Circulating condensation boiler

A technology for condensing boilers and boiler shells, which is used in steam boilers, steam boiler accessories, boiler cleaning devices, etc., can solve the problems of reduced boiler safety, low operation efficiency, slow steam production speed, etc. Compact structure and small water level fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

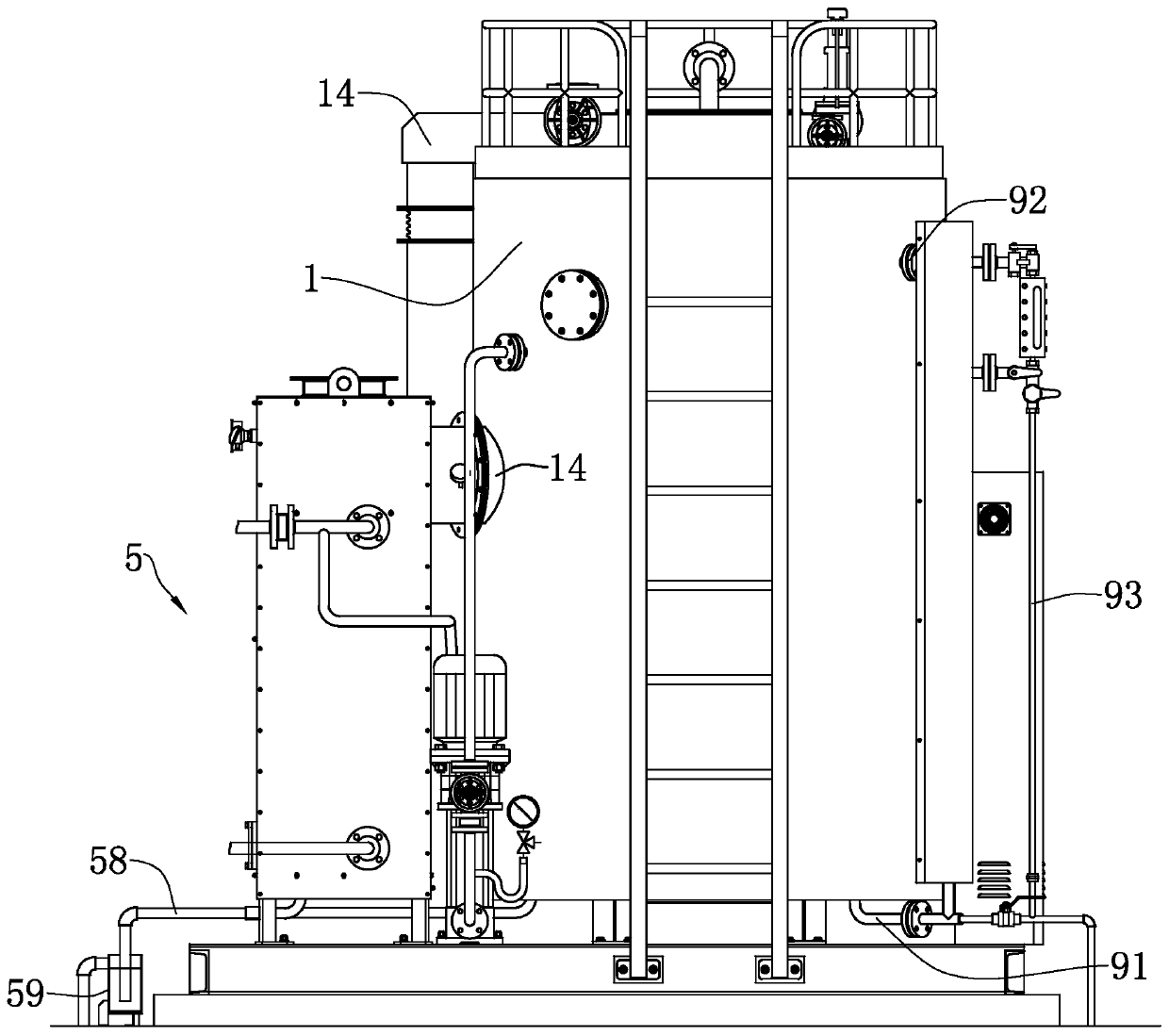

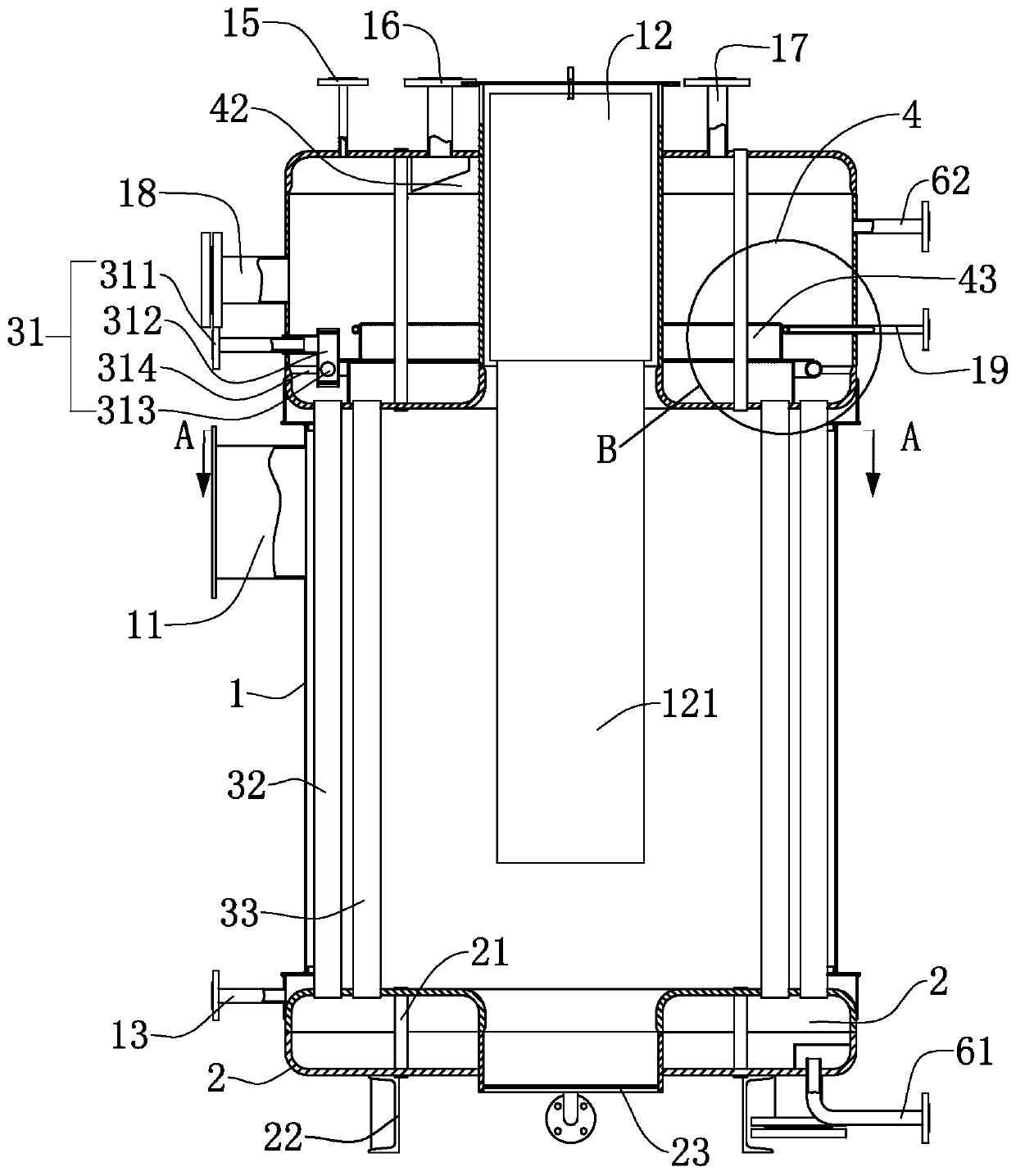

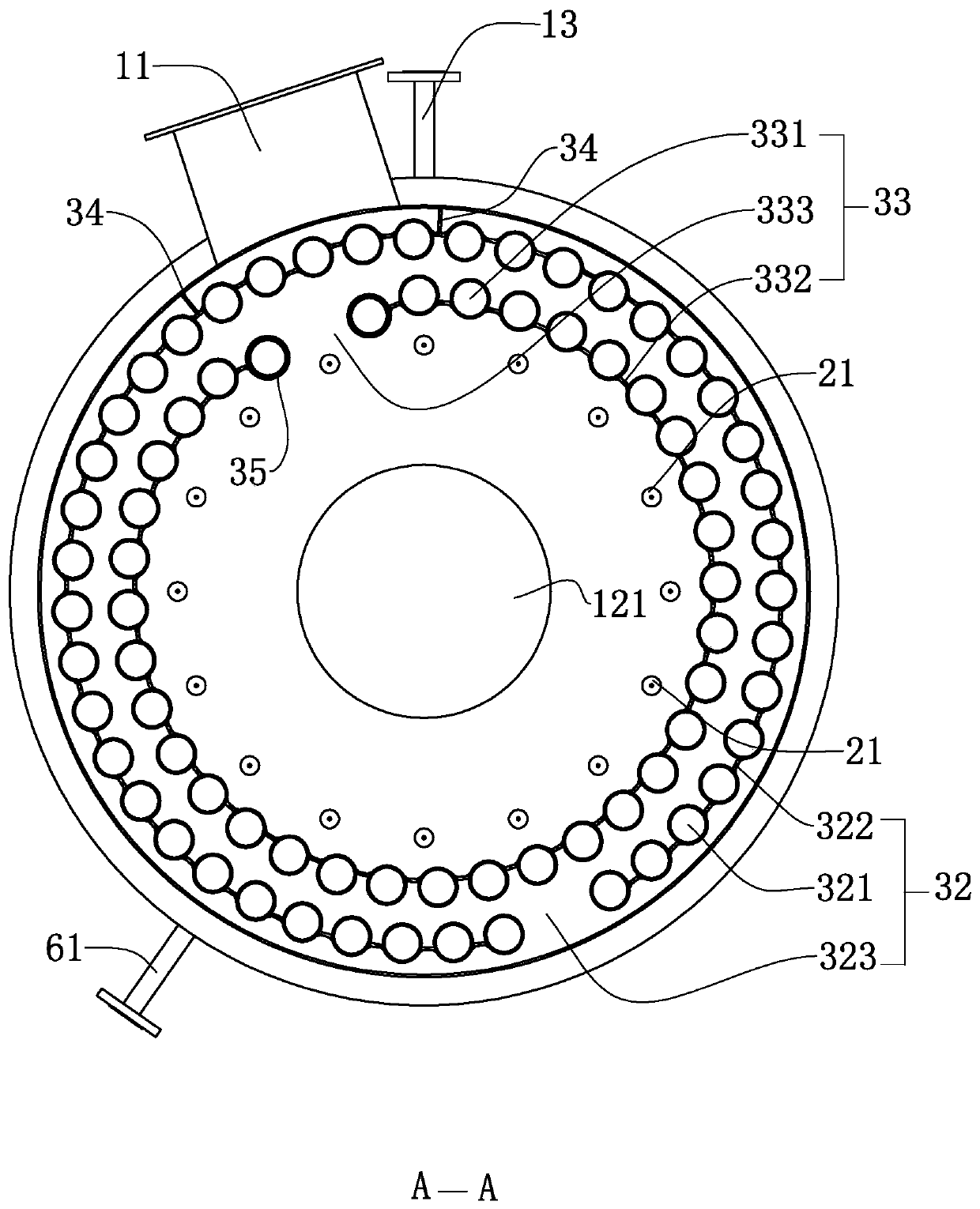

[0039] refer to figure 1 and figure 2 , for the present invention discloses a circulating condensing boiler, comprising a boiler shell 1, the boiler shell 1 is a circular tube shell structure, the inner cavity diameter of the boiler shell 1 is 1230 mm, and the wall thickness of the boiler shell 1 is The axis of the boiler shell 1 is set along the vertical direction. The side of the boiler shell 1 is pierced with a smoke exhaust joint 11 welded to the boiler shell 1 and communicated with the inner cavity of the boiler shell 1. The smoke exhaust joint 11 is located at The part of the boiler shell 1 near the upper end.

[0040] refer to figure 2 The end of the boiler shell 1 facing the ground is provided with a lower header 2, the lower header 2 is a hollow ring, and the end of the lower header 2 facing away from the boiler shell 1 is fixed on the inner wall of the lower header 2. The disc 23 of the boiler shell 1 is provided with an upper header 4 at one end of the boiler s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com