Bioreactor-direct microbe fuel cell and use thereof

A bioreactor and fuel cell technology, applied in biochemical fuel cells, fuel cells, electrochemical generators, etc., can solve the problem of single raw material and low efficiency, and achieve the effects of good stability, clean power generation, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

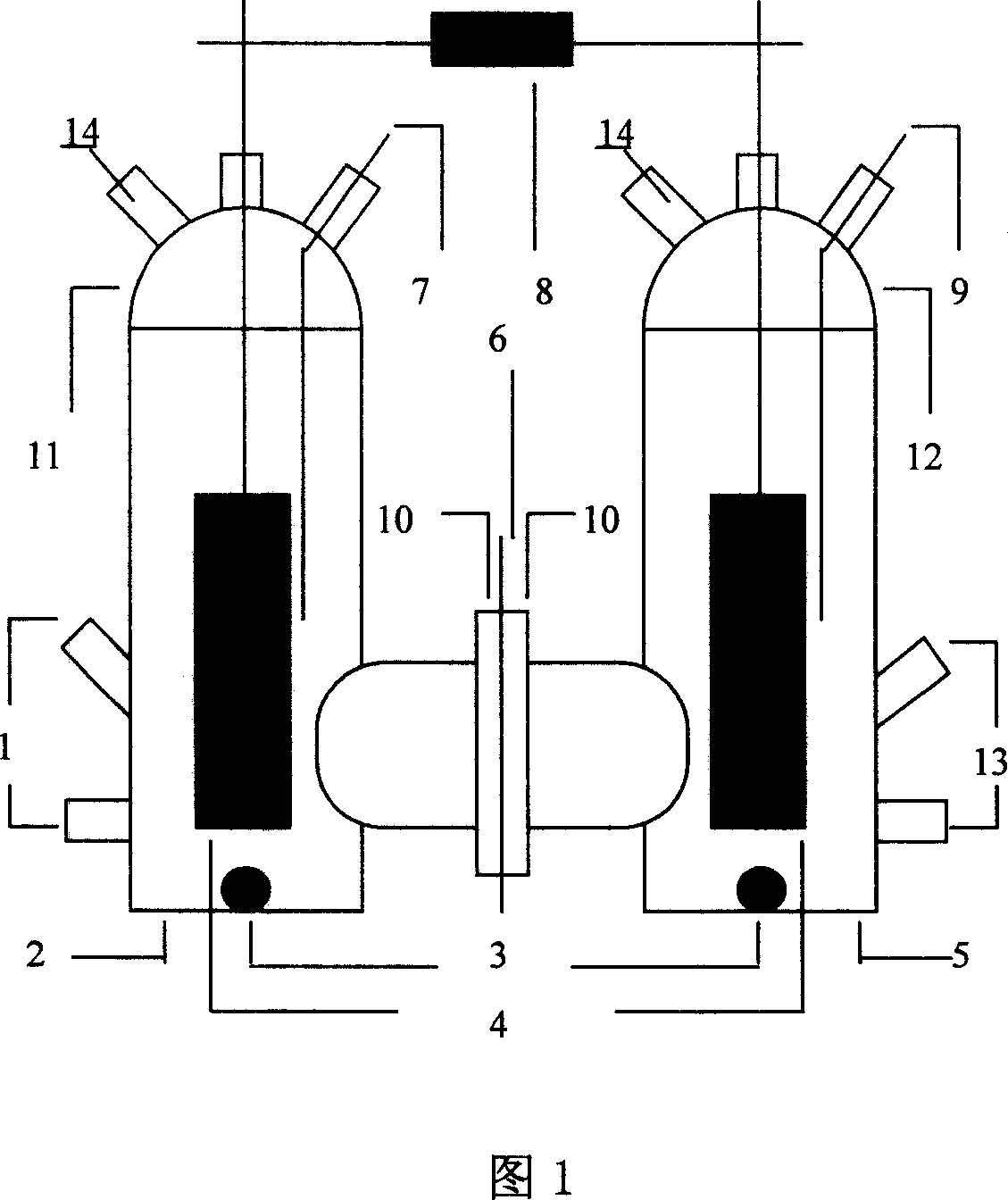

[0042] See Figure 1. The bioreactor-direct microbial fuel cell mainly includes an anode chamber 2, a cathode chamber 5, a polytetrafluoroethylene flange (with a groove and a gasket) 10 separating the two chambers, and a proton exchange is fixed between the two flanges. Membrane 6, the main components of the anolyte (200mL) in the anode chamber 2 are: 0.6g sodium chloride, 0.12g sodium dihydrogen phosphate, 0.5g sodium bicarbonate, pH 6.8-7.0. The anode chamber has an interface 1 for inoculation, sample addition and sampling analysis, and a cover 11 connected to the grinding port on the upper end. The graphite rod 4 is fixed on the cover, and there is a sterile N 2 -CO 2 (Volume ratio 80:20) mixed gas inlet 7, mixed gas enters the anolyte through the latex tube sealed with raw material tape through the injection needle shaped inlet pipe installed at the inlet. The main components of catholyte (200 mL) in cathode chamber 5 are: 0.6 g sodium chloride, 0.12 g sodium dihydrogen p...

Embodiment 2

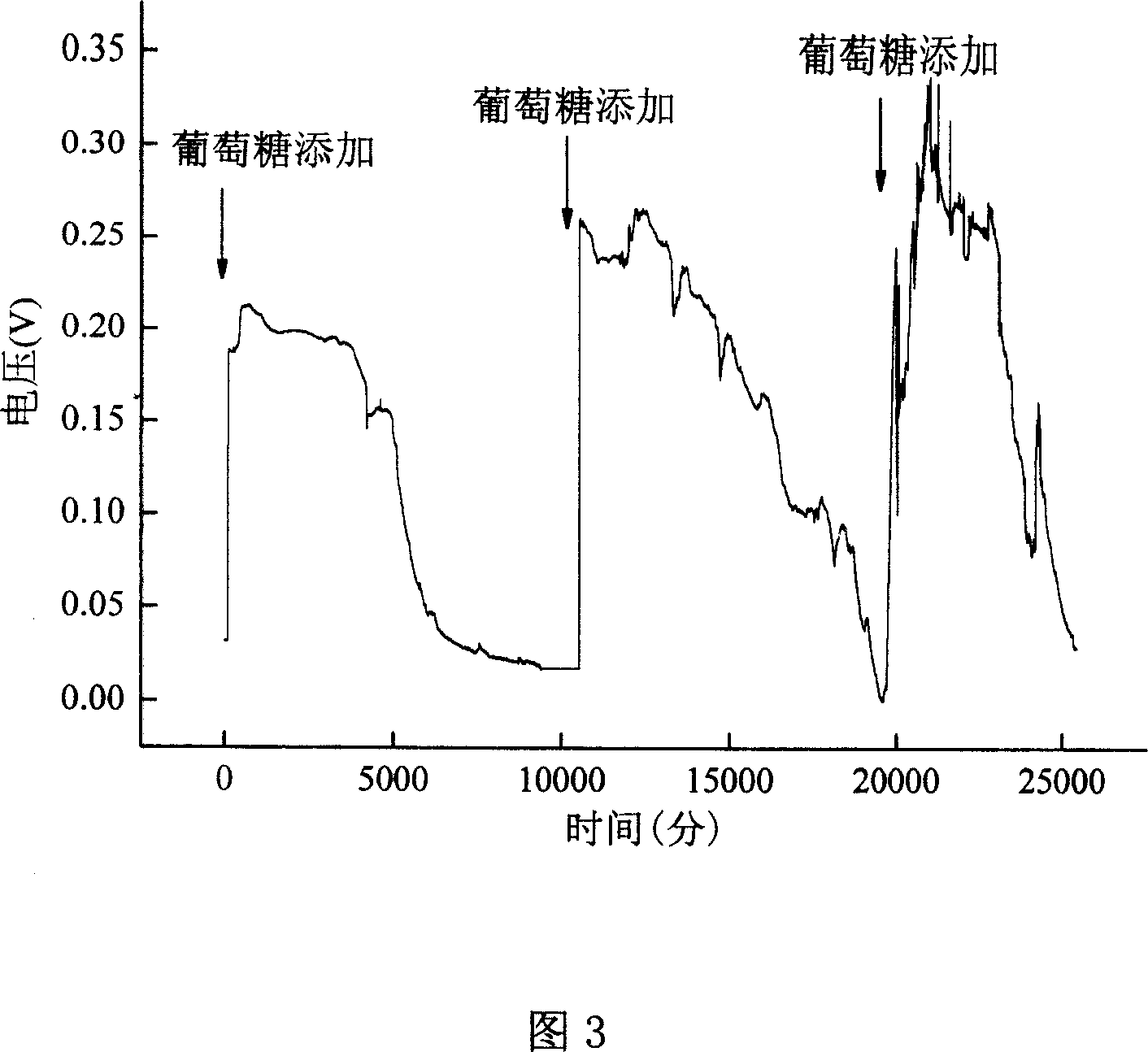

[0044] Utilizing the bioreactor and reaction conditions of Example 1, wherein the diameter of the magnetic stirring bar used is 1.5 cm, 0.36 g of glucose was added into the anode chamber 2, and R. ferrireducens was inoculated with a syringe at 10%. After a period of growth, under the condition of an external resistance of 500Ω and without adding any catalyst to the cathode, the voltage between the two electrode chambers can reach 0.25V, and the current density can reach 80mA / m 2 , the voltage can last for about 15 days. After the voltage drops to the baseline voltage, that is, when the glucose is exhausted, add 0.036g of glucose (fuel) in time, and the voltage can quickly return to the original level for about 3 days, as shown in Figure 3 .

Embodiment 3

[0046] As in the reactor and reaction conditions of Example 2, after the battery is operating normally, when the glucose is exhausted, that is, when the voltage drops to the baseline voltage, inject 5ml of monosodium glutamate wastewater, the initial COD is 1500mg / L, and the voltage will quickly rise to about 0.2V , the voltage can last for about 7 days, and after 7 days of reaction, the COD of the wastewater is reduced to 200mg / L, as shown in Figure 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com