Apparatus and process for producing biological energy source by household organic waste and sludge

A technology of organic waste and bio-energy, applied in gas production bioreactors, biological sludge treatment, energy wastewater treatment, etc., can solve the problems of long gas production time, incomplete biochemistry, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

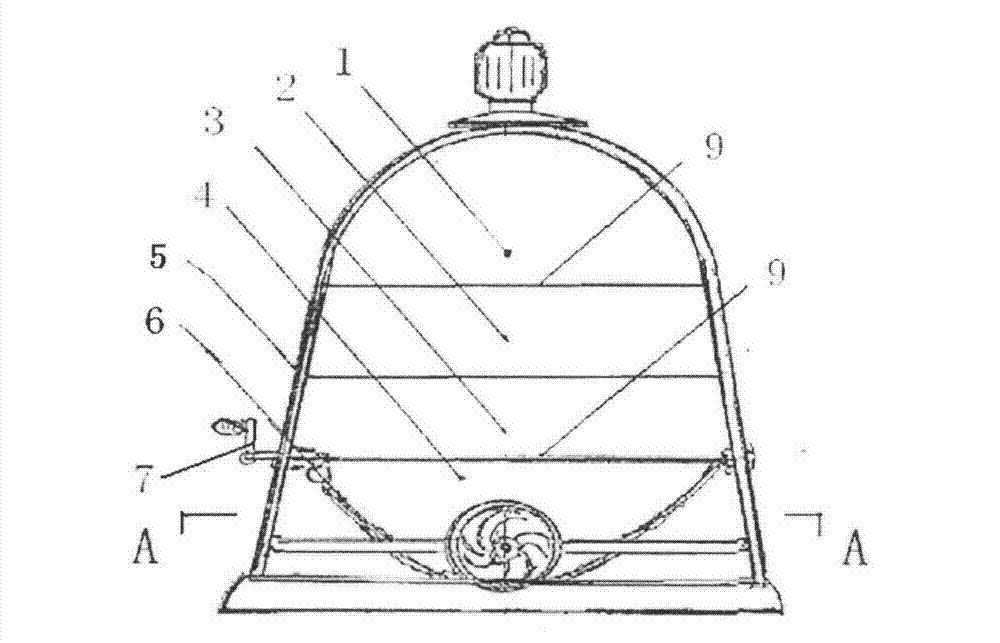

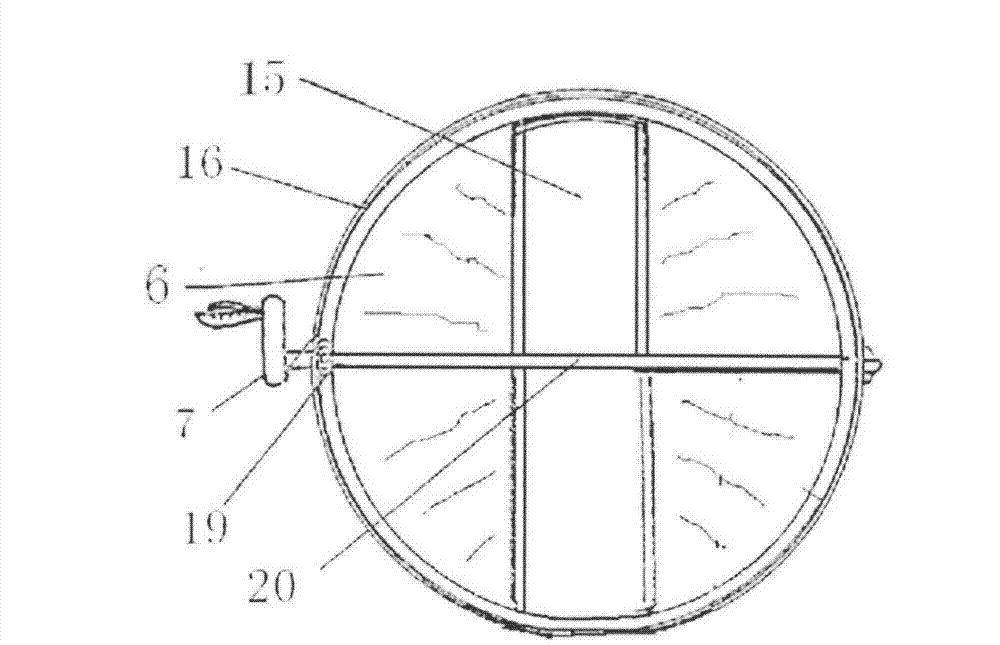

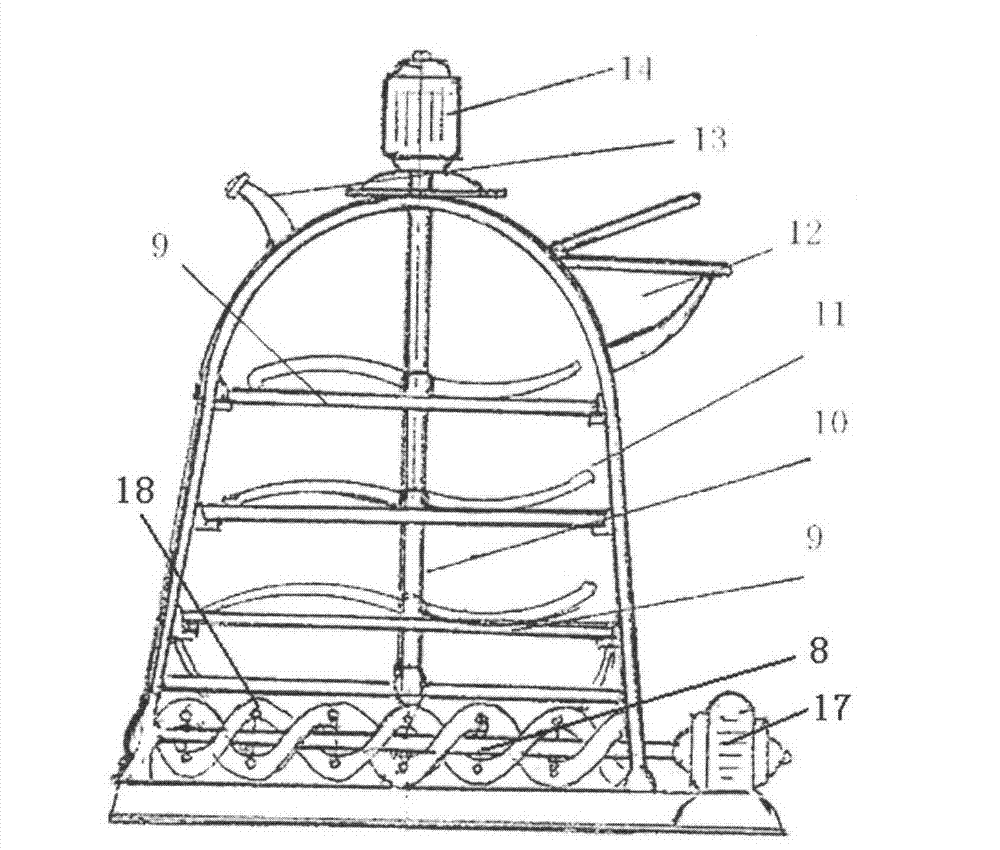

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: 1 ton of organic waste and sludge is poured into the silo through the feed port 24, and the stirring shaft 25 is stirred evenly and enters the hydrolysis chamber 1 through the feed port 12 for hydrolysis reaction. Under the action of anaerobic bacteria, the polysaccharides are decomposed into soluble monosaccharides; soluble monosaccharides enter the acidification chamber 2 acidification reaction, the fermentation bacteria in the sludge absorb acidification to produce acid, hydrogen, carbon dioxide; then enter the gasification chamber 3 gasification reaction to generate gas; Press down, the gas in the biogas residue in the gas residue separation chamber 4 is discharged from the gas outlet 13 and filtered and then loaded into the gas storage tank, and the biogas residue is discharged downward through the discharge tank 15 to the batching machine to become fertilizer, and the reaction temperature of hydrolysis, acidification, and gasification Control at 25°C-...

Embodiment 2

[0024] Embodiment 2: 2 tons of organic waste and sludge are poured into the silo through the feed port 24, and the stirring shaft 25 is stirred evenly and enters the hydrolysis chamber 1 through the feed port 12 for hydrolysis reaction. Under the action of anaerobic bacteria, the polysaccharides are decomposed into soluble monosaccharides; soluble monosaccharides enter the acidification chamber 2 acidification reaction, the fermentation bacteria in the sludge absorb acidification to produce acid, hydrogen, carbon dioxide; then enter the gasification chamber 3 gasification reaction to generate gas; Press down, the gas in the biogas residue in the gas residue separation chamber 4 is discharged from the gas outlet 13 and filtered and then packed into the gas storage tank, and the biogas residue is discharged downwards through the discharge groove 15 to the batching machine to become fertilizer. The reaction temperature of hydrolysis, acidification and gasification is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com