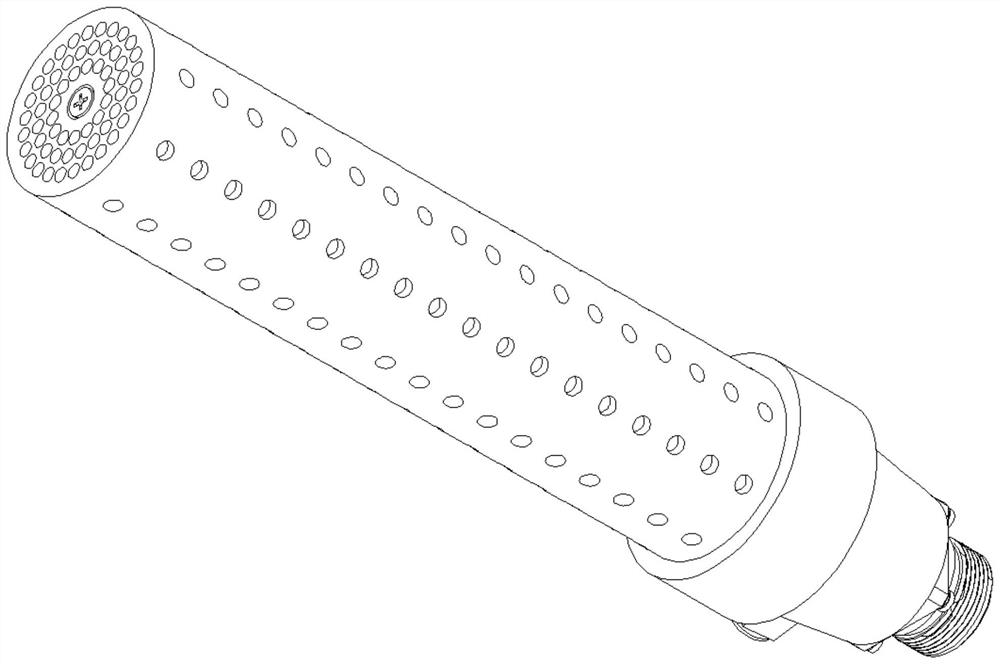

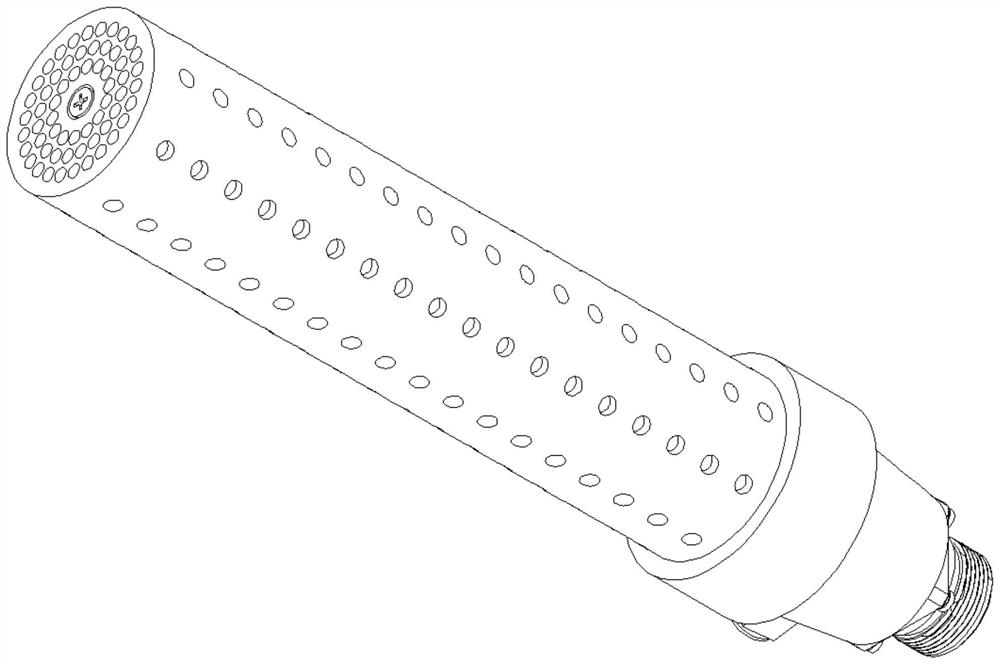

A microwave electrodeless ultraviolet lamp device

ActiveCN112837992BCompact structureIncrease powerElectric discharge lampsUltraviolet lightsMicrowave technology

The invention discloses a microwave electrodeless ultraviolet lamp device, belonging to the field of microwave technology, comprising a radiation rod, a metal mesh cover and a lamp body; the metal mesh cover is covered with a lamp body; the lamp body is covered with a radiation rod; The lamp body includes an inner wall layer and an outer wall layer; an interlayer is arranged between the inner wall layer and the outer wall layer; a filler is sealed in the interlayer; a microwave feeding space is arranged between the inner wall layer and the radiation rod. The microwave electrodeless ultraviolet lamp device of the present invention has compact structure, high power and long service life, can radiate ultraviolet light uniformly in all directions, has high working efficiency, reduces microwave leakage, and is safer and more reliable.

Owner:四川麦克优威环保科技有限责任公司

A continuously conveying focused microwave reactor

ActiveCN106334508BAvoid the effects of extensionUniform effectMicrowave heatingEnergy based chemical/physical/physico-chemical processesProduction lineMicrowave

The invention belongs to the field of microwave energy application devices, and provides a continuous transmission focused microwave reactor, including a reaction device, a transmission device, a feeding device and a supporting device; it is characterized in that the feeding device includes a metal reflecting surface, a radiation horn, a Axial transmission line, waveguide coaxial conversion and microwave source, the metal reflection surface is set on the inner wall of the top surface of the metal cavity, the microwave source is connected to the radiation horn through the coaxial transmission line and the coaxial conversion of the waveguide, the radiation horn is fixed on the side wall of the metal cavity, and passes through the The radiation passes through the metal cavity and is inclined at a certain angle with the cavity wall, so that the focus of the metal reflection surface is located in the direction of the main lobe of the radiation horn. The invention adopts the mode of feeding the side end of the waveguide into the reflection focusing of the metal wall to realize the point of maximum field strength to irradiate the detection object, so as to improve the reaction efficiency, speed up the reaction speed, improve the uniformity of the reaction and save energy, and combine it with the continuous transmission production line , used in large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Microwave electrodeless ultraviolet lamp device

ActiveCN112837992ACompact structureIncrease powerElectric discharge lampsUltraviolet lightsEngineering

The invention discloses a microwave electrodeless ultraviolet lamp device, which belongs to the technical field of microwaves. The microwave electrodeless ultraviolet lamp device comprises a radiation rod, a metal mesh cover and a lamp body; the lamp body is sleeved in the metal mesh cover; the radiation rod is sleeved in the lamp body; the lamp body comprises an inner wall layer and an outer wall layer; an interlayer is arranged between the inner wall layer and the outer wall layer; a filler is sealed in the interlayer; and a microwave feed-in space is arranged between the inner wall layer and the radiation rod. The microwave electrodeless ultraviolet lamp device is compact in structure, high in power, long in service life, capable of uniformly radiating ultraviolet light in all directions, high in working efficiency, capable of reducing microwave leakage and safer and more reliable.

Owner:四川麦克优威环保科技有限责任公司

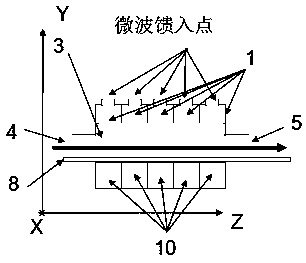

Fully coherent modular microwave heating device

In the invention, a microwave heating device is divided into several heating modules connected in series along a Z axis. Only a fundamental mode TE10 mode is propagated in different microwave feedingwaveguides in each module, and the electric field direction only has an X-axis component. The working microwaves in the different microwave feeding waveguides in each heating module are coherent and share the same phase, and the isolation degree between the working microwave feeding waveguides of different heating modules is very high. Non-coherent microwave sources can be employed in different heating modules, or coherent microwave sources can be employed in different heating modules arranged along the Z axis, so the working microwaves in microwave feeding waveguides belonging to different heating modules which are aligned and adjacent along the Z axis have an equal amplitude and inverted phases, and TEn0 waves which are propagated in a -Y direction from top to bottom and along a Y axis from bottom to top are excited in a heating cavity composed of cavities belonging to different heating modules, n is an integer and is greater than or equal to 2. The device can be used for heating various materials or speeding up chemical reactions.

Owner:成都赛纳微波科技有限公司

75 kw / 915 mhz high-power continuous wave magnetron

ActiveCN103258704BSimple structureNovel structureMagnetronsTransit-tube collectorsMicrowaveCharacteristic impedance

The invention discloses a 75 kW continuous wave magnetron. The 75 kW continuous wave magnetron comprises a positive pole cavity combination (1), a negative pole lead wire combination (2), a water pipe (3) which is connected with the positive pole cavity (1), an output window combination (4) which is connected with the negative pole cavity combination (1), an antenna combination (5) which is fixed on the negative pole cavity combination (1), and an inner pole shoe (6) which is fixed at one end of the positive pole cavity combination (1), wherein the antenna combination (5) is located inside the output window combination (4). The continuous wave magnetron is reasonable in structural design, high in power, high in output efficiency, less in microwave leakage, and high in safety performance. Particularly, due to the fact that a negative pole structure of a fan-shaped resonator system structure with high characteristic impedance is adopted and an n-shaped water line cooling structure is adopted on a negative pole, heat dissipation effect is better, light striking probability is less, working is stable, structure is novel, and the magnetron is suitable for being used in a high-power microwave heating device in industries.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com