High Power Magnetron Cathode Cable Microwave Leakage Protection Device

A magnetron cathode and protective device technology, applied in the field of magnetron, can solve the problems that the product cannot meet the electromagnetic compatibility standard, affect the normal operation of the control system, and affect the normal operation of the magnetron, so as to solve the problem of microwave leakage and avoid Creates hot spots for easy and full absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment takes a 2.45GHz high-power magnetron cathode cable microwave leakage protection device as an example for illustration.

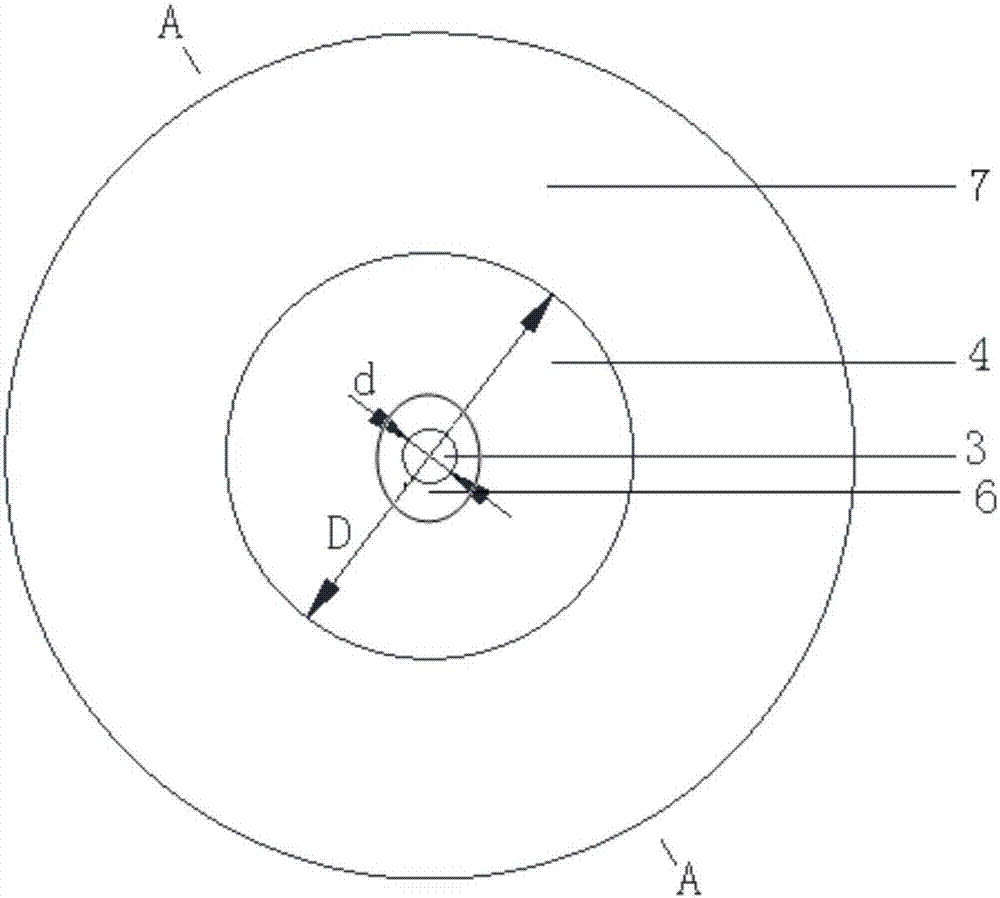

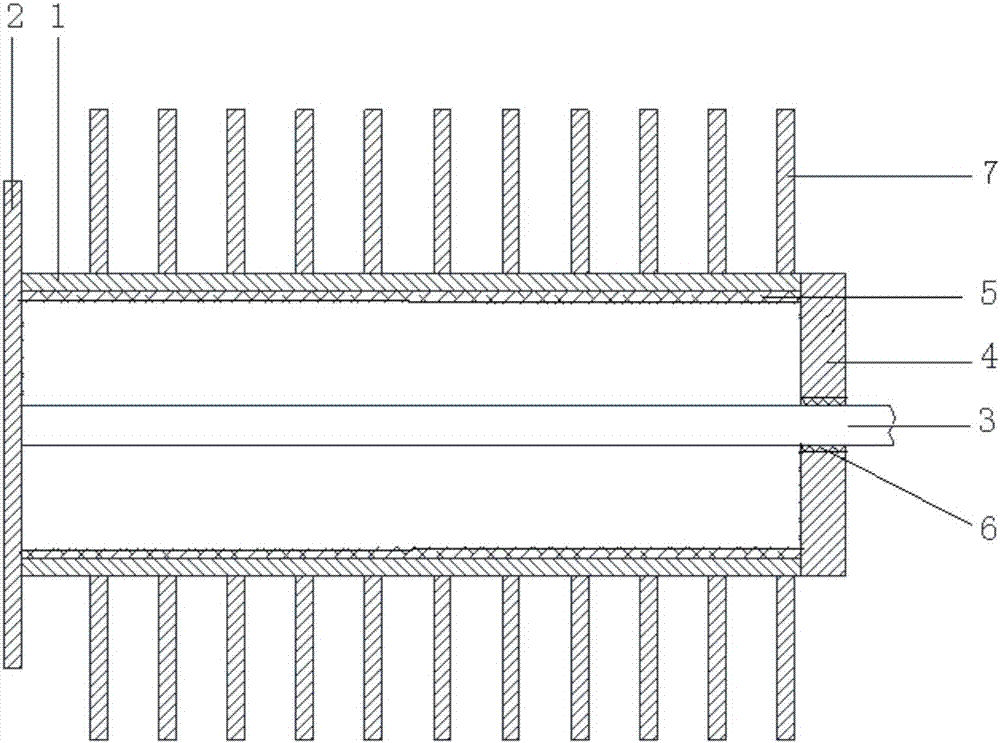

[0028] Such as figure 1 , 2 As shown, the magnetron cathode cable microwave leakage protection device in this example includes a sleeve 1, a connecting surface 2, an inner conductor 3, a short circuit 4, a resistive film 5, a ceramic insulating sheet 6 and a heat sink 7. In this example, the resistive thin film 5 is made of nickel-chromium alloy with a thickness of 0.02mm. In this example, the connection surface 2 is installed at the beginning of the sleeve 1, the short circuit 4 is installed at the end of the sleeve 1, and the ceramic insulating sheet 6 is installed between the inner conductor 3 and the short circuit 4, by figure 1 and figure 2 It can be seen that the cross-section of the sleeve in this example is circular, and the cooling fins 7 installed on the sleeve are installed at intervals along the axial direction of the s...

Embodiment 2

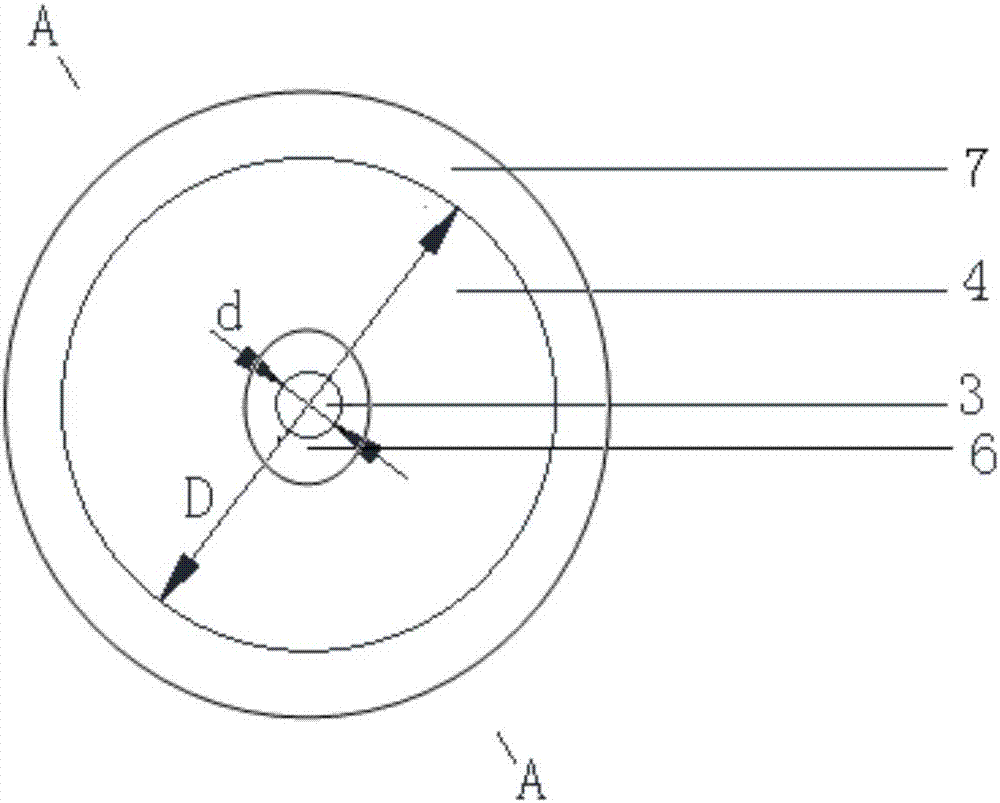

[0031] Such as image 3 , Figure 4 As shown, the heat dissipation device 7 of this example is a water-cooled box structure, forming a cylindrical annular airtight space along the outer surface of the sleeve 1, the lower left is the water inlet, and the upper right is the water outlet, so as to facilitate the heat generated during the microwave loss process. Distribute it in time. The heat dissipation device 7 of this example can be formed by welding the outer surface of the sleeve 1 with a hollow sleeve and metal sheets and copper sheets at both ends. The structure of the microwave leakage protection device for the cathode cable of the magnetron in this example is the same as that of Embodiment 1, and will not be repeated here.

[0032] Adopting the magnetron cathode cable microwave leakage protection device of the present invention replaces the design of the λ / 4 choke sleeve and the LC filter sleeve, reduces the design cost and the complexity of the system, and has the adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com