Microwave log-drying device

A drying equipment and microwave technology, applied in the field of microwave log drying equipment, can solve the problems of difficult temperature control, large electrothermal inertia, long drying time, etc., and achieve the effects of easy automatic control, high thermal efficiency and good heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

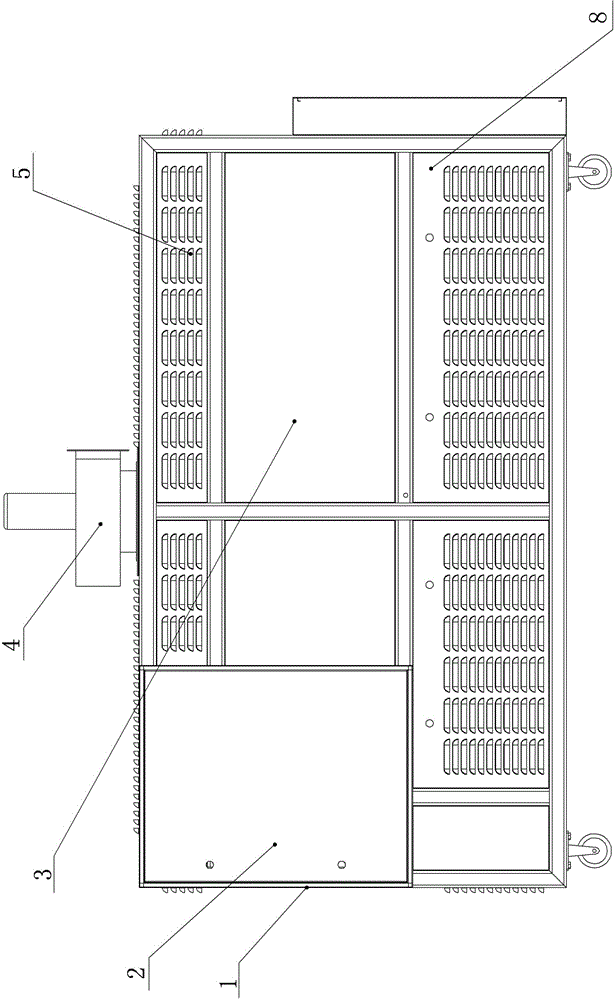

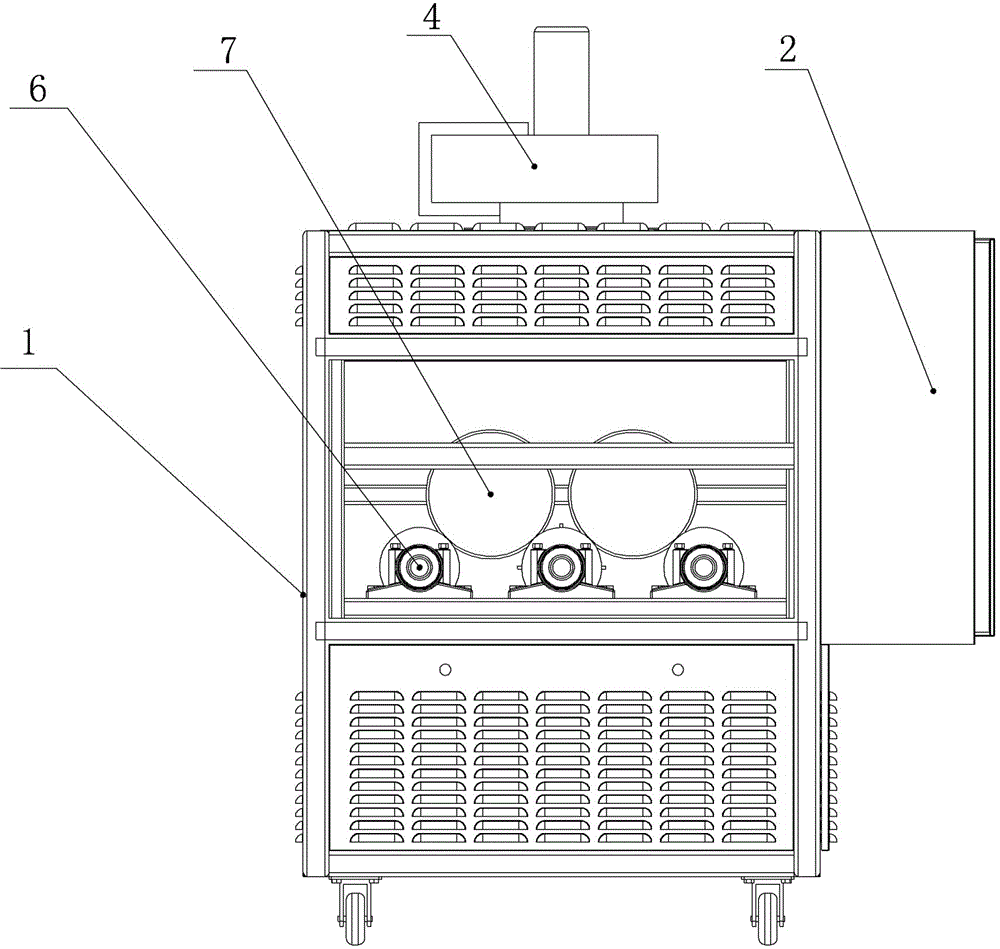

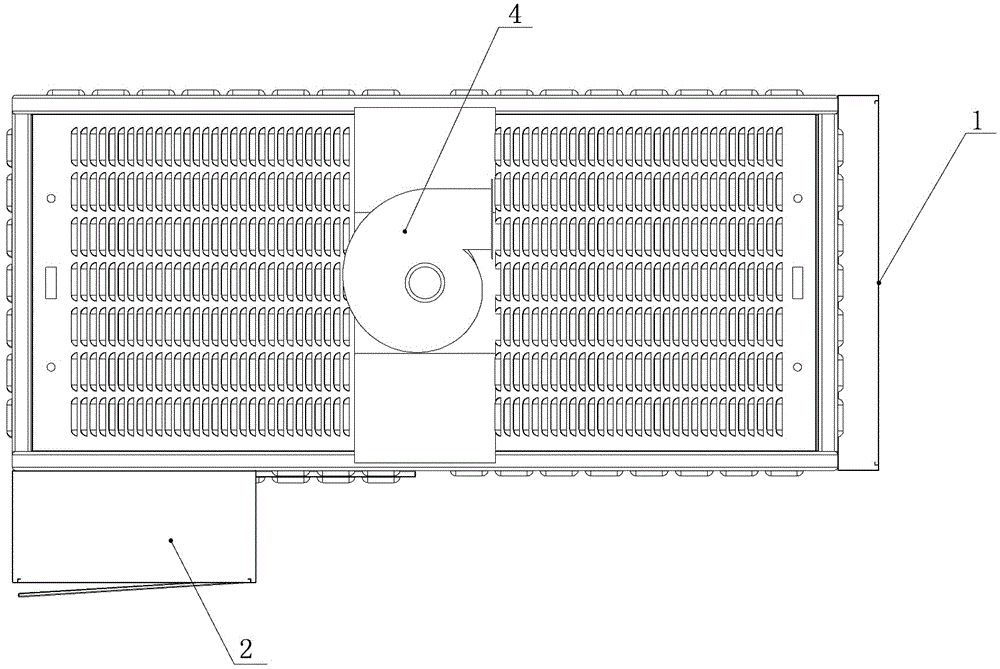

[0018] Embodiment one: see figure 1 — image 3 , The microwave round log drying equipment includes a box body 1, an electrical control cabinet 2, a power machine 8 and other components. Among them, the microwave generating source 5 is arranged on the top of the box body 1, the microwave acting cavity 3 is arranged on the bottom of the microwave generating source 5, the two ends of the microwave acting cavity 3 are respectively provided with doors, and a plurality of rows of rollers are arranged longitudinally in the microwave acting cavity 3 6. Each roller has the same size and height, and two adjacent rollers 6 cooperate to jointly support the rotation of the log 7, and the rollers 6 rotate forward and reverse. A power machine room is arranged below the roller 6, and a power machine 8 driving the rotation of the roller is installed in the power machine room. A fan 4 is arranged on the upper side of the box body 1 , and the air inlet of the fan 4 communicates with the microw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com