A 2450mhz high-power continuous wave magnetron and its preparation method

A magnetron, high-power technology, applied in the field of magnetron, can solve the problems of microwave power affecting heating effect, restricting production scale, and large heating object, and achieving the effects of superior performance, low microwave leakage and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

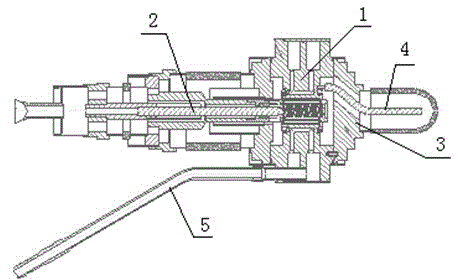

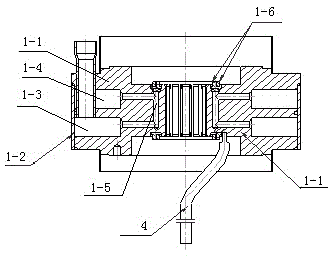

[0044] like Figure 1 to Figure 4 As shown, a 2450MHz high-power continuous wave magnetron includes an anode cavity assembly (1), a cathode lead-out wire assembly (2), an output window assembly (3) connected to the anode cavity assembly (1), and a fixed The output antenna (4) on the anode cavity assembly (1), the other end of the output antenna (4) is located inside the output window assembly (3); the anode cavity assembly (1) is connected with cavity cooling water inlet and outlet pipes (5);

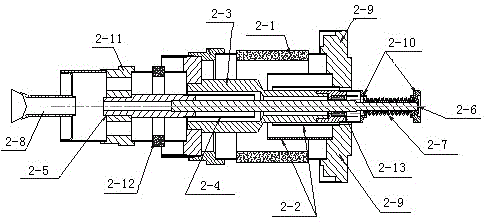

[0045] The cathode lead-out wire combination (2) includes an insulating ceramic cylinder (2-1), a choke cylinder (2-2) located in the insulating ceramic cylinder (2-1), and a choke cylinder (2-2) located in the choke cylinder (2-2) The support barrel (2-3) of the Lead rod (2-6), filament (2-7) mounted on one end of lead rod (2-6), exhaust pipe (2-8) connected to one end of inner lead assembly (2-5), choke The upper pole shoe (2-9) is connected to one end of the barrel (2-2), the shie...

Embodiment 2

[0050] A preparation method of a 2450MHz high-power continuous wave magnetron, comprising the following steps:

[0051] (a) Preparation of the cathode lead-out wire combination: first, gold is used as the solder, and the auxiliary welding mold (2-14) (such as Figure 5 shown), weld the upper pole shoe (2-9), the choke tube (2-2), and the insulating ceramic tube (2-1) to form the upper pole shoe combination, wherein the choke tube (2-2) is located in the insulating ceramic tube inside the tube (2-1), and keep it coaxial; then use the argon arc welding method to weld the support tube (2-3) in the choke tube (2-2), and keep the two coaxial; then The other end of the lead rod (2-6) is assembled in the support cylinder (2-3), and a gemstone porcelain (2-13) is welded between the lead rod (2-6) and the support cylinder (2-3); auxiliary Welding dies (2-15) (eg Image 6 shown), and finally the filament (2-7) is welded to the other end of the lead rod (2-6) by argon arc welding;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com