Concentration mass energy conversion pool

A technology for concentrating mass-energy conversion and drying tank, which is used in dewatering/drying/concentrating sludge treatment, biological sludge treatment, etc., which can solve the problems of long time, the difficulty of dewatering filtrate to meet the discharge standard, and the high investment cost of mechanical dewatering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

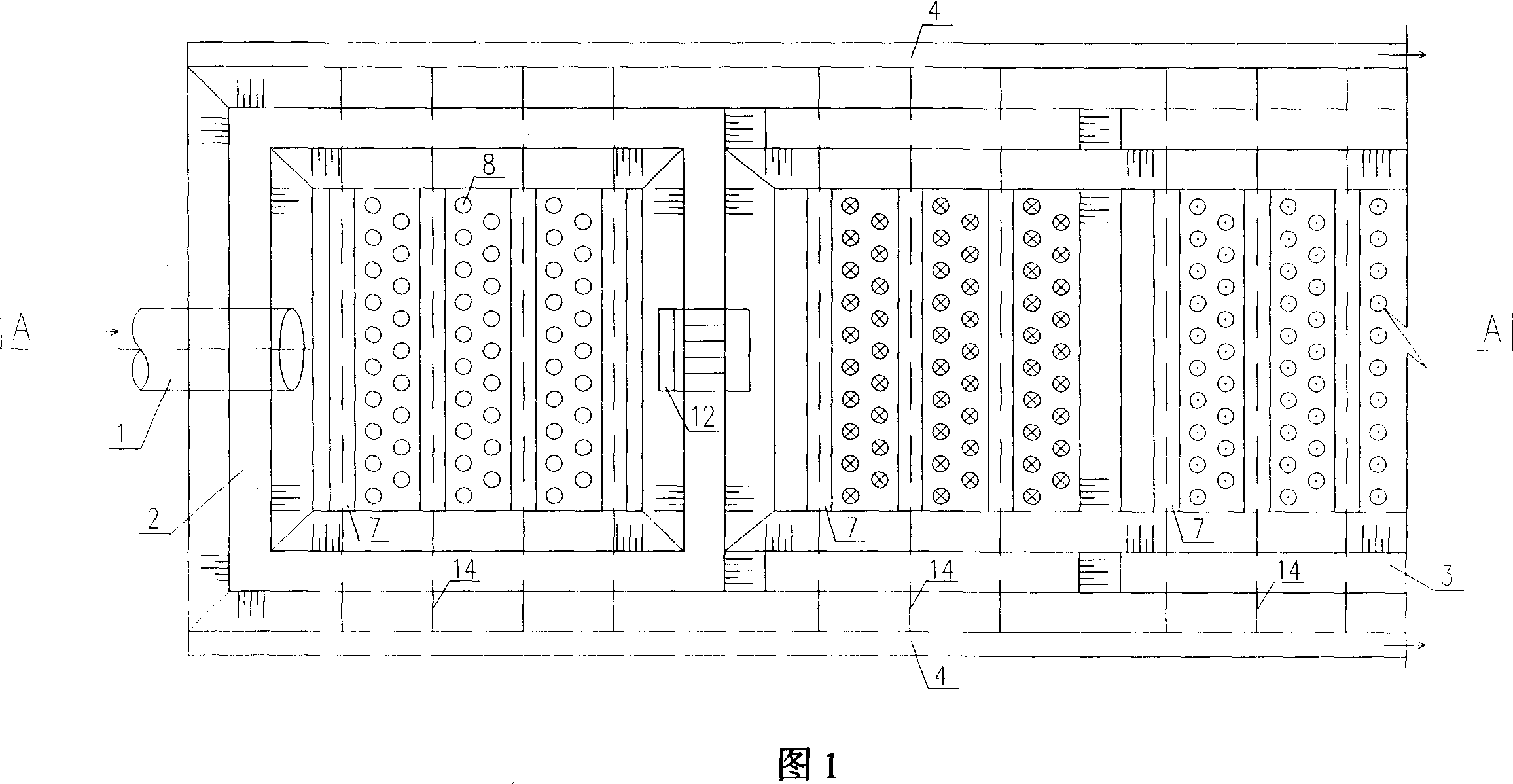

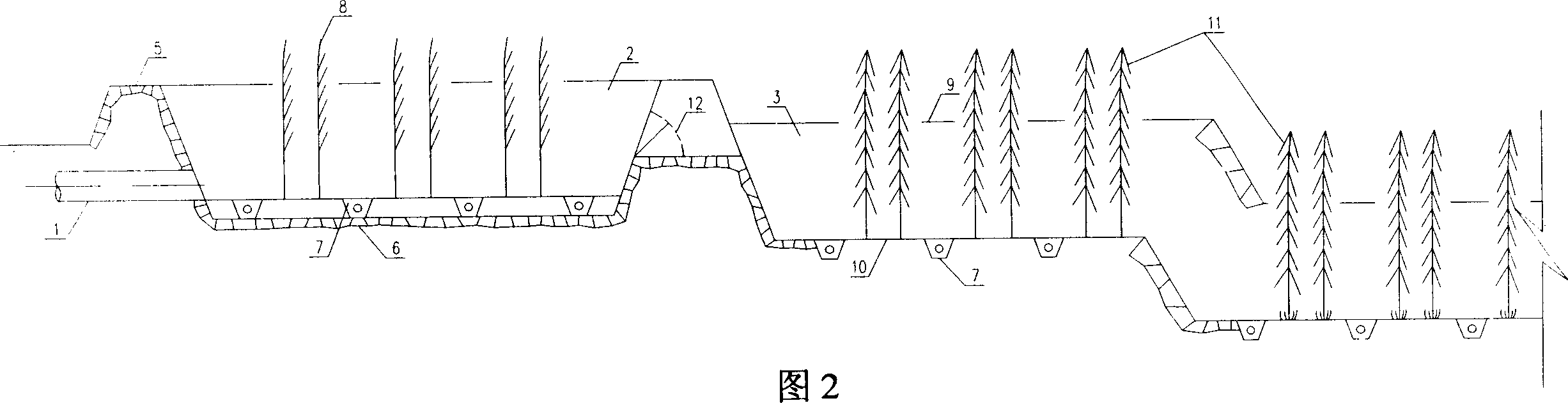

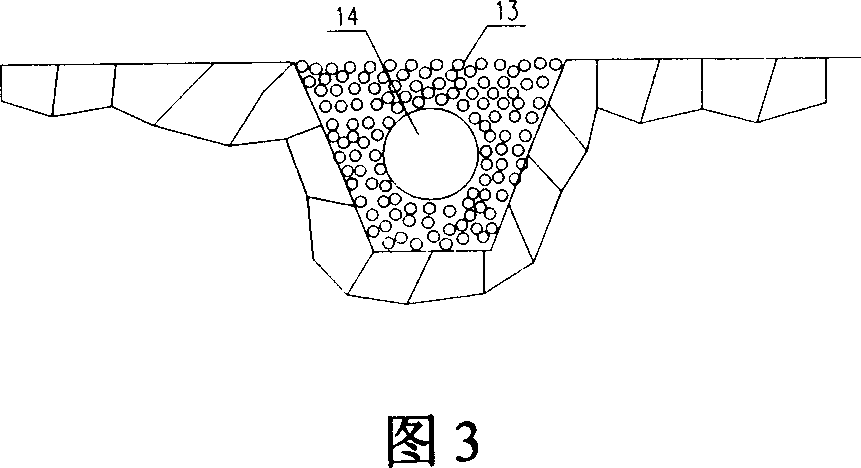

[0012] A concentrated mass-energy conversion tank, comprising a water inlet pipe 1, a sludge concentration and drying tank 2 connected to the water inlet pipe 1, characterized in that the sludge concentration and drying tank 2 is connected to a biomass conversion tank 3, and the sludge concentration A clear water outlet 12 is provided at the joint between the drying pond 2 and the biomass conversion pond 3 , and bioenergy plants 11 are planted in the biomass transformation pond 3 . Among them, the sludge thickening and drying pool 2 is paved with mortar block stones for the pool wall 5 and the pool bottom 6, and blind ditch infiltration devices 7 and perennial wetland aquatic plants 8 such as reeds are arranged at intervals in the pool. According to the site conditions such as the size of the pool body, blind The distance between the trench infiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com