Fully coherent modular microwave heating device

A microwave heating equipment and modular technology, applied in microwave heating, electric/magnetic/electromagnetic heating, electric heating devices, etc., can solve problems such as microwave energy loss, electromagnetic interference, and personal safety threats, so as to prevent energy loss and reduce Effect of microwave leakage and high overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

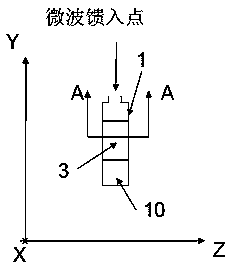

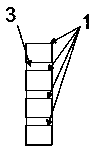

[0063] like Figure 1-3 shown.

[0064] A fully coherent modular microwave heating device includes 5 heating modules. Any one of the heating modules includes a cavity 3, and above the cavity 3, four microwave feeding waveguides arranged along the X-axis communicate with the cavity 3 and feed microwave energy thereinto. Working microwaves from the outside first supply microwave energy to each microwave feed-in waveguide through each microwave feed-in point. Different heating modules are arranged along the Z axis, and the cavities 3 are sequentially connected along the Z axis.

[0065] On each of the heating modules, below the cavity 3, corresponding to each microwave feeding waveguide, a lower end short circuit whose cross section in the horizontal plane has the same shape as the corresponding microwave feeding waveguide is provided short-circuit waveguide. All short-circuit waveguides have the same size in the Y-axis direction.

[0066] It constitutes a fully coherent mod...

Embodiment 2

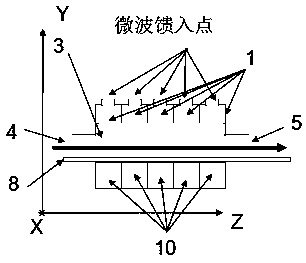

[0079] like Figure 4 and Figure 5 shown.

[0080] Compared with Embodiment 1, the only difference is that only one heating module is used, and only one microwave feeding waveguide 1 and short-circuit waveguide 10 are used in this heating module.

[0081] This implementation example can constitute a microwave oven. At this time, any feed port 4 and discharge port 5 may not be provided. The microwave door panel is arranged on one side of the -X axis of the cavity. Compared with general microwave ovens where working microwaves are fed from the side and the working microwaves in the microwave oven work in multiple modes, this implementation example feeds working microwaves from above. At the same time, by controlling the waveguide mode of the working microwave in the cavity to be the fundamental mode TE10 wave, the uniformity of the microwave in the X direction is guaranteed.

Embodiment 3

[0083] like Figure 4 and Image 6 shown.

[0084] Compared with Embodiment 2, the only difference is that four microwave feeding waveguides 1 are arranged along the X direction on one heating module. All the working microwaves fed into the waveguide are coherent waves with the same spectrum, the same amplitude and the same phase. It can be used as a fully coherent modular microwave heating device, and it can be used in occasions where the X direction is wider than that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com