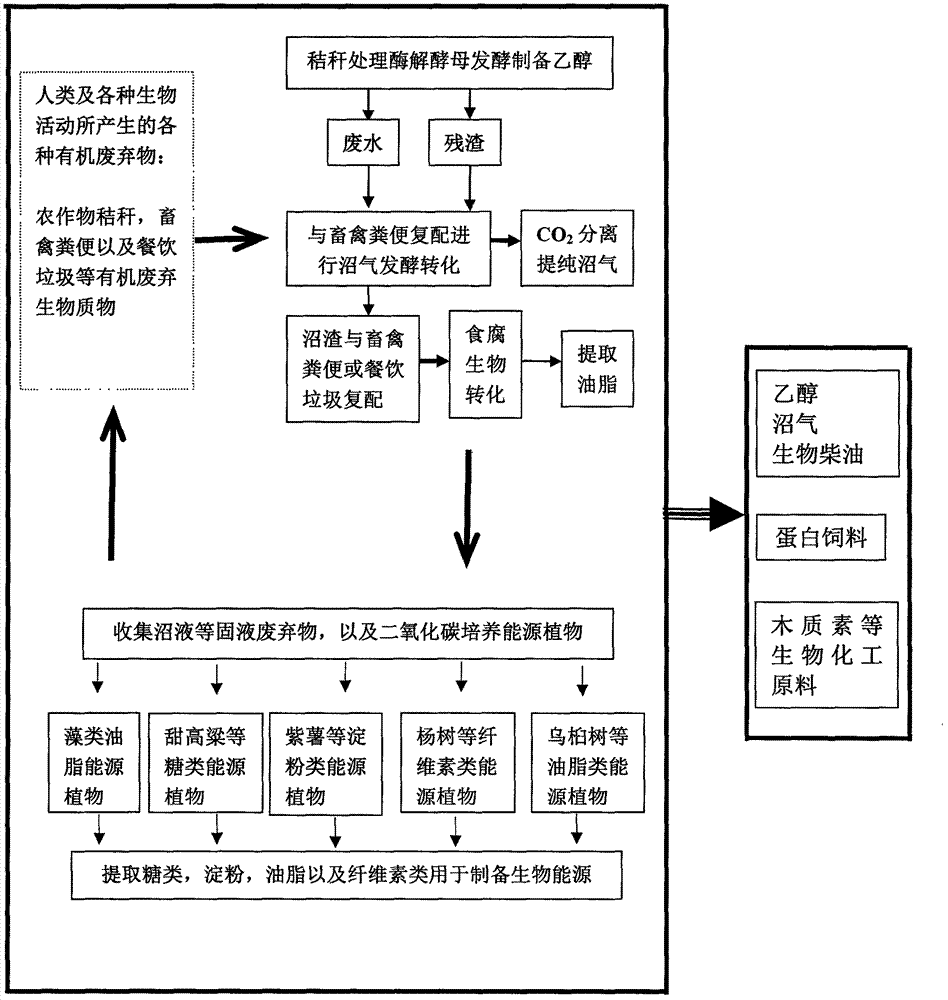

Co-production method for preparing ethanol, biogas and biodiesel by using organic waste

A technology of organic waste and biodiesel, which is applied in fertilizers, organic fertilizers, biofuels and other directions made of biological wastes, to achieve the effects of less by-products, high bioenergy yield and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

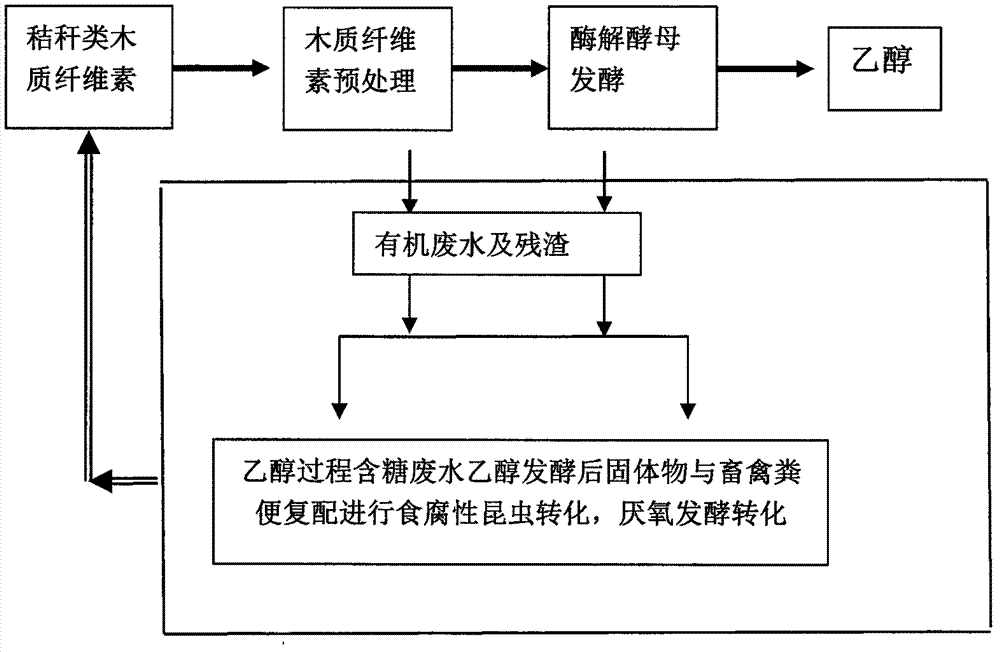

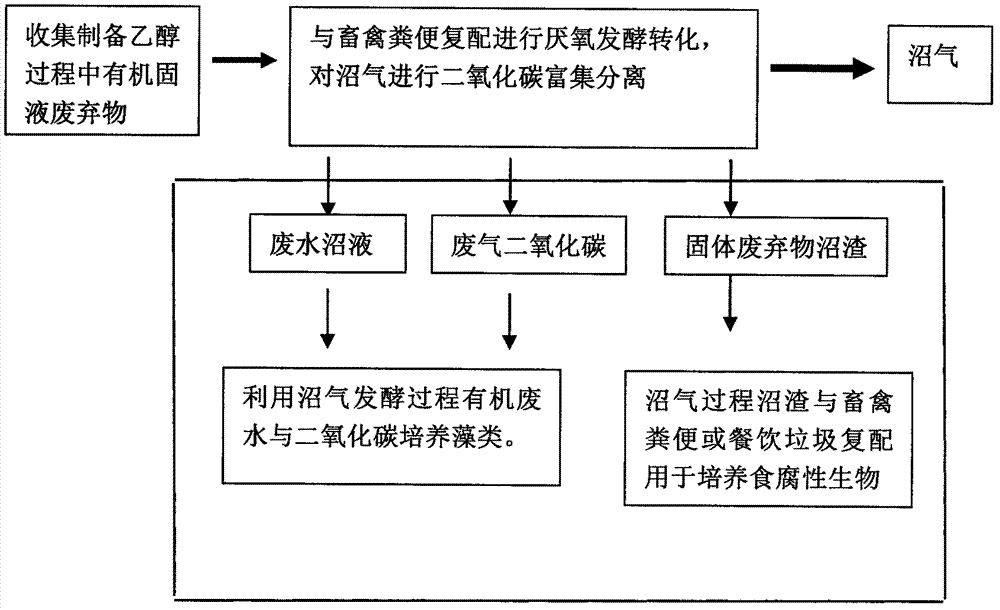

[0015] The present invention is realized through the following technical solutions: straws are used as raw materials to produce fuel ethanol, and the unit includes the following steps: (1) crushing of straws: crushing straws to 80 mesh sieves; Add 1.0% NaOH solution to the lignocellulose powder; (2) hydrolyze and saccharify by cellulase; add cellulase to the straw powder prepared in step (1), stir and hydrolyze for 48 hours at 40°C and pH 4.5 , to obtain cellulase hydrolysis and saccharification hydrolyzate; (3) ethanol fermentation In a fermenter, reduce the temperature of cellulase hydrolysis and saccharification hydrolyzate to 35°C, add yeast 2g / L, and carry out constant temperature fermentation reaction to obtain fuel ethanol. Biogas anaerobic fermentation part, this unit includes the following steps: (4) carry out flocculation and sedimentation treatment to (3) cellulosic ethanol waste liquid; (5) mix the substrate of anaerobic fermentation, put into anaerobic fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com