Patents

Literature

88 results about "Bioelectric Energy Sources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implantable devices which convert biological energy (chemical energy of the metabolism of continuously regenerating body fluids or mechanical energy of periodic movements) to electrical energy. The sources include biogalvanic cells, biofuel cells, and ionic concentration cells.

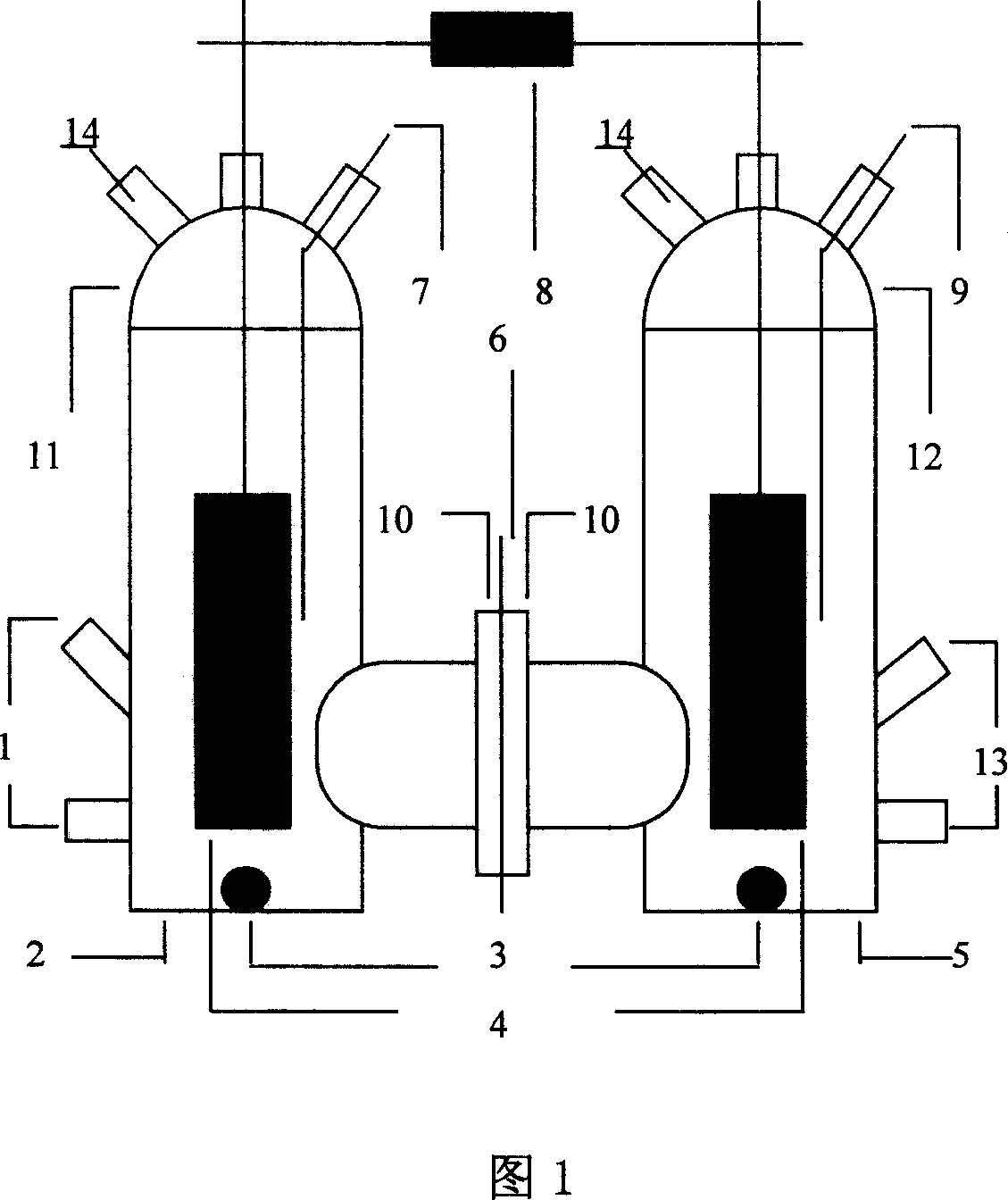

Bioreactor-direct microbe fuel cell and use thereof

InactiveCN1949577AEfficient conversion of chemical energyWide variety of sourcesBiochemical fuel cellsMaltoseBioreactor

The invention belongs to bioenergy source utilizing field, especially relating to a bioreactor-direct microbial fuel cell and its use. And it mainly comprises tubular anode chamber and cathode chamber and proton exchange membrane to isolate the two chambers, where both the electrodes are of unpolished high-purity graphite rod; the anode is inoculated with bacteria, where before inoculation, charging aseptic N2-CO2(80:20) mixed gas to remove all oxygen gas from culture medium and after inoculation, slowly charging mixed gas and keeping strict anaerobic environment; the cathode keeps charging aseptic air and keeps dissolved oxygen concentration in the aseptic air; in the two chambers, slowly blending with magnetic blender; before used, the battery device is processed by high pressure moisture-heat sterilization. And the invention can use glucose, fructose, xylose, sucrose, maltose, and other sugar-containing matters and organic waste water as raw materials and directly converts their chemical energies into electric energy, having characters of no medium toxicity, good stability, moderate operating conditions, clean power generation, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

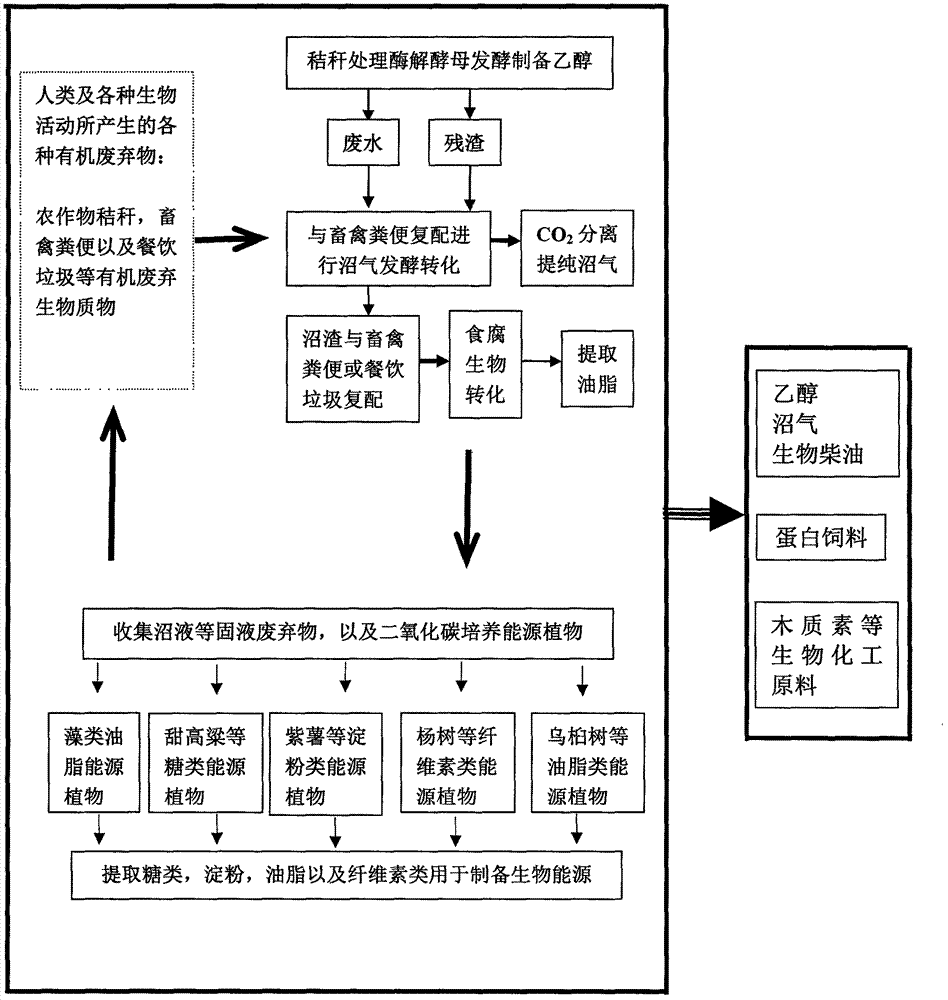

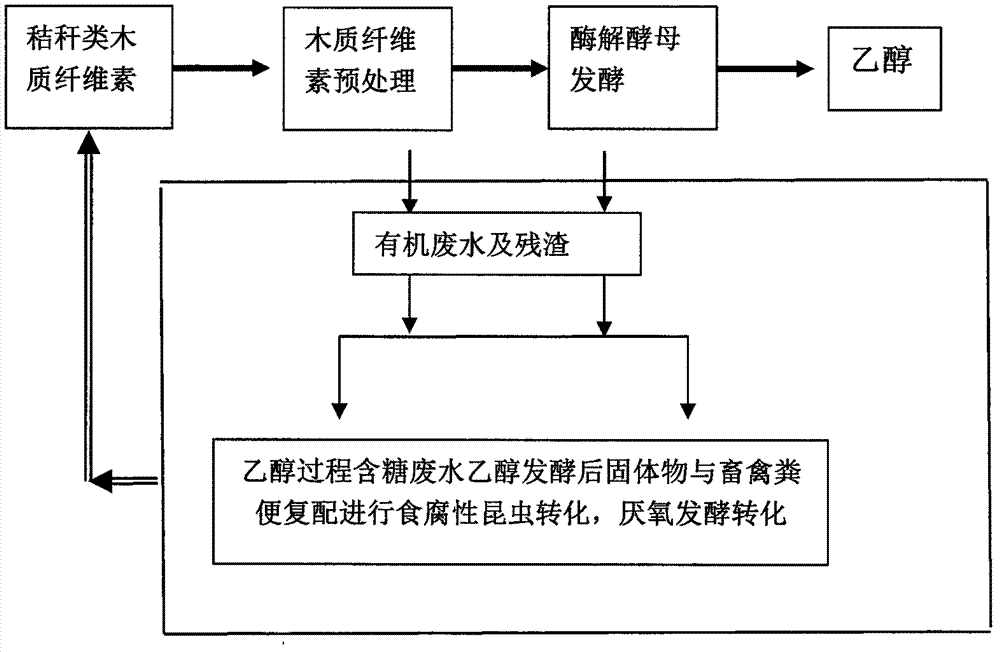

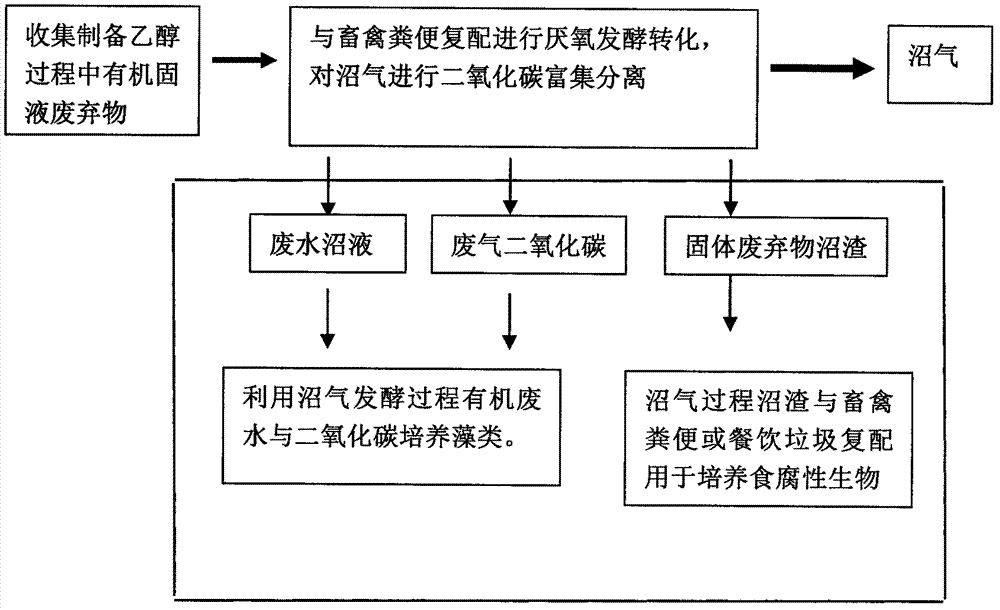

Co-production method for preparing ethanol, biogas and biodiesel by using organic waste

ActiveCN103923948AHigh yieldAbundant raw materialsBio-organic fraction processingClimate change adaptationCelluloseBiodiesel

The present invention provides a method for co-producing ethanol, biodiesel, biogas and other biological energy sources by using organic waste as a raw material. The method comprises that: a lignocellulose raw material is pretreated, enzymolysis sugar production and ethanol fermentation are performed, livestock and poultry manure is added to the enzymolysis residue, anaerobic fermentation is performed to produce biogas, the biogas residue is converted through saprophagous insects, organic wastewater is adopted to culture microalgae, and the insects and the microalgae are adopted to prepare the biodiesel; and an energy source plant conversion and utilization system is adopted to collect the process wastewater, the biogas liquid, the waste gas, the biogas residue and other solids and separate and enrich the biogas process carbon dioxide so as to be used for culture of sweet sorghum, sugar cane and other sugar-containing energy source plants, purple sweet potato and other starch-containing energy source plants, aspen and other cellulose-containing energy source plants, and sapium sebiferum and other grease-containing energy source plants, and the biomass produced by the energy source plants can further be used for extracting sugar sources, starch, fat and cellulose for biological energy source production.

Owner:HUAZHONG AGRI UNIV +1

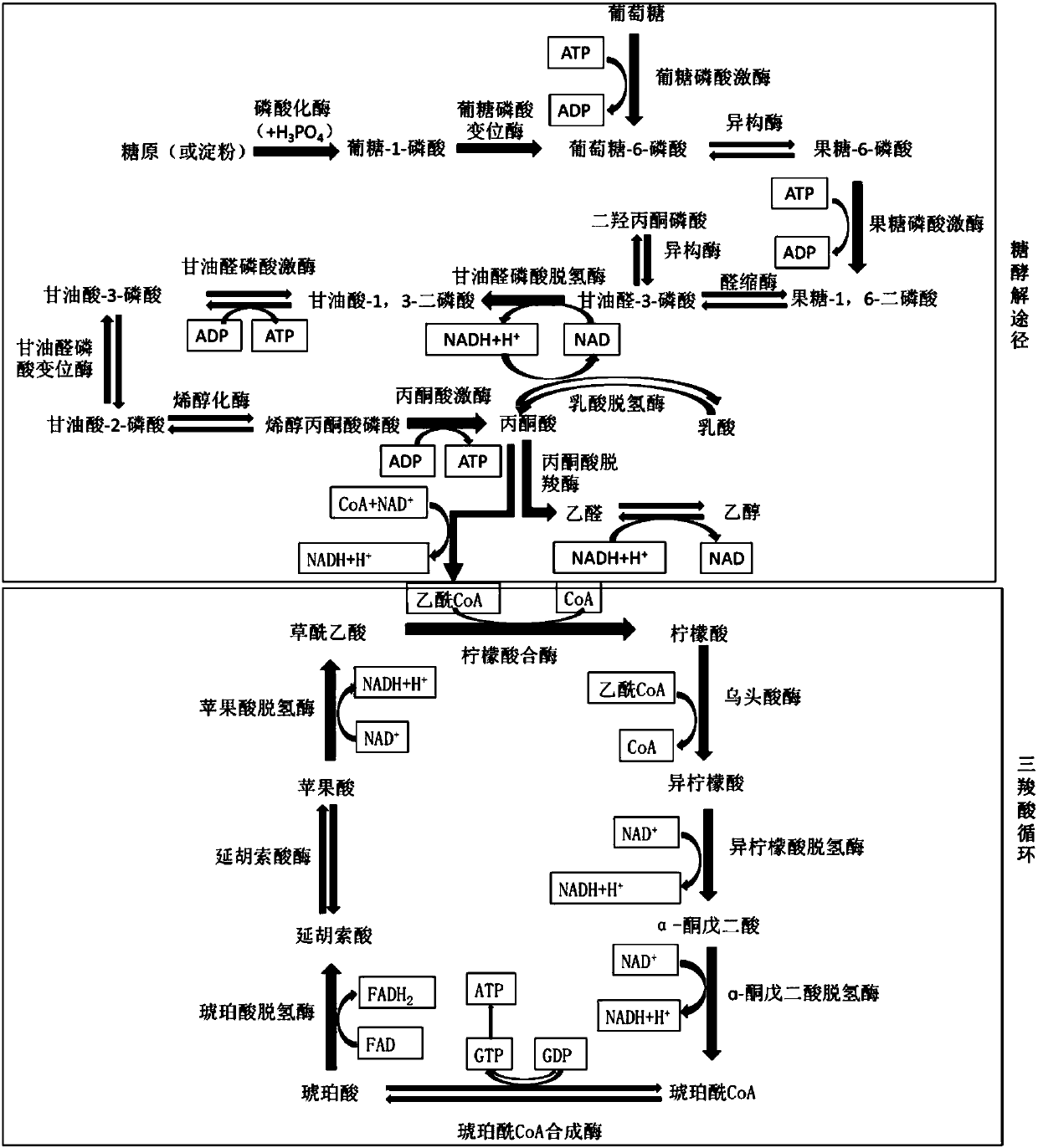

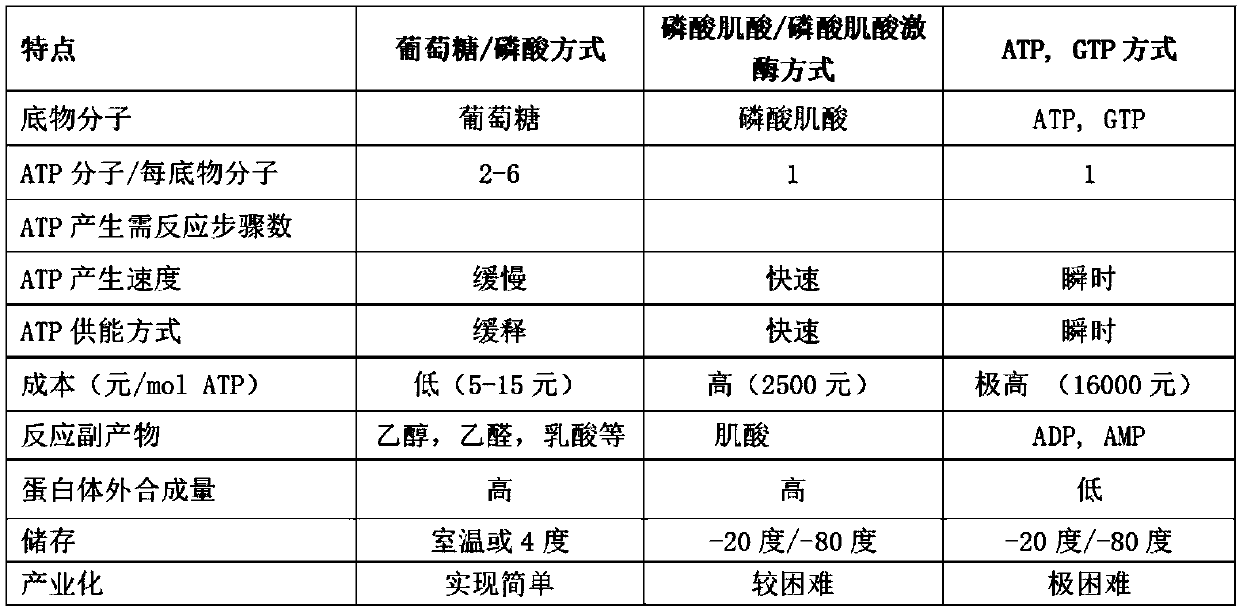

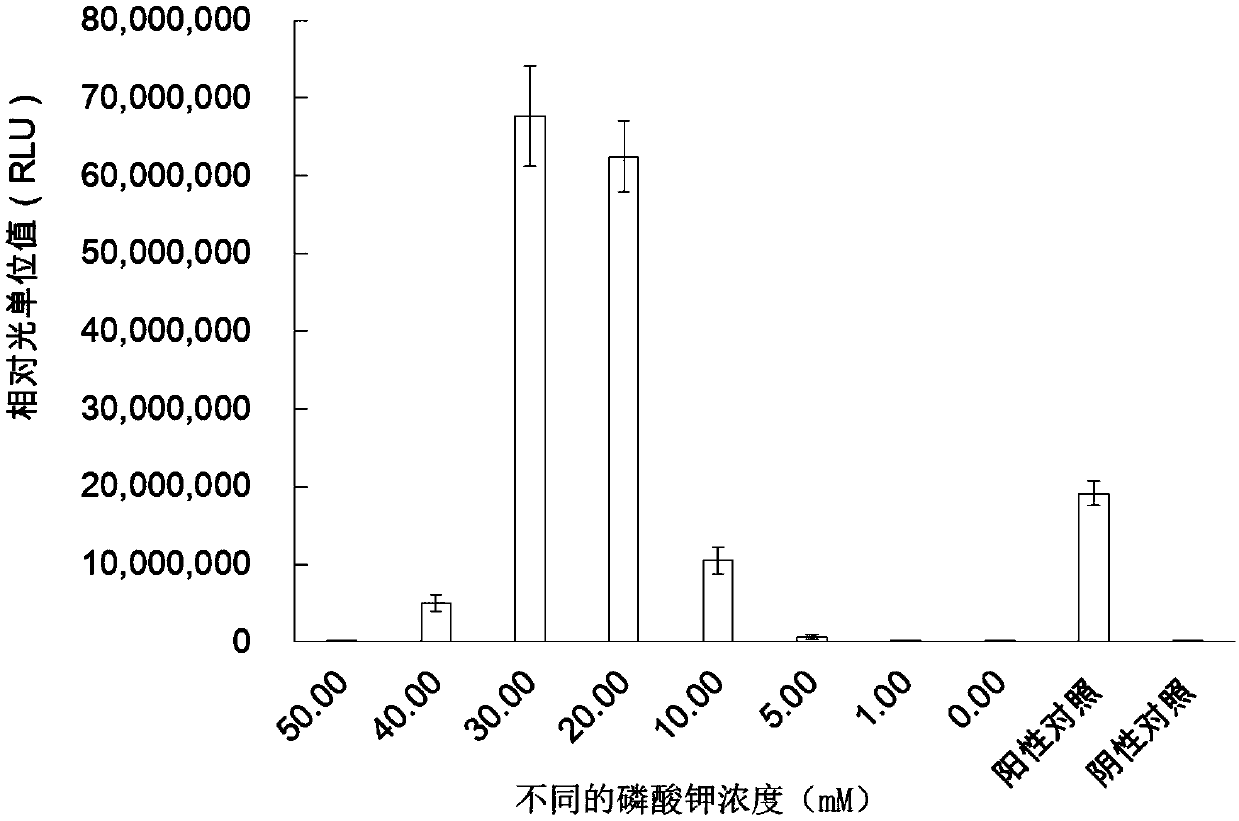

New-type efficient biological energy regeneration system (BES) for in-vitro biological reaction system, kit and preparation method

The invention provides a new-type efficient biological energy regeneration system (BES) for an in-vitro biological reaction system, a kit and a preparation method. The biological energy regeneration system can be applied for energy supply of in-vitro biosynthesis, and applied to a cell-free in-vitro biological reaction system. Cost of the in-vitro biosynthesis is saved, and capacity of in-vitro cell-free biosynthesis is improved.

Owner:KANGMA SHANGHAI BIOTECH LTD

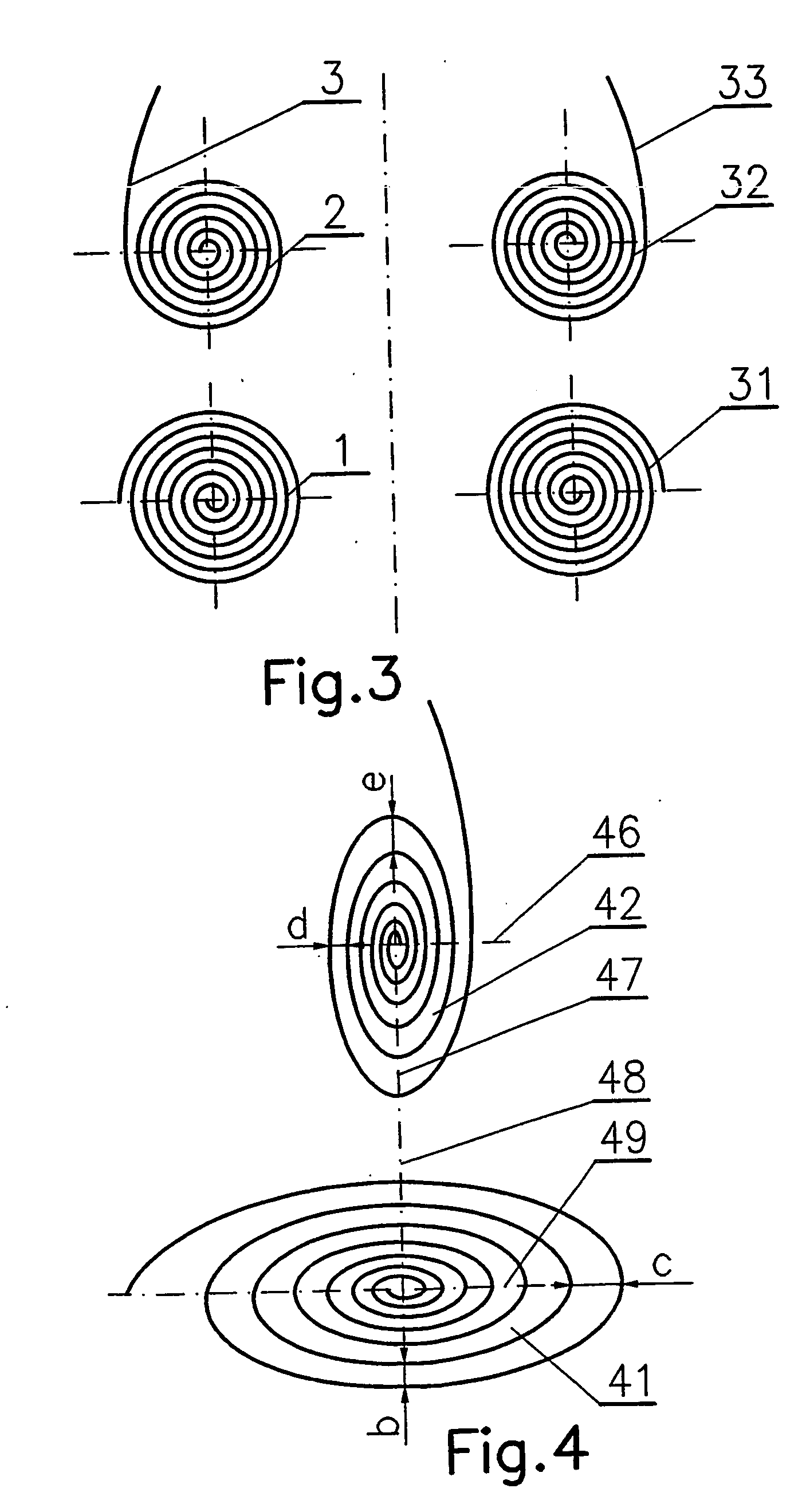

Method for generating hydrogen and converting electricity generation with biological fuel cell reactor

InactiveCN101560524ASolve the problem of multi-function and convenient useImprove efficiencyClimate change adaptationBioloigcal waste fertilisersWhole bodyEngineering

The invention provides a method for generating hydrogen and converting electricity generation with a biological fuel cell reactor, relating to the filed of environment and biological energy source. The invention uses the biological fuel cell (BFC) reactor to treat solid or liquid organic wastes and convert organic matter into hydrogen gas fuel with high added value or electric energy. By adjusting the process of generating hydrogen / converting electricity generation electrode of the BFC reactor, the invention can improve the conversion efficiency and the use efficiency of the energy. The method couples the electrode of the anaerobic BFC reactor with microorganism into a whole body, ferments the organic matter in way of anaerobism as required, and links a bioelectricity chemical unit to react so as to generate hydrogen or convert electricity generation. By directly converting the electrode process of the BFC reactor of the organic matter biological fermentation, the method can develop the clean biological energy source for generating hydrogen or generating electricity, reasonably switches the hydrogen generation into the electricity generation, and improves reacting efficiency.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for preparing titanium dioxide ceramic micro filter membrane on the porous stainless steel base

InactiveCN101053781AHigh strengthAccelerated corrosionSemi-permeable membranesChemical industryAdhesive

The invention discloses a method for preparing TiO2 ceramics micro-filter film on the porous stainless steel matrix, and to the field of metallurgical chemistry. The technical proposal is that: titanic acid four dinbutyl phthalate is hydrolyzed to get TiO2 sol, dilute, add binder, aging the film coating liquid, wash the porous stainless steel matrix, coat film, dry, heat treatment the xerogel film, and then get the TiO2 ceramics micro-filter film. The TiO2 ceramics micro-filter film with an aperture of 0.3-0.8 mum can be prepared on the porous stainless steel matrix with an aperture of 1 mum based on the said technical proposal, and the ceramics micro-filter film can be prepared to be micro-filter film component to replace the organic micro-filter film used at present, is used abroad in the field of electron, foodstuff, environmental protection, chemical industry, metallurgy, medicine, biology, energy sources, petroleum, bionics and so on, can separate the water, waste water and other suspended liquid material, and has a broad market prospect.

Owner:SHAANXI NORMAL UNIV

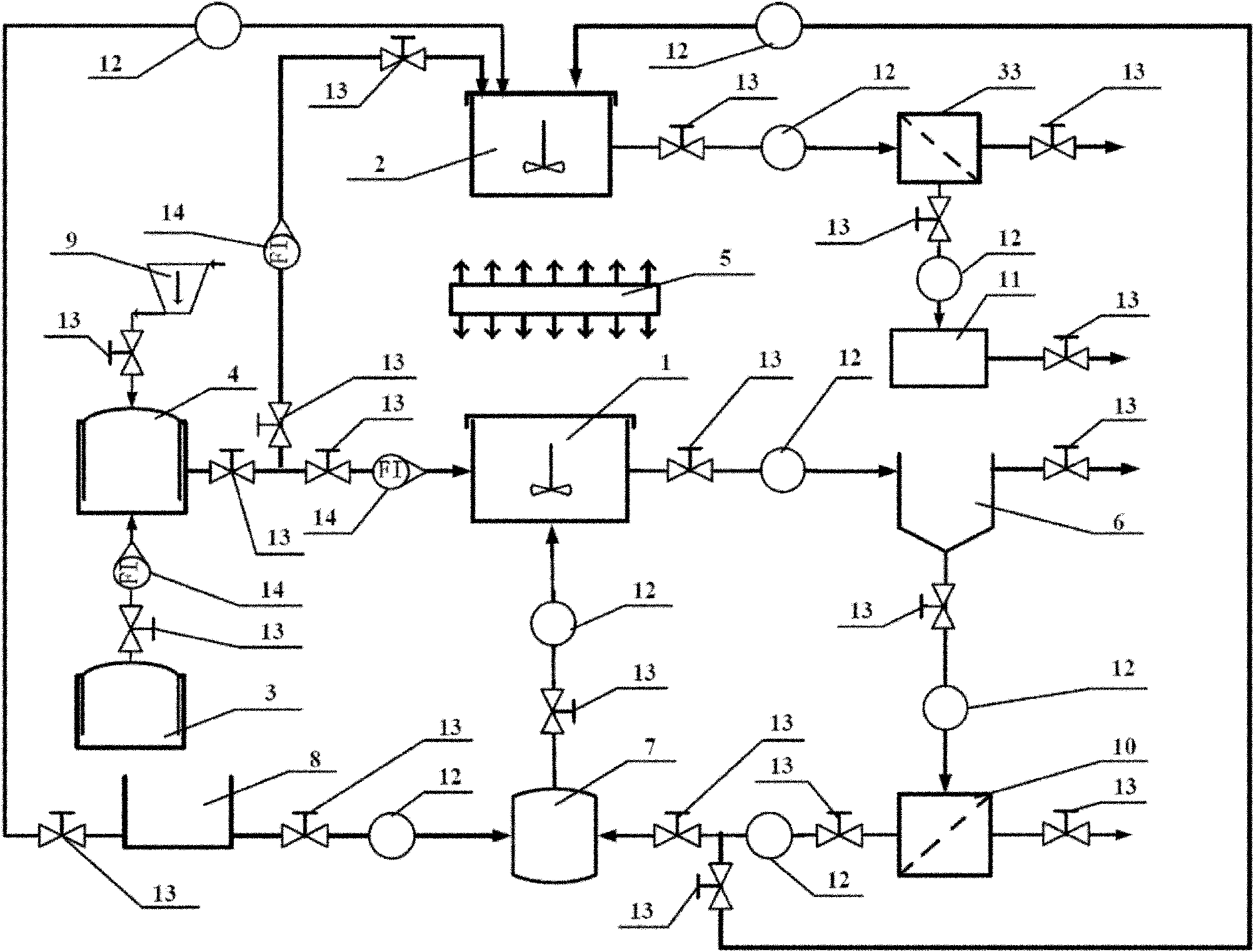

System for treating sewage and producing biological oil by using microalgae and method

ActiveCN102583767AReduced batch processing timeImprove utilization efficiencyEnergy based wastewater treatmentFermentationOil and greaseMixing tank

The invention provides a system for treating sewage and producing biological oil by using microalgae. A first light source device and a second light source device of the system are respectively arranged in a photo-biological reactor and an oil accumulating tank; a CO2 gas supply device is respectively connected with the photo-biological reactor and the oil accumulating tank through air passages; a sewage sedimentation tank is connected with the oil accumulating tank through a pipeline and connected with the photo-biological reactor via a pipeline through a microalgal liquid mixing tank; the photo-biological reactor is respectively connected with the microalgal liquid mixing tank and the oil accumulating tank via pipelines through a first microalgal liquid separating device; and the oil accumulating tank is connected with a second separating device through a pipeline. The invention further provides a method for using the system to treat sewage and produce biological oil. Through the use of the invention, the production of biological energy sources and other byproducts (such as protein, cosmetic raw materials, animal feed and the like) is realized while sewage is treated, so that the production cost is lowered, and the comprehensive utilization of waste resources and the energy-saving and emission-reducing green production are achieved. The invention is suitable for cultivating microalgae from a laboratory to a factory, is skillful and unique in design, and is applicable to large-scale promotion and application.

Owner:JIANGNAN UNIV

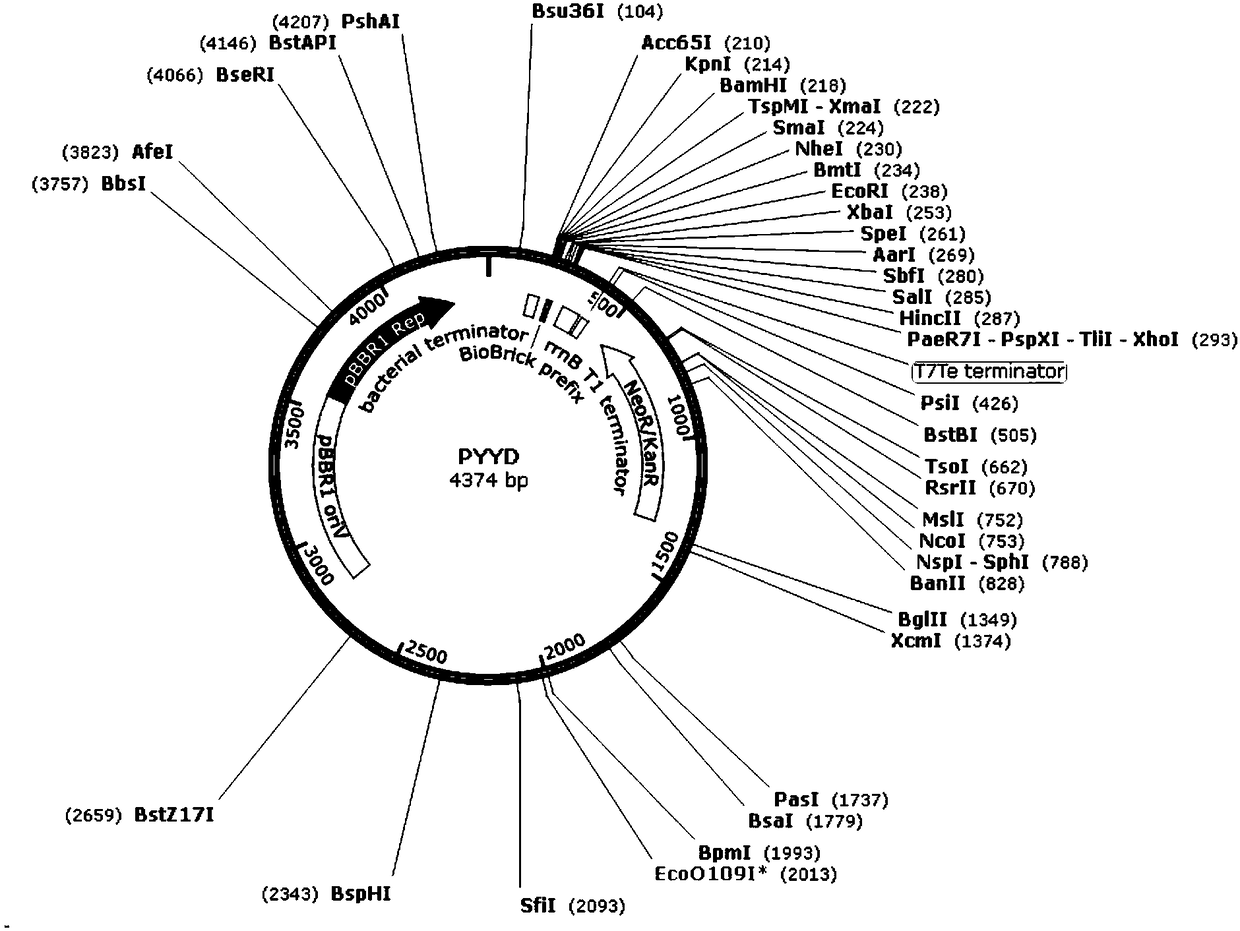

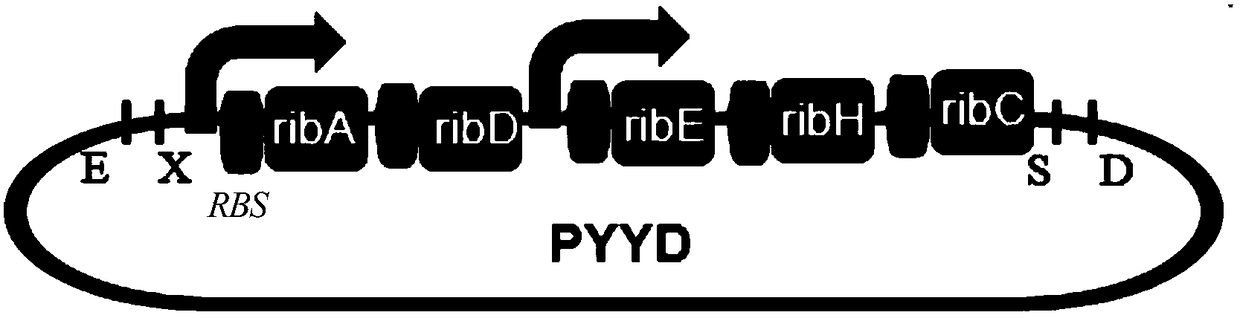

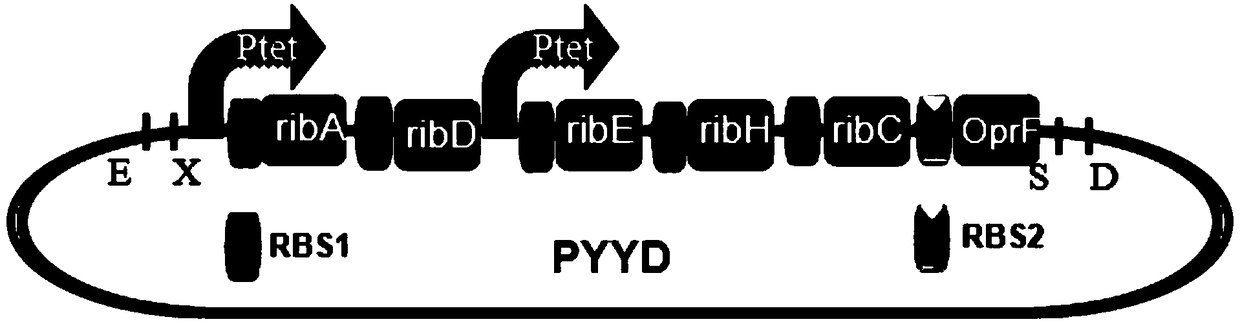

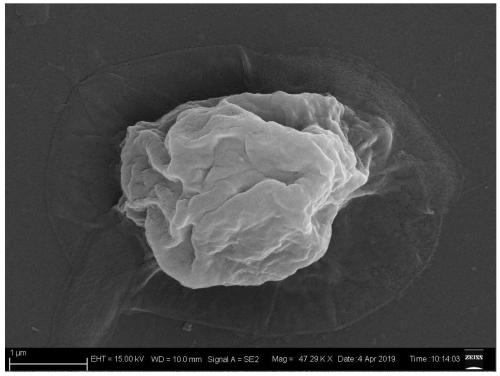

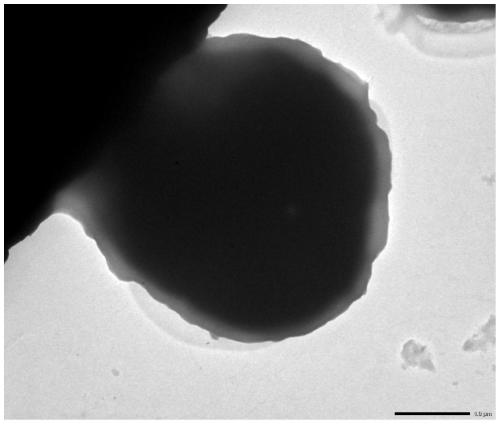

Recombinant plasmid, recombinant shewanella and electricity generation method of microbial fuel cell (MFC)

The invention relates to the technical field of biological energy, and discloses a recombinant plasmid, recombinant shewanella and an electricity generation method of a microbial fuel cell (MFC). A promoter suitable for the shewanella is selected to be connected with an exogenous electron carrier flavins gene, so that the shewanella is enabled to generate more flavis, and the electrochemical performance of the MFC is improved; furthermore, a mutant strain is combined with a porin oprF gene, so that the formation of a biofilm is further improved, the going in and out of the flavins in the shewanella can be promoted, the electron transfer rate is increased, and electrons are better transmitted. Furthermore, biocompatible graphene oxide (GO) is used and can be self-assembled into the three-dimensional multilayer biofilm together with the shewanella, so that the thickness of the biofilm and the anode biocapacity are further greatly improved; the operation is simple and fast, and the electrochemical performance of the MFC is effectively improved.

Owner:TIANJIN UNIV +1

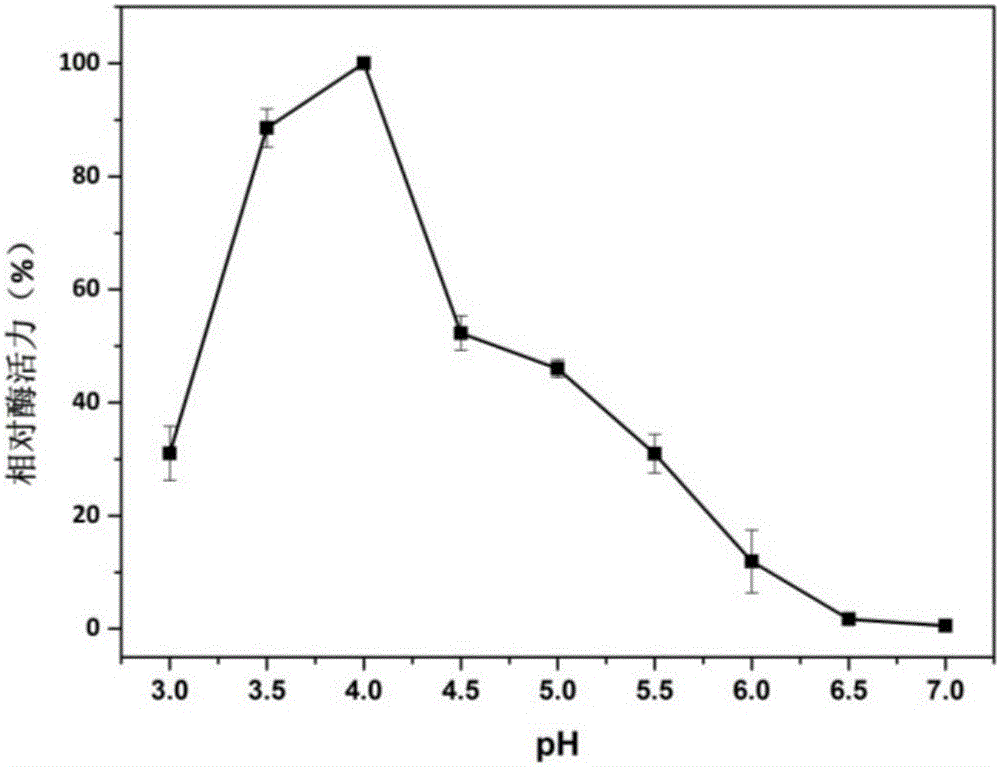

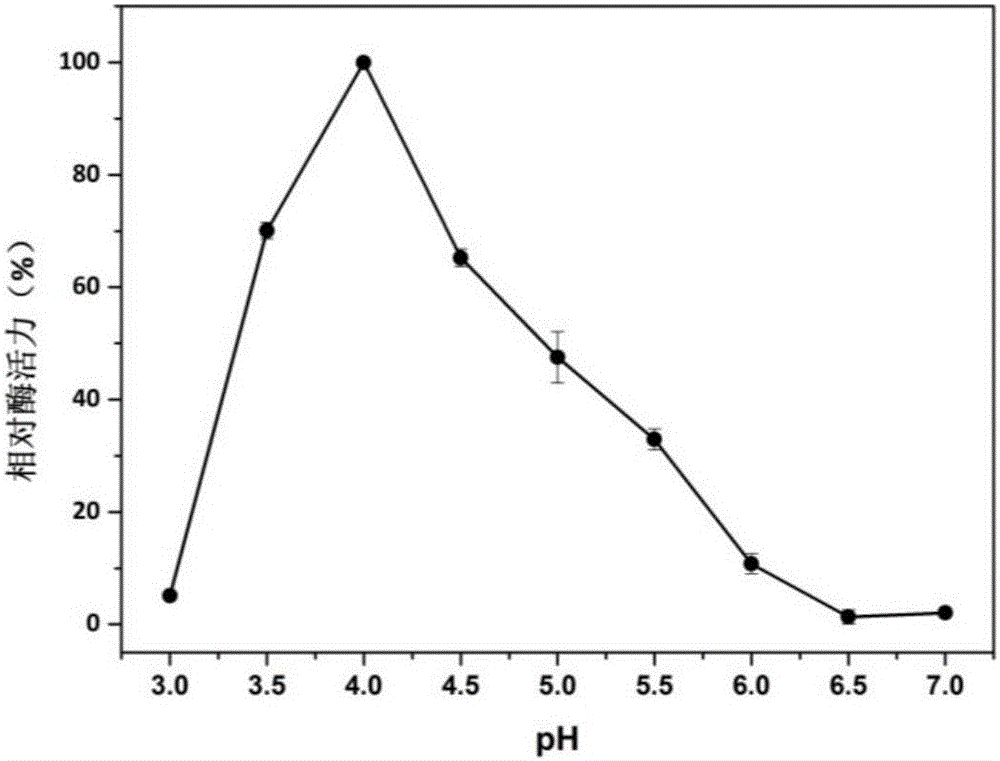

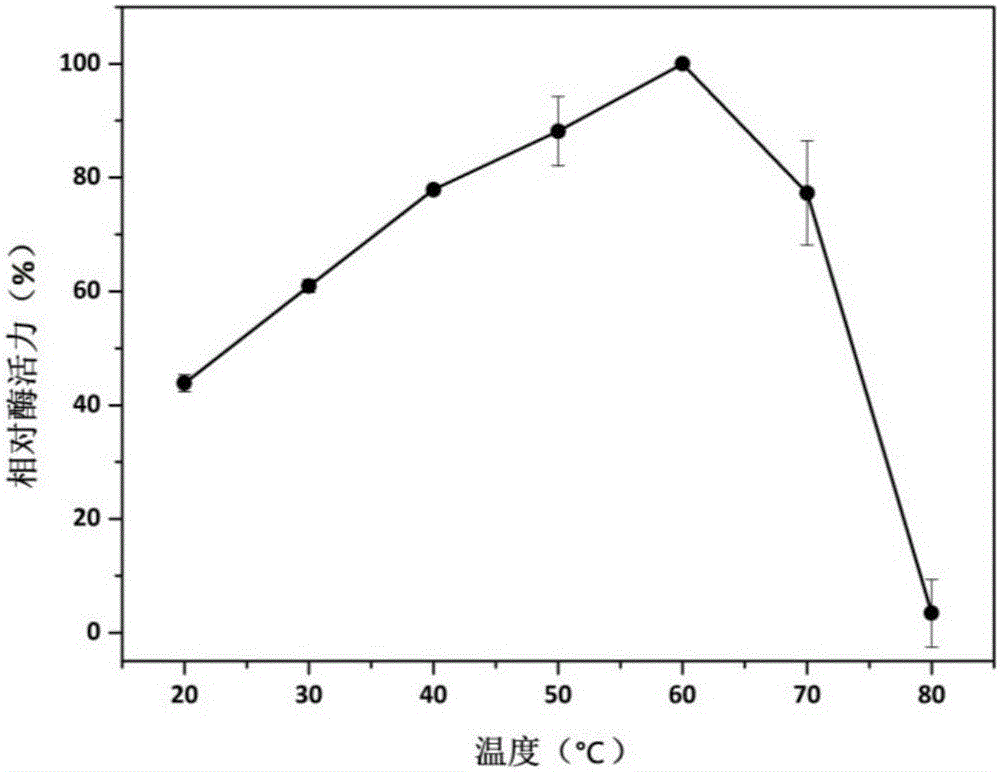

Manganese peroxidase MNP-2, gene and applications thereof

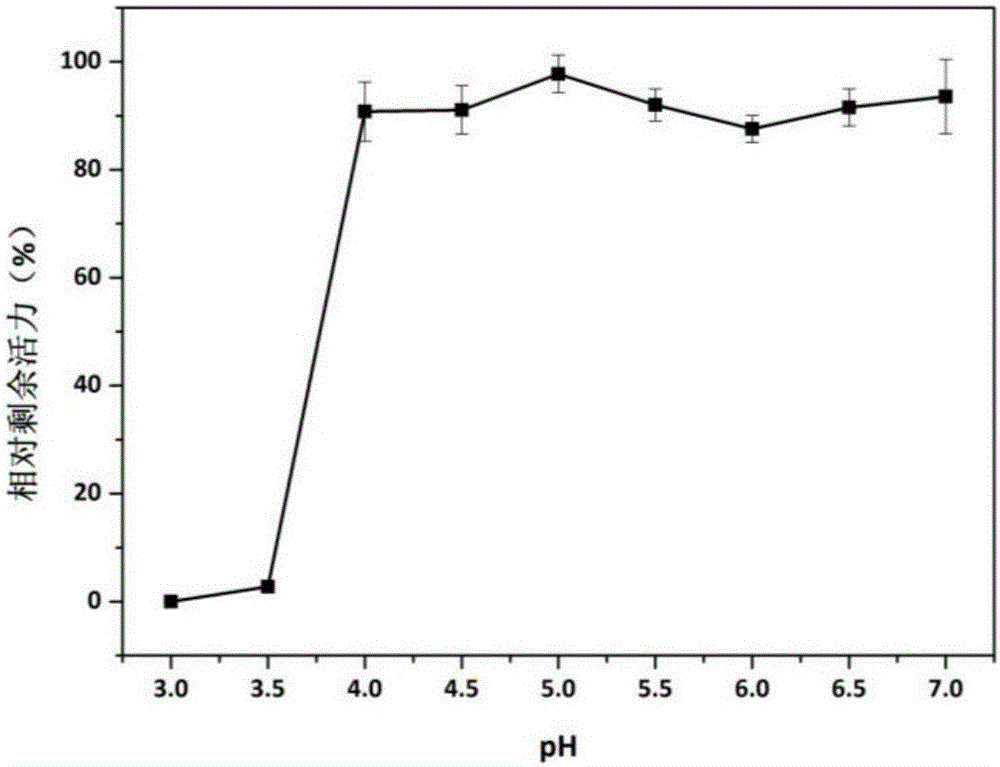

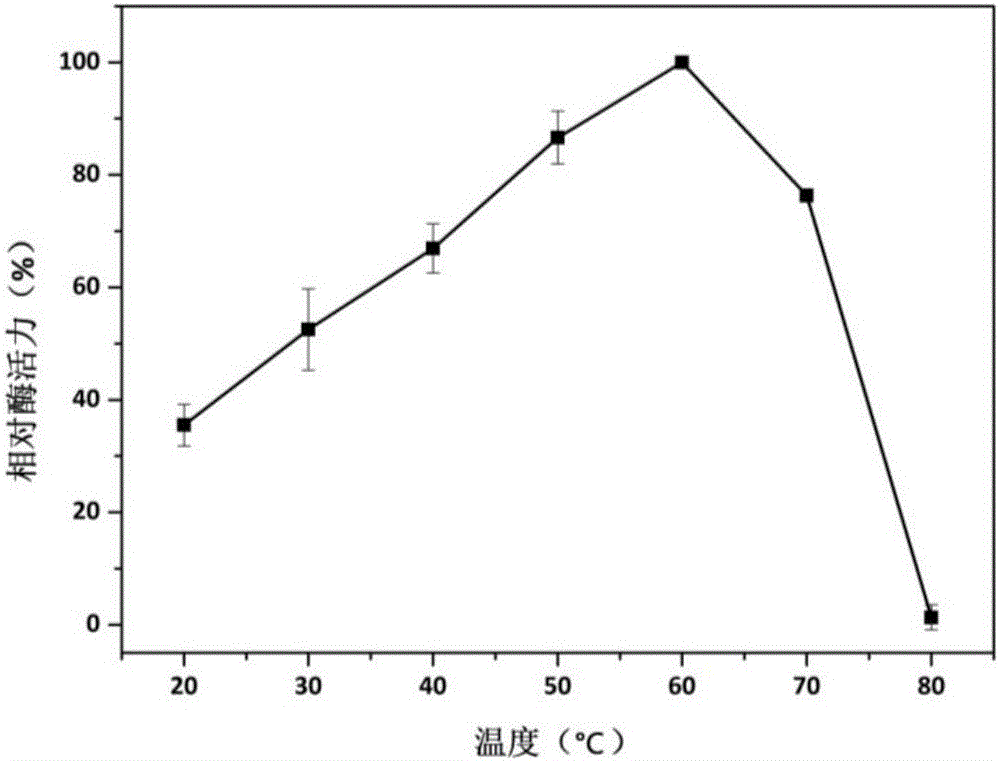

The present invention relates to the field of genetic engineering, particularly to a manganese peroxidase MNP-2, a gene and applications thereof. The present invention provides a manganese peroxidase MNP-2 derived from lignocellulose degradation bacteria, wherein the amino acid sequence is represented by SEQ ID NO.1. According to the present invention, the manganese peroxidase has the following properties that the optimal pH value is 4.0, the optimal temperature is 60 DEG C, the manganese peroxidase MNP-2 can effectively degrade dyes having different structure types, and can be used as the novel enzyme preparation so as to be widely used in the fields of bioremediation, biological energy sources, textile, papermaking, food industry, and the like.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

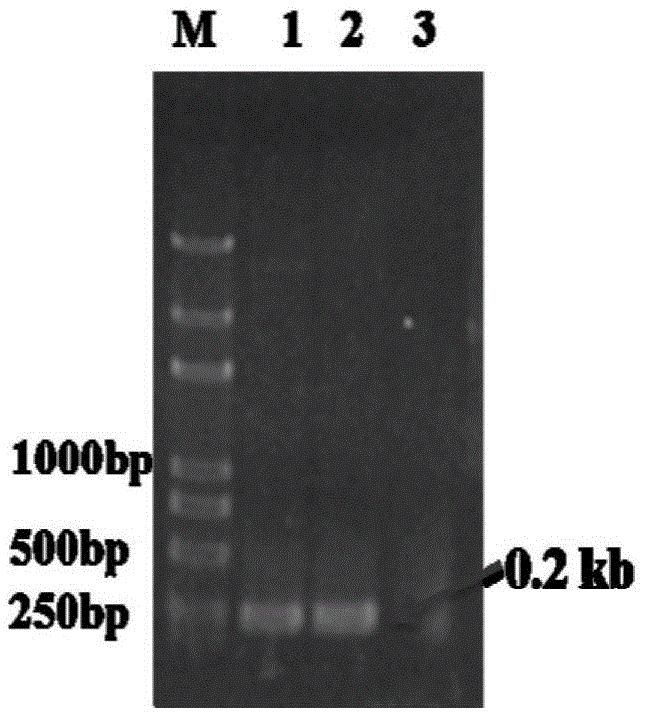

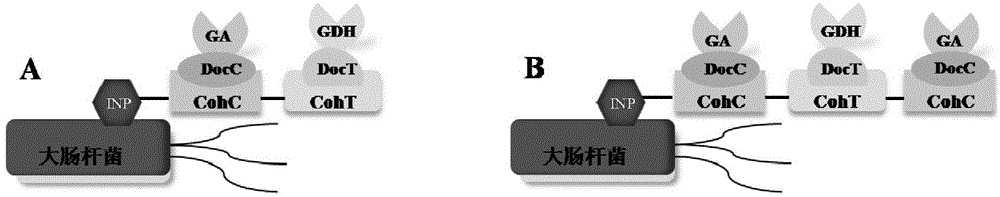

Sequential enzyme surface co-display system and use thereof

InactiveCN105624077ASolve complexityFix stability issuesBacteriaMicrobiological testing/measurementSurface displayProtein target

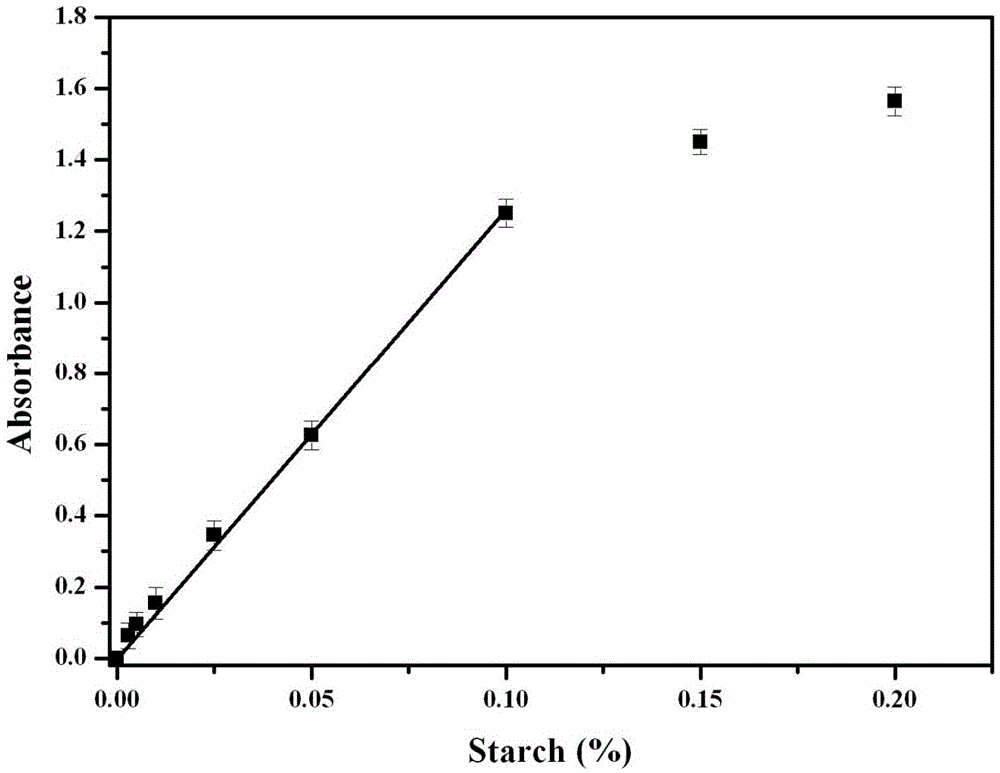

The invention relates to the technical field of biotechnology and analysis technology and concretely relates to a sequential enzyme proportional bacterial surface co-display system and a use thereof. The sequential enzyme surface co-display system comprises a gene sequence (ga) for coding a target protein glucoamylase, a gene sequence (gdh-m) of a glucose dehydrogenase mutant, a gene sequence (coh-dock) of a cohesion-dockerin protein and a gene sequence inaPb-N of an ice nucleating protein N end structural domain for transmembrane positioning and transport. The bacterial surface display system is used for starch detection. The starch detection method has high sensitivity and simple processes. The whole cell catalyst can be used in the fields of biosensing, foods, medicine and health, and biological energy sources.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

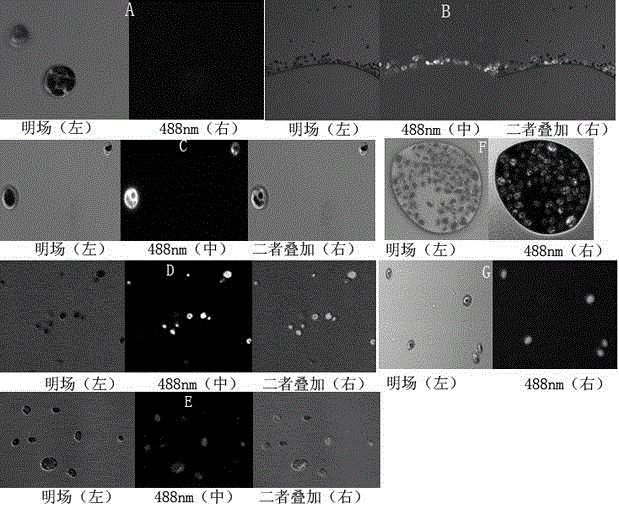

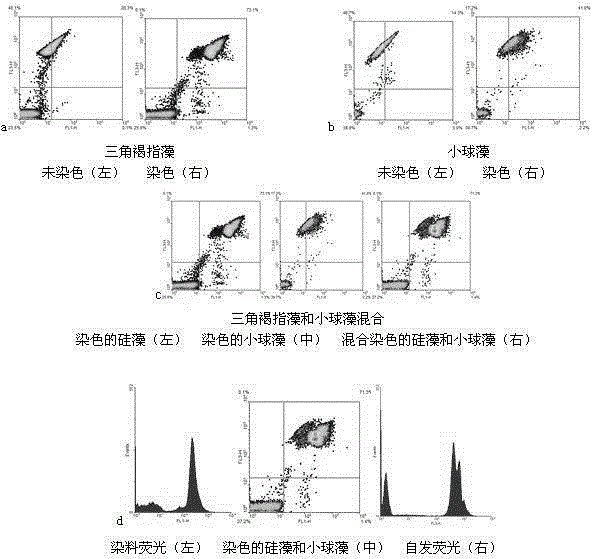

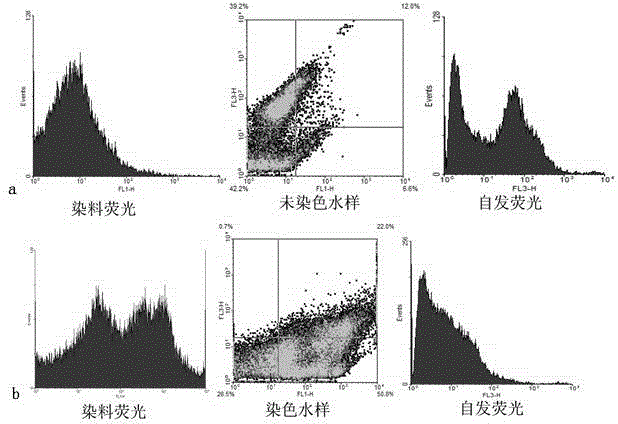

Method of screening high grease algae from natural water body

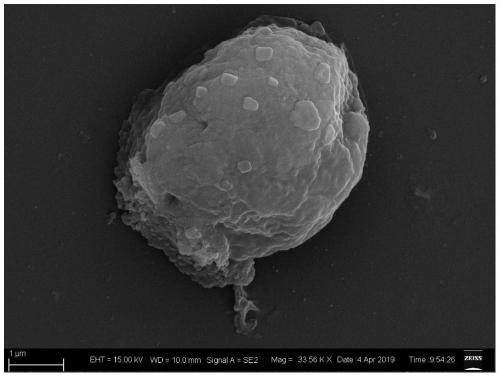

InactiveCN103555587AHigh intracellular lipid contentRapid identificationUnicellular algaeMicroorganism based processesFluorescenceBioelectric Energy Sources

The invention relates to the technical field of algae screening, and specifically discloses a method of screening high grease algae from a natural water body quickly and effectively. The method comprises the following steps: firstly, dyeing a collected algae water sample by a fluorescent dye; then, quickly screening high grease excellent algae groups in the natural water body environment through a flow cytometry screening technology with a sorter; and further separately culturing under a condition of a laboratory to obtain pure micro-algae seeds with high grease content. The method provided by the invention can quickly and conveniently separate algae with high grease content from natural samples in various types, provide a genetic resources center for development of a biological energy, and have prospect and potential of producing algae energy resources on a large scale.

Owner:SANYA INST OF DEEP SEA SCI & ENG

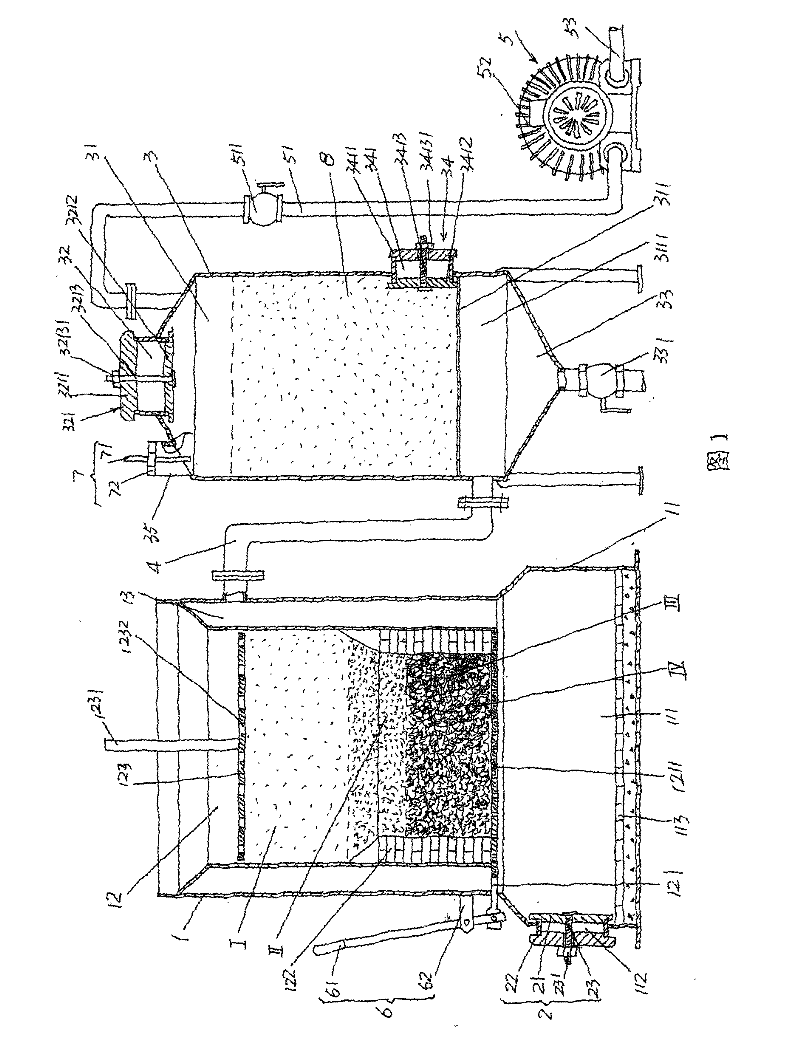

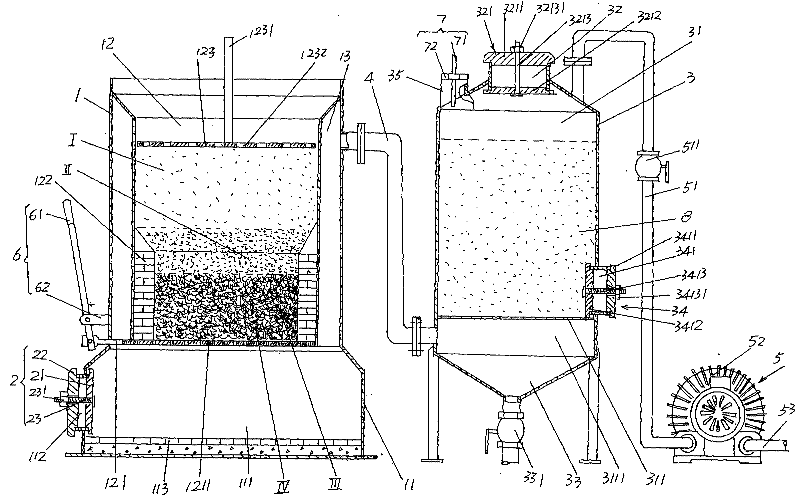

Biological gasifying furnace

InactiveCN101531925BEfficient use ofCombined combustion mitigationCombustible gas productionBioelectric Energy SourcesEngineering

The invention relates to a biological gasifying furnace, and belongs to the technical field of furnaces. The biological gasifying furnace comprises a furnace body, at least one cleaning hole opening and closing device, a purifying cylinder, an adapting pipe and a fuel gas lead-out device, wherein the furnace body consists of a base, a furnace chamber and a spacer bush, the base corresponds to thelower part of the furnace chamber, the lateral part is provided with a cleaning hole, and the spacer bush is formed between the inner wall of the furnace body and the outer wall of the furnace chamber; the cleaning hole opening and closing device is arranged on the cleaning hole; the purifying cylinder is provided with a filter material chamber, the top of the purifying cylinder is provided with a filter material intake which is matched with a first opening and closing door, the bottom of the purifying cylinder is provided with a tar hopper of which the bottom is provided with a valve, the lower lateral part of the purifying cylinder is provided with a filter material outlet which is matched with a second opening and closing door, the bottom of the filter material chamber is provided witha filter material cushion, and a bleed air chamber is formed between the filter material cushion and the tar hopper; one end of the adapting pipe is connected with the furnace body and communicated with the spacer bush, while the other end is connected with the lower lateral part of the purifying cylinder and communicated with the bleed air chamber; and the fuel gas lead-out device is connected and communicated with the purifying cylinder. The biological gasifying furnace has the advantages of making biological energy source utilized effectively and protecting the environment.

Owner:常熟市多能铆焊厂

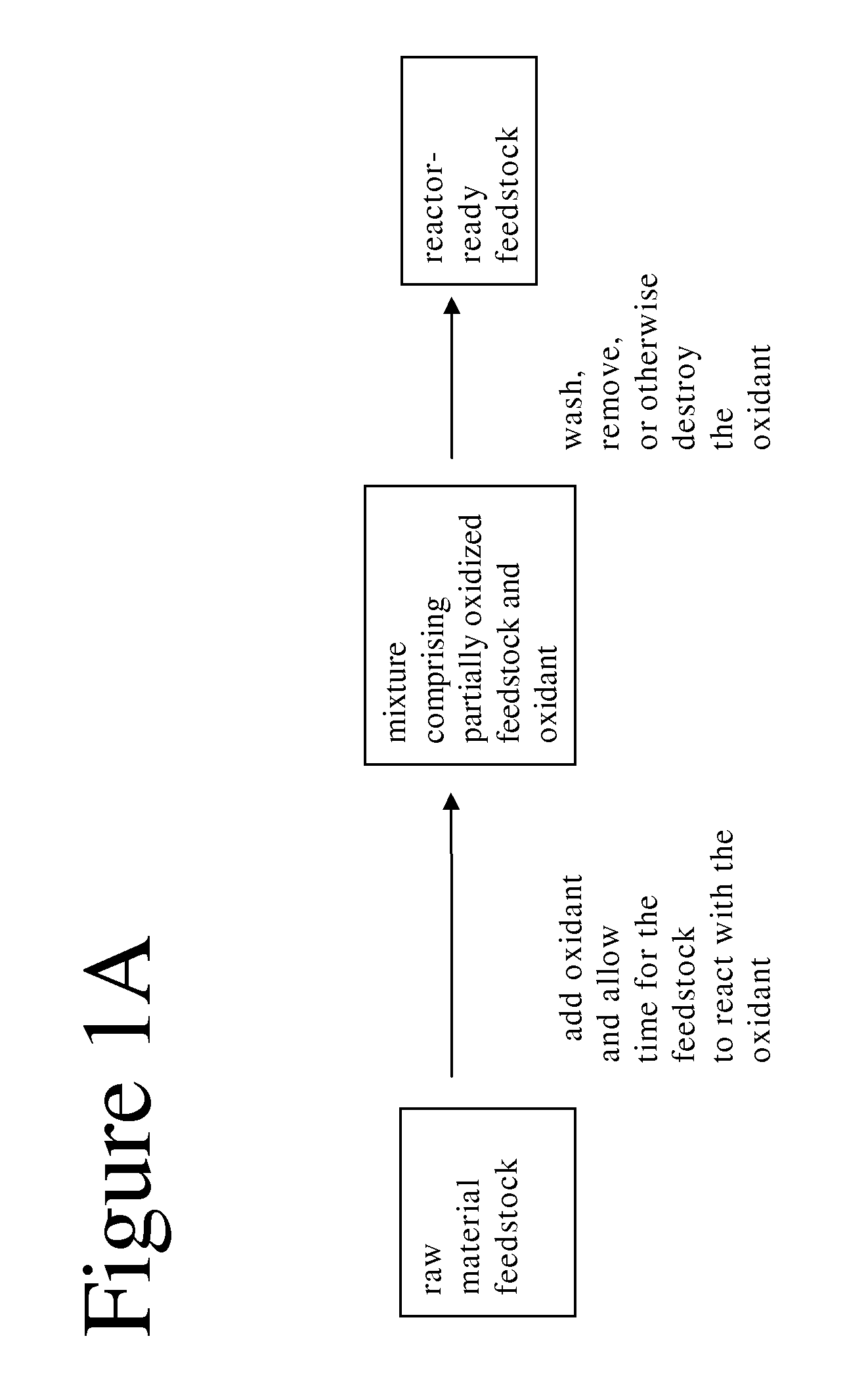

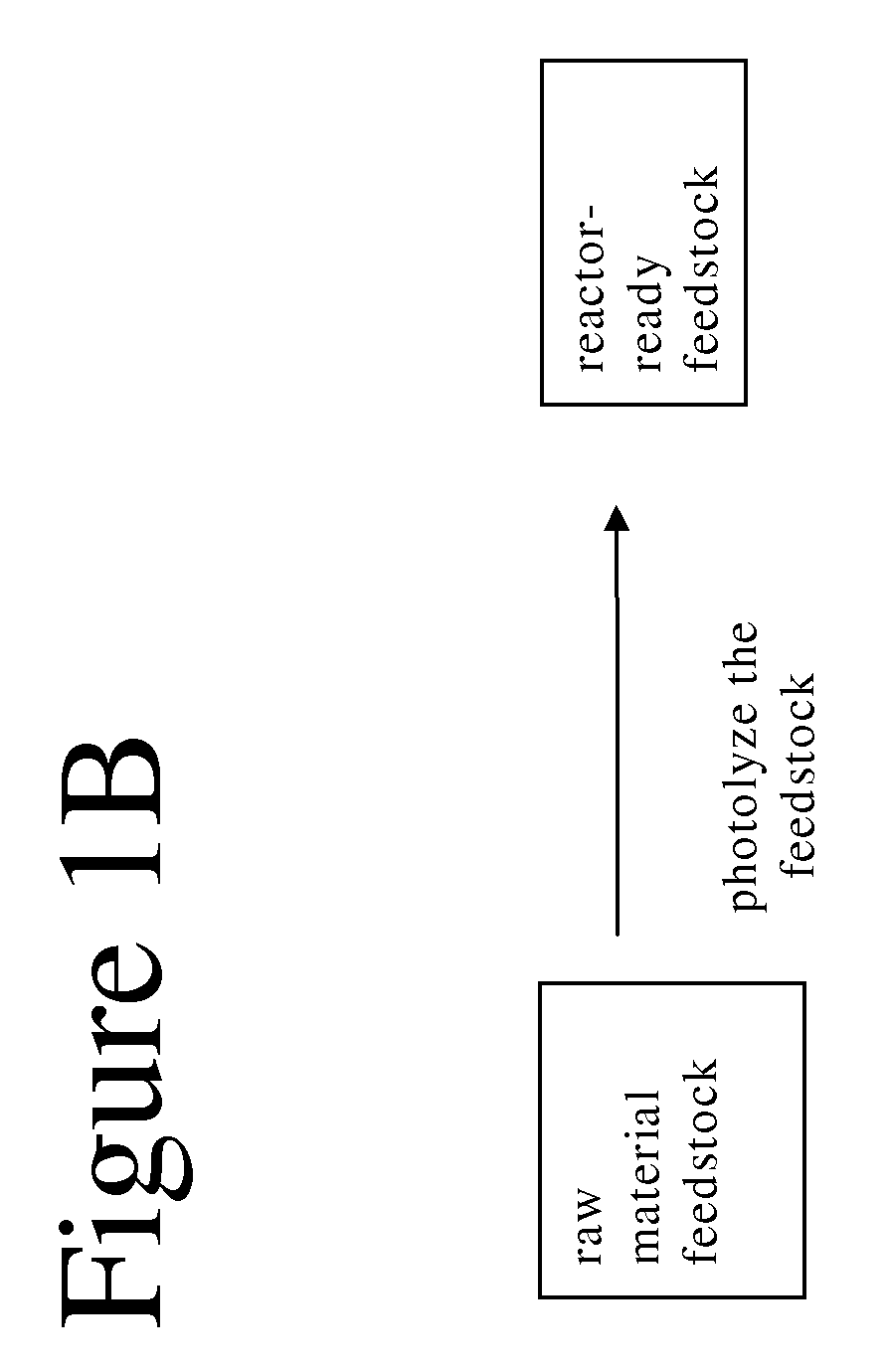

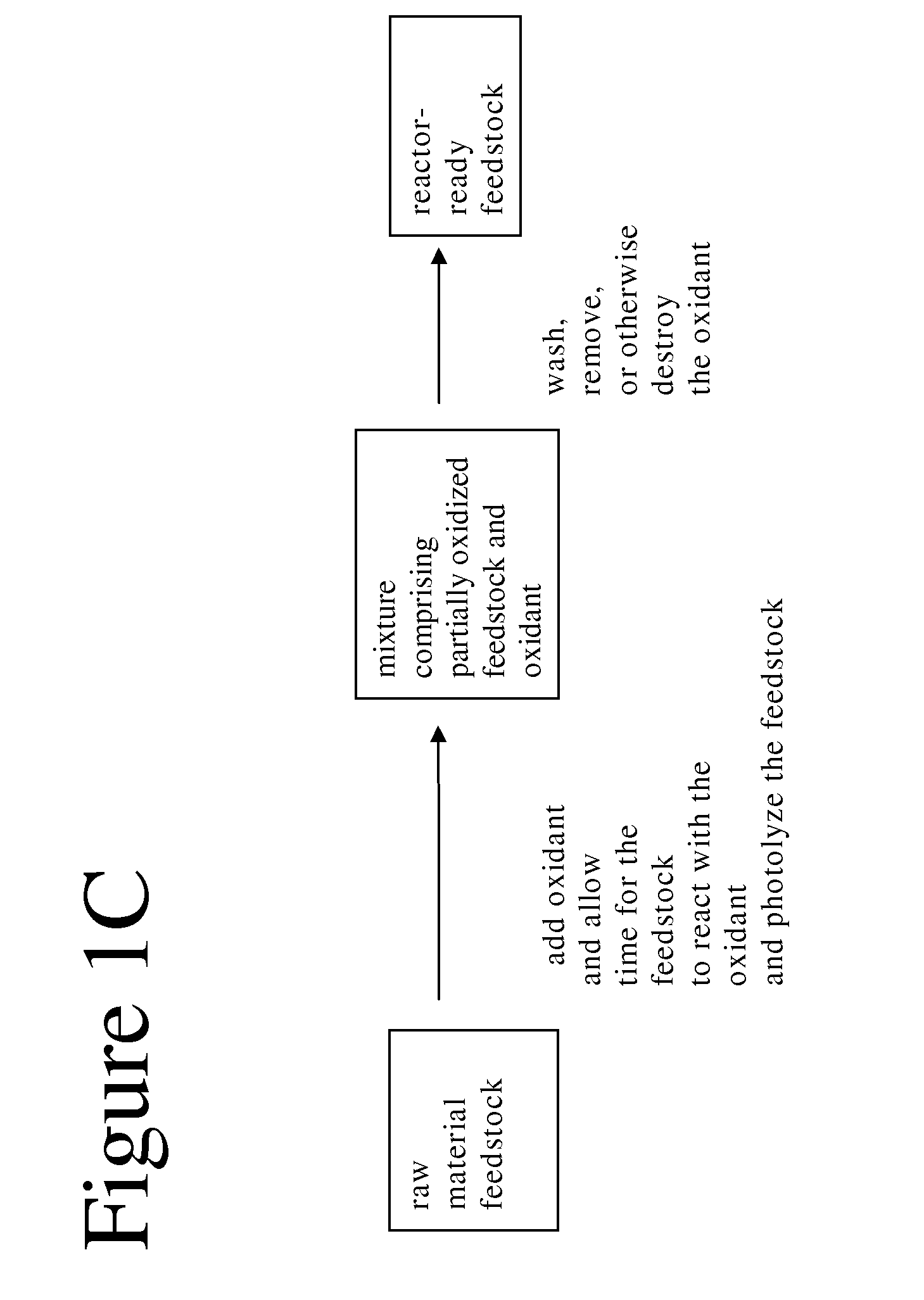

Method for pretreatment of cellulosic and lignocellulosic materials for conversion into bioenergy

InactiveUS8449773B2Minimize cost-benefit ratioReduce the total massTreatment using aerobic processesPeptide/protein ingredientsCellulosePretreatment method

A process for converting organic waste materials into usable products and products thereof is disclosed. According to the process, organic waste materials are contacted with an oxidant to form a product and then an amount of the oxidant is removed from the product to form a reactor-ready feedstock. The oxidant is removed by various means, including washing, photolysis, catalytic means, oxidation of the oxidant, reduction of the oxidant, and heat. The reactor-ready feedstock may then be introduced into a reactor, such as a digester or incubator, and the reactor-ready feedstock is converted by microorganisms into biofuel or other products.

Owner:BRIGHAM YOUNG UNIV

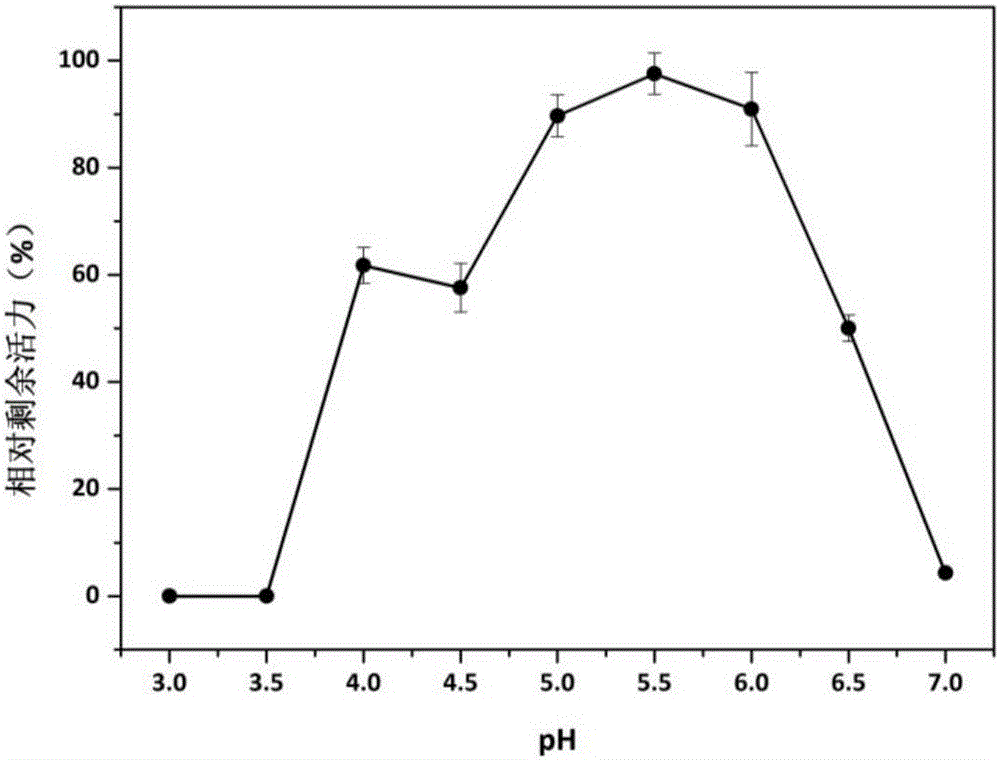

Manganese peroxidase MNP-1 and gene and application thereof

The invention relates to the field of gene engineering, in particular to manganese peroxidase MNP-1 and a gene and an application thereof. An amino acid sequence is shown in SEQ ID No.1. The manganese peroxidase has the following properties that the most suitable pH (potential of hydrogen) value is 4.0, and the most suitable temperature is 60 DEG C; the different structural types of dyes can be effectively degraded; the manganese peroxidase is used as a novel enzyme preparation, and can be widely applied to the fields of biological restoration, biological energy source, textiles, papermaking and food industry.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

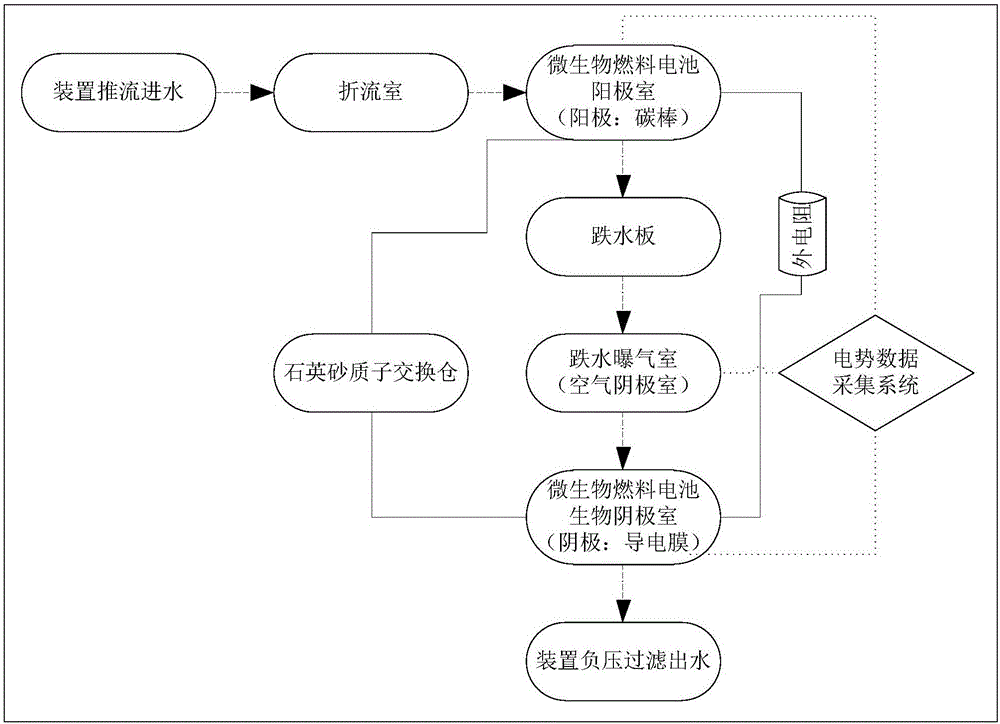

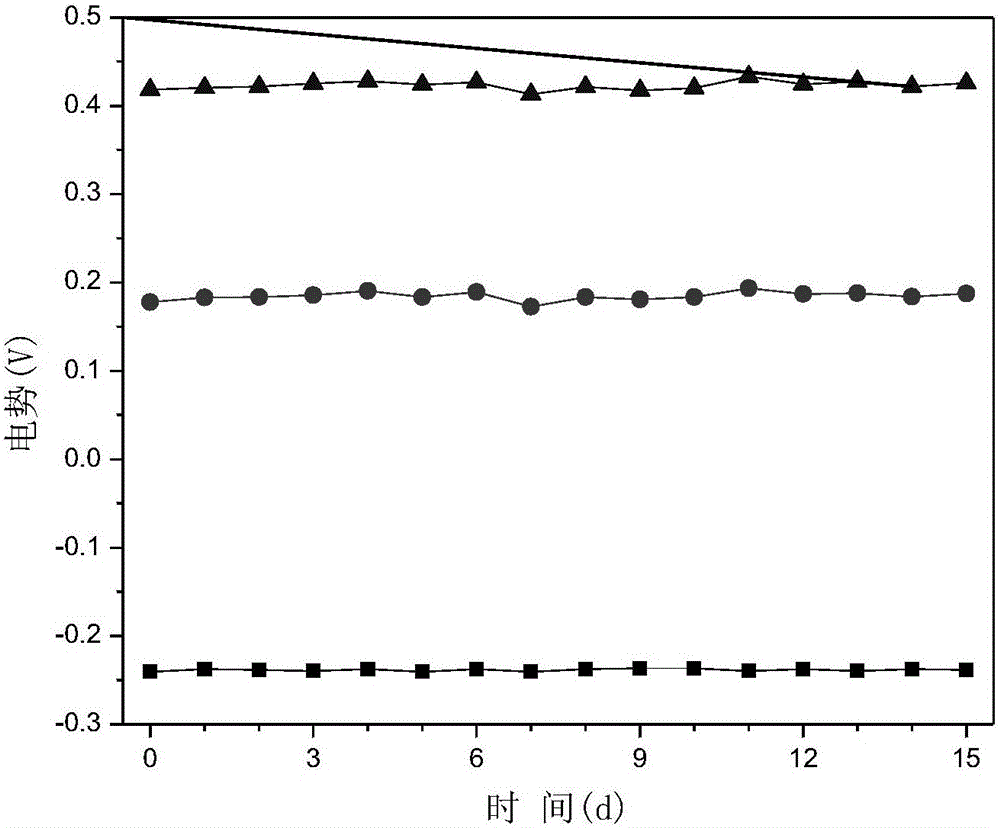

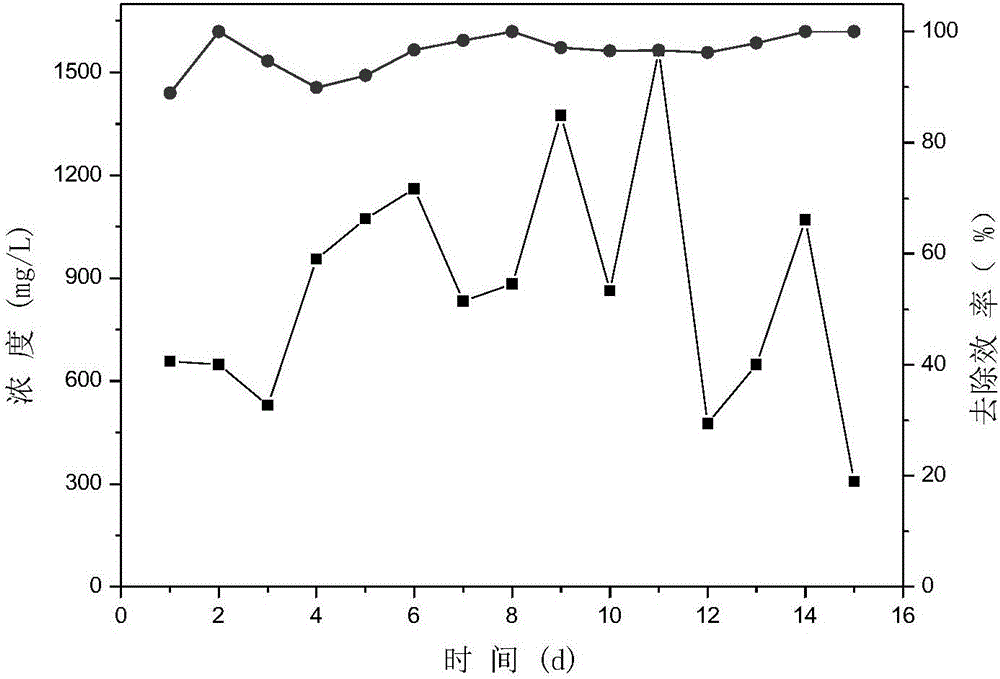

Drop aeration type microbial fuel cell

ActiveCN106374127AIncrease dissolved oxygen contentSolve the problem of low decomposition efficiencyBiochemical fuel cellsTreatment with aerobic and anaerobic processesElectricityNew energy

The invention belongs to the technical field of new energy and waste water resource utilization, and discloses a drop aeration type microbial fuel cell. Specifically, a drop aeration dissolved oxygen technology will be introduced to waste water treatment process and design based on a microbial fuel cell principle, a mechanical blast aeration mode is substituted, and dissolved oxygen is provided for a negative electrode chamber of the MFC (Microbial Fuel Cell). By a new drop aeration dissolved oxygen and coupling organism power generation principle process and equipment design, biological energy conversion and waste water high-efficient treatment are achieved; and waste water enters the negative electrode chamber of a drop aeration unit after passing through a positive electrode of the microbial fuel cell, anaerobic and aerobic secondary process treatment is achieved, fully dissolved oxygen is also provided for a negative electrode of the MFC and is taken as an electron acceptor of the negative electrode, and waste water treatment recycle and biological power generation are simultaneously achieved.

Owner:DALIAN UNIV OF TECH

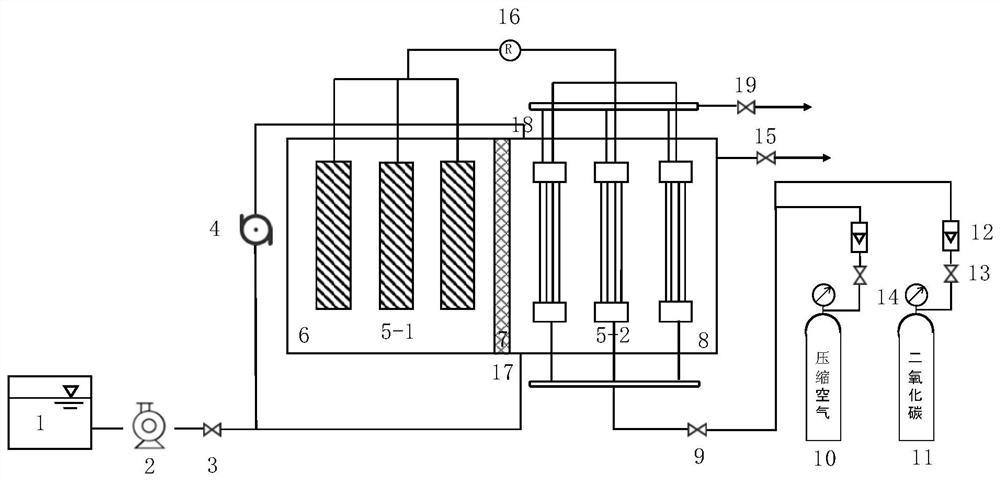

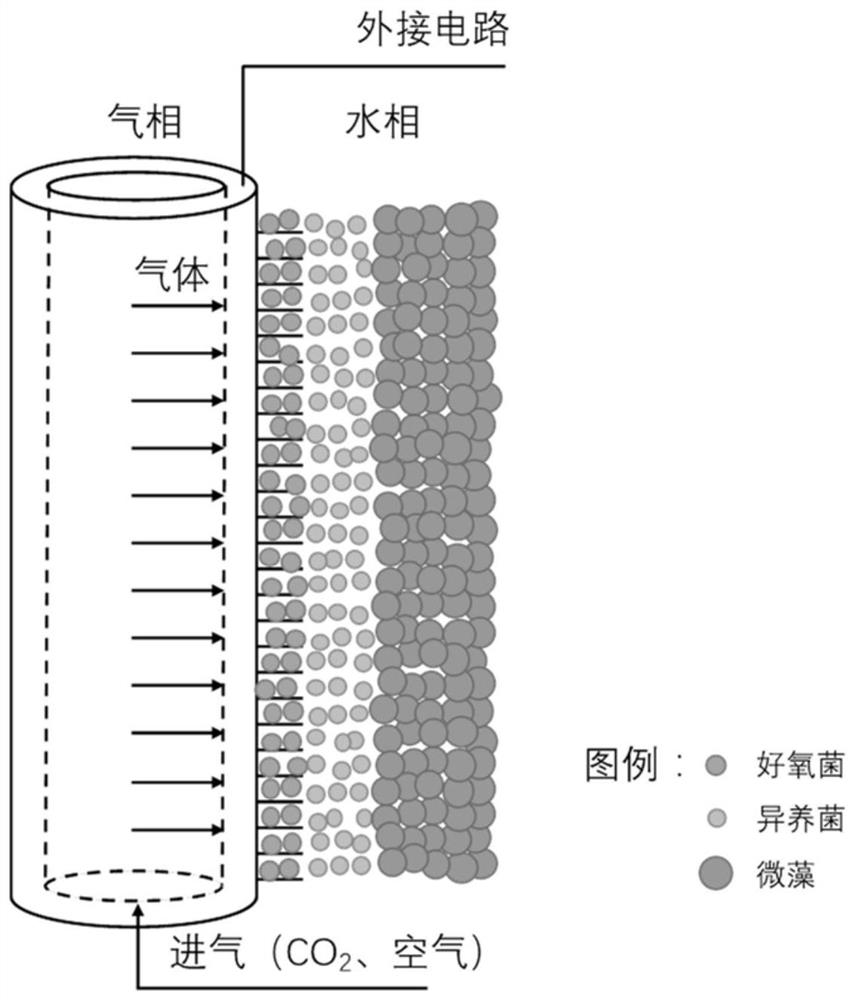

Electrochemical performance enhanced bacteria-algae membrane aeration bio-membrane reactor system and application thereof

InactiveCN112607864AHigh affinityLarge specific surface areaWater treatment parameter controlTreatment by combined electrochemical biological processesElectrochemistryMembrane reactor

The invention relates to an electrochemical performance enhanced bacteria-algae membrane aeration bio-membrane reactor system and an application thereof. The system comprises an anode chamber, a cathode chamber and a separation membrane, and also comprises a membrane aeration assembly arranged in the cathode chamber, a biological cathode electrode and a biological electrode arranged in the anode chamber. The external air supply device which is connected with the membrane aeration assembly is provided with a circulating pipeline, wherein the input end of the circulating pump is connected with the top end of the reactor, and the output end of the circulating pump is connected into a water inlet pipeline for connecting the water inlet pump and the reactor; moreover, the biological anode electrode is electrically connected with the biological cathode electrode through an external circuit, and the system is used for treating ammonia-nitrogen-containing wastewater. Compared with the prior art, the system is simple in structure, adopts bubble-free aeration, is high in gas utilization rate, is low in energy consumption in the operation process, is stable in operation, has pollutant treatment and power generation functions, can recover microalgae biological energy, and has a wide application prospect in the fields of sewage treatment and recycling.

Owner:TONGJI UNIV

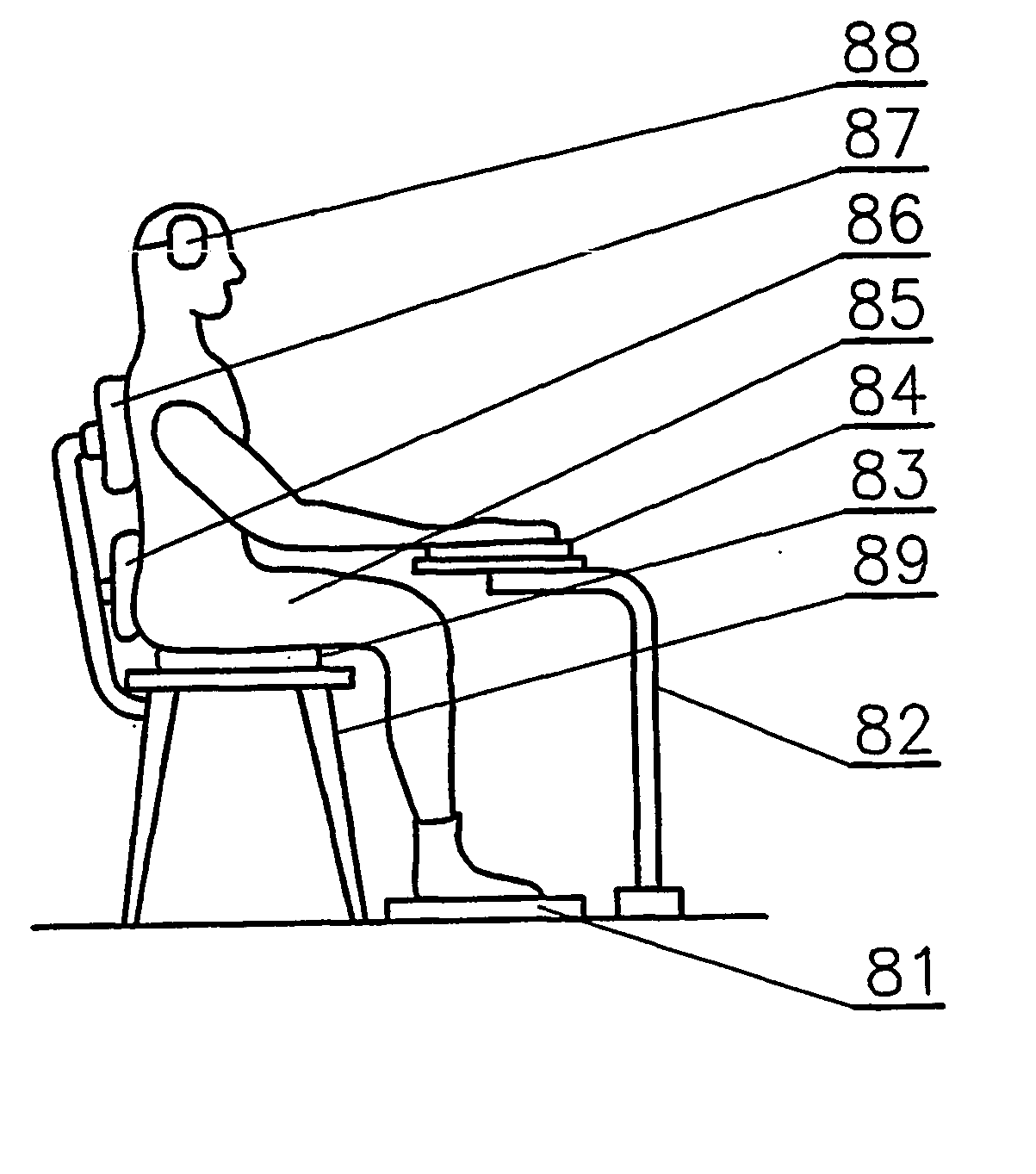

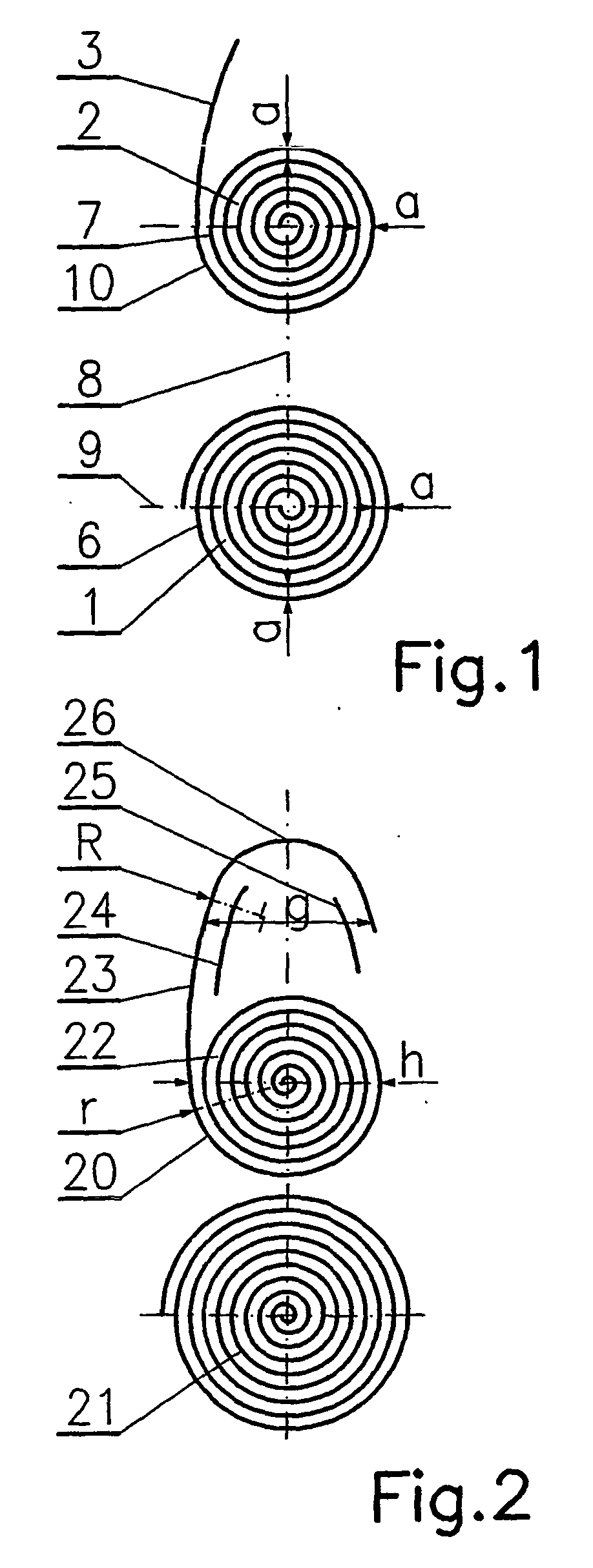

Therapeutic bio-energy unit

InactiveUS20040039433A1Easy to useNot to damageMagnetotherapy using coils/electromagnetsExternal electrodesBioelectric Energy SourcesEngineering

Owner:WODNICKI JANUSZ

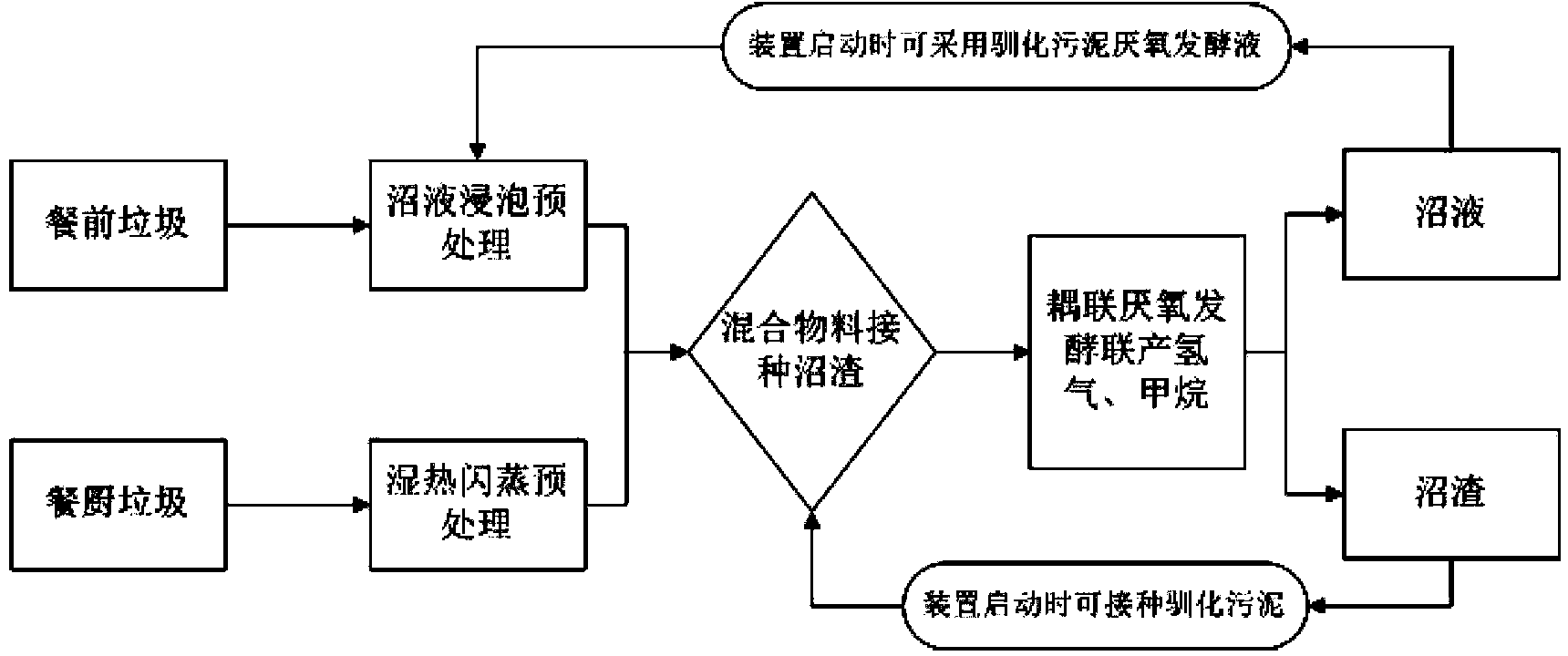

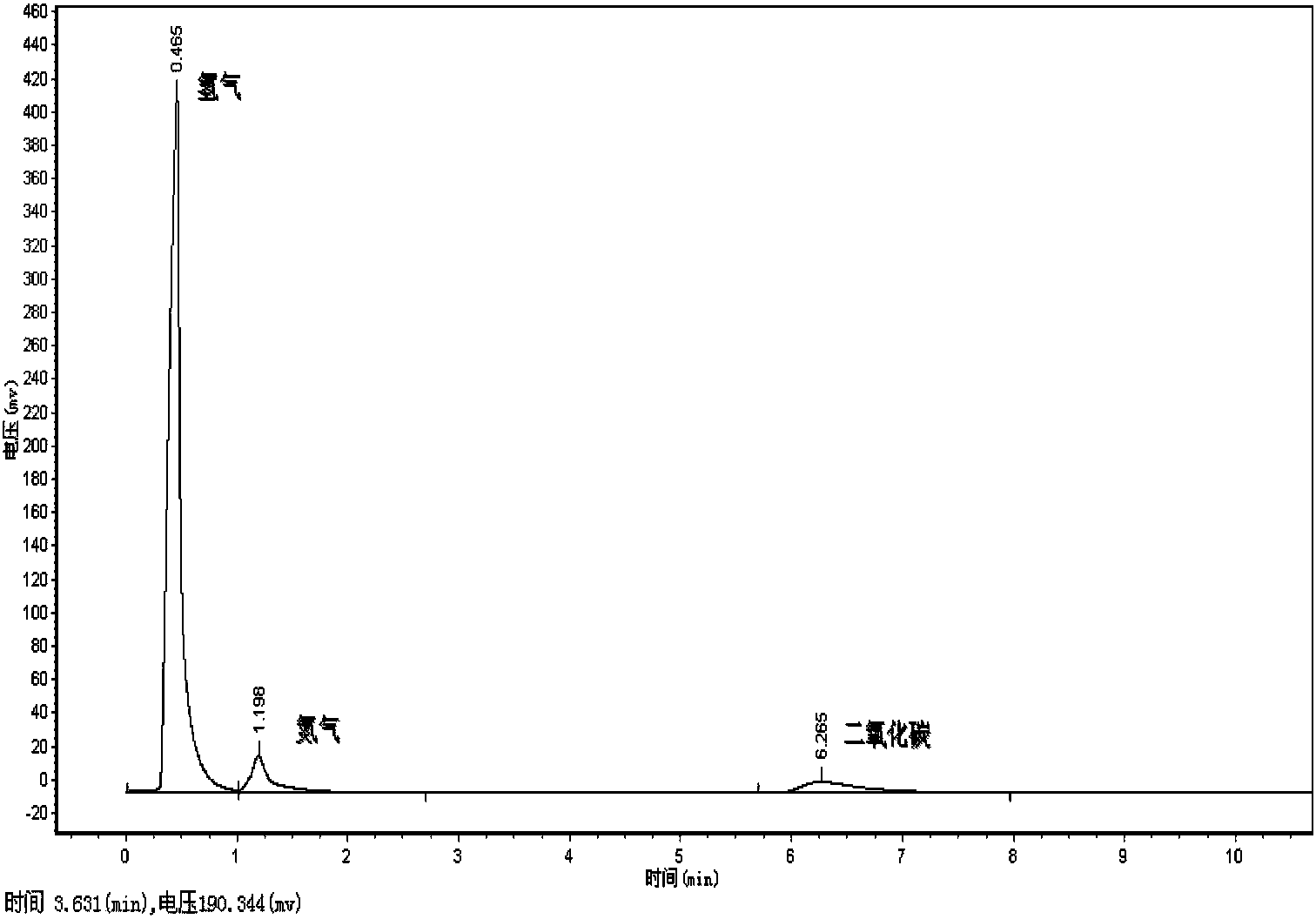

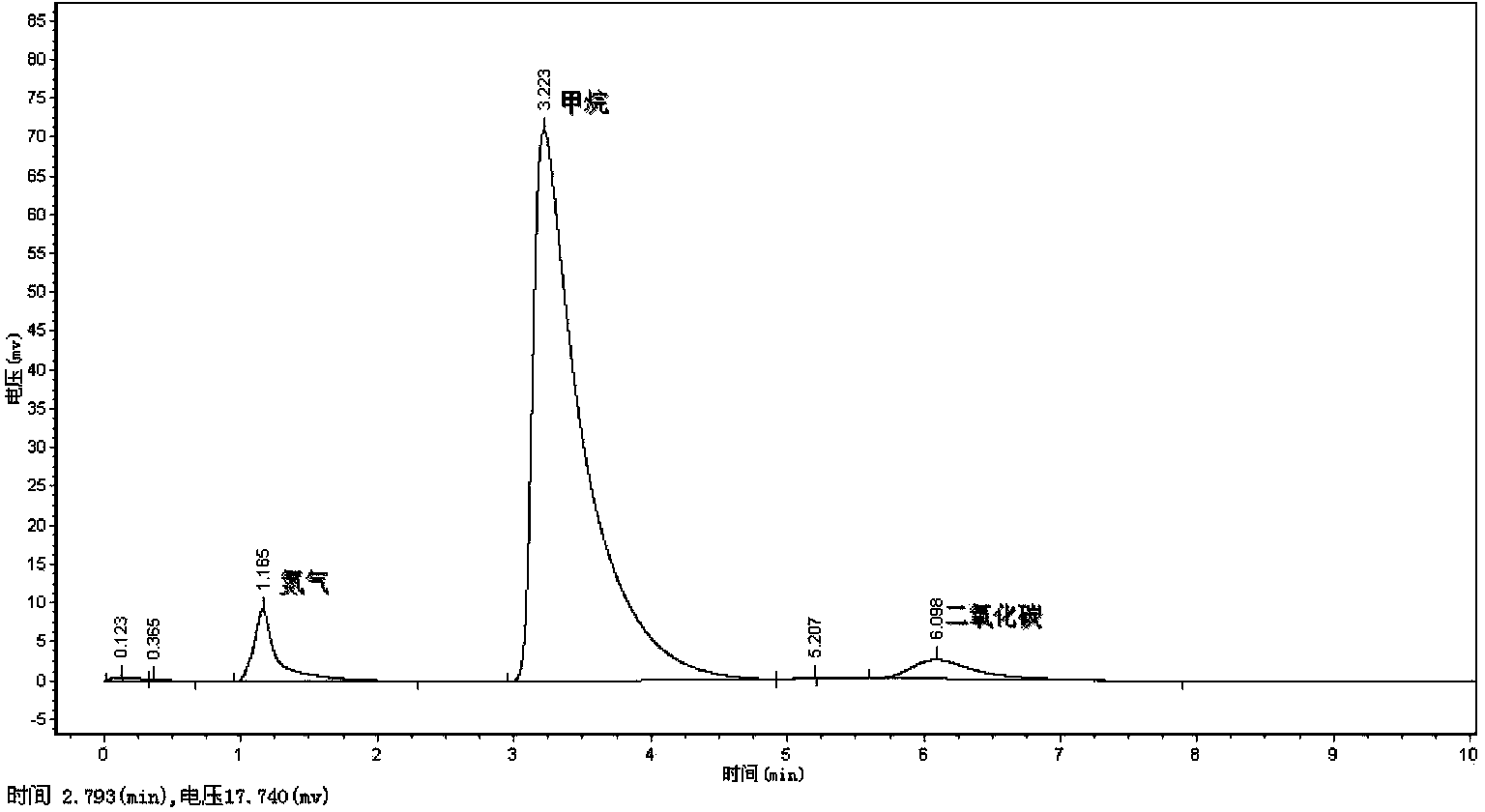

Method for jointly producing hydrogen and methane by carrying out coupling anaerobic fermentation on preprandial garbage and kitchen garbage

ActiveCN103451236ASolve secondary processing problemsReduce startup timeWaste based fuelFermentationCelluloseSlurry

The invention discloses an environment-friendly method for jointly producing hydrogen and methane by carrying out coupling anaerobic fermentation on preprandial garbage and kitchen garbage, and belongs to the technical field of solid waste treatment and biological energy. The method comprises the following steps: firstly carrying out soaking pretreatment on the preprandial garbage by utilizing biogas slurry generated through the anaerobic fermentation, and carrying out damp heat flash evaporation pretreatment on the kitchen garbage; then mixing the pretreated preprandial garbage and kitchen garbage to prepare the hydrogen and the methane through an anaerobic fermentation process by taking biogas residues discharged by a system after a methane production stage as inocula. The method disclosed by the invention is suitable for recovering the biomass energy contained in solid organic matters with multiple high-organic matters, high-water ratio and high-cellulose organic solid wastes in hydrogen and methane forms, integrates energy conservation, emission reduction, renewable resource utilization and pollution control into a whole, is a pollution-free, low-energy consumption and high-productive capacity kitchen garbage anaerobic fermentation treatment process and has the advantages of important environmental benefit and wide application prospect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for producing biological energy source substance by using chitin

The present invention provides a method capable of utilizing modern bio-technical process to implement production of biological energy source substances by using chitin-natural L-acetylglucosamine multipolymer. It is characterized by that said method includes the following steps: (1), pretreatment of chitin raw material: (2), adopting modern bio-technical process, utilizing natural or recombinant or artificially-engineered chitin metabolic enzyme system and utilizing internal conversion or external conversion method to make chitin be converted into biological energy source precursor substance 6-phosphofructose; and (3), using 6-phosphofructose as carbon source, adopting biological conversion method to produce the biological energy source substances of alcohol, etc.

Owner:DALIAN UNIV OF TECH

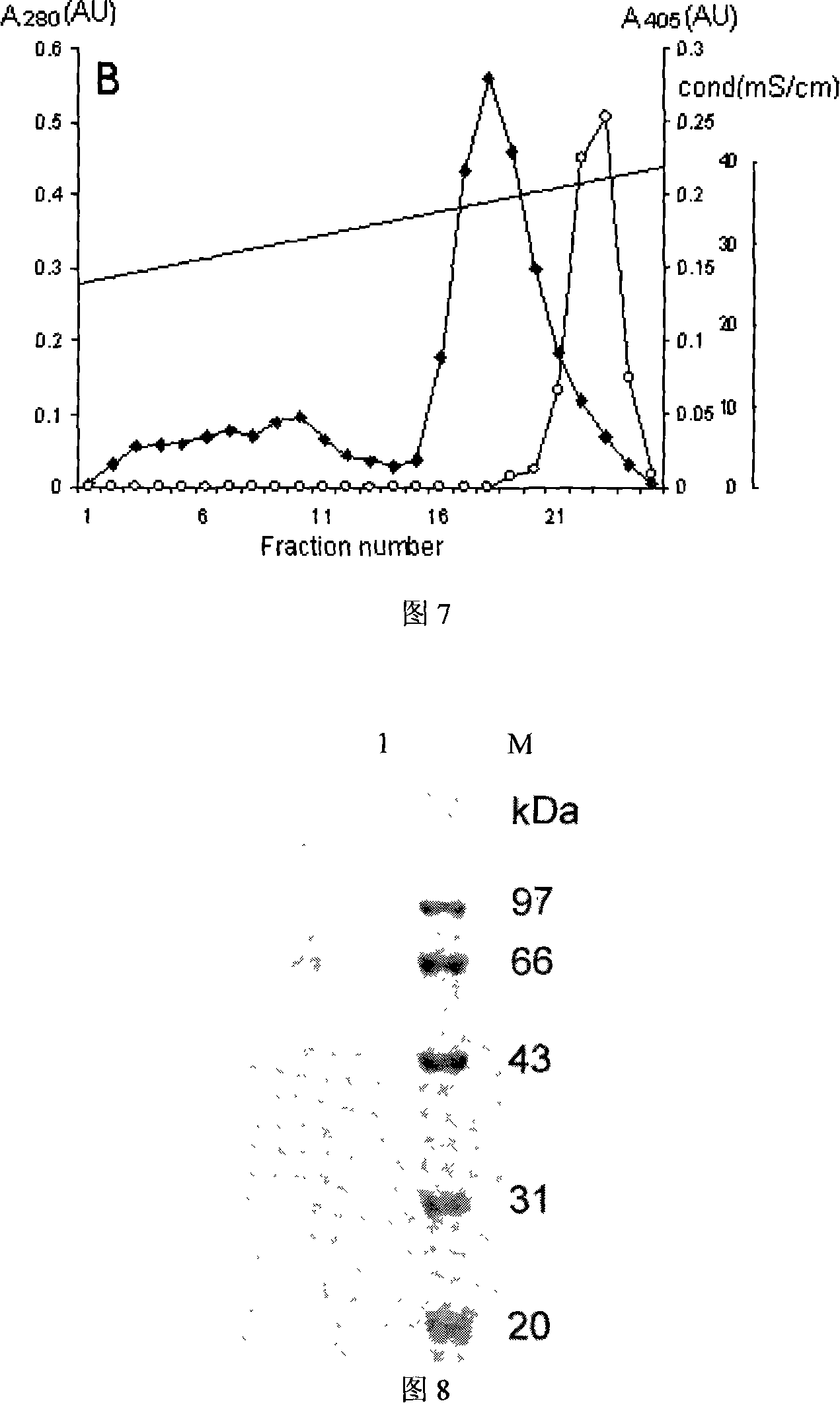

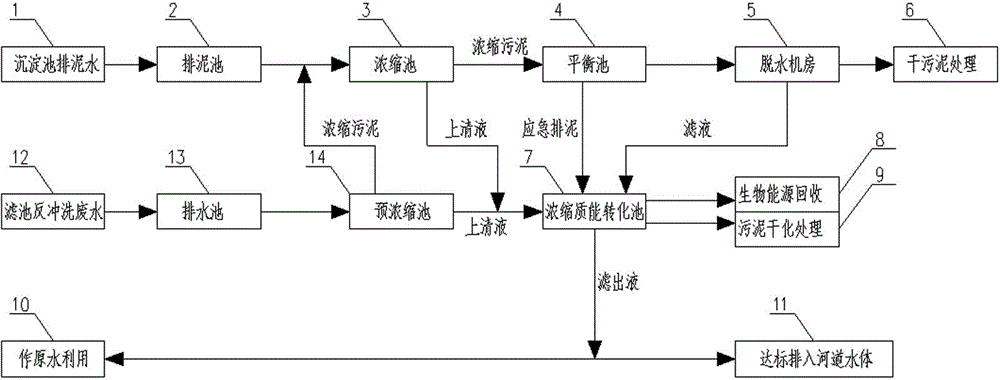

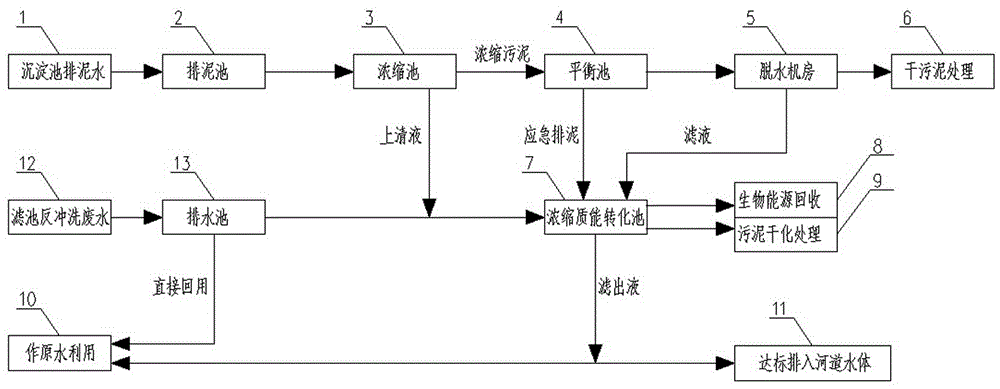

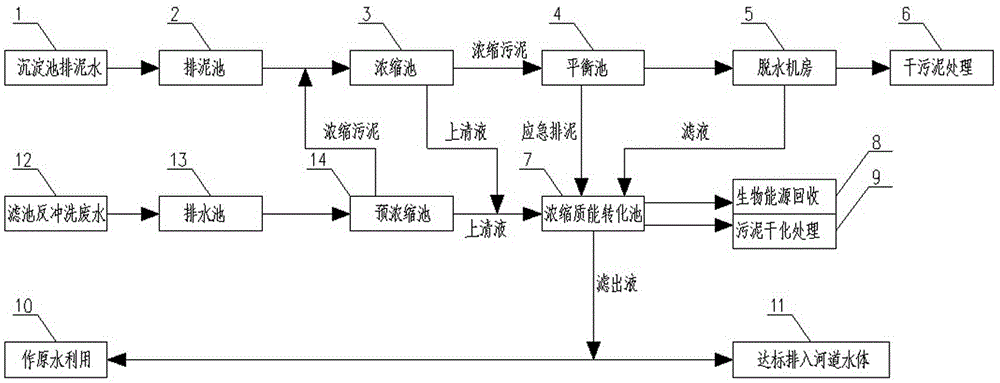

Mass-energy transformation treatment process for production wastewater

InactiveCN104418481ASmall footprintAchieve water discharge standardsSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWater dischargeSludge

The invention discloses a mass-energy transformation treatment process for production wastewater. The mass-energy transformation treatment process is characterized in that firstly, the treatment process is divided into a pre-concentration aftertreatment process for backwash wastewater of a filter chamber, a treatment process for directly reusing the backwash wastewater of the filter chamber, and a treatment process for mixing and concentrating the backwash wastewater of the filter chamber according to different treatment modes of the backwash wastewater of the filter chamber; and then a complete treatment system composed of three sets of treatment processes is formed according to different operation conditions and requirements. The process has the advantages that the process can adapt to different site conditions and operation requirements; supernate of a concentration pool and dehydration filtrate, which are easy to discharge beyond standards in the production wastewater concentration and dehydration processes are subjected to secondary treatment by virtue of a concentrated mass-energy transformation pool when concentration and dehydration of muddy water discharged by production are solved; the floor area is saved; and the discharge with the standard level of effluent of a sludge treatment process and transformation of organic matters in the production wastewater into an biological energy source to be further recycled are achieved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

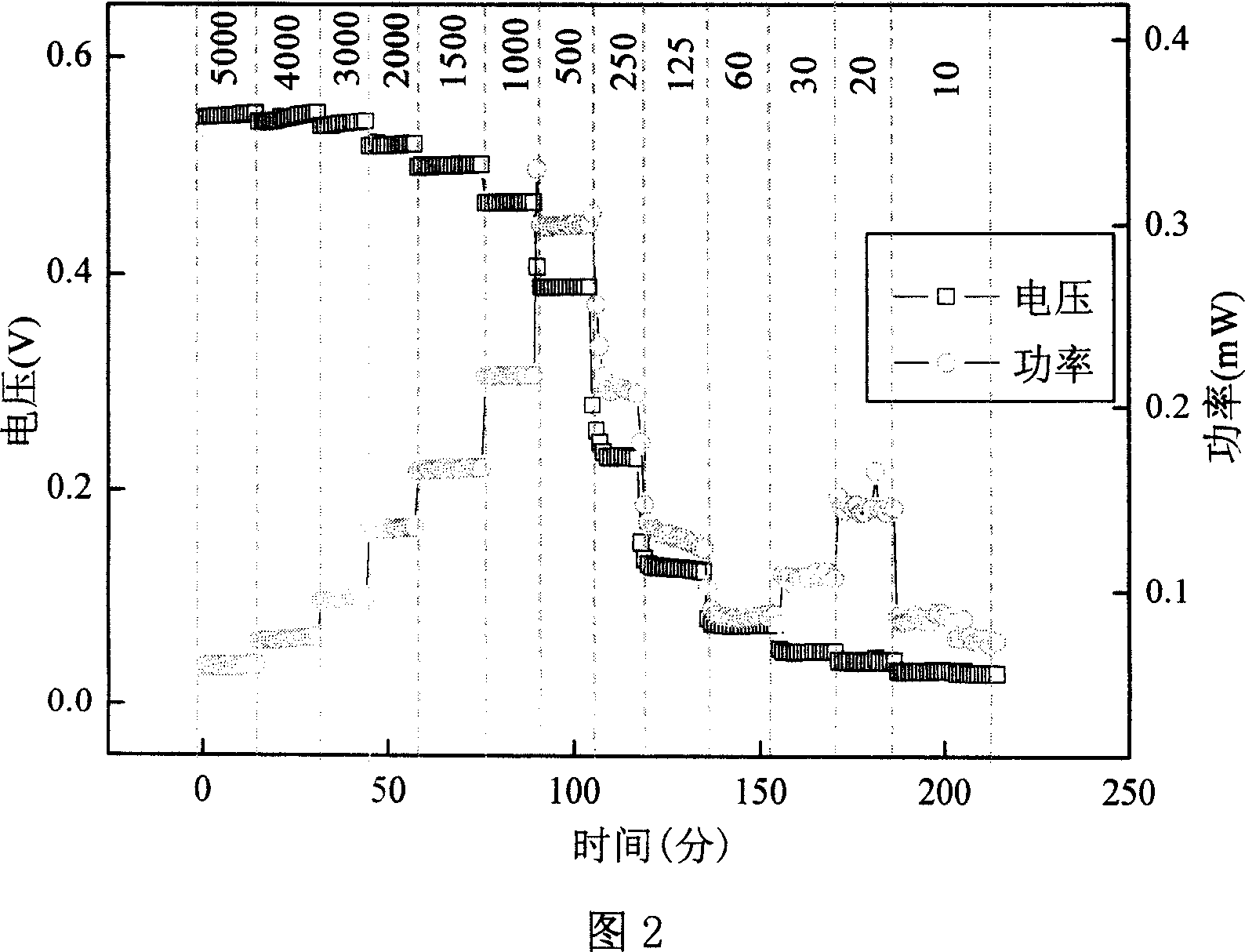

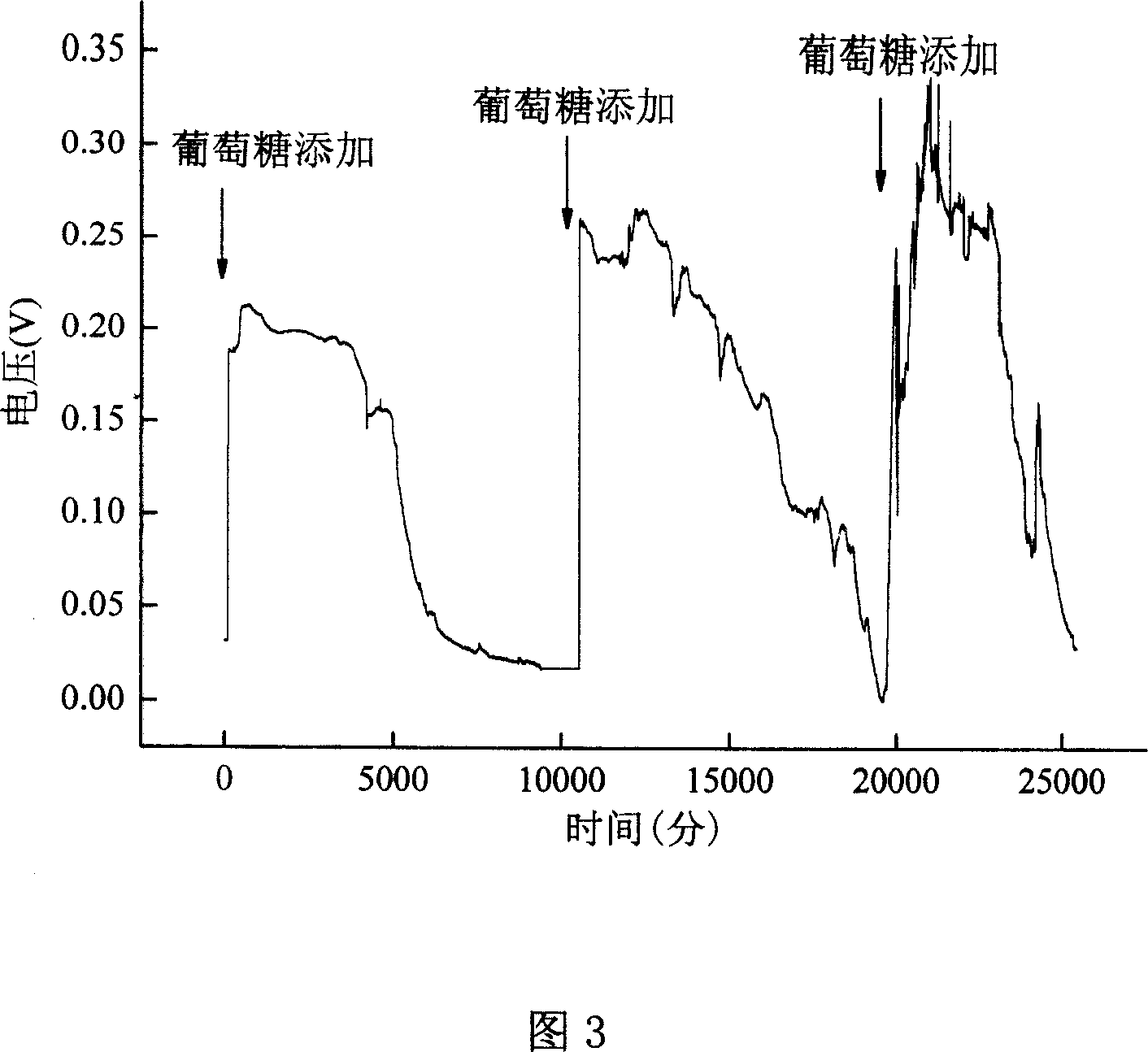

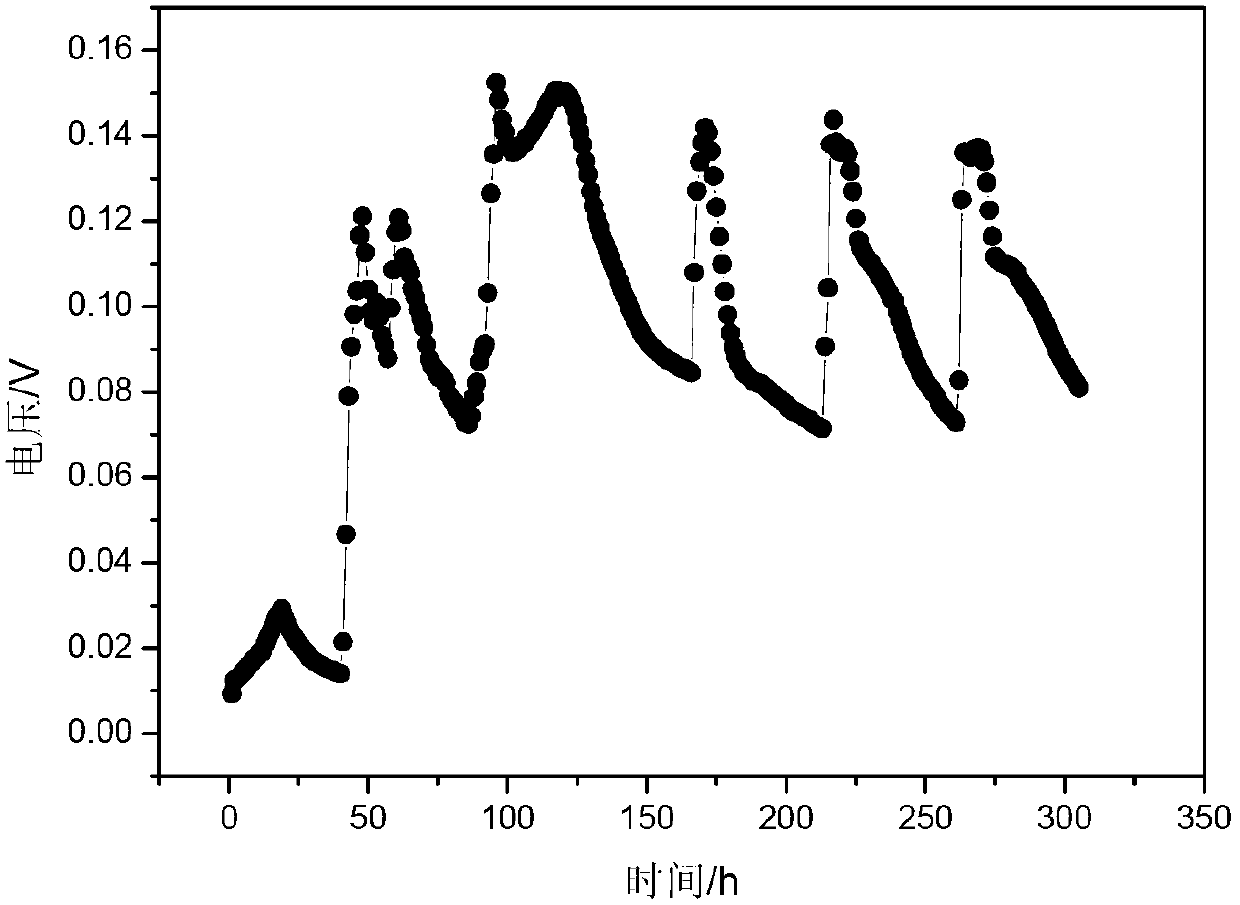

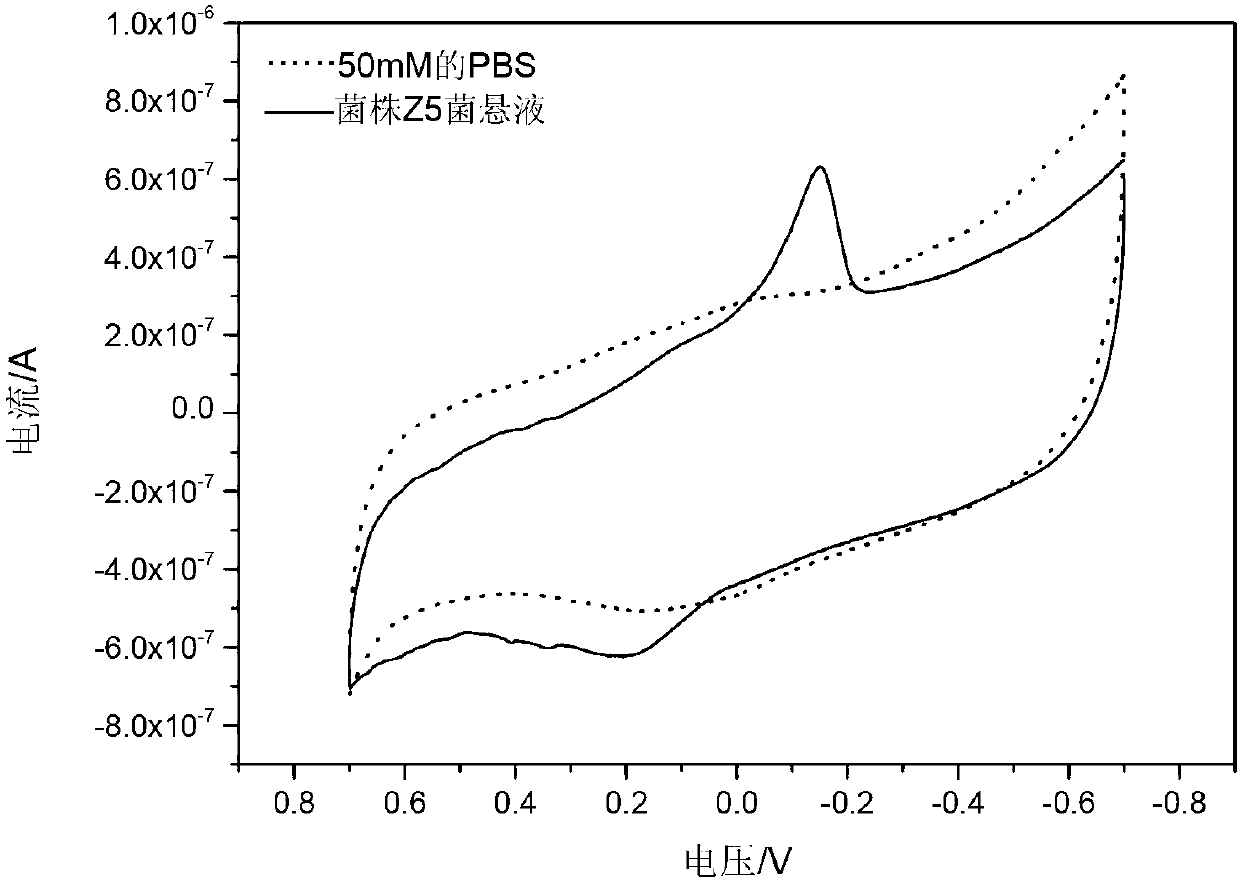

Enterococcus faecalis and its application in bioelectricity production

ActiveCN103215200ALower requirementImprove electrochemical activityBacteriaFinal product manufactureBiotechnologyEnergy recovery

The invention discloses an Enterococcus faecalis strain and its application in bioelectricity production. The strain is characterized in that it is Enterococcus faecalis Z5, which is preserved by China Center for Type Culture Collection (called CCTCC for short) on November 6, 2012 and has a preservation number of CCTCC NO: M2012445. When the strain is inoculated into a microbial fuel cell, it can degrade organic matters and generate electricity simultaneously, but probably does not transmit electrons by secreting its electron transmission intermediates. The Enterococcus faecalis Z5 strain has very strong electrochemical activity, and also can use multiple types of organic matters as the sole carbon source for electricity generation. Based on the above characteristics, the strain has very good application prospects in environmental pollution remediation and bio-energy recovery.

Owner:SOUTH CHINA UNIV OF TECH

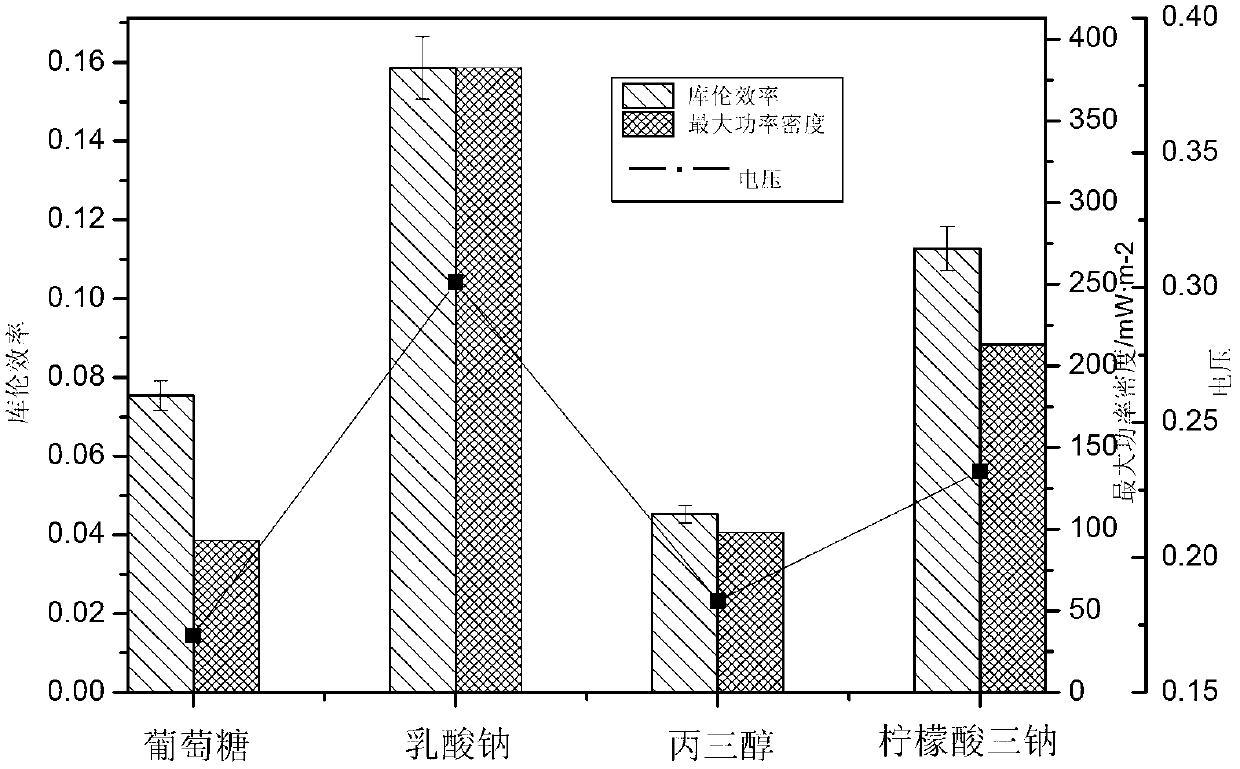

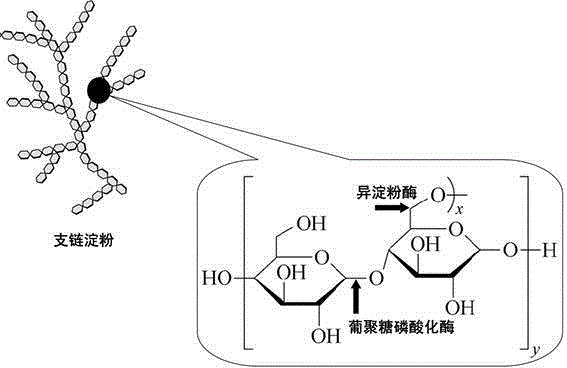

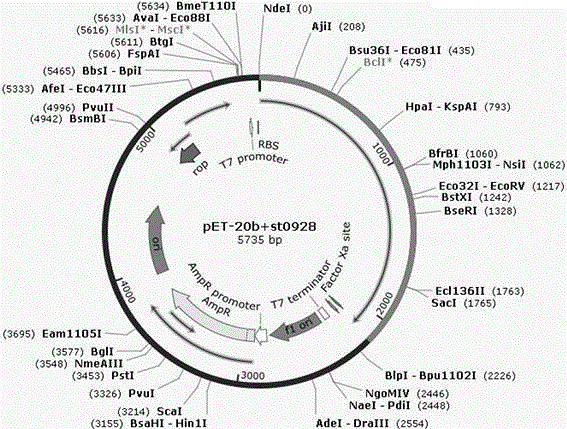

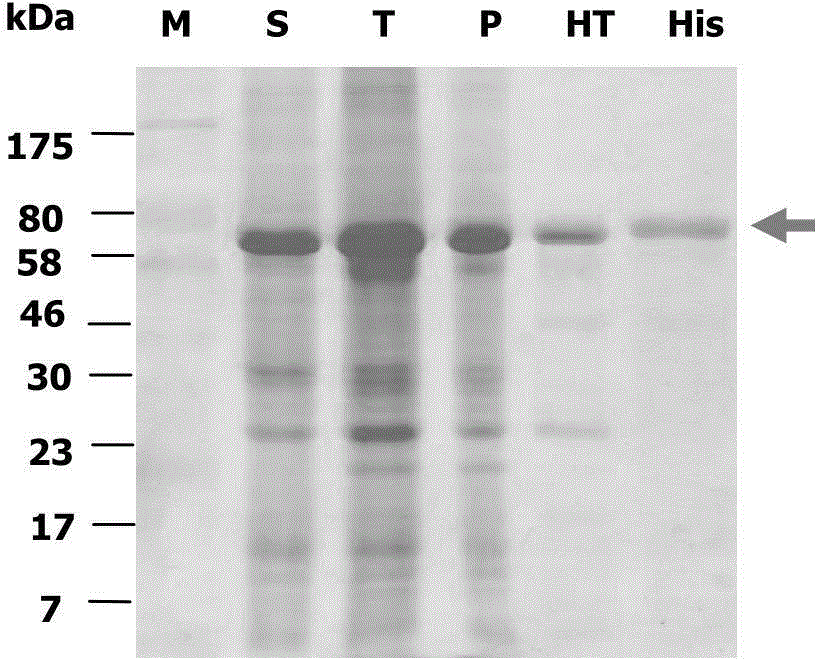

Cloning, expression and application of high temperature resistance isoamylase genes

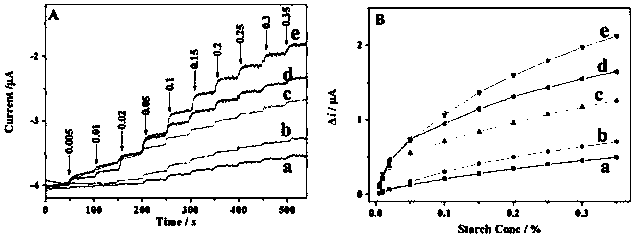

InactiveCN104988166AImprove thermal stabilityIncrease enzyme activityFinal product manufactureBiochemical fuel cellsBiotechnologyEnzymatic biofuel cell

The invention belongs to the technical field of genetic engineering and biological energy sources, and particularly relates to cloning and expression of high temperature resistance isoamylase genes and application in enzymatic biofuel cells. The DNA sequence of amylase is shown in the SEQ ID NO.1, and the total length of the DNA sequence is 2151bp. The sequence of high temperature resistance isoamylase amino acids is shown in the SEQ ID NO.2 and includes 716 amino acids, the molecular weight is 83.1KDa, and the amino acids with the coded sequences being 17-108 are carbohydrate combined module order belonging to the 48th family; the amino acids with the coded sequences being 204-545 are the amylase catalytic structural domain. The high temperature resistance isoamylase can be used for enzymatic biofuel cells. The high temperature resistance isoamylase has the beneficial effects that the isoamylase is resistant to high temperature and stable in activity, and has the strong industrial application potential; and when the isoamylase is used for a sugar fuel cell, the starch substances can be completely hydrolyzed into glucose, so that the energy conversion efficiency is improved, and the application range of the biofuel cells is enlarged.

Owner:HENAN AGRICULTURAL UNIVERSITY

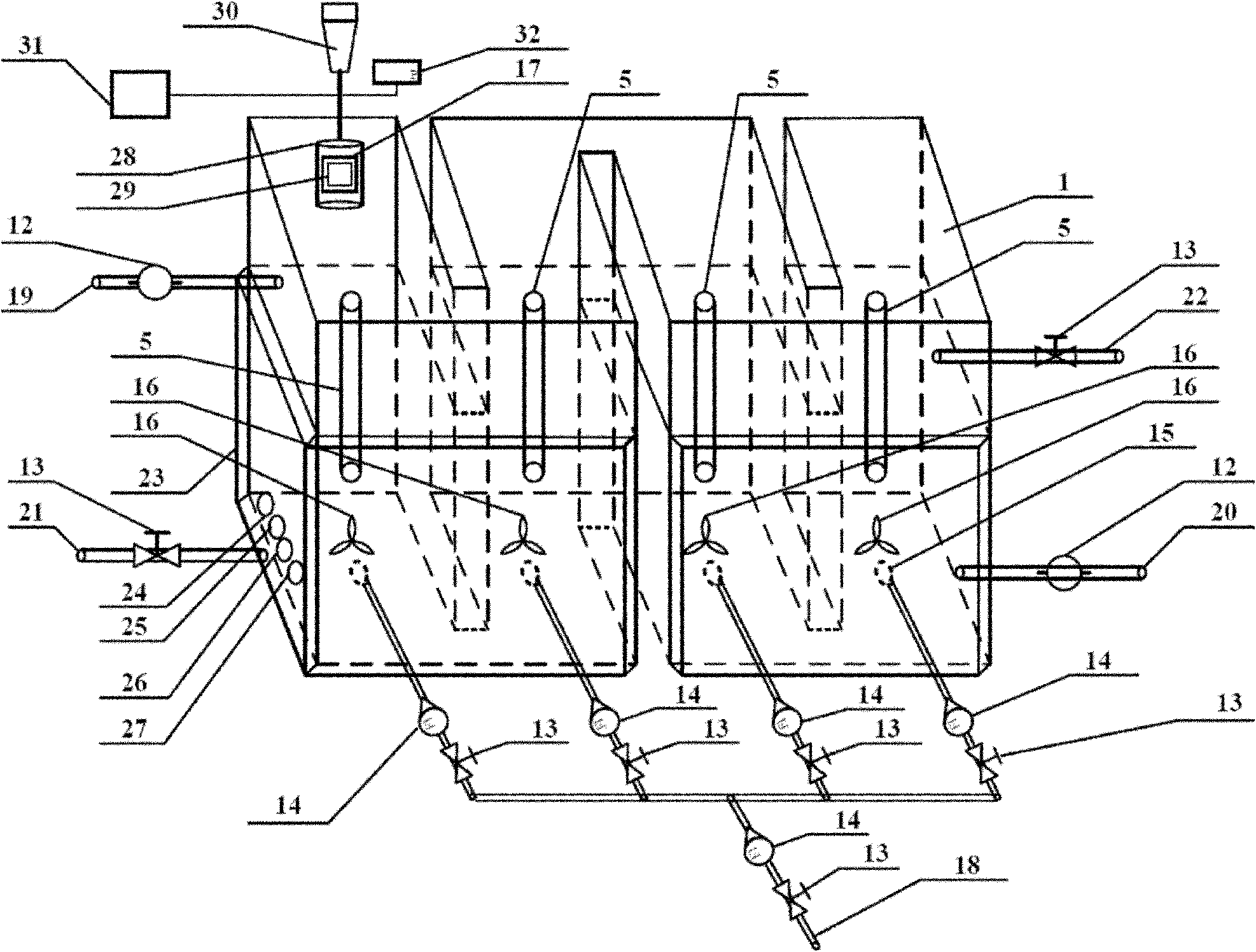

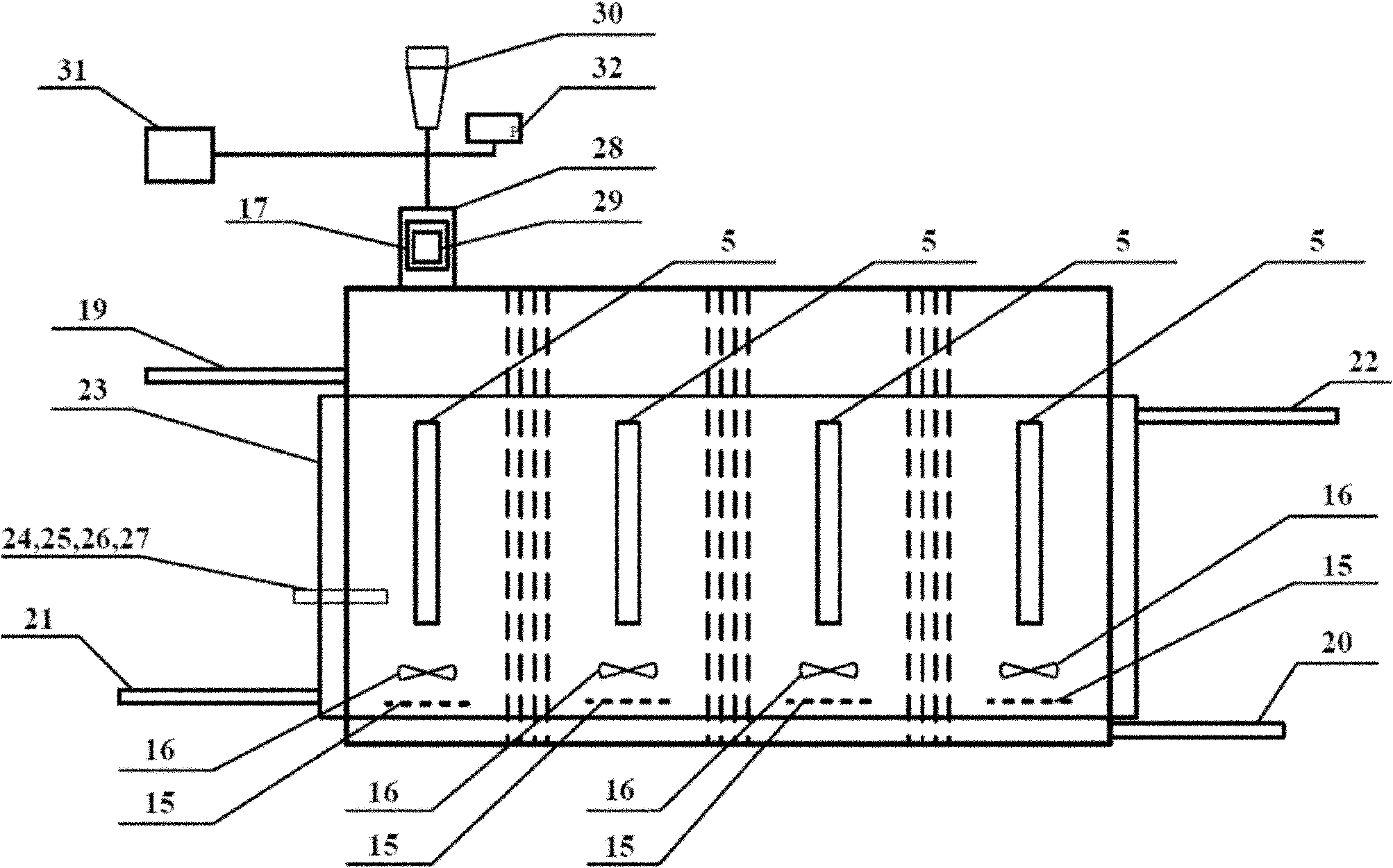

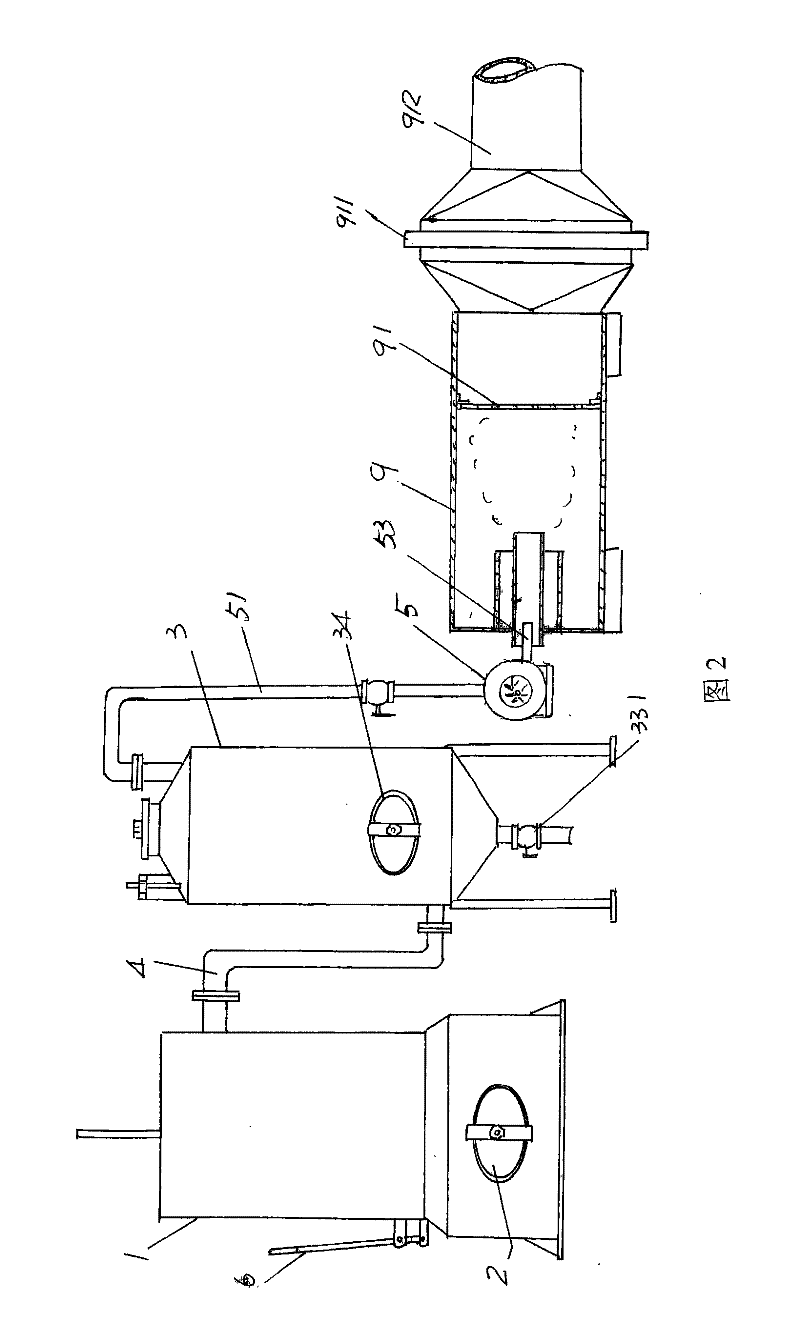

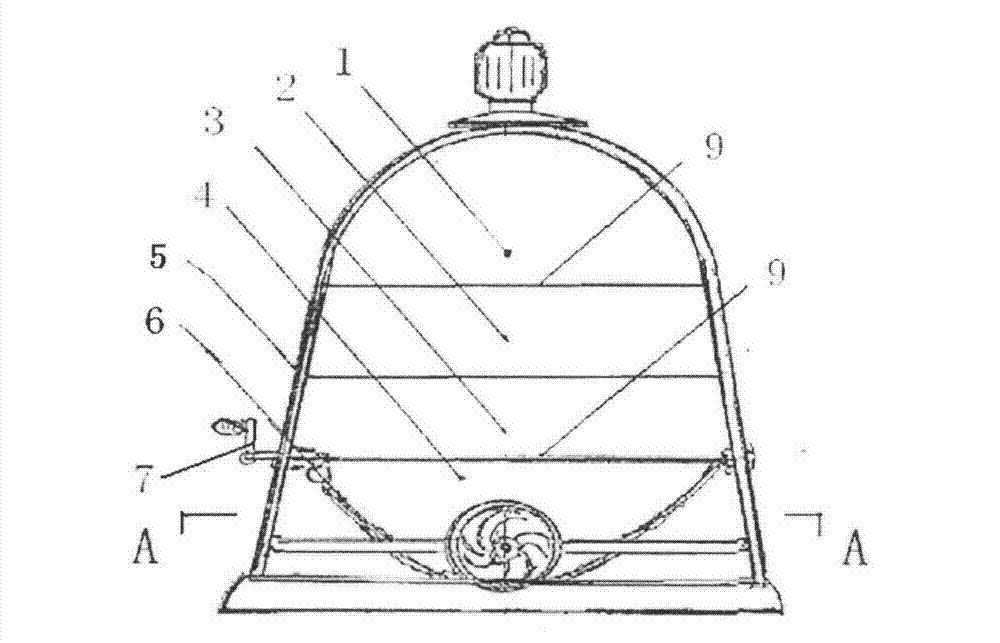

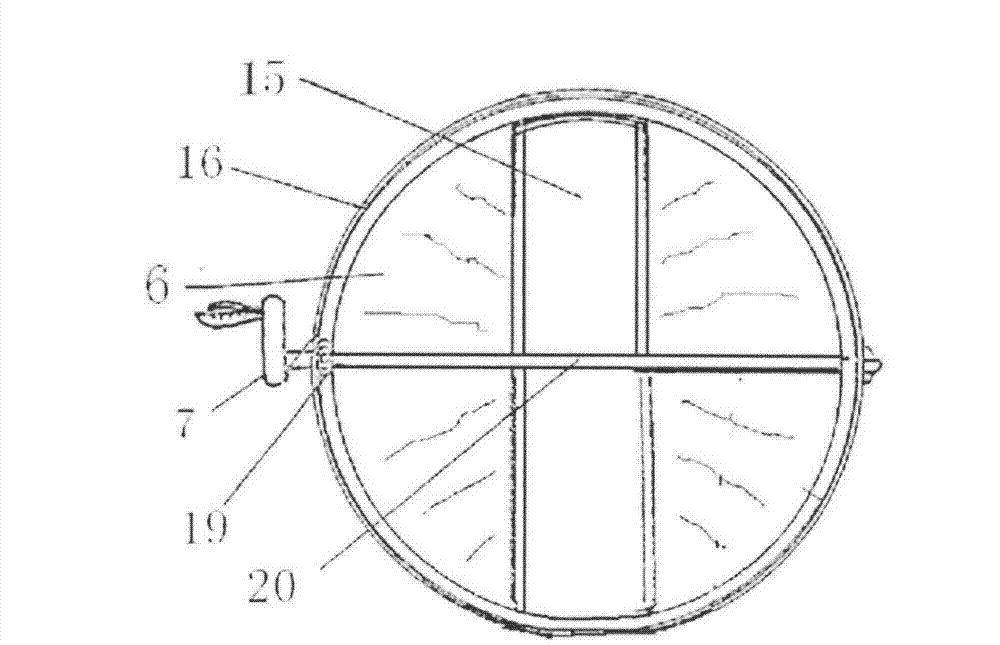

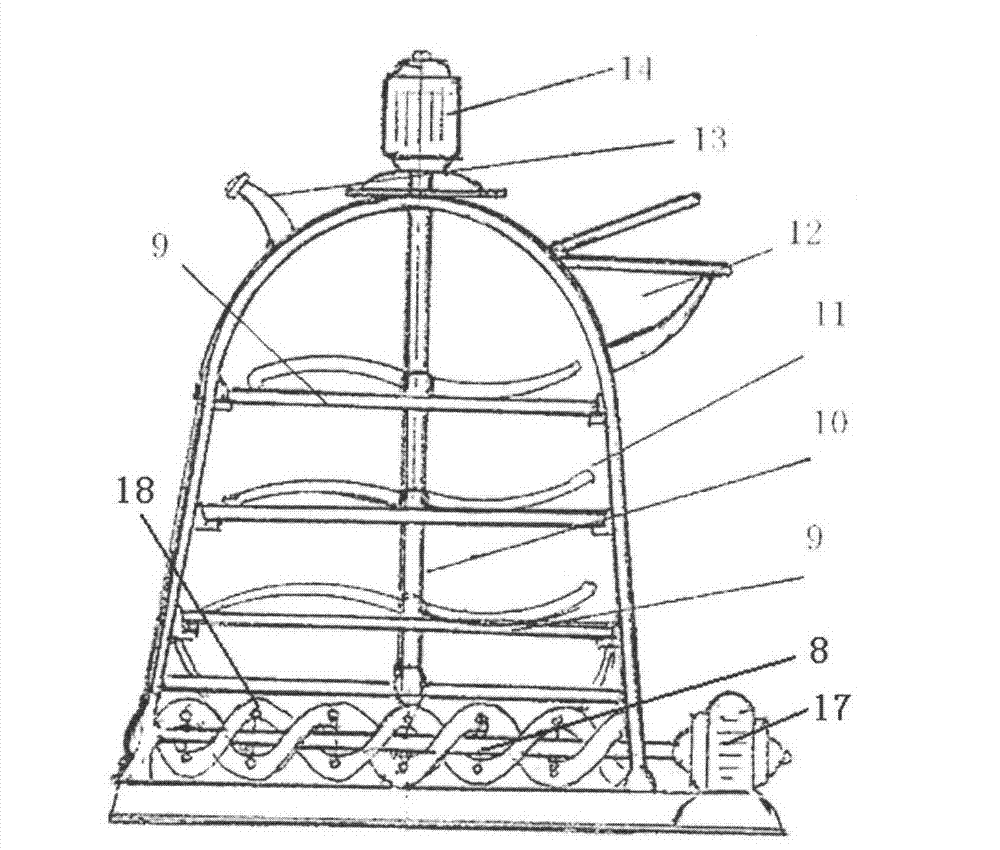

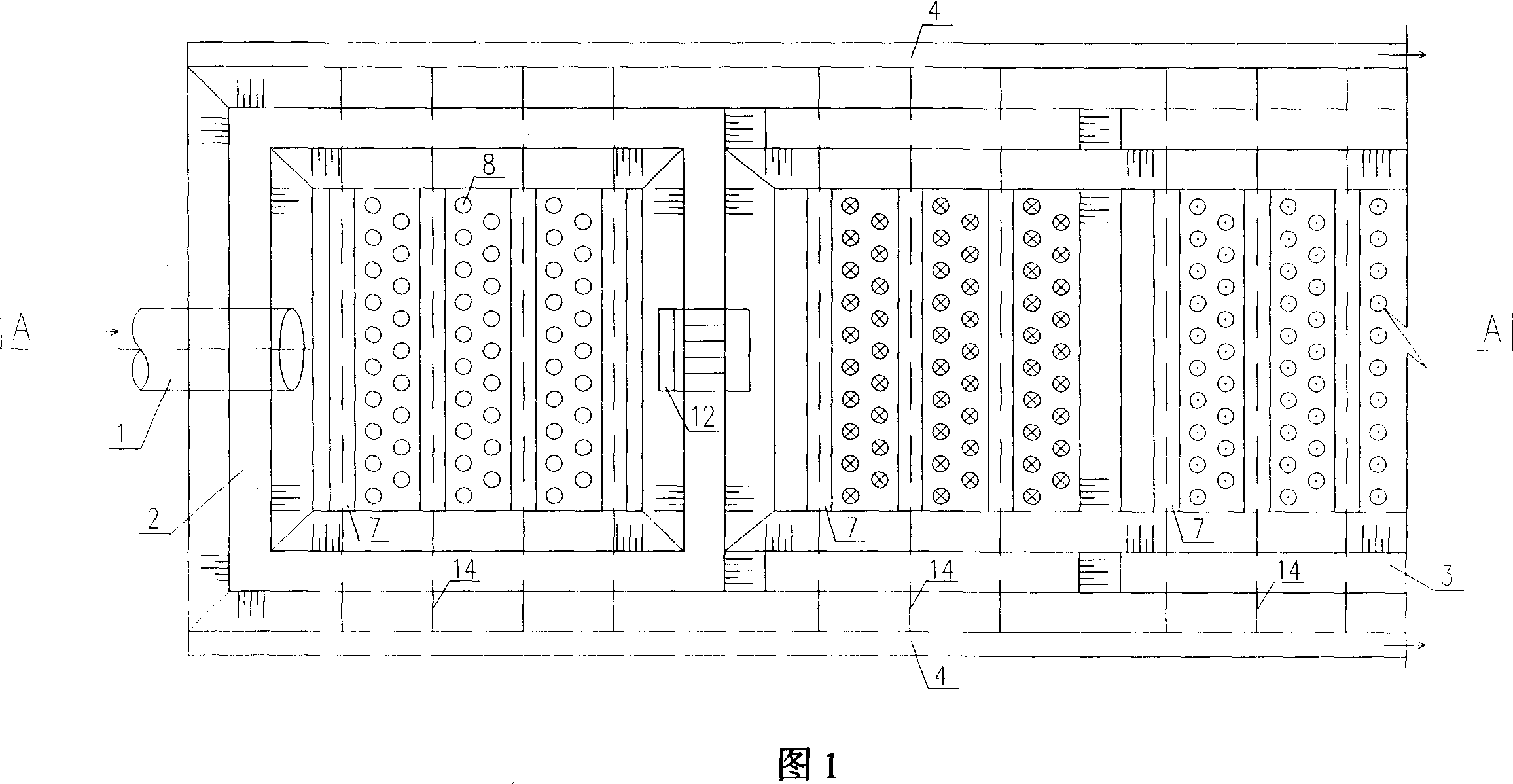

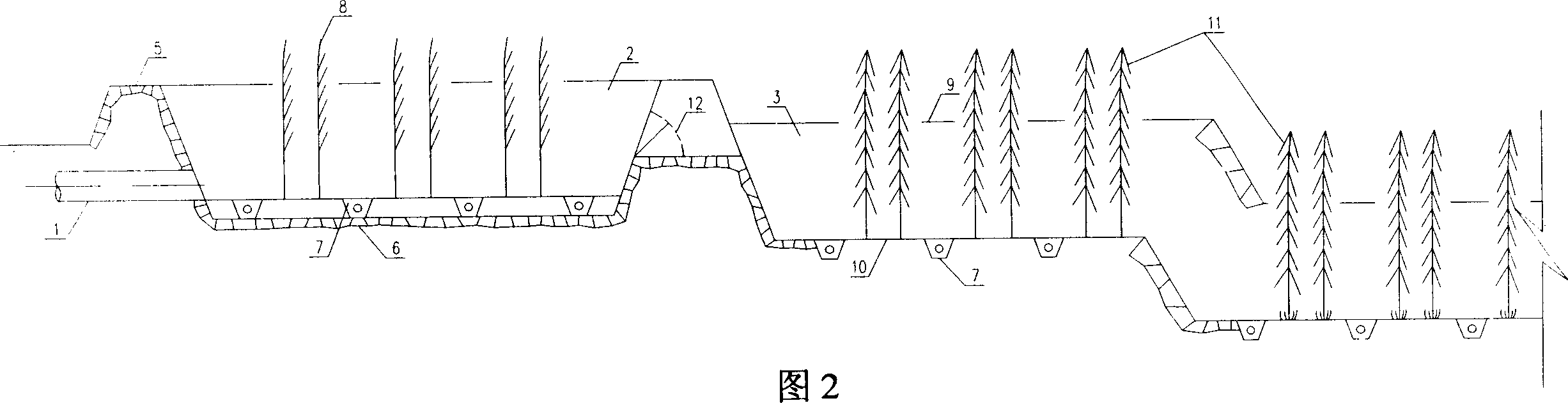

Apparatus and process for producing biological energy source by household organic waste and sludge

InactiveCN103243019AGood solid-gas separation effectGas production time is shortGas production bioreactorsWaste based fuelEngineeringMethane gas

The invention discloses an apparatus for producing biological energy source by organic waste and sludge. The apparatus comprises a biological reaction tower, the inner cavity of the reaction tower is divided into a plurality of separate functional spaces vertically by separation plates; the inner cavity of the reaction tower is provided with a vertical stirring shaft provided with a plurality of stirring blades which are respectively disposed in the separate functional spaces; the separation plates are fixed on the inner cavity of the reaction tower; and the separation plates are provided with through holes. A process for producing the biological energy source comprises 1, hydrolysis reaction: polysaccharides are decomposed into soluble monosaccharides under the effect of anaerobic bacteria; 2, acidification reaction: the soluble monosaccharides are absorbed and acidified into organic acids, alcohols, hydrogen and carbon dioxide by fermentation bacteria in the sludge; 3, gasification reaction: organic acids, hydrogen and carbon dioxide are subjected to the biochemical treatment by methane bacteria to generate methane; and 4, gas-residue separation: methane gas in solid residue rises and is discharged, and the solid residue is discharged downward, under extrusion of horizontal spiral vanes. The apparatus and process are short in gas production time, high in efficiency, high in gas production rate and good in solid-gas separation effect.

Owner:彭世英 +1

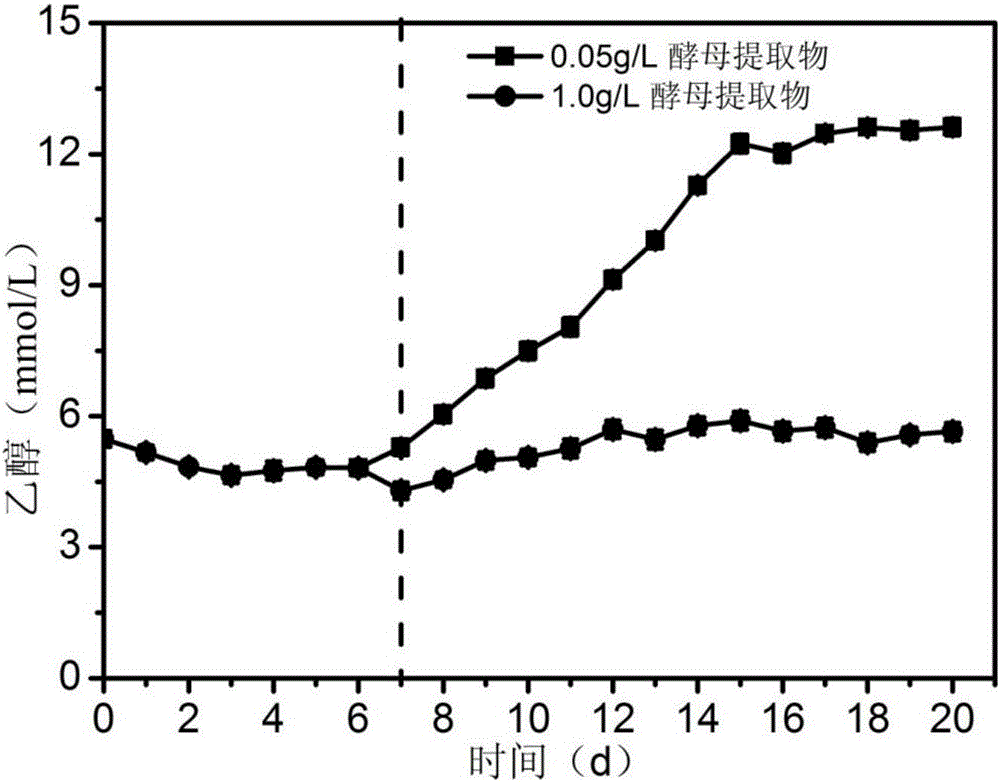

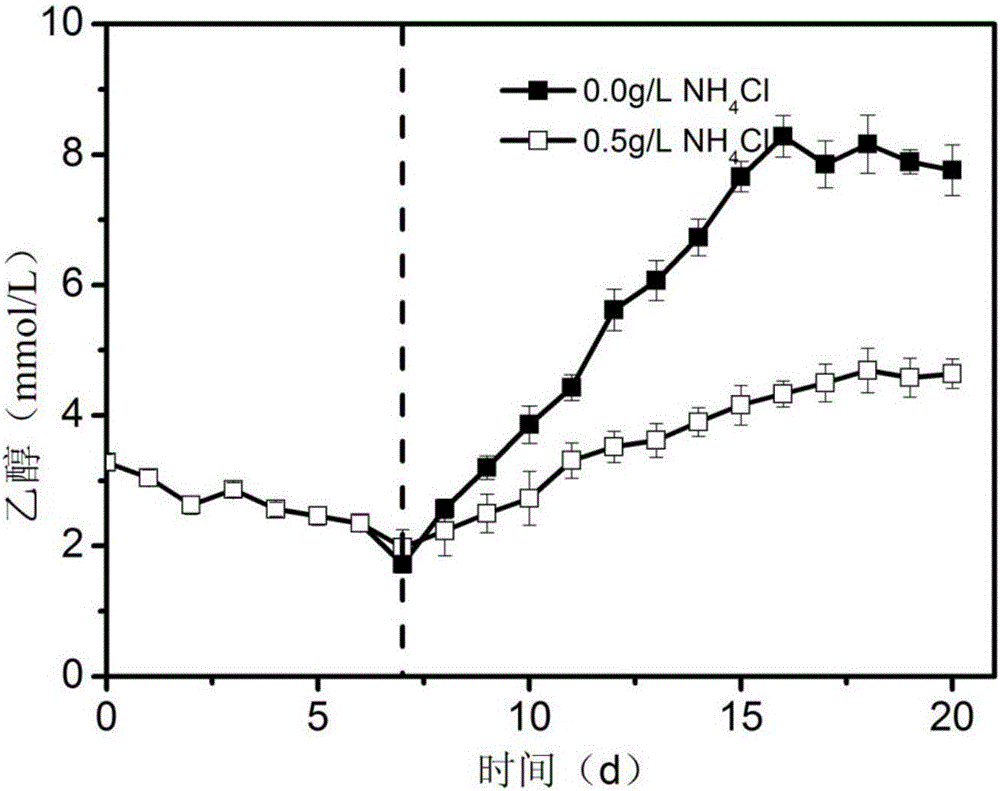

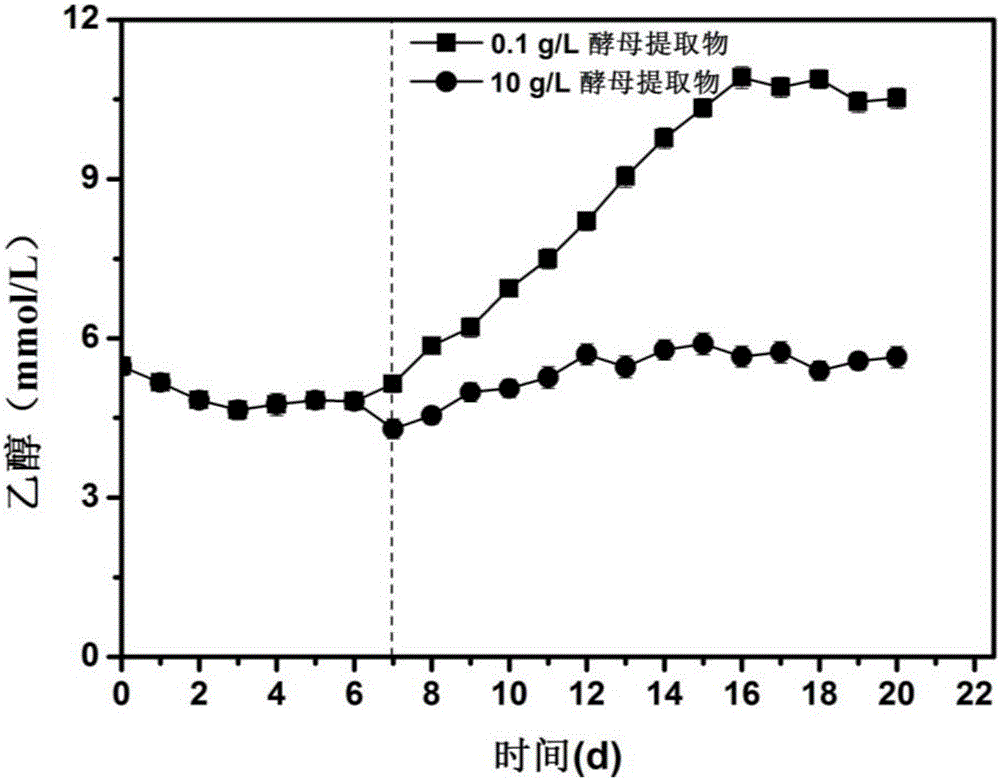

Nitrogen defect control method for production of ethanol through fermentation of synthesis gas with mixed bacteria

The invention belongs to the field of biological energy sources and particularly relates to a nitrogen defect control method for production of ethanol through fermentation of synthesis gas with mixed bacteria. The method comprises steps as follows: a first stage: mixed bacteria are cultured to grow in a fermentation medium to reach a stable state, that is, the yield of fermentation products is stable and unchanged; a second stage: the mixed bacteria growing to reach the stable state are cultured at the second stage, the nitrogen concentration of the fermentation medium at the stage is controlled to be lower than that at the first stage, the mixed bacteria are the same type of acetogenic bacteria which come from cow dung, urban excess sludge and enriched products thereof, as ethanol is a non-growth coupling type product of the acetogenic bacteria, insufficient nitrogen nutrients possibly cause abnormal cell metabolism, cells enter a non-growth state or dormant state, the condition not beneficial to growth of the acetogenic bacteria is created through nitrogen nutrient defects, so that the metabolism pathway is changed from the acid producing phase to the solvent producing phase, and ethanol production is controlled.

Owner:JIANGNAN UNIV

Method for realizing efficient hydrogen production based on chlorella cell biomineralization

ActiveCN111471722AChange basic propertiesAchieve spontaneous transformationOrganic-compounds/hydrides/coordination-complexes catalystsUnicellular algaeCatalytic effectPyrenoid

The invention discloses a method for realizing efficient hydrogen production based on chlorella cell biomineralization. The invention belongs to the technical field of biological energy, and particularly relates to a method for achieving efficient hydrogen production based on chlorella cell biomineralization. The invention aims to solve the problems that existing biological hydrogen production processes are complicated and high in cost, and cannot realize large-scale hydrogen production. According to the method, chlorella pyrenoidosa is taken as a basic living cell, layer-by-layer self-assembly is carried out on the surface of the chlorella pyrenoidosa based on electrostatic interaction, and finally a functional MOF material which takes GMP as a ligand and Cu<2+> as a metal center and hasnano-enzyme activity is formed. By adding an oxygen consumption substrate, the oxygen concentration of a system is quickly reduced under the catalytic action of MOF, so that efficient and quick hydrogen production is realized. The whole system is easy to construct, mild in process and environmentally friendly, meanwhile, the functionalized MOF shell layer not only serves as a catalytic effect, butalso can maintain the basic activity of cells, and the life cycle of the cells in an unfavorable environment is prolonged. The method is used for biological hydrogen production.

Owner:HARBIN INST OF TECH

High-temperature hydrogen production and microalgae oil production coupling capacity method

ActiveCN111763694ALow costHigh substrate conversion rateUnicellular algaeBiofuelsOil and greaseBiochemical engineering

The invention discloses a high-temperature hydrogen production and microalgae oil production coupling capacity method, and belongs to the technical field of biological energy. The method comprises thestep of introducing wastewater into a CSTR anaerobic reactor, inoculating secondary sedimentation tank sludge subjected to high-temperature domestication culture to carry out a continuous high-temperature hydrogen production reaction, and continuously conveying a fermentation liquor separated by the CSTR anaerobic reactor into a microalgae growth reactor during the high-temperature hydrogen production reaction, continuously conveying carbon dioxide and hydrogen generated in a high-temperature hydrogen production reactor to a position below the liquid level of the fermentation liquor in the microalgae growth reactor, after continuously introducing a fermentation product generated in the high-temperature hydrogen production reactor into the microalgae growth reactor for one day, inoculatingmicroalgae into the microalgae growth reactor, and culturing the microalgae; and then conveying the cultured microalgae fermentation liquor into a microalgae oil production reactor for circular oil production culture, collecting microalgae subjected to oil production culture, collecting hydrogen, and extracting grease in the microalgae. The method can realize continuous flow operation and is suitable for industrial production.

Owner:HARBIN INST OF TECH

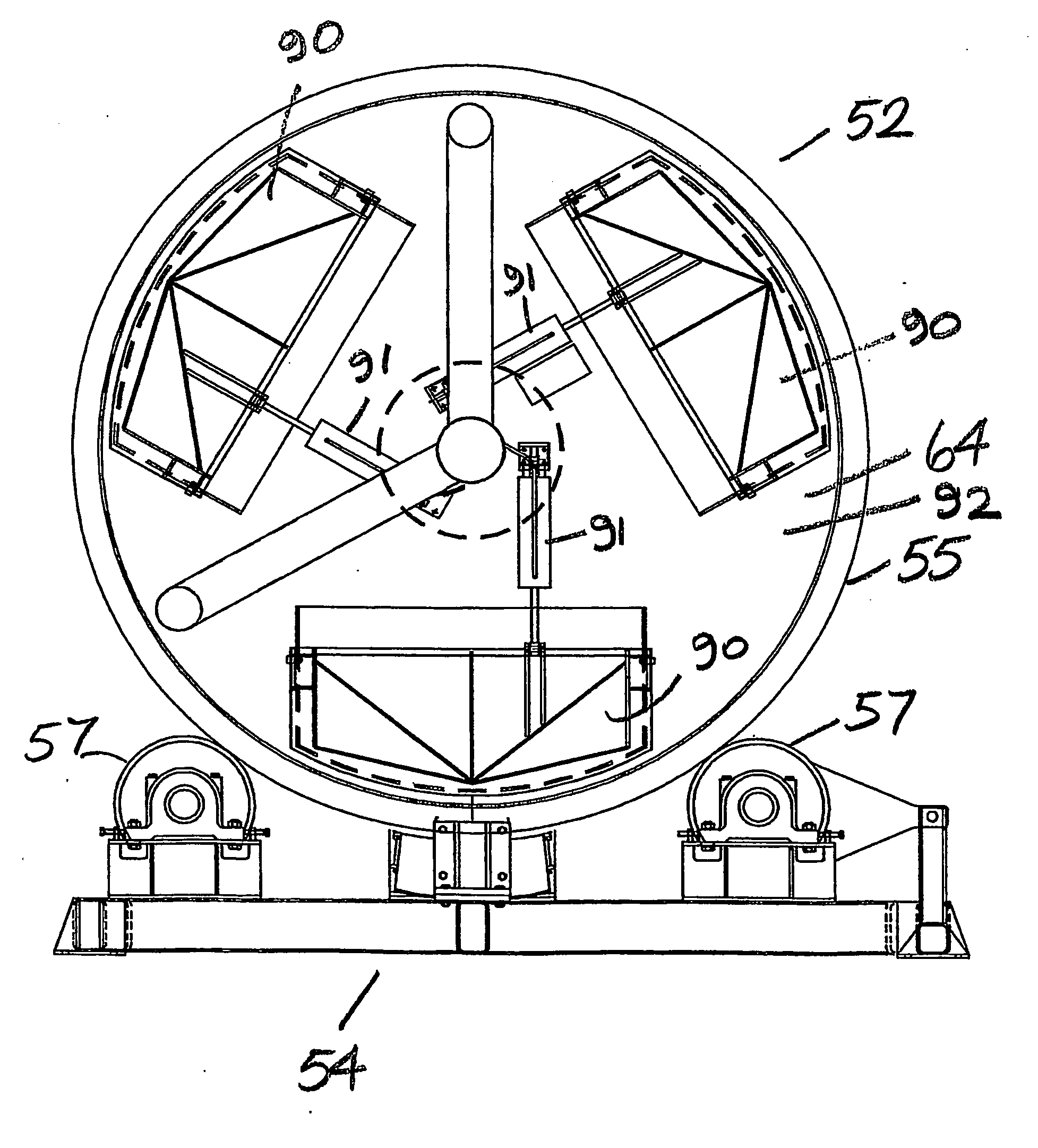

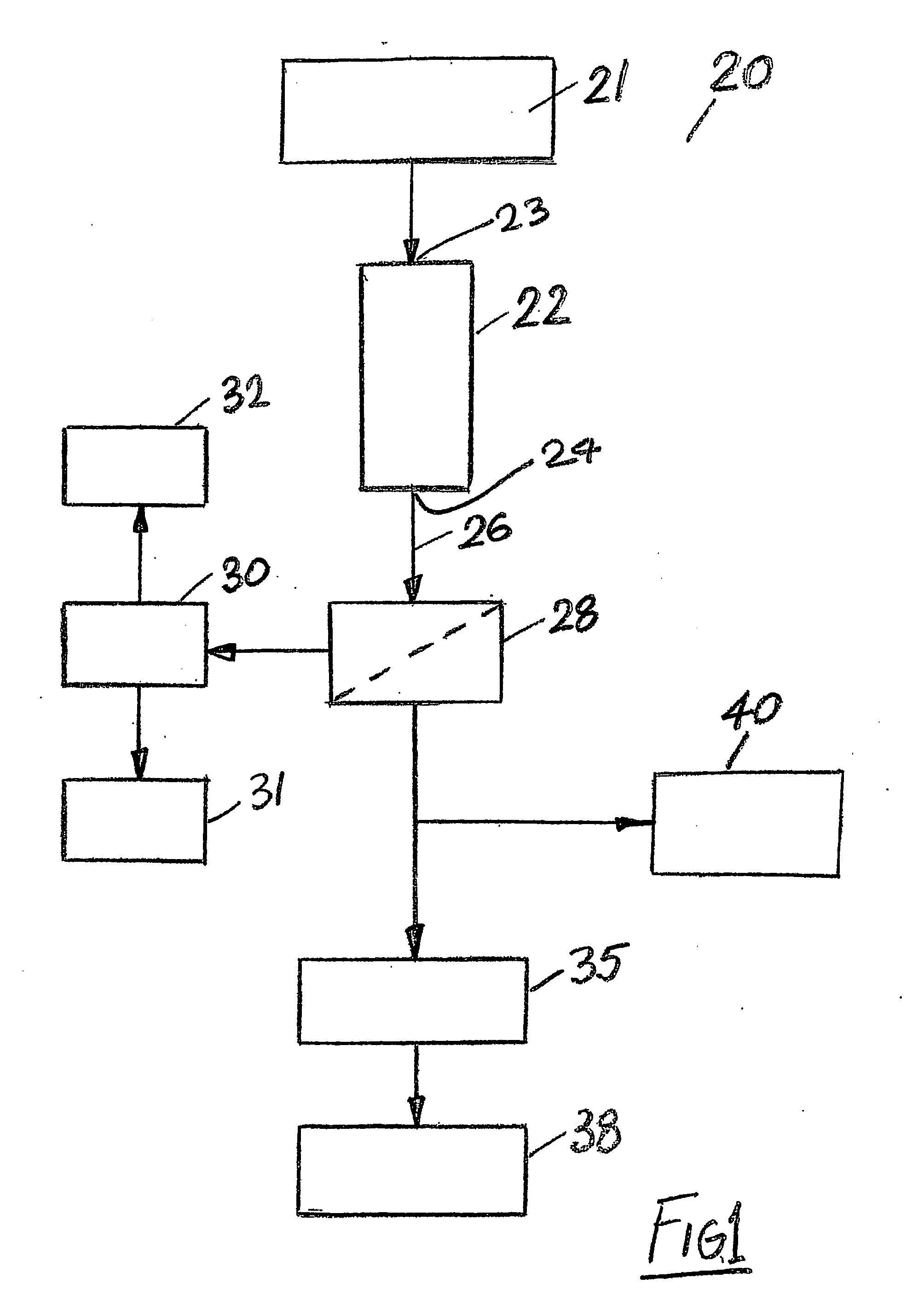

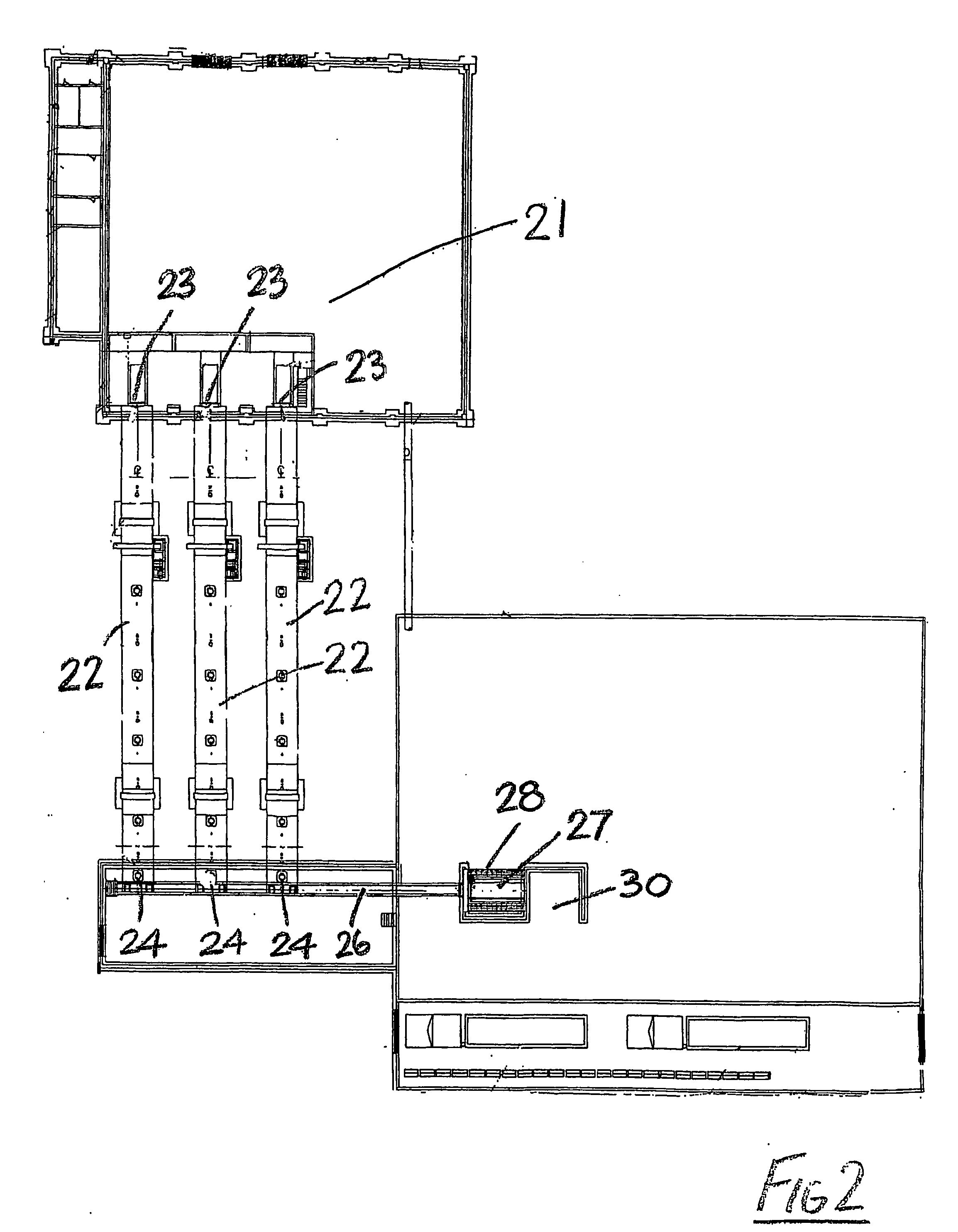

Bio-energy system and apparatus

InactiveUS20100055767A1Improve impact absorption performanceChemical protectionBioreactor/fermenter combinationsCombustionBioelectric Energy Sources

A bio-energy system includes a waste collecting station at which raw waste material such as municipal waste, household waste and the like is collected. The waste is delivered through a rotating organic material digester in a controlled manner for converting the organic waste material content of the raw waste to a bio-fuel. Treated material discharged from the digester is passed through a screen to remove any inorganic materials, leaving the bio-fuel. The bio-fuel is dried at a drying station and then delivered to a boiler for combustion to generate energy.

Owner:BEDMINSTER INT

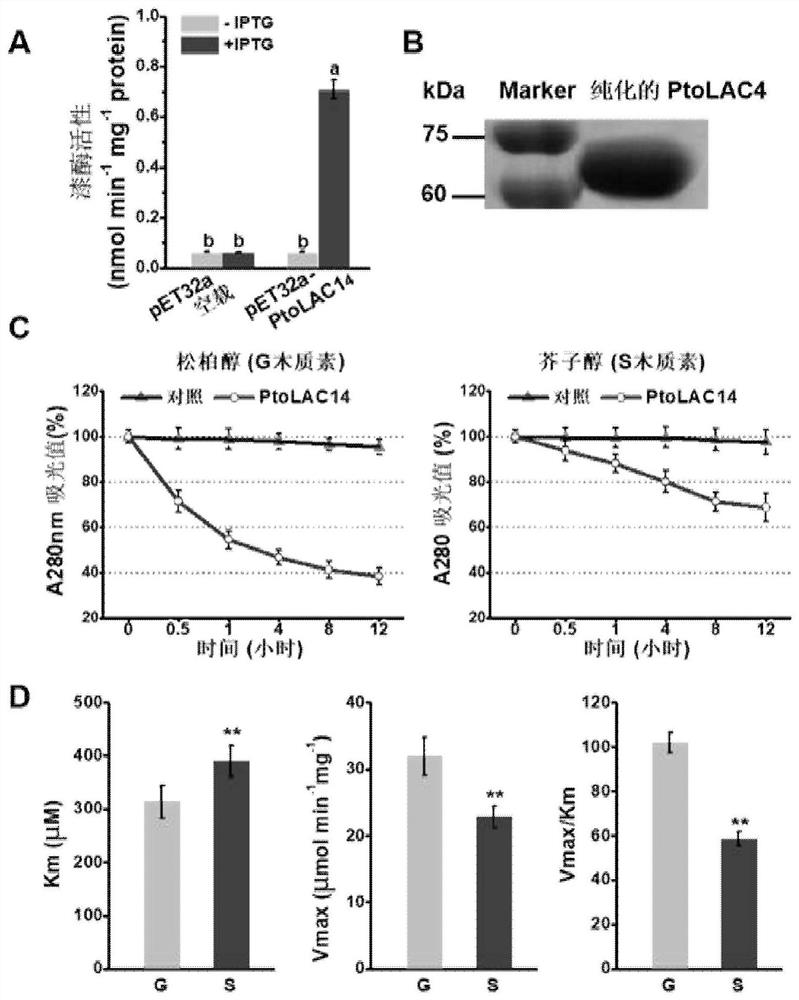

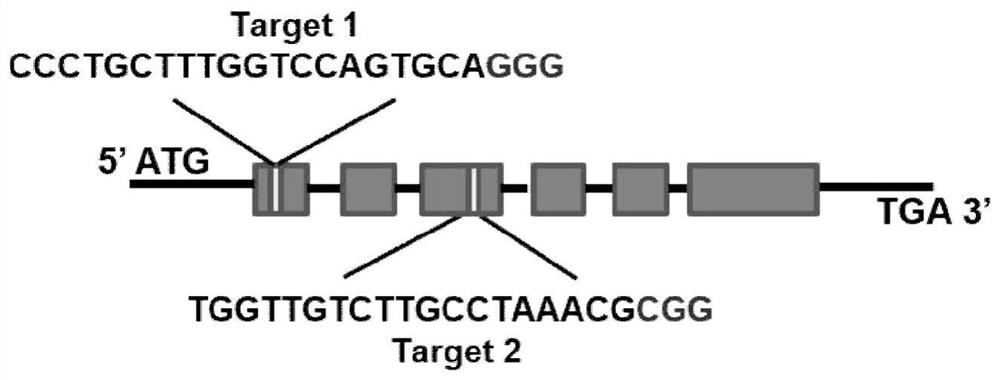

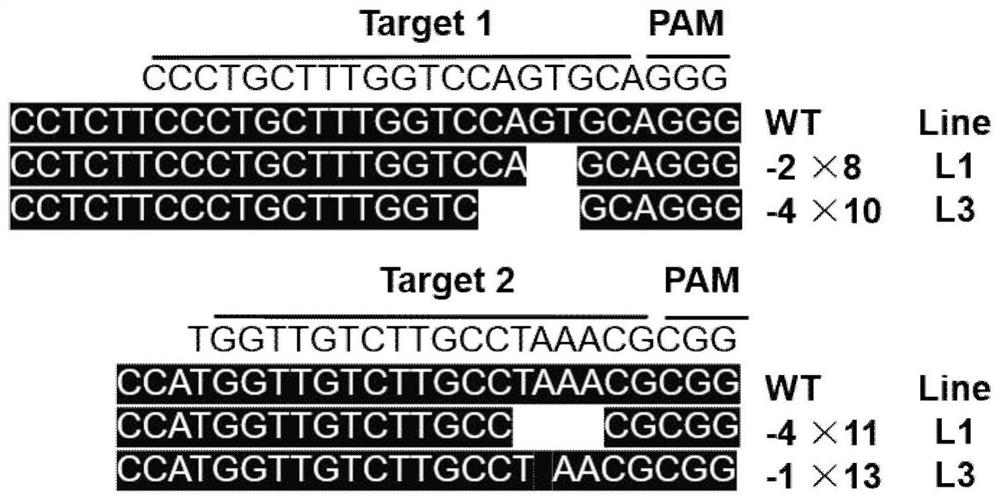

Method for regulating proportion of S/G type lignin and improving degradation and conversion efficiency of cell walls by using laccase PtoLAC14

ActiveCN111718945AReduce contentReduce removal costsOxidoreductasesFermentationBiotechnologyTransformation efficiency

The invention discloses a method for regulating the proportion of S / G type lignin and improving the degradation and conversion efficiency of cell walls by using laccase PtoLAC14, and belongs to the technical field of plant genetic engineering. The CDS sequence of the PtoLAC14 is shown as SEQ ID No. 1. It is discovered for the first time that the populus tomentosa PtoLAC14 can specifically regulateand control polymerization of G-type lignin monomers, and the PtoLAC14 is edited by using a CRISPR / Cas9 technology, so that transgenic plants with reduced total lignin content, reduced G-type lignincontent and increased lignin S / G ratio are obtained; the cell wall degradability of the transgenic plants is obviously improved, so that the removal cost of lignin during biological energy source production and papermaking is reduced. The invention lays a foundation for lignin genetic improvement and directed molecular breeding of plants, provides a new gene resource for plant genetic engineering,and has a wide application prospect.

Owner:SOUTHWEST UNIVERSITY

Method used for detecting carbohydrates based on microorganism surface controllable co-display sequential enzyme electrochemical biosensor

ActiveCN107727704AResponsiveGood reproducibilityMaterial electrochemical variablesChemical industryElectrochemical biosensor

The invention belongs to the field of electrochemical biosensor, and more specifically relates to a method used for detecting carbohydrates through construction of a sequential enzyme electrochemicalbiosensor based on microorganism surface controllable co-display sequential enzymes. According to the method, glucose oxidase (GOx) single-display on yeast strain surface is carried out, or glucoamylase (GA) and GOx co-display at a certain ratio on yeast strain surface is carried out; the yeast strain treated via single-display or co-display are modified onto a treated electrode so as to obtain anelectrochemical glucose biosensor or an electrochemical starch biosensor, and realize quantitative detection on glucose or starch in sample solutions. The obtained biosensors are capable of providingan effective approach to solve a problem that component analysis using a single enzyme sensor is difficult to perform, and the method can be widely used in the fields such as optimization and controlof biomass raw material pretreatment, biological energy source, food fermentation, medicine, and chemical industry, and clinical detection.

Owner:QINGDAO UNIV

Concentration mass energy conversion pool

ActiveCN1919757AConcentrated and driedAchieve emission standardsSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeBioelectric Energy Sources

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

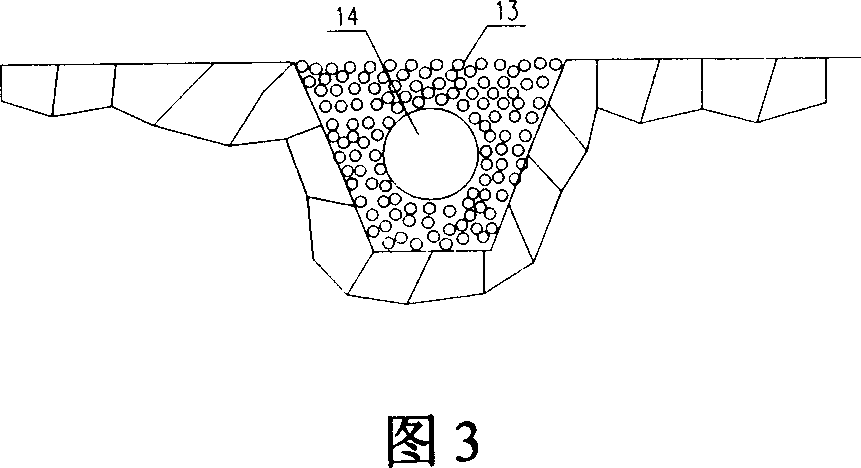

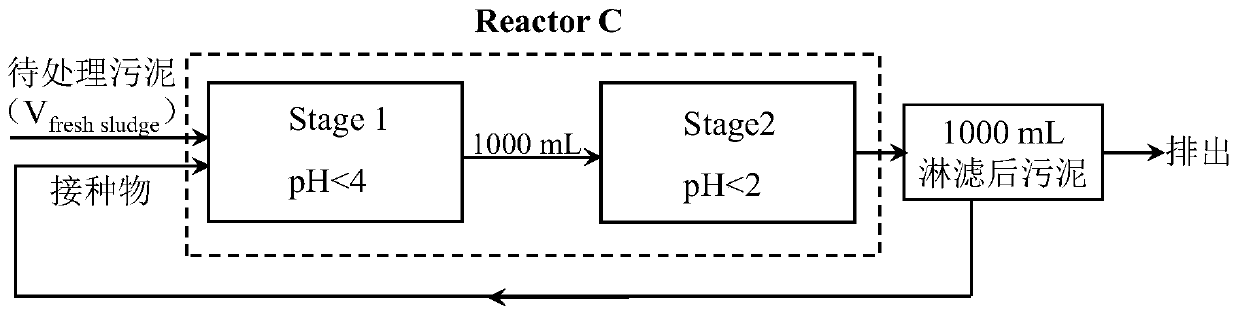

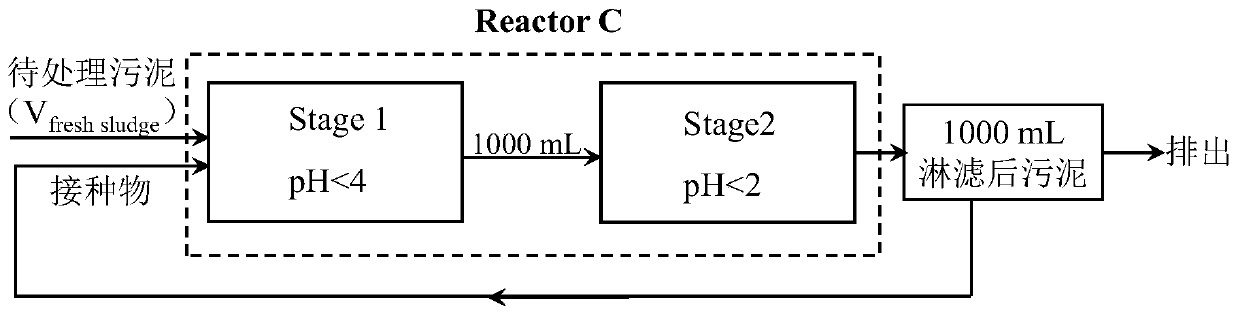

Secondary bioleaching continuous process for efficiently removing heavy metal chromium from leather making sludge

ActiveCN110040926AImprove bioleaching performanceIncrease concentrationWater contaminantsWaste water treatment from animal processingSludgeBioleaching

The invention discloses a secondary bioleaching continuous process for efficiently removing heavy metal chromium from leather making sludge. The secondary bioleaching continuous process comprises thefollowing steps: adding microflora, a microorganism energy substance and sludge to be treated into a first-level reactor and a second-level reactor respectively, supplementing to working volume with water, and meanwhile starting the first-level reactor and the second-level reactor; carrying out a bioleaching reaction on the first-level reactor and the second-level reactor; when the pH values of the first-level reactor and the second-level reactor are lower than a set value, draining the sludge bleached in the second-level reactor by a certain volume, and supplementing sludge in the first-levelreactor for reacting continually; supplementing the sludge bleached in the second-level reactor and the sludge to be treated containing the bioenergy substrate into the first-level reactor for reacting continually; repeating the step 3 and the step 4 to realize continuous bioleaching reaction for removing chromium. By adopting the secondary bioleaching continuous process, corresponding reaction environments can be provided for different microorganisms, the long-term continuous running of the bioleaching reaction is promoted, and the engineering application of the bioleaching process is realized.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com