Mass-energy transformation treatment process for production wastewater

A technology of treatment process and quality-energy conversion, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. The problem of high mud content, to achieve the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

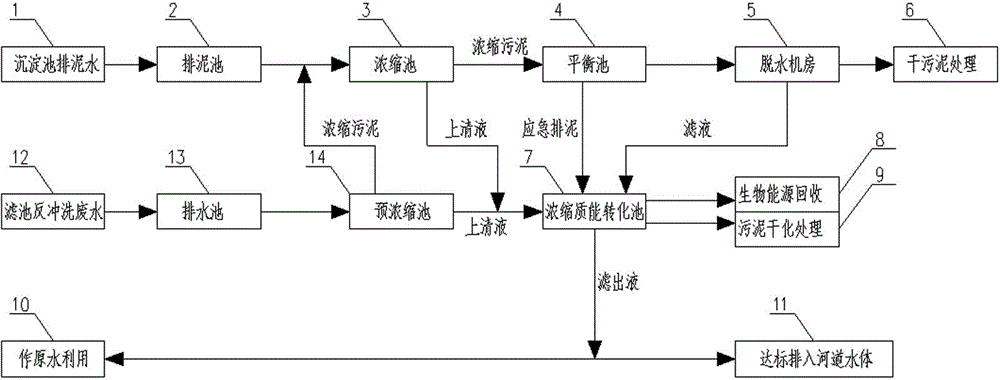

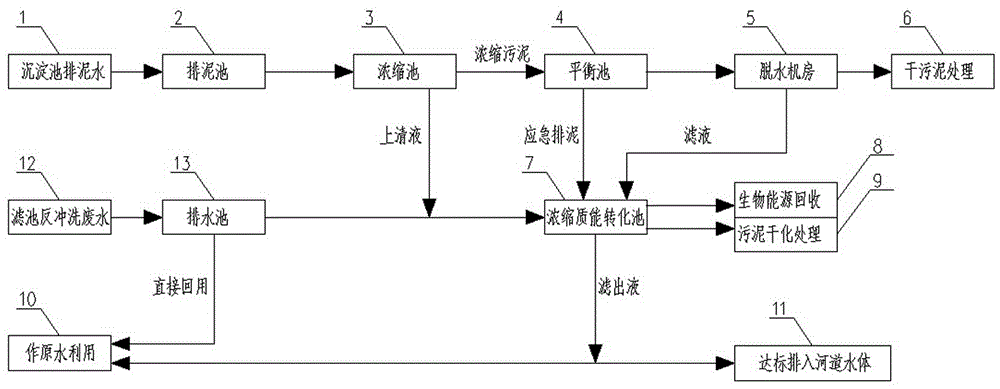

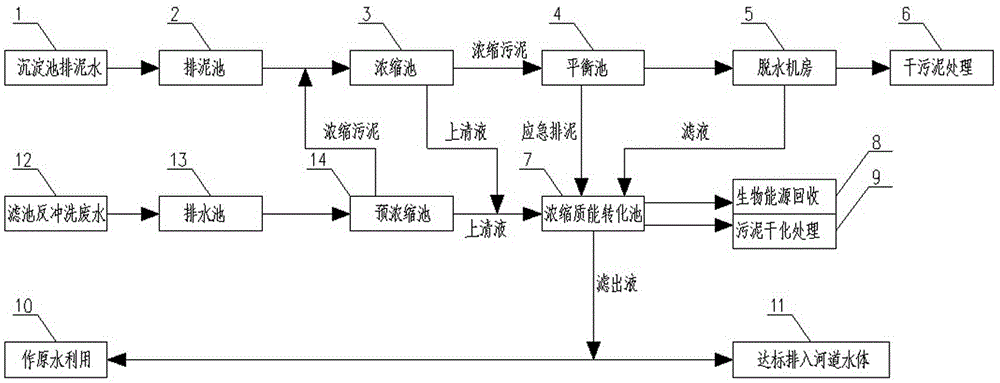

[0015] The present invention relates to a treatment process for converting production wastewater into quality and energy. Firstly, according to different treatment methods of filter backwash wastewater, the treatment process is divided into pre-concentration post-treatment process for filter backwash wastewater and direct reuse treatment process for filter backwash wastewater. There are three types of mixed concentration treatment processes for sedimentation tank discharge sludge water and filter backwash wastewater. Among them, the pre-concentration and post-treatment process of filter backwash wastewater is suitable for the situation where the site area is large and the filter backwash wastewater cannot be directly reused or discharged; the direct reuse treatment process of filter backwash wastewater is suitable for filter backwash wastewater It can directly meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com