Tunnel type multi-mode microwave resonant cavity with rotation function

A microwave resonator with multiple functions, which is applied in microwave heating, electric/magnetic/electromagnetic heating, electric heating devices, etc., can solve the problems of poor radiation uniformity of microwave resonators and reduced focus of microwave energy Good uniformity of illumination, fewer microwave focusing hot spots, and uniform distribution of microwave energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

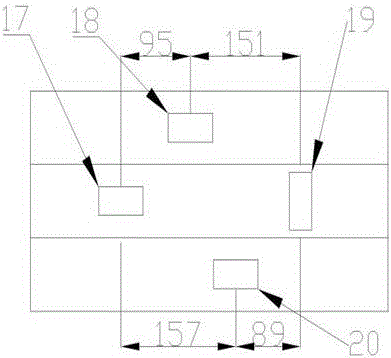

[0022] Example 1: If figure 1 As shown, the exterior of the two ends of the hexagonal main cavity 16 are fixed by two sets of four hexagonal flanges 7 fixed together by bolts. The left and right ends of the body 16 are sealed by two hexagonal end caps 9 . The four waveguides 10 installed externally can be installed with four 1KW microwave tubes, the infrared temperature probe 11 monitors the surface temperature of the ceramic tube 12, the hexagonal flange 7 and the bearing seat 6 are fixed by 6 bolts, and the bearing seat has installed bearings 1 , the bearing 1 cooperates with the left ceramic tube outer sleeve 4 and the right ceramic tube outer sleeve 13. Connected to each other, the inside is matched with the ceramic tube 12, and there is an air distribution plate 15 between the outer sleeve 13 of the ceramic tube and the exhaust pipe 14, which has the functions of air distribution and microwave leakage prevention. The outside of the left ceramic tube outer sleeve 4 coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com