Magnetron cathode cable microwave leakage protective device

A technology of magnetron cathode and protective device, applied in the field of magnetron, can solve problems such as microwave leakage, and achieve the effect of preventing microwave leakage, reducing microwave leakage, and ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, a 2.45 GHz magnetron cathode cable microwave leakage protection sleeve is taken as an example for illustration.

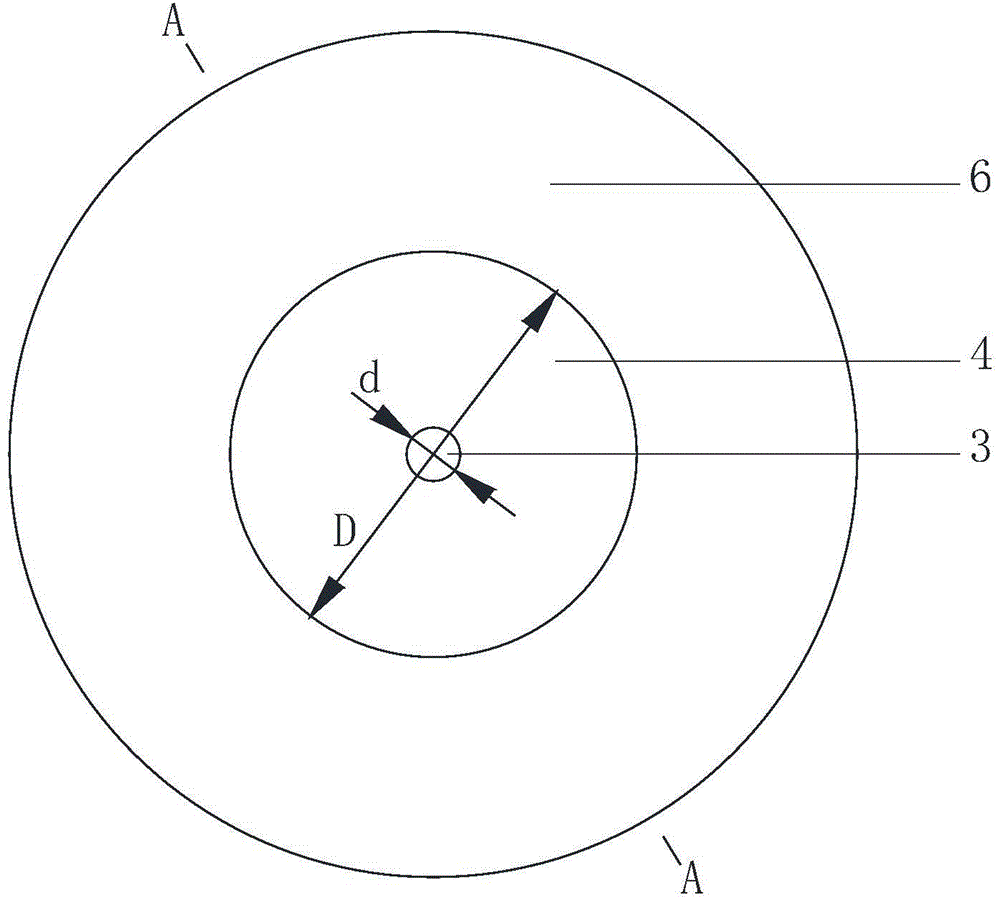

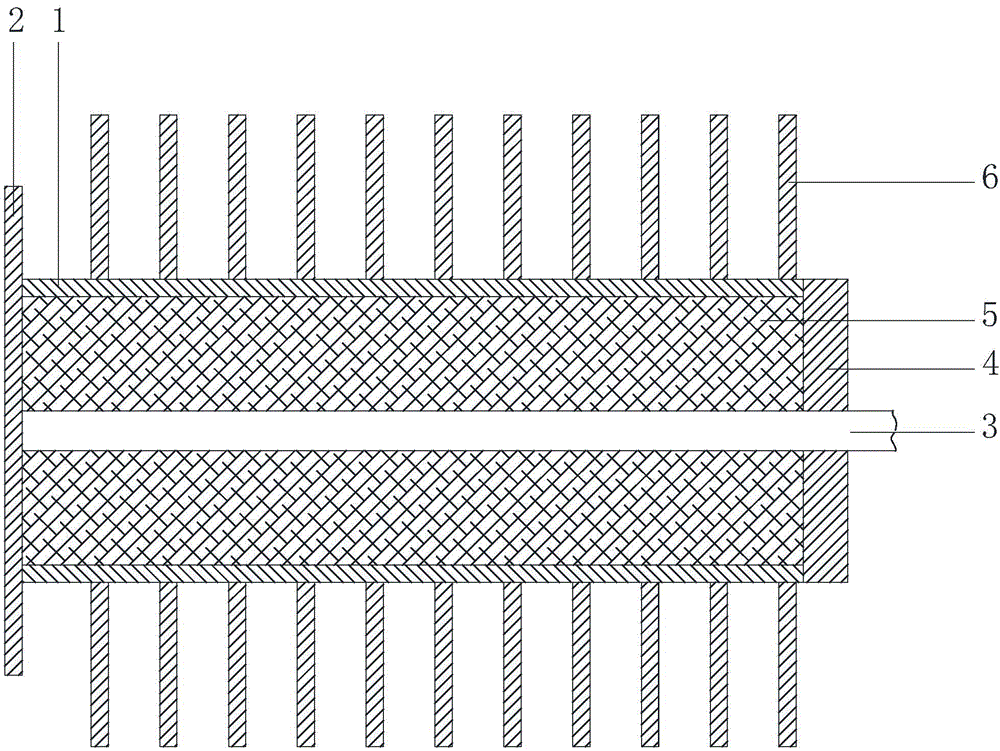

[0027] Such as figure 1 , 2 As shown, the magnetron cathode cable microwave leakage protection device in this example includes a sleeve 1 , a connecting surface 2 , a cathode cable 3 , a short circuit 4 , a wave-absorbing material 5 and a heat sink 6 . The absorbing material 5 of this example adopts the ECCOSORB SF type absorbing material of Emerson Company, and its electric loss tangent is tanδ E =5. In this example, the connection surface 2 is installed at the beginning of the sleeve 1, and the short circuit 4 is installed at the end of the sleeve 1. figure 1 with figure 2 It can be seen that the cross-section of the sleeve 1 in this example is circular, and the cooling fins 6 installed on the sleeve 1 are installed at intervals along the axial direction of the sleeve 1 to form a uniform distribution. The cathode cable 2 is connec...

Embodiment 2

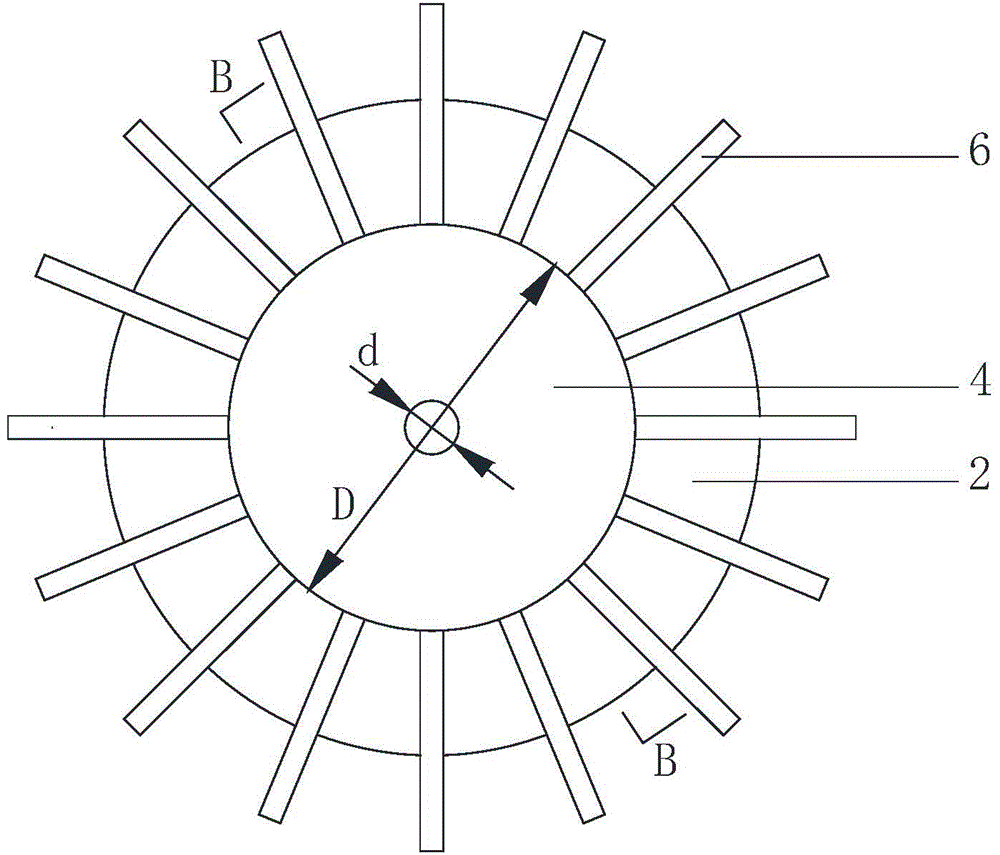

[0030] Such as image 3 , Figure 4 As shown, in this example, the cooling fins are evenly distributed along the radial direction of the sleeve 1, and the cooling fins are radial. In this example, the heat sink 6 can be formed by welding a rectangular copper sheet on the sleeve. The structure of the microwave leakage protection device for the cathode cable of the magnetron in this example is the same as that of Embodiment 1, and will not be repeated here.

[0031] Adopting the magnetron cathode cable microwave leakage protection device of the present invention replaces the design of the λ / 4 choke sleeve and the LC filter sleeve, reduces the design cost and the complexity of the system, and has the advantages of simple structure, compact size, and convenient processing. The characteristics of low cost and easy production.

[0032] Through actual measurement, before the device of the present invention is installed, the leakage electric field of the external field has reached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com